Professional Documents

Culture Documents

2011 Cat Biomass GB

2011 Cat Biomass GB

Uploaded by

t_i_f_anoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2011 Cat Biomass GB

2011 Cat Biomass GB

Uploaded by

t_i_f_anoCopyright:

Available Formats

Environmentally Sound Technology

Biomass Fuelled Energy Plants

BONO SISTEMI can boast 50 years experience, gained in the design and Another important and high demand field is district heating, in

production of biomass fired steam generators and thermal fluid locations where biomass is easily available and can represent a

heaters using a variety of waste fuels such as olive husks, rice husks and competitive alternative to fossil fuel.

wood chips, with more than 42 installations worldwide.

Moreover, being active since over ten years in projects financed by

The BONO technology fields of application in the biomass fuelled United Nations Organisations in compliance with the “Sustainable

plants are in the process industry and particularly the food and wood Development” programs, BONO SISTEMI has got unique skills in

industries, where the production wastes, such as wood chips, saw dust, carrying out projects for the substitution of Ozone Depleting

rice husks, olive husks etc, represent a free of charge fuel to produce Substances (according to the Montreal Protocol recommendations) and

both heat to the process and electric power. for the application of the Kyoto Protocol on the “greenhouse gases”

global reduction (CDM and JI projects).

Up to 10 MWel Up to 54 MWth

Steam turbine

Process Heat

Power to the grid Combined Heat

Biomass Fired Steam Generator

and Power Supply

The BONO SISTEMI biomass fuelled plant is the heart

of an energy system able to generate pure heat for

industrial processes, district heating for small and

medium communities, and electrical power if coupled

to power generators such as steam engines and

turbines, or other devices.

Biomass Fired Thermal Oil Heater When the two purposes are jointed we then talk

about CHP plant (Combined Heat and Power plants).

Thanks to consolidated experience in the energy field

BONO SISTEMI engineering is able to study and design

full turn-key plants starting from the greenfield.

District Heating

ORC turbine

Up to 2 MWel Up to 10 MWth

Power to the grid

The Reciprocating Grate

Combustion System

Reciprocating grate is state of the art combustion technology suitable for any

kind of biomass ranging from:

• High moisture content one, as for dump wood waste or virgin wood

• Biomass mixture

• Dusty biomass, as for olive residues

• Low specific gravity ones, as for rice husk

Let's follow the biomass path through the combustion system.

The fuel, coming from the storage area, is fed into a loading hopper, being an The grate is divided in three or four zones, depending on the plant size,

intermediate and constant biomass volume upon the fuel feeder. respectively for drying, combustion and burn out of the fuel. The bars speed

movement and the combustion air flow are independently programmable for

The hopper design prevents clogging due to entrance of irregular pieces, and is each single section in order to compensate different biomass composition, to

equipped with control level and fire fighting system. perform the proper residence time and to adequate the boiler load.

From the hopper the fuel passes into Ashes are automatically removed by reciprocating action of the grate and

the fuel feeder. It is a linear collected at its end into a specific hopper and moved out through an automatic

hydraulically driven drawer, water conveyor.

cooled, with the front end covering

the full width of the chamber and The primary combustion air is independently injected underneath each zone and

able to distribute uniformly the is pre-heated for high moisture biomass combustion.

biomass on the grate. The coverage

The high speed secondary air, together with recirculated flue gas, are distributed

of the grate is mandatory and always

over the combustion chamber to generate high turbolence. In this way low NOx

achieved. The multiple stroke

emissions and good mixing of flue gas for combustion completion are achieved.

actuator gradually pushes forward

the biomass according to the

combustion demand.

The fuel is now on the reciprocating

grate. It is a “walking inclined

floor”, with alternative fixed and

movable rows hydraulically driven.

The structure is simply air cooled

thanks to the choice of refractory

Ni-Cr cast steel bars composing each

row, for high thermal and

mechanical resistance also in case of Further more alternative combustion system technologies are available:

power black out.

The bars keep moving the biomass • Screw burners, suitable for uniform and small size biomass up to 10mm

and assure its intimate contact with having moisture content below 15% wt.

the combustion air. The wide surface • Blow burners, suitable for handling powder biomass.

available allows a margin in case of

incorrect operation or quick change • Fixed grate, suitable for very low specific gravity biomass as for sunflower

of fuel characteristics. husks and rice husks

Biomass Fired Water Tube Biomass Fired Thermal

Steam Generator Oil Generator

• Large combustion chamber made of refractory brick

walls to assure adequate residence time at high

temperature for combustion completion.

• Patented heater design.

• Horizontal multi-tubular-parallelepiped heater with square cross section.

• Radiant section made of tangent tubes welded to distribution headers,

and convective section made of wide spaced bent tubes banks.

• The BONO patented parallelepiped heater has been designed to assure

extended exchange surfaces, to assure uniform thermal oil circulation and

to prevent tubes from clogging, granting high efficiency reliability and

availability.

• The parallelepiped heater is complete with fouling cleaning system by

means of soot blower.

• Hopper for ash collection.

• Combustion chamber made of membrane water tube walls protected by a • Package heater configurations ready to be placed on combustion chamber.

refractory liner against corrosion, erosion and severe high temperature environment.

• Wide furnace volume for optimised combustion and low specific thermal load.

• Secondary combustion air distribution and flue gas recirculation generating

turbulence to ensure complete flue gas mixing and combustion efficiency.

• Integrated non catalytic NOx reduction system.

• Geometry of the flue gas path in the boiler is designed to reduce the speed

and thus erosion and fouling phenomena on the tubes.

• Convective section with evaporating section with drums, superheater,

pre-heater, economiser and air pre-heater according to process characteristics.

• Hoppers are placed along the boiler for ash collection.

BONO water tube steam generator configuration allows to achieve these

important results:

• High efficiency 84-85%

• Reduced fouling

• High availability 7500-7800 hours/year

• Simple inspection and maintenance

• Low thermal inertia for quicker cooling down and heating up of boiler.

• Reduced CO and NOx emissions

Engineering, Manufacturing,

Assembly and Start Up

A biomass fuelled energy plant project originates as Our three workshops in Italy manufacture all the

a delicate balance of technical and economical pressure parts and steelworks according to the main

requirements. European and American codes.

BONO SISTEMI offers the support in the very early The plant parts are then delivered pre-assembled in

analysis of the project, developing with the modules according to transportation limitations and

customer the different options up to the final installed on-site under the responsibility of a dedicated

solution. We are able to customize the energy team of skilled site managers, up to the final

plant, to choose and provide the flue commissioning and start-up.

gas treatment system, the water

treatment system, the power

generator and ancillaries, as

well as the civil works up to a

full turn-key supply.

Biomass Fired Thermal Oil Heater

1 Wedge floor silo

2 Feeding conveyor

3 Combustion system

4 Thermal Oil Heater

5 Air Heater + ECO

6 Cyclone

7 Flue gas treatment 8

8 Chimney 4 7

9 Ash conveyors 6

5

2

1

3

9

9

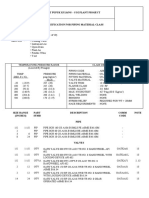

Model BIO-OIL 3 BIO-OIL 5 BIO-OIL 7 BIO-OIL 10 BIO-OIL 12

Thermal

capacity 3,5 MW 5 MW 7 MW 9 -10 MW 12 MW

T in / T out 250 : 310 ° C 250 : 310 ° C 250 : 310° C 250 : 310 ° C 250 : 310 ° C

Air

pre-heater Yes Yes Yes Yes Yes

Soot

Blowing Yes Yes Yes Yes Yes

Process

Direct Yes Yes Yes Yes Yes

Heat

0,6 MWe + 1 MWe + 1,3 MWe + 1,8 MWe + 2 MWe+

ORC +DH

2,8 MWth 4 MWth 5 MWth 7,7 MWth 9,9 MWth

Biomass Fired Water Tube Steam Generator

1 Wedge floor silo

2 Feeding conveyor

3 Combustion system

4 Steam generator

5 Economizer

6 Cyclone 8

7 Flue gas treatment

4 7

8 Chimney 5

9 Ash conveyors 2 6

9 9

Model BIO-STEAM BIO-STEAM BIO-STEAM BIO-STEAM BIO-STEAM BIO-STEAM BIO-STEAM BIO-STEAM BIO-STEAM BIO-STEAM

Model

SH 7,5 SH 15 SH 22,5 SH 30 SH 37,5 SH 45 SAT 3,5 SAT 7 SAT 10 SAT 14

Thermal Thermal

7,5 MW 15 MW 22,5 MW 30 MW 37,5 MW 45 MW 3,5 MW 7 MW 10 MW 14 MW

capacity capacity

Superheated Saturated

10 t/h 20 t/h 30 t/h 40 t/h 50 t/h 60 t/h 5 t/h 10 t/h 15 t/h 20 t/h

Steam Steam

Pressure up to 50 bar up to 50 bar up to 50 bar up to 50 bar up to 50 bar up to 50 bar Pressure up to 30 bar up to 30 bar up to 30 bar up to 30 bar

Temperature up to 450° C up to 450° C up to 450° C up to 450° C up to 450° C up to 450° C Efficiency up to 87 % up to 87 % up to 87 % up to 87 %

Efficiency up to 87 % up to 87% up to 87% up to 87% up to 87% up to 87% Economizer Yes Yes Yes Yes

Air Yes Yes Yes Yes

Economizer Yes Yes Yes Yes Yes Yes

pre-heater

Electrical Direct

2 MW 4 MW 6 MW 8 MW 10 MW 12 MW Process Yes Yes Yes Yes

Power Heat

You might also like

- 2KD-FTV Engine MechanicalDocument1 page2KD-FTV Engine Mechanicaladdis gilleNo ratings yet

- EPRI - Renewable Energy Technology Guide 2012Document856 pagesEPRI - Renewable Energy Technology Guide 2012sulemankhalid100% (1)

- CogenerationDocument21 pagesCogenerationRohit Jindal100% (1)

- Forester UFS & MGS: Wood Chip BoilersDocument16 pagesForester UFS & MGS: Wood Chip BoilersmarioLhrNo ratings yet

- BiogasDocument15 pagesBiogasСемен ГассеевNo ratings yet

- 4 PDFDocument4 pages4 PDFRasoulNo ratings yet

- Factsheet - Thermochemical Gasification of BiomassDocument8 pagesFactsheet - Thermochemical Gasification of BiomassFlorin LunguNo ratings yet

- Biomass GensetDocument7 pagesBiomass GensetPauloCPinheiroNo ratings yet

- RYA CHP (Göteborg Energi) : Case Study Factsheet Europe, SwedenDocument1 pageRYA CHP (Göteborg Energi) : Case Study Factsheet Europe, SwedenNander Acosta OyarceNo ratings yet

- ETIP Bioenergy Factsheet Hybrid FacilitiesDocument2 pagesETIP Bioenergy Factsheet Hybrid FacilitiesKamran AhmedNo ratings yet

- Article From Coal To Biomass at MN PowerDocument3 pagesArticle From Coal To Biomass at MN PowerCory LukerNo ratings yet

- Wood Heating SystemsDocument24 pagesWood Heating Systemsanon_411130333No ratings yet

- Module 4 Sep-Ktunotes - inDocument26 pagesModule 4 Sep-Ktunotes - inmujeebNo ratings yet

- Energy Production From Biomass (Part 2) : Conversion TechnologiesDocument8 pagesEnergy Production From Biomass (Part 2) : Conversion TechnologiesKjuiNo ratings yet

- Biomass Combustion Manual - 6 October 2015 PDFDocument12 pagesBiomass Combustion Manual - 6 October 2015 PDFpriyankaNo ratings yet

- CO-Generation: 2 Need of CogenerationDocument7 pagesCO-Generation: 2 Need of Cogenerationajay kumar royNo ratings yet

- Biofuel and Green BiotechnologyDocument4 pagesBiofuel and Green BiotechnologynavneetNo ratings yet

- VtervrdvDocument3 pagesVtervrdvAdhit Mart DithaNo ratings yet

- CogenerationDocument11 pagesCogenerationeddy hernandezNo ratings yet

- Hks Lazar Kotly I Piece Na Pellet enDocument21 pagesHks Lazar Kotly I Piece Na Pellet enLaura-MariaDragomirNo ratings yet

- Single Bucket Telescopic Furnace Versus Continuous Optimised Single Shaft (COSS) FurnaceDocument5 pagesSingle Bucket Telescopic Furnace Versus Continuous Optimised Single Shaft (COSS) Furnacelucas123No ratings yet

- How To Know If Cogeneration Is The Right Choice For YouDocument4 pagesHow To Know If Cogeneration Is The Right Choice For YouRicardo BecNo ratings yet

- Cea 223 Mod 4Document6 pagesCea 223 Mod 4PhoemelaNo ratings yet

- Biogas Plants MonitoringDocument12 pagesBiogas Plants MonitoringDeepak Dev BurmanNo ratings yet

- Combined CycleDocument8 pagesCombined CycleRi KoNo ratings yet

- Cogeneration - WikipediaDocument137 pagesCogeneration - Wikipediaknward828No ratings yet

- 01 - GT - 01 - Carbo - Tar Free - LogDocument4 pages01 - GT - 01 - Carbo - Tar Free - LogUmar MajeedNo ratings yet

- Thermochem Conversion of Ical BiomassDocument47 pagesThermochem Conversion of Ical BiomassKhoi HoangNo ratings yet

- BiomassDocument30 pagesBiomassJhonloyd Rosete LittauaNo ratings yet

- Impact of Retrofitting Existing Combined Heat and Power Plant With Polygeneration of Biomethane PDFDocument16 pagesImpact of Retrofitting Existing Combined Heat and Power Plant With Polygeneration of Biomethane PDFAwais Salman0% (1)

- Co-Generation SystemDocument5 pagesCo-Generation SystemPavan AherNo ratings yet

- Assignment No 4: Power PlantDocument5 pagesAssignment No 4: Power PlantusamaNo ratings yet

- Analytical Method To Determine The Potential of Using Rice Husk For Off Grid Electricity and Heat GenerationDocument4 pagesAnalytical Method To Determine The Potential of Using Rice Husk For Off Grid Electricity and Heat Generationrazor six fourNo ratings yet

- Improvement Efficiency and Energy Savings Consumes Fuel On BoilerDocument6 pagesImprovement Efficiency and Energy Savings Consumes Fuel On BoilerFabriansyah Aprilya Natha YusufyNo ratings yet

- UNITENICEE2006 Externally Fired Gas Turbinefor Small Scale Power Unit Hot Air Production Unitfor Drying Processes Using Biomass FuelDocument6 pagesUNITENICEE2006 Externally Fired Gas Turbinefor Small Scale Power Unit Hot Air Production Unitfor Drying Processes Using Biomass FuelLuis Antonio CNo ratings yet

- MELECDocument4 pagesMELECJeston TamayoNo ratings yet

- Biomass in BoilerDocument13 pagesBiomass in Boilermbkluimp100% (2)

- FILE - 20201025 - 100720 - CHP-Steam TurbineDocument4 pagesFILE - 20201025 - 100720 - CHP-Steam TurbineNGUYEN QUANG100% (1)

- Combustion of Syngas in A Pressurized MicroturbineDocument12 pagesCombustion of Syngas in A Pressurized MicroturbineSudkate BoonthawornNo ratings yet

- Electrot EcDocument6 pagesElectrot EcEmiro Revilla CatariNo ratings yet

- Biomass Energy InstallationsDocument7 pagesBiomass Energy InstallationsdrrooNo ratings yet

- Aspen Plus Simulation of Biomass Integrated Gasification Combined Cycle Systems at Corn Ethanol PlantsDocument14 pagesAspen Plus Simulation of Biomass Integrated Gasification Combined Cycle Systems at Corn Ethanol PlantsMugdho HossainNo ratings yet

- Steam Turbinea NalysisDocument10 pagesSteam Turbinea NalysiswasayNo ratings yet

- Energy in Buildings Industry Retrofit Heat Pumps. January 21. 1Document1 pageEnergy in Buildings Industry Retrofit Heat Pumps. January 21. 1fjNo ratings yet

- Combination of A Wood-Pellet Boiler-Stove With Other Conventional and Renewable Heating System For Space Heating and Domestic Hot Water Within A Passive House in BelgiumDocument8 pagesCombination of A Wood-Pellet Boiler-Stove With Other Conventional and Renewable Heating System For Space Heating and Domestic Hot Water Within A Passive House in BelgiumVan Long LêNo ratings yet

- Estimating Natural Gas Demand at A Petrochemical ComplexDocument4 pagesEstimating Natural Gas Demand at A Petrochemical ComplexJarodNo ratings yet

- HTP 00604 P 054Document3 pagesHTP 00604 P 054Amazonas ManutençãoNo ratings yet

- CogenerationDocument27 pagesCogenerationArchit MadaanNo ratings yet

- Baxi Biomass BrochureDocument12 pagesBaxi Biomass BrochureAndrius GonestasNo ratings yet

- Agricultural BiogasDocument4 pagesAgricultural BiogasdakNo ratings yet

- 2286 - Nikolay Milkov trans&MOTAUTO'15Document7 pages2286 - Nikolay Milkov trans&MOTAUTO'15Selvakumar PNo ratings yet

- Fuel & Energy AssignmentDocument6 pagesFuel & Energy AssignmentZarar SaleemNo ratings yet

- A Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)Document5 pagesA Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)luis hyungNo ratings yet

- Utilizing Gland SteamDocument7 pagesUtilizing Gland SteamZulhakim SharudinNo ratings yet

- Honeywell Burner ModelsDocument16 pagesHoneywell Burner ModelswassiiqbalNo ratings yet

- Biomass Combustion & Co-FiringDocument16 pagesBiomass Combustion & Co-Firingsebascian100% (1)

- Offshore Wind Energy in EuropeDocument15 pagesOffshore Wind Energy in EuropeSundar KumarNo ratings yet

- Valuable Energy!: Engine Manufacturers. Genset IntegratorsDocument2 pagesValuable Energy!: Engine Manufacturers. Genset IntegratorsJeff LangleyNo ratings yet

- The Large Capacity Gas Turbine For Pressurized Fluidized Bed Combustion (PFBC) Boiler Combined Cycle Power PlantDocument3 pagesThe Large Capacity Gas Turbine For Pressurized Fluidized Bed Combustion (PFBC) Boiler Combined Cycle Power PlantParmeshwarPaulNo ratings yet

- Overview of Mejia Thermal Power StationDocument35 pagesOverview of Mejia Thermal Power StationNitish KhalkhoNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Good Stoves Facilitation: How to Innovate and Change the WorldFrom EverandGood Stoves Facilitation: How to Innovate and Change the WorldNo ratings yet

- Daily Activity Report 30 Nov 2022Document25 pagesDaily Activity Report 30 Nov 2022t_i_f_anoNo ratings yet

- Daily Activity Report 28 Okt 2022Document27 pagesDaily Activity Report 28 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 28 Des 2022Document28 pagesDaily Activity Report 28 Des 2022t_i_f_anoNo ratings yet

- Daily Activity Report 27 Sept 2022Document25 pagesDaily Activity Report 27 Sept 2022t_i_f_anoNo ratings yet

- Daily Activity Report 2 Okt 2022Document23 pagesDaily Activity Report 2 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 29 Sept 2022Document23 pagesDaily Activity Report 29 Sept 2022t_i_f_anoNo ratings yet

- Daily Activity Report 30 Okt 2022Document26 pagesDaily Activity Report 30 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 17 Okt 2022Document23 pagesDaily Activity Report 17 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 5 Okt 2022Document23 pagesDaily Activity Report 5 Okt 2022t_i_f_anoNo ratings yet

- Daily Report 02 Sept 22Document2 pagesDaily Report 02 Sept 22t_i_f_anoNo ratings yet

- Daily Activity Report 3 Okt 2022Document23 pagesDaily Activity Report 3 Okt 2022t_i_f_anoNo ratings yet

- Daily Report 05 Sept 2022Document2 pagesDaily Report 05 Sept 2022t_i_f_anoNo ratings yet

- Daily Report 03 Sept 22Document2 pagesDaily Report 03 Sept 22t_i_f_anoNo ratings yet

- Daily Report 04 Sept 22Document2 pagesDaily Report 04 Sept 22t_i_f_anoNo ratings yet

- Tesla Literature BrochureDocument16 pagesTesla Literature Brochuret_i_f_anoNo ratings yet

- Daily Report 01 Sept 22Document2 pagesDaily Report 01 Sept 22t_i_f_anoNo ratings yet

- D-ILA Series Heatless Desiccant Dryers 2.7-141.6 m3 - Min, 90-5,000 CFMDocument2 pagesD-ILA Series Heatless Desiccant Dryers 2.7-141.6 m3 - Min, 90-5,000 CFMt_i_f_anoNo ratings yet

- Insania Energi COMPANY PROFILEDocument50 pagesInsania Energi COMPANY PROFILEt_i_f_anoNo ratings yet

- Attachment - 1 Reference List N-GEN Omega AirDocument51 pagesAttachment - 1 Reference List N-GEN Omega Airt_i_f_anoNo ratings yet

- General Brochure - Johnson ControlsDocument4 pagesGeneral Brochure - Johnson Controlst_i_f_anoNo ratings yet

- SMC Production SampleDocument14 pagesSMC Production Samplet_i_f_anoNo ratings yet

- Katalog Heat CarryDocument8 pagesKatalog Heat Carryt_i_f_anoNo ratings yet

- Piping Material ClassesDocument42 pagesPiping Material Classest_i_f_anoNo ratings yet

- Bellmer Group CataloqueDocument20 pagesBellmer Group Cataloquet_i_f_anoNo ratings yet

- TRAIN AWAY E-Ticket PDFDocument2 pagesTRAIN AWAY E-Ticket PDFt_i_f_anoNo ratings yet

- Lycom - Ring - Apps SUPERIOR PARTS PDFDocument10 pagesLycom - Ring - Apps SUPERIOR PARTS PDFElmer VillegasNo ratings yet

- Ppe Unit 2Document25 pagesPpe Unit 2rp0212No ratings yet

- Direct Contact Water Heater - Kemco SystemsDocument11 pagesDirect Contact Water Heater - Kemco SystemsabdulanisNo ratings yet

- 33 Strings With Y Connector SLD RefDocument1 page33 Strings With Y Connector SLD RefSAEL SOLARNo ratings yet

- 04 - Solar Turbines - About - Solar - Turbines PDFDocument4 pages04 - Solar Turbines - About - Solar - Turbines PDFAli AbasabadarabNo ratings yet

- Other Models Are Available, Please E-Mail Us.: Automatic Water Refill !Document1 pageOther Models Are Available, Please E-Mail Us.: Automatic Water Refill !marcello_oliveiraNo ratings yet

- Method For Thermoelectric Cooler Utilization Using Manufacturer's Technical InformationDocument6 pagesMethod For Thermoelectric Cooler Utilization Using Manufacturer's Technical Informationehtisham khanNo ratings yet

- Ra410202 Non Conventional Energy Sources Set1Document2 pagesRa410202 Non Conventional Energy Sources Set1Srinivasa Rao G100% (1)

- Storage Heaters Containing AsbestosDocument9 pagesStorage Heaters Containing AsbestosandresNo ratings yet

- Startup & Shutdown Procedure and Maintenance GuidelinesDocument2 pagesStartup & Shutdown Procedure and Maintenance GuidelinesKrystianNo ratings yet

- CompressorsDocument34 pagesCompressorsShanza AsifNo ratings yet

- A. The Following Table Contains Figures OnDocument48 pagesA. The Following Table Contains Figures OnAliNo ratings yet

- High Pressure Boilers Features and AdvantagesDocument2 pagesHigh Pressure Boilers Features and AdvantagesMusycal Fynnc100% (2)

- Six Stroke EngineDocument15 pagesSix Stroke EnginesaRAth asgaRdianNo ratings yet

- Basics of PVDocument117 pagesBasics of PVJay SinghNo ratings yet

- Ktunotes - In: Lecture Notes On Power Generation, Transmission, and DistributionDocument11 pagesKtunotes - In: Lecture Notes On Power Generation, Transmission, and Distributionlakshmi dileepNo ratings yet

- Dokumen - Tips - Castrol Renault Booklet 105x240 3 Renault 13 h5ht 55 16 h4m 45 Clio 12 Tabela Lubrificantes MotorDocument2 pagesDokumen - Tips - Castrol Renault Booklet 105x240 3 Renault 13 h5ht 55 16 h4m 45 Clio 12 Tabela Lubrificantes MotorEduardoNo ratings yet

- 한국선급 - 선박용 배터리시스템 지침 - 2020Document24 pages한국선급 - 선박용 배터리시스템 지침 - 2020Yo LeeNo ratings yet

- Clyde - SB Smart Clean System (Shared by ED - 220928 - 104318Document2 pagesClyde - SB Smart Clean System (Shared by ED - 220928 - 104318Sanjana SanjanaNo ratings yet

- Lecture No.4 The Ideal Regenerative Rankine CycleDocument22 pagesLecture No.4 The Ideal Regenerative Rankine CycleJohn Michael Go AbalosNo ratings yet

- Volvo RemanDocument72 pagesVolvo Remanrizki hidayat100% (1)

- Solar Energy EPIADocument76 pagesSolar Energy EPIAjaviNo ratings yet

- PT Ppe 1Document5 pagesPT Ppe 1Amjad PathanNo ratings yet

- Atd Unit 1Document157 pagesAtd Unit 1saikiran pendkar100% (1)

- Worldwide Panorama of Nuclear EnergyDocument161 pagesWorldwide Panorama of Nuclear Energydamp1rNo ratings yet

- Off-Grid Micro-Hydro Power Generator Integrated With Solar Water Pump System For Rural AreasDocument7 pagesOff-Grid Micro-Hydro Power Generator Integrated With Solar Water Pump System For Rural AreasKYLE LEIGHZANDER VICENTENo ratings yet

- Fuel CellsDocument16 pagesFuel Cellspramod gaikwadNo ratings yet

- Muhammad Safdar-1Document2 pagesMuhammad Safdar-1ßígrà KíńgNo ratings yet