Professional Documents

Culture Documents

Document No: Rev: A Number of Page: 1 OF 4: Inspection and Test Plan (Itp)

Document No: Rev: A Number of Page: 1 OF 4: Inspection and Test Plan (Itp)

Uploaded by

Ghilman0529Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Document No: Rev: A Number of Page: 1 OF 4: Inspection and Test Plan (Itp)

Document No: Rev: A Number of Page: 1 OF 4: Inspection and Test Plan (Itp)

Uploaded by

Ghilman0529Copyright:

Available Formats

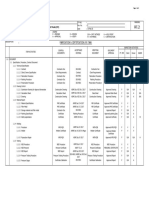

INSPECTION AND TEST PLAN (ITP)

DOCUMENT NO : REV : A

STEEL STACK NUMBER OF PAGE :

LMU-SS-ITP-001

1 OF 4

CLIENT :

FABRICATOR : PT. LESTARI MARINA UTAMA

PROJECT :

STEEL STACK

LOCATION :

PROJECT NO. :

REFERENCES : CONTRACT DOCUMENT

A 14 July 2022 First Issue AB MAS

PREP CHECK APPR CHECK APPR

REV DATE DESCRIPTION

CV. RAJAWALI PUTRA PRATAMA PT. AMMAN

INSPECTION AND TEST PLAN (ITP)

DOCUMENT NO : REV : A

STEEL STACK NUMBER OF PAGE :

LMU-SS-ITP-001

2 OF 4

REVISION SHEET

NO REV DATE PAGE DESCRIPTION

1 A 14 July 2022 All Page First Issue

ITP NO. : LMU-SS-ITP-001

Request date : 15 July 2022

SHOP INSPECTION & TEST PLAN

Revision :A

Page : 3 OF 4

STEEL STACK

METHOD OF REFRENCE DOCUMENTS / VERIFIED INSPECTION ACTIVITIES

NO DESCRIPTION

INSPECTION ACCEPTANCE CRITERIA DOCUMENTS LMU CLIENT

1 DOCUMENT REVIEW

Contract document, approved Approved WPS & PQR

1.1 WPS & PQR Review P R

drawing, AWS D.1.1 with latest revision

Contract document, approved Approved WPQT with

1.2 Welder/welding operator qualification test (WPQT) Review P R

WPS & PQR, AWS D.1.1 latest revision

Approved penetrant

1.3 NDE procedure & NDE personel certificate Review Contract document, AWS D.1.1 test procedure with P R

latest revision

Contract document, SSPC, Approved painting

1.4 Painting procedure & SSPC level 2 certificate Review engineering specification procedure with latest P R

painting revision

2 RECEIVING MATERIAL & EQUIPTMENT

2.1 Material & equipments compliance : quantity, visual Approved drawing, mill Material receiving

Review, visual P R

and material testing (if any) certificate inspection report

3 FABRICATION

Approved drawing, approved

3.1 Fit-up and welding Visual Welding report P, W R

WPS & PQR, AWS D.1.1

Approved penetrant test

3.2 Penetrant test Test Penetrant test report P, W R

procedure, AWS D.1.1

Approved radiographic test Radiographic test

3.3 Radiographic Test Test P, W R

procedure, AWS D.1.1 report

3.4 Dimensional check Measurement Approved drawing Dimension report P, W R

3.5 Visual inspection Visual Approved drawing Visual report P, W R

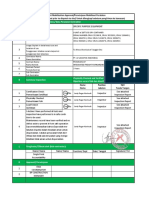

4 ERECTION / INSTALLATION

Approved drawing, approved

4.1 Fit-up and welding Visual Welding report P, W R

WPS & PQR, AWS D.1.1

Approved penetrant test

4.2 Penetrant test Test Penetrant test report P, W R

procedure, AWS D.1.1

Approved radiographic test Radiographic test

4.3 Radiographic Test Test P, W R

procedure, AWS D.1.1 report

4.4 Dimensional check Measurement Approved drawing Dimension report P, W R

4.5 Visual inspection Visual Approved drawing Visual report P, W R

5 PAINTING

Approved painting procedure, Surface preparation

5.1 Surface preparation Visual P, W R

technical data sheet, SSPC inspection report

Approved painting procedure, Painting inspection

5.2 Dry film thickness (DFT) check Measurement P, W R

technical data sheet, SSPC report

ITP NO. : LMU-SS-ITP-001

Request date : 15 July 2022

SHOP INSPECTION & TEST PLAN

Revision :A

Page : 4 OF 4

STEEL STACK

METHOD OF REFRENCE DOCUMENTS / VERIFIED INSPECTION ACTIVITIES

NO DESCRIPTION

INSPECTION ACCEPTANCE CRITERIA DOCUMENTS LMU CLIENT

6 DOCUMENT COMPLETION

Inspection release

6.1 Inspection release notice Review Approved inspection report P R

certificate (IRC)

Contract document, technical Certificate of

6.2 Manufacturing certificate Review P R

specification compliance (COC)

Contract document, technical Manufacturing data

6.3 Manufacturing documentation Review P R

specification record (MDR)

LEGEND CLASSIFICATION

NOTIFICATION : Inspection Request in writing and require a minimum of 24 hours notice of impending inspection/test

H : Hold Point, no work squence can proceed without inspection

W : Witness of inspection by Client/Owner & Subcontractor may proceed if Client/Owner not appearance at the pointed time witness point shall be given by notification

notification

SW : Spot Witness, Inspection on the spot

T : 100% Inspection or test

RI : Partial or Random Inspection

P : Prepare document of work

R : Review of Report or Documentation

A : Approval documentation (Procedure, Work Instruction, Inspection Report, etc)

ABBREVIATIONS

AWS : American Welding Society PWHT : Post Weld Heat Treatment ASME : American Society of Mechanical Engineers

WPS : Welding Procedure Specification ITP : Inspection Test Plan ASNT : American Society for Non Destructive Testing

PQR : Procedure Qualification Record Tech. Spec. : Technical Specification ASTM : American Society for Testing of Materials

NDE : Non destructive Examination WPQT : Welder/Welding Operator Performance API : American Petroleum Institute

N/A : Not Aplicable Qualification Test SSPC : The Society for Protective Coatings

NOTES :

1) Ref. Inspection activities & Approval Section of Document

a : Where there is a Subcontractor element, the Subcontractor involved will sign the approval of the activity (NDE/PWHT)

b : Where there is a Subcontractor element, Tame will sign approval of activity and present to the Client.

2) Inspection Test Plan Status

It is to be understood that the inspection forms an integral parts of the control/verification documentation needed

How ever no other documents are required or exit "The Inspection Test Plan" only will be understood to be the control/verification document

You might also like

- BS-230 LIS Interface Manual V3.0 enDocument85 pagesBS-230 LIS Interface Manual V3.0 enAlex KimNo ratings yet

- 652-100-FINAL (ITP) Rev1Document4 pages652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgENo ratings yet

- Dowhole Tools - SlicklineDocument34 pagesDowhole Tools - SlicklineAdonis Saidler100% (8)

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- Pressure Testing ProcedureDocument7 pagesPressure Testing ProcedureHammad AminNo ratings yet

- S-000-1310-101-Rs-00077 Site Inspection and Test Plan (Itp) For Civil WorkDocument33 pagesS-000-1310-101-Rs-00077 Site Inspection and Test Plan (Itp) For Civil Workderi yuliantoNo ratings yet

- F5063a-K-003-00 NDT Procedure PDFDocument11 pagesF5063a-K-003-00 NDT Procedure PDFJatmika Budi SantosaNo ratings yet

- Field Inspection and Test Plan For Civil Work (ITP CIVIL WORK)Document8 pagesField Inspection and Test Plan For Civil Work (ITP CIVIL WORK)Angga Dwi PutrantoNo ratings yet

- Method Statement For Derrick Structure00Document3 pagesMethod Statement For Derrick Structure00khaled saeed100% (1)

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument19 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNo ratings yet

- Murphy Offshore Inspection and Maintenance ReportDocument20 pagesMurphy Offshore Inspection and Maintenance ReportJaowad DabielNo ratings yet

- LPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewDocument13 pagesLPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewabdiNo ratings yet

- (Guide) Steel Compact & Noncompact RequirementDocument7 pages(Guide) Steel Compact & Noncompact RequirementShaileshRastogiNo ratings yet

- Bolt TighteningDocument13 pagesBolt Tighteningwali banNo ratings yet

- Precommissioning of Pipelines: Technical SpecificationDocument40 pagesPrecommissioning of Pipelines: Technical SpecificationLizeth RamirezNo ratings yet

- 0610.1 - Shell and Tube Heat ExchangersDocument30 pages0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003No ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- PHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor BoltDocument14 pagesPHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor Boltchristian210789No ratings yet

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanNo ratings yet

- Pressure Vessel SpecificationDocument15 pagesPressure Vessel Specificationmichael chiwuezeNo ratings yet

- Tower DesignDocument49 pagesTower Designriz2010No ratings yet

- Full Water Test ProcedureDocument3 pagesFull Water Test Procedureasmira rosliNo ratings yet

- Inspection & Test Plan: Dangote Oil Refinery CompanyDocument7 pagesInspection & Test Plan: Dangote Oil Refinery CompanyGowtham VenkatNo ratings yet

- Seismic LoadDocument1 pageSeismic LoadJae Kyoung LimNo ratings yet

- Fabrication Procedur 1Document33 pagesFabrication Procedur 1Hermansyah PratamaNo ratings yet

- Certificate QC Pass: Hal. 1 Dari 4Document4 pagesCertificate QC Pass: Hal. 1 Dari 4p' radenNo ratings yet

- Design Consideration For Internal Welding Attachments in Clad Pressure VesselsDocument6 pagesDesign Consideration For Internal Welding Attachments in Clad Pressure VesselsJose ManuelNo ratings yet

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanNo ratings yet

- Standard Drawing Adr PDFDocument10 pagesStandard Drawing Adr PDFJR RZNo ratings yet

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- Radiographic Testing ProcedureDocument12 pagesRadiographic Testing ProcedureAdham AhmedNo ratings yet

- 60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingDocument109 pages60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingTauqeer SalimNo ratings yet

- Double Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - GeneralDocument7 pagesDouble Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - Generalhcsharma1967No ratings yet

- QAP CondenserDocument3 pagesQAP CondenserisaacNo ratings yet

- Hydrotest Ansi b31.3 2017Document13 pagesHydrotest Ansi b31.3 2017Bangkit SusiloNo ratings yet

- Krs-Oe-01!12!007 - Prosedur Pekerjaan Galian Tanah Untuk Under (Rev. 2)Document9 pagesKrs-Oe-01!12!007 - Prosedur Pekerjaan Galian Tanah Untuk Under (Rev. 2)Checep SuyantoNo ratings yet

- PV Elite Örnek PDFDocument223 pagesPV Elite Örnek PDFakın ersözNo ratings yet

- 50.0m GUYED Tower-TA-ZRI681 - A-040811-ADocument105 pages50.0m GUYED Tower-TA-ZRI681 - A-040811-Aredflex9001889No ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- CJP WeldsDocument1 pageCJP WeldsbsagguNo ratings yet

- FRP Procedure Rev DDocument13 pagesFRP Procedure Rev DDaengkulle Firmansyah PuteraNo ratings yet

- Weld Brite TDSDocument3 pagesWeld Brite TDSrinthusNo ratings yet

- Equipment DesignDocument88 pagesEquipment DesignbigbossNo ratings yet

- W2021C-DNGF-CV-900-SPE-0001 - RevBSpecification For Structural SteelDocument22 pagesW2021C-DNGF-CV-900-SPE-0001 - RevBSpecification For Structural SteelDidi Hadi RiantoNo ratings yet

- Test Package: Pt. TTN (Tambang Tondano Nusajaya)Document18 pagesTest Package: Pt. TTN (Tambang Tondano Nusajaya)unto gunungNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Lecture 36 - Lacing SystemsDocument16 pagesLecture 36 - Lacing SystemsGajendra JoshiNo ratings yet

- ASME 2046-2 - 2046-2 Pneumatic Testing of Pressure Vesels, UG-90 (C) (2) Section VIII, Division 1Document1 pageASME 2046-2 - 2046-2 Pneumatic Testing of Pressure Vesels, UG-90 (C) (2) Section VIII, Division 1Mike DukasNo ratings yet

- 6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFDocument20 pages6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFsumit kumarNo ratings yet

- Piping Fitup ReportDocument4 pagesPiping Fitup ReportMUHAMMAD WARIS SQNo ratings yet

- Itp For Field Erected Tank Rev A PDF FreeDocument9 pagesItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNo ratings yet

- Reverse Engineering Pressure Vessel ChecklistDocument5 pagesReverse Engineering Pressure Vessel ChecklistES RouzaNo ratings yet

- Schedule of Test Welder Qualification:: 041/VIII/STWQ/2014Document2 pagesSchedule of Test Welder Qualification:: 041/VIII/STWQ/2014Muhammad Fitransyah Syamsuar PutraNo ratings yet

- ACI 318-11 Appedix DDocument2 pagesACI 318-11 Appedix DJonathan SchauderNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- Itp Vessel PDFDocument4 pagesItp Vessel PDFBUDAPESNo ratings yet

- TIMAS-PR-PI-002 - Installation Procedure For Pipe SupportDocument14 pagesTIMAS-PR-PI-002 - Installation Procedure For Pipe SupportMechanical Static WRKNo ratings yet

- Prosedur Penetran TestingDocument11 pagesProsedur Penetran TestingIkhsan DalimuntheNo ratings yet

- Itp Tank RappDocument4 pagesItp Tank Rapprizky youlandaNo ratings yet

- Fabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Document3 pagesFabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Rifki HasyaNo ratings yet

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Warma - Geophysical Survey OPHIR Madura - Rev 1Document4 pagesWarma - Geophysical Survey OPHIR Madura - Rev 1Ghilman0529No ratings yet

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- PDF Itp Tbkjtitp qc001 Rev01egis - CompressDocument20 pagesPDF Itp Tbkjtitp qc001 Rev01egis - CompressGhilman0529No ratings yet

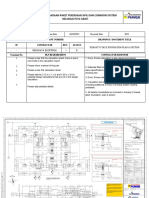

- 222501-00-S-18-UHN-003-4 R1 Exhaust Stack Anchor Box Detl 4 of 4 Sign 260522-Status A-SignedDocument3 pages222501-00-S-18-UHN-003-4 R1 Exhaust Stack Anchor Box Detl 4 of 4 Sign 260522-Status A-SignedGhilman0529No ratings yet

- 222501-00-S-18-UHN-002-1 R2 Exhaust Stack FDN Plan 1 of 2 Sign 180522-Status B-SignedDocument2 pages222501-00-S-18-UHN-002-1 R2 Exhaust Stack FDN Plan 1 of 2 Sign 180522-Status B-SignedGhilman0529No ratings yet

- 222501-00-S-18-UHN-003-1 R2 Exhaust Stack Anchor Box Det 1 of 4 Sign180522-Status A-SignedDocument6 pages222501-00-S-18-UHN-003-1 R2 Exhaust Stack Anchor Box Det 1 of 4 Sign180522-Status A-SignedGhilman0529No ratings yet

- Total Quallity ManagementDocument86 pagesTotal Quallity Managementprathamesh kaduNo ratings yet

- Maintenance ManualDocument48 pagesMaintenance ManualTed Moore50% (2)

- Ceragon FibeAir IP-20C Technical Description C8.5 ETSI Rev ADocument261 pagesCeragon FibeAir IP-20C Technical Description C8.5 ETSI Rev ALê Hữu ÁiNo ratings yet

- WSND Iat I (16-9-23)Document2 pagesWSND Iat I (16-9-23)karthikkumarenNo ratings yet

- EM300-50 (LectroCount Remote Display) PDFDocument12 pagesEM300-50 (LectroCount Remote Display) PDFLazzarus Az GunawanNo ratings yet

- Siemens DTC PresentationDocument8 pagesSiemens DTC Presentationgiolgau01No ratings yet

- 7-Raspberry Pi Camera Interface-Final PDFDocument27 pages7-Raspberry Pi Camera Interface-Final PDFRagini Gupta100% (1)

- Watch?v X 3 M 1 R0 TUSokDocument52 pagesWatch?v X 3 M 1 R0 TUSokanon-393508No ratings yet

- Computer Networking Principles BonaventureDocument282 pagesComputer Networking Principles Bonaventureal_mi_mo100% (1)

- Integration of ITIL V3 ISO 20000 and ISODocument18 pagesIntegration of ITIL V3 ISO 20000 and ISOmisjarw9600No ratings yet

- Networking Essentials: Jogesh K. MuppalaDocument12 pagesNetworking Essentials: Jogesh K. MuppalaAshihsNo ratings yet

- PIPE - : Prefunctional Test Checklist 03/02 15997-08-1 OF 6 D:/DOCS/DIV1/03-02/15997-08Document6 pagesPIPE - : Prefunctional Test Checklist 03/02 15997-08-1 OF 6 D:/DOCS/DIV1/03-02/15997-08rakeshamechNo ratings yet

- Suhail Memon Front PageDocument7 pagesSuhail Memon Front PageSHOAIB MEMONNo ratings yet

- 0.1.05 Abu Dhabi WaterSupplyRegs2009Guide - P.22-24Document3 pages0.1.05 Abu Dhabi WaterSupplyRegs2009Guide - P.22-24MMMOH200No ratings yet

- The Difference Between NPT, BSPP and BSPT SealsDocument2 pagesThe Difference Between NPT, BSPP and BSPT SealsRam SinghNo ratings yet

- TLS and DTLS: A Tale of Two Protocols Kenny Paterson: Information Security GroupDocument75 pagesTLS and DTLS: A Tale of Two Protocols Kenny Paterson: Information Security GroupSayantan DasNo ratings yet

- IncineratorDocument11 pagesIncineratorRavi Chetan100% (1)

- MapperDocument42 pagesMapperArturo CadenaNo ratings yet

- Triac Tic206mDocument5 pagesTriac Tic206mKristian Aram Perez RuedaNo ratings yet

- Ricoh Aficio 3224c Copier BrochureDocument6 pagesRicoh Aficio 3224c Copier BrochurescarpantoNo ratings yet

- Mikro - Voltage RelayDocument12 pagesMikro - Voltage Relaycharadeg100No ratings yet

- Renewable Energy Certificates: Fee & ChargesDocument4 pagesRenewable Energy Certificates: Fee & ChargescpgeorgeNo ratings yet

- Hillman RollersDocument16 pagesHillman RollersLuis LuperdiNo ratings yet

- ATEX Du 496-185888Document14 pagesATEX Du 496-185888Bright OkunkpolorNo ratings yet

- Porsche Academy Training - Vehicle Quick Reference MY2007-08Document36 pagesPorsche Academy Training - Vehicle Quick Reference MY2007-08Michele Colombo100% (4)

- 4.1 Banking in FranceDocument7 pages4.1 Banking in Francevincent.reynaud.74No ratings yet

- Flow Control and Error ControlDocument5 pagesFlow Control and Error ControlThaddeus MooreNo ratings yet