Professional Documents

Culture Documents

Ulatr R2 RBAC2021

Ulatr R2 RBAC2021

Uploaded by

K60 Vũ Ngọc YếnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ulatr R2 RBAC2021

Ulatr R2 RBAC2021

Uploaded by

K60 Vũ Ngọc YếnCopyright:

Available Formats

INTRODUCTION

EXECUTIVE SUMMARY

SITUATION

SP Co. is one of the leading companies in the FMCG industry in Vietnam.

COMPLICATION

However, in Y0, SPCo. lost its business opportunity as ⅝ of product types could not be supplied enough for the overall year demand.

Besides, there were a few months the number of products are not enough to fulfill demand (about 1.6 million rcs).

The current Primary Cost has not been optimized due to the large of primary volume of high-demand products to meet market

between regions, consuming lots of financial resources.

The Can HF is going to be potential (Y1) when the demand has increased in the last 3 months in the North.

Besides, SP Co. is planning to launch Can HF (New) product in the North.

QUESTION

1/ Which products were not met the overall year demand and accounted for large proportion of primary cost in year Y0?

RBAC 2021 - Round 2

2/ Which solution for transportation routes will help SP Co. optimize the Primary Cost?

3/ What is the best option for launching Can HF (New) product in the North?

Executive Summary Gross Revenue Evaluation NOBPT Evaluation Recommendation

SPCo. lost its business opportunity in Y0,

as demand planning was not effective in the first 3 months.

Sales Demand and Production Volume in Y0 Sales Demand and Production Volume in Jan & Mar

thousand

14,000 thousand rcs

Production Volume 11,750

12,000

11,500

10,000 Sales Demand 11,250

11,000 1,686 rcs 1,127 rcs

8,000

10,750

10,500

6,000

10,250

4,000

10,000

9,750

2,000

9,500

Month

-

9,250

1 2 3 4 5 6 7 8 9 10 11 12

January March

Basically, SP Co. responds quite well to market fluctuations. In January and March, SP Co. lost the opportunity to

RBAC 2021 - Round 2

Especially when the demand in April dropped sharply, SP Co. sell 2,813 million rcs when the supplied volume was

quickly reduced the production supply to match demand. not enough to completely fulfill demand.

However, there was a problem in the first 3 months.

Which products ?

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

PET HF, Can CF, Water are products with great demand

but have not been completely fulfilled

by Product Types in Y0 by Product Types

Thousand

Thousand Accumulated contribution

200

150

100

50

0

RGB HF RGB HF PET CF

-50

RGB CF

-100 Can HF

RGB HF PMX

-150

PET CF Water Can CF PET HF

-200

RBAC 2021 - Round 2

Up to 5/8 product types (Water, PET HF, RGB CF, CAN CF, CAN PET HF, Can CF, Water and PET CF are high-demand products

HF) have not been fully fulfilled in Y0 for the whole market on the market ( contributing nearly 90% sales demand)

Other problem

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

Moreover, these products account for large proportion of company's

Primary Cost as being transported in large quantities between regions

The percentage of primary volume (rcs) of PET HF, Water, Can CF Primary Cost by Product Types in Y0

50,000

45,000

23% 40,000

Other

35,000

Product Types

77% 30,000

PET HF,

Water 25,000

Can CF

20,000

76,87%

15,000

10,000

5,000

PET HF WATER CAN CF Other

RBAC 2021 - Round 2

Only the above 3 products (PET HF, Can CF, Water) accounted The transportation of these 3 products costs the business

for 77% of the transportation volume between regions. 36,195 billion VND (76,87% of all products).

Which regions?

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

The transportation from other regions to South costs the most primary cost

(especially the transportation of PET HF, Can CF, and Water)

SP Co.’s supply chain network & transportation routes

of 3 products: PET HF, CAN CF, and Water

1. Among routes, shipping by sea accounts for the lowest

proportion in route South <-> Central (75%).

As South needs to be supplied large amount of products

2. (PET HF, Can CF, Water), SP Co had to transport from

the North and Central, which increases the Primary

Cost.

RBAC 2021 - Round 2

Evaluate each product

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

In long-term, SP Co. needs to review the production efficiency of

PET HF products in South instead of transporting from Central & North

Sales Volume & Production Volume Production Capacity & Production Volume Primary Cost of PET HF

of PET HF of PET HF

15,610 Unmet demand

15,500

15,171 Wasted

15,500 Primary Cost of PET HF from

15,000 Central to South

15,000

14,500

14,500 14.543 billion VND/year

14,000 14,000

13,500 13,500

13,000 12,767 13,000 12,767

12,500 12,500 Primary Cost of PET HF from

12,000

North to South

12,000

11,500 11,500 356 million VND/year

Sales Demand Production Volume Production Capacity Production Volume

RBAC 2021 - Round 2

If production volume is at current levels Meanwhile, production volume has not been To meet the demand in the South, SP Co.

without transporting from other maximized, which is lower than the shipped mainly from Central & North.

regions, SPCo cannot meet the 2.843 production capacity of 2.404 million rcs. This has cost up to 14.9 billion VND/year.

million rcs needs.

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

In short-term, SP Co. can optimize costs by utilizing of Sea transport for

PET HF from Central to South.

Primary Cost (per rcs) for each route Primary volume and Max Capacity from

Central to North by Sea

(VND/rcs)

(tons)

5400 37,000

Not been fully utilized

36,000

5200

Cheapest route 35,000

5000 34,000

33,000

4800

32,000

4600 31,000

30,000

4400 29,000

28,000

4200

To South Central South Central North North 27,000

From Central North North South Central South Primary volume Max Capacity

RBAC 2021 - Round 2

Average Primary Cost (per rcs) from Central to South is the Capacity of Sea transport for from Central to South has

lowest and more efficient than from North to South. not been fully utilized. Because in Y0, this method can

still transport 6000 tons more.

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

SP Co. should have some solutions to optimize the Primary Cost of Water

as benefit could be threatened by these costs

Primary Volume by product types in Y0 Sales Volume by product types by month in Y0

4,000

60,000 tons

3,500

50,000

3,000

Can CF

40,000 2,500 Water

2,000

30,000

1,500 Pet HF

20,000

1,000

10,000 RGB CF

500

Can HF

- -

PET HF Water PET CF CAN CF CAN HF 1 2 3 4 5 6 7 8 9 10 11 12

Uncertain events in FMCG Industry

RBAC 2021 - Round 2

Water has a low price but its Primary Volume ranked Water and Can CF demand are more sensitive compared

2nd (after PET HF) in all of product types which can make to other product types. In April, when the FMCG market is

COGS higher. volatile, Water and Can CF suffer the most drops

Assumption: Water is the lowest priced product in beverage industry

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

SP Co. needs to reduce production volume in North and

increase the production volume in South

Production Capacity & Production Volume & Sales Demand Sales Demand & Production Volume in the North by product types

in the South by product types

30,000 8,000

28,051

24,816 25,233 7,000

25,000 24,406

6,000

Utilize

20,000

5,000 Excess

16,235

15,458

4,000

15,000

Excess

3,000

10,000

2,000

5,000 1,000

-

- RGB CF CAN CF CAN HF PET CF PET HF Water

Water Can CF

RBAC 2021 - Round 2

Production Volume of CAN CF and Water is not enough Meanwhile, due to Production Volume in the North is

to completely met their demand while their capacity is exceeding sales demand here. So, SP Co. transported

available to fulfill their demand in South CAN CF & Water from North to South

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

SUMMARIZE KEY FINDINGS & SUGGESTION FOR Y0

Product Key findings & Problems Solutions Action

Maximize the production volume

3.2 million rcs had to be transported from

Increase production from 12.7 mil to 13.6 mil.

Central to North, costing 14.9 billion VND.

With 63,000 products had to be transported volume (90% production

capacity) of PET HF in 2 millions of remaining products

in expensive route (North to South)

South will be shipped from the Central

(Slide 7)

(not shipped from the North)

PET HF

The proportion of PET HF transportation by Optimize costs by

Adjust the proportion of

Rail and Road from Central (27.5%) is higher utilizing of Sea Transport

Transportation routes to be

than average proportion of Rail & Road in for PET HF products from

transported at 80%: 15%: 5%

whole (20-25%) Central to South

(equivalent to the average level)

(Slide 6, 8)

Water have a low price but its Primary Cost

is too high.

Increase production

Increase the average production

Water & CAN CF did not completely meet its

volume (Water and

Can CF) instead of

efficiency of Water and Can CF

RBAC 2021 - Round 2

25.2455 mil to meet 25.322 mil

CAN CF demand. Moreover , the production

capacity of this product in the South can

transporting from other

sales demand)

regions

meet its own demand if maximizing their

production volume

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

IMPACTS FOR OUR SUGGESTIONS (Y0)

Solutions Cost-savings (*) Advantages Disadvantages

Reduce Primary Costs Increased operating costs of the

Maximize production Southern factory.

volume of PET HF in 4.066 billion VND Take advantage of economy of

South scale in the production line in The production line in Central

the South. may not be utilized

Increase average lead time.

Utilize Sea transport for Increase the cost of reducing From there, it is possible to

PET HF from Central to 0.128 billion VND Sea Transportation but reducing reduce product availability in the

South SP Co's overall Primary Cost South

Water's production line may not

Reduce Primary Cost from North

be utilized

Maximize production to South

volume (Water and 2.69 billion VND Risk of unmet demand if the

Can CF) in South Reduce production costs in

production line in the South is

RBAC 2021 - Round 2

North.

not efficient

Planning for Y1

(*) Detailed calculation in appendix (Slide 20)

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

SP Co. should find a way to increase the supply volume of CAN HF in North

because its demand has great growth

Thousand

Sales Demand of Can HF in North What’s happened?

600

515

500 Growth Rate + 187.7%

From M8, Can HF has great growth as it grew continuously until M12

400 in North.

298 Besides, SP Co. has decided to launch Can HF (New) in this region. (*)

300 264

242

200 179

100 What’s next?

-

Aug Sep Oct Nov Dec The demand of CAN HF (New) is forecasted to reach 150,000 rcs in North.

Demand Forecasting for Can HF (New) in North (Y1)

rcs

Q1 (Y1) Q2 (Y1) Q3 (Y1) Q4 (Y1) How to respond?

1. What is SP Co's current solution for this Can HF product?

RBAC 2021 - Round 2

25,000 25,000 50,000 50,000 2. What is the best solution for supplying of Can HF (New)?

(*) From case study Answer

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

In South, CAN CF and CAN HF only run together in one production line (*)

and CAN HF is transported to North

PROCESS PROBLEM

Primary cost for South-North route is the most

expensive at the average cost of 5,400VND/rcs

(VND/rcs)

The most expensive route

5400

5200

Operating plants in Warehousing for Delivering finished

South (Run together incubating in South goods from South to

North 5000

in one production line

with Can CF)

4800

4600

- Product Cost/ Raw & - Rental fee for - Primary cost from

4400

Packaging Material hiring a third-party Warehouse in South

Cost Warehouse in the to Distribution 4200

- Manufacturing Cost South Centre in North To South Central South Central North North

From Central North North South Central South

RBAC 2021 - Round 2

56,000 VND/rcs 800 VND/rcs 4,214 VND/rcs COGS = 61,014 (VND/rcs)

Noted: After increasing production volume to 90% production capacity in South of CAN CF as suggested (slide 11), (*) Detailed calculation in appendix & Excel (Slide 20)

it’s not necessary to transport CAN CF from North to South

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

However, the transportation from South will cost more in the future.

So, SP Co. should upgrade the production line in North by 67%

PROCESS

FURTHER INFORMATION

1. Lead time to upgrade takes 1

month without affecting the

production schedule.

2. The initial investment is $1.0

Upgrading production line

to increase 67% production Operating new production line million (with 70% Capex and

capacity

30% Opex) and maintenance cost

per year is 2.5% of the Capex value.

- Operating Expenses

- Capital Expenditure

- Product Cost/ Raw & Packaging

- Loan Capital

Material Cost

(WACC=9% & Inflation Rate=4%) 4. Useful life cycle is 7 years

- Maintenance Cost

1,518 VND/rcs 56,392 VND/rcs COGS = 57,910 (VND/rcs)

RBAC 2021 - Round 2

(*) Detailed calculation in appendix (Slide 20)

But, this solution will bring many risks in 7 years of operating The third option

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

SP Co can consider hiring the Co-packaging service in North

PROCESS

Purchasing raw materials from Hiring Co-packaging services to Shipping finished goods from Co-

suppliers and delivering it to manufacture finished goods packaging plants to SPCo’s

Co-packaging plant (including package) Distribution Centre

- Co-packaging fee

- Product Cost/ Raw & - Primary Cost from the Co-

- Operating Expenses

Packaging Material Cost packer to SPCo’s Distribution

Centre

35,000 VND/rcs 22,000 VND/rcs 1,000 VND/rcs

RBAC 2021 - Round 2

COGS = 58,000 (VND/rcs)

The best solution

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

SP Co should upgrade the CAN HF production line in Y1

Solution The best solution Solution

Use Primary Transportation to Upgrade the CAN HF production

Hire a Co-packing service for

Action transfer CAN HF from the South line in the North to increase the

CAN HF (New) in the North

to North production capacity by 67%

COGS 61,014 VND/rcs 57,910 VND/rcs 58,000 VND/rcs

- Improve production productivity

- Not require large initial - Not require large initial

by 67% without affecting

investment. investment.

production schedule.

Pros - Take advantage of the - Low shipping cost

- Lead time is shortened

remaining resources in the - Able to supply for high demand

- Able to supply for demand in

business in the short term and seasonality

the long term.

- Require large investment capital

- May be at risk because of the

- The cost of inter-regional - Risk of not directly controlling,

change in inflation rate in

Cons transportation is too high. depends on the third party

investment

- Lead time is extended.

- If demand is not stable in the

long term, it will be a waste.

RBAC 2021 - Round 2

How to reduce Primary Cost ? How to launch Can HF (New) ? Planning for Y1

Executive Summary Primary Trans Evaluation Launching CAN HF (New) Recommendation

PLANNING FOR SPCO IN Y1 (CONCLUSION)

QUESTION 1 & 2 QUESTION 3

Recommendation 1 Recommendation 2 Recommendation 3 Recommendation 4

Timeline Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

Save more than 4 billion Save more than 0.128 billion Reduce more than 2.69

Successfully supplying 150k rcs

VND in Y1 by increasing PET VND in Y1 by taking billion VND in primary

of CAN HF (New) in the North

Objective HF production capacity in advantage of sea mode for costs of Water between

with the reasonable cost.

South. PET HF. regions in Y1.

Reduce Primary Cost from

Consider expanding the Increasingly use the Upgrade 67% production

North to South

Action capacity of the South transport by sea instead of capacity in the North for Can HF

Reduce production costs in

factory. road and rail. New product.

North

-Increasing the proportion

- Need large capital investment .

- Increased operating costs of shipping by sea lead to - Water's production line

- May be at risk because of the

of the Southern factory. the increase of average lead may not be utilized.

RBAC 2021 - Round 2

Constraints - The production line in the time - Risk of unmet demand if

change in inflation rate in

investment.

Central region may not be - Therefore, availability of the production line in the

- If demand is not stable in the

utilized. the products in South may South is not efficient.

long term, it will be a waste.

decrease.

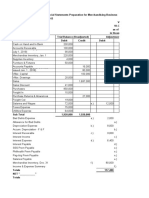

APPENDIX FOR SLIDE 12

Cost saving for maximizing production capacity of PET HF in the South

Weight of each case: 12,5 kg/Rcs

Cost for transportation of each raw case PET HF from

Average Primary cost for Central-South: 363,42 VND/kg

Central to South

12,5 * 363,4 = 4542,5 (VND/Rcs)

Production supply after optimizing capacity in South: 15,17 * 90% = 13,65 (million Rcs)

Reducing transportation of PET HF from Central to South Current Production supply: 13,65 (million Rcs)

Reducing transportation of PET HF: 13,65 - 12,77 = 0,88 (million rcs)

Volume of PET HF transported from North to South: 63.225 (Rcs)

Change route from North-South to Central-South Average cost of North-South: 450,7 VND/kg

Average cost of Central-South: 363,4 VND/kg

Cost Savings 4542,5 * 0,88 * 10^6 + (450,7 - 363,4) * 12,5 * 63255 = 4,066 (billion VND)

Cost saving for utilizing of Sea transport for PET HF from Central to South

Current Primary cost of Central- South route 14.881.487.584 (VND)

Primary cost of Central- South route when changing to 40.949 * (351.218,25 *80% + 390.588,53 *15% + 414.156,57 *5%) = 14.752.625.390,19 (VND)

80% Sea -15% Rail -5% Road

Cost savings 14.881.487.584 -14.752.625.390,19 = 128.862.194,20 (VND)

RBAC 2021 - Round 2

Cost saving for maximizing production volume (Water and Can CF) in South

Reducing transportation of Water from North to Weight of each case: 13,7 kg/rcs

South Average Primary cost for North-South: 363,42 VND/kg

Cost savings 13,7 * 363,42 * 540.839 = 2,69 (billion)

APPENDIX FOR SLIDE 14 & 15

The initial Material & Manufacturing cost per Rcs is 56,000 VND/Rcs

COGS

Process Cost Detail

(VND/rcs)

Primary transport

= (Weight of each Rcs * Average Primary Cost for Central-South) +WH Fee

from Warehouse in Primary Cost + 61,014

= 8.6 kg/Rcs * 489.9 VND/kg +800 VND/rcs

South (hire) to DC in Warehouse VND/rcs

= 5014 (VND/rcs)

North (SLIDE 14)

Variable = Capital Investment * Exchange Rate * (30%) / 7

Manufacturing = 1,000,000 * 23,000 * (30%)/7= 985,714,285.7 (VND)

(With: WACC_real = (1+WACC_nominal) / (1 + Inflation rate) - 1

= (1+9%)/(1+4%) - 1 = 4.8%

Upgrade the CAN HF Fixed

production line in = Capital Investment * Exchange Rate * (70%/7 + WACC_real +

Manufacturing

the North to Maintenance Cost)

= 1,000,000 * 23,000 * (70%/7 + 4,8% + 70% * 2,5%) 57,909.67

increase the

= 3,806,500,000 (VND) VND/rcs

production capacity

by 67% (SLIDE 15)

(With: current capacity of CAN HF is 3,745,440 rcs)

Volume = 3.745.440 * 67%

= 2,509,444.8 (rcs)

= Material and (Variable Manufacturing Cost + Fixed Cost) / Volume

COGS = (985,714,285.7 + 3,806,500,000) / 2,509,444.8

(VND/Rcs) = 1,909.67 (VND)

Assumption: The exchange rate is 1 USD = 23,000 VND

You might also like

- The Gone Fishin' Portfolio: Get Wise, Get Wealthy...and Get on With Your LifeFrom EverandThe Gone Fishin' Portfolio: Get Wise, Get Wealthy...and Get on With Your LifeNo ratings yet

- Educated REIT Investing: The Ultimate Guide to Understanding and Investing in Real Estate Investment TrustsFrom EverandEducated REIT Investing: The Ultimate Guide to Understanding and Investing in Real Estate Investment TrustsNo ratings yet

- Gross Profit Variation Analysis-EXERCISE-1-3Document3 pagesGross Profit Variation Analysis-EXERCISE-1-3Trisha MaeNo ratings yet

- Case Study Week 2Document3 pagesCase Study Week 2namunaNo ratings yet

- PETR 3310 Homework 02 SolutionDocument6 pagesPETR 3310 Homework 02 SolutionBrian AndersonNo ratings yet

- Kate CompanyDocument3 pagesKate CompanyLucile Lleva80% (5)

- Membership Status Verification Slip (MSVS, HQP-HLF-063, V01)Document1 pageMembership Status Verification Slip (MSVS, HQP-HLF-063, V01)reynancutay462450% (2)

- Problem 1: Solution Guide - Requirement 1Document4 pagesProblem 1: Solution Guide - Requirement 1Lerma MarianoNo ratings yet

- Daily Market Update - 07.03.2024Document2 pagesDaily Market Update - 07.03.2024Kavindu KamanthaNo ratings yet

- Gindonesia eDocument2 pagesGindonesia eSaksang BabiNo ratings yet

- Company Update Aditya Birla Fashion and Retail LTDDocument8 pagesCompany Update Aditya Birla Fashion and Retail LTDamitNo ratings yet

- Actuals BudgetDocument1 pageActuals BudgetShaheryar SheikhNo ratings yet

- Merrimack Tractors and Mowers, Inc 1Document12 pagesMerrimack Tractors and Mowers, Inc 1KshitishNo ratings yet

- 151208CapitalMarketsDay EnQuestDocument88 pages151208CapitalMarketsDay EnQuestredevils86No ratings yet

- ARL Sustainability Report 2021Document121 pagesARL Sustainability Report 2021IMRAN MUSHTAQ AUTOSNo ratings yet

- Latihan Aklan 2 Lab UTSDocument10 pagesLatihan Aklan 2 Lab UTSpermataayu31No ratings yet

- Macroeconomic Analysis 2003: InvestmentDocument32 pagesMacroeconomic Analysis 2003: InvestmentDalvir ThakurNo ratings yet

- CHUA - Exercise 3 - BudgetingDocument1 pageCHUA - Exercise 3 - BudgetingClaudeen Jade Antoinette ChuaNo ratings yet

- Empleo Chapter 6 Investments in Financial Instruments PDFDocument19 pagesEmpleo Chapter 6 Investments in Financial Instruments PDFRhenielou CristobalNo ratings yet

- A2 Book For June 2023 p3 FinalDocument532 pagesA2 Book For June 2023 p3 Finals.alisufyaanNo ratings yet

- Billed Price Sample ProblemDocument2 pagesBilled Price Sample ProblemGlory Nicol OrapaNo ratings yet

- Qu Hưu Trí Na Uy - Gpfg-Half-Year-Report - 2022Document41 pagesQu Hưu Trí Na Uy - Gpfg-Half-Year-Report - 2022huynhtruonglyNo ratings yet

- Intercompany Sale of Merchandise - AdditionalDocument4 pagesIntercompany Sale of Merchandise - AdditionalJaimell LimNo ratings yet

- Assembly Line Sept'20: Line 1 Line 2 Line 4 Line 5Document4 pagesAssembly Line Sept'20: Line 1 Line 2 Line 4 Line 5Mohammad KamruzzamanNo ratings yet

- 2022 Academic Writing GuideDocument7 pages2022 Academic Writing GuideNamita GoburdhanNo ratings yet

- CONSO FS Cost MethodDocument21 pagesCONSO FS Cost MethodMaurice AgbayaniNo ratings yet

- (Download PDF) Matching Supply With Demand An Introduction To Operations Management 3rd Edition Cachon Solutions Manual Full ChapterDocument29 pages(Download PDF) Matching Supply With Demand An Introduction To Operations Management 3rd Edition Cachon Solutions Manual Full Chapterruziczeada100% (7)

- Starapple Company 1Document15 pagesStarapple Company 1anan.zakzukNo ratings yet

- DB6 - Worksheet & FS Prep For Merchandising BusinessDocument4 pagesDB6 - Worksheet & FS Prep For Merchandising BusinessArrianeNo ratings yet

- Financial AnalysisDocument18 pagesFinancial Analysismaizatul rosniNo ratings yet

- Roskill PreseentationDocument21 pagesRoskill Preseentationjiawen dingNo ratings yet

- Chap 12 - Inventory (Prob 24-32)Document10 pagesChap 12 - Inventory (Prob 24-32)Kloie SanoriaNo ratings yet

- 2011-2016 2nd Lesson Question and AnswersDocument17 pages2011-2016 2nd Lesson Question and AnswersNawoda SamarasingheNo ratings yet

- Midterms I Answer KeyDocument5 pagesMidterms I Answer Keyaldric taclanNo ratings yet

- HOBA Notes 2Document4 pagesHOBA Notes 2Hana GNo ratings yet

- NBS-7026A Workshop 2 Answers - AccountingDocument3 pagesNBS-7026A Workshop 2 Answers - Accountingizudominic03No ratings yet

- Pt. Senang List of Merchadise Inventory Fifo Inventory MethodDocument3 pagesPt. Senang List of Merchadise Inventory Fifo Inventory MethodJustice_tiezNo ratings yet

- MAC3701 Question Bank 2016Document65 pagesMAC3701 Question Bank 2016Blessings MunkuliNo ratings yet

- Form IcDocument4 pagesForm IcNitha ArdelyaNo ratings yet

- Tutorial 5 SolutionDocument8 pagesTutorial 5 Solutionfinance.assistantNo ratings yet

- Jawaban Persediaan (FIFO LIFO Avr)Document2 pagesJawaban Persediaan (FIFO LIFO Avr)Komang MulianaNo ratings yet

- Ak - 111219Document3 pagesAk - 111219lisa filiNo ratings yet

- Variable Costing April Revenues 8,400,000Document10 pagesVariable Costing April Revenues 8,400,000Hiền NguyễnNo ratings yet

- Mike Beveridge - Doing Business Under The OceanDocument18 pagesMike Beveridge - Doing Business Under The OceanGiacomo CalligarisNo ratings yet

- Accounting AssignmentDocument5 pagesAccounting AssignmentVivek SinghNo ratings yet

- FAR 1 Chapter - 10Document12 pagesFAR 1 Chapter - 10Klaus DoNo ratings yet

- FAR 1 Chapter - 10Document12 pagesFAR 1 Chapter - 10Klaus DoNo ratings yet

- Fartilizer Report NovemberDocument1 pageFartilizer Report NovemberSantanu PalNo ratings yet

- Questions Chapter 3 No.11: PEROT CORPORATION - Patay2 Chip ProjectDocument6 pagesQuestions Chapter 3 No.11: PEROT CORPORATION - Patay2 Chip ProjectddNo ratings yet

- Cannafarm Growing Business PlanDocument35 pagesCannafarm Growing Business PlanJoseph Israel83% (6)

- CHAPTER 6 - Joint VentureDocument10 pagesCHAPTER 6 - Joint VentureminmenmNo ratings yet

- HomeworkDocument1 pageHomeworksimonroigNo ratings yet

- TM 6Document29 pagesTM 6hasnaNo ratings yet

- Audit of Financial Statements Part 2Document2 pagesAudit of Financial Statements Part 2Brit NeyNo ratings yet

- 2011 Pre-Budget PresentationDocument25 pages2011 Pre-Budget PresentationlabradoreNo ratings yet

- Inventory Chapter 10 Practice SetsDocument13 pagesInventory Chapter 10 Practice SetskikoNo ratings yet

- ACT2PROJDocument8 pagesACT2PROJCedric RepradoNo ratings yet

- Intersol GL FinacleDocument31 pagesIntersol GL FinacleManish WaniNo ratings yet

- Inventory (Questions) : Question No. H-1Document4 pagesInventory (Questions) : Question No. H-1manadish nawazNo ratings yet

- Modern Portfolio Management: Moving Beyond Modern Portfolio TheoryFrom EverandModern Portfolio Management: Moving Beyond Modern Portfolio TheoryNo ratings yet

- Cooper Pharmaceuticals IncDocument12 pagesCooper Pharmaceuticals IncRALLAPALLI VISHAL VIJAYNo ratings yet

- Sap TutorialsDocument2 pagesSap TutorialspappuNo ratings yet

- VERTICAL ANALYSIS OF INCOME STATEMENT of Toyota 2022-2021Document8 pagesVERTICAL ANALYSIS OF INCOME STATEMENT of Toyota 2022-2021Touqeer HussainNo ratings yet

- BUS 4407 - Written Assignment Unit 7Document5 pagesBUS 4407 - Written Assignment Unit 7Benedicta NgwinuiNo ratings yet

- Qatar. Labour Act No. 3 of 1962Document1 pageQatar. Labour Act No. 3 of 1962LazarNo ratings yet

- Ritz Carlton: Case StudyDocument3 pagesRitz Carlton: Case StudyInstallment4u PakistanNo ratings yet

- Act 30-34Document5 pagesAct 30-34ジェフ ァーソンNo ratings yet

- L4 - Business CultureDocument16 pagesL4 - Business CultureOlivia SaundersNo ratings yet

- Project DocumentationDocument44 pagesProject DocumentationRaees KhanNo ratings yet

- Sbi (HRM)Document45 pagesSbi (HRM)Sumit Rajai75% (4)

- Business Strategy Report 500 WordsDocument7 pagesBusiness Strategy Report 500 WordsRameen Arshad RajaNo ratings yet

- WWW Law Activity 7 & 8Document4 pagesWWW Law Activity 7 & 8Tan ToyNo ratings yet

- "Zero To One" Summary and Review - West Stringfellow - MediumDocument23 pages"Zero To One" Summary and Review - West Stringfellow - MediumGabriel Soares CostaNo ratings yet

- The Role of Strategic Leadership in Supporting Strategic Planning and Increasing Organizational CompetitivenessDocument6 pagesThe Role of Strategic Leadership in Supporting Strategic Planning and Increasing Organizational CompetitivenessEditor IJTSRDNo ratings yet

- HRM NotesDocument82 pagesHRM NotesUday GowdaNo ratings yet

- Order ListDocument1 pageOrder ListelioNo ratings yet

- (Geographic Information Systems) : Applications in MarketingDocument50 pages(Geographic Information Systems) : Applications in MarketingSeif TalalNo ratings yet

- Cdroussiots ch4 ExcerptDocument17 pagesCdroussiots ch4 ExcerptArief MaulanaNo ratings yet

- DB Toys-Case StudyDocument16 pagesDB Toys-Case StudyNitin ShankarNo ratings yet

- Whole Foods Market: The Deutsche Bank ReportDocument13 pagesWhole Foods Market: The Deutsche Bank ReportSafi Ullah KhanNo ratings yet

- CW-hand-out-BEED 1ADocument18 pagesCW-hand-out-BEED 1ARolly AbayaNo ratings yet

- Micro Chap6 Acts Draft FinishedDocument5 pagesMicro Chap6 Acts Draft FinishedBhebz Erin MaeNo ratings yet

- Audit (Final)Document16 pagesAudit (Final)jongin kaiNo ratings yet

- Floki Inu White PaperDocument11 pagesFloki Inu White PaperR Murugesan SINo ratings yet

- Marketing Strategy of Colgate (History)Document10 pagesMarketing Strategy of Colgate (History)Priyanka ShimpiNo ratings yet

- A-Z of Facilities and Property ManagementDocument418 pagesA-Z of Facilities and Property ManagementArman BhuiyanNo ratings yet

- Finance RatioDocument18 pagesFinance RatioJazmidah Rosle100% (3)

- Chapter 5 Additional ExercisesDocument2 pagesChapter 5 Additional ExercisesThe sorcererNo ratings yet