Professional Documents

Culture Documents

CPU Trip Limit 1

CPU Trip Limit 1

Uploaded by

Bikash Kumar SahooCopyright:

Available Formats

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- 000 5Document185 pages000 5fahad jamilNo ratings yet

- B C N (None) : C-Spool H-SpoolDocument2 pagesB C N (None) : C-Spool H-SpoolPasqualeNo ratings yet

- Attachment C - HAZOP WorksheetDocument18 pagesAttachment C - HAZOP Worksheetwibowo wibowo50% (2)

- PCV Data Sheet PDFDocument5 pagesPCV Data Sheet PDFveenaNo ratings yet

- Relays Selection Chart: FeaturesDocument8 pagesRelays Selection Chart: FeaturesNoCopyrightMusicsNo ratings yet

- Pipeline Capacity IncreaseDocument8 pagesPipeline Capacity IncreaseElendu Emmanuel ChigozieNo ratings yet

- Watts by Dixon R119 06C Specification SheetDocument2 pagesWatts by Dixon R119 06C Specification SheetGIANNo ratings yet

- hdm18 - 200 P 991210 enDocument19 pageshdm18 - 200 P 991210 enAlejandro NavaNo ratings yet

- r119 16j Parker Air Regulator DatasheetDocument2 pagesr119 16j Parker Air Regulator DatasheetGIANNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- KA3511BS: Intelligent Voltage Mode PWM ICDocument20 pagesKA3511BS: Intelligent Voltage Mode PWM ICPlamenPetrovNo ratings yet

- Song - Chuan 845HN 1C C 24VDC DatasheetDocument7 pagesSong - Chuan 845HN 1C C 24VDC DatasheetYul GoncalvesNo ratings yet

- Bucher Vent IlDocument16 pagesBucher Vent IlOl WebNo ratings yet

- Electric Amplifiers VT-VRPA2 RE30048 01.09Document8 pagesElectric Amplifiers VT-VRPA2 RE30048 01.09cnidstpsNo ratings yet

- 24.operation of SSDocument2 pages24.operation of SSNishantNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit Agarwal100% (1)

- Mill Reject System NTPC FarakkaDocument26 pagesMill Reject System NTPC FarakkapntripathiNo ratings yet

- Deliver The Well: Rodney Howard Halliburton, AberdeenDocument100 pagesDeliver The Well: Rodney Howard Halliburton, AberdeenЮрий Усков100% (1)

- m16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedDocument54 pagesm16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedsfssullconnectNo ratings yet

- MT28JE5PVEDocument5 pagesMT28JE5PVEJo PastorNo ratings yet

- FRDALAN Es Us LetterDocument1 pageFRDALAN Es Us LetterIsaac Ticona MenesesNo ratings yet

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- AnnexureDocument391 pagesAnnexureTommy ArjanggiNo ratings yet

- 55 50 SN Diagnosis Valve BodyDocument29 pages55 50 SN Diagnosis Valve BodyPatricio ArredondoNo ratings yet

- Valvula de DiluvioDocument4 pagesValvula de DiluvioJJ GOLE PRECIOS UNITARIOSNo ratings yet

- B757 36 B757 Pneumatics T S Job AidDocument19 pagesB757 36 B757 Pneumatics T S Job Aidprzytul2007No ratings yet

- NCP1396A, NCP1396B Controller, High Performance Resonant Mode, With High and Low Side DriversDocument26 pagesNCP1396A, NCP1396B Controller, High Performance Resonant Mode, With High and Low Side DriversMaria VaccarielloNo ratings yet

- Ut 1201Document2 pagesUt 1201pathivadasirishNo ratings yet

- RECLOSER-FARADAY-33KV Auto Recloser BrochureDocument9 pagesRECLOSER-FARADAY-33KV Auto Recloser BrochureJoel Alevxandr OsorttoNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- DatasheetDocument25 pagesDatasheetDaniel LeinadNo ratings yet

- 16.04.2022 - Description of CSSDocument2 pages16.04.2022 - Description of CSSYazhisai SelviNo ratings yet

- Vt-Vrpa2-5 - 1XRTPDocument8 pagesVt-Vrpa2-5 - 1XRTPPanca AriefNo ratings yet

- P6SD Series: Technical Specifications Features and BenefitsDocument8 pagesP6SD Series: Technical Specifications Features and BenefitsEduardo Rogelio Prado LevanoNo ratings yet

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- Cable Schedule (FF.17001)Document51 pagesCable Schedule (FF.17001)josejohn1No ratings yet

- 59 270001 Relay 793Document5 pages59 270001 Relay 793Ethan JanusNo ratings yet

- Liq ProdData 71-385Document4 pagesLiq ProdData 71-385mohan.tijare.mtNo ratings yet

- Model RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)Document4 pagesModel RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)asimnaqvi2008No ratings yet

- DMDAMAN Full en Us LetterDocument3 pagesDMDAMAN Full en Us LetterjmmcaptainNo ratings yet

- 00100W N G0 G020 SR LST 0001 0 - 76029Document2 pages00100W N G0 G020 SR LST 0001 0 - 76029Jalal AlbadriNo ratings yet

- SECTION 3.3.8 PAGE 114 OF 172: Section 3.3.8 - Protection Indication System R4Document21 pagesSECTION 3.3.8 PAGE 114 OF 172: Section 3.3.8 - Protection Indication System R4ramNo ratings yet

- Updated Cable Schedule (FF (12-04-17)Document58 pagesUpdated Cable Schedule (FF (12-04-17)josejohn1No ratings yet

- Gruas KrancoDocument13 pagesGruas KrancoYorchOwnsNo ratings yet

- A XW-118 A XW-128 Ami-926lw/rwDocument34 pagesA XW-118 A XW-128 Ami-926lw/rwpata saladaNo ratings yet

- Peak 3A Bus Termination RegulatorDocument12 pagesPeak 3A Bus Termination RegulatormkubawatNo ratings yet

- FAN7380 Half-Bridge Gate Driver: Features DescriptionDocument12 pagesFAN7380 Half-Bridge Gate Driver: Features Descriptionflo72afNo ratings yet

- RS 210 RS 210: Sectional Directional Control Valve Control ValveDocument20 pagesRS 210 RS 210: Sectional Directional Control Valve Control ValveAnemNo ratings yet

- Fuse, Bussman Time Delay FNQ-RDocument3 pagesFuse, Bussman Time Delay FNQ-RSerNo ratings yet

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- Model 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotDocument2 pagesModel 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotVignesh PandiyanNo ratings yet

- Ut-1201 Flow MeterDocument12 pagesUt-1201 Flow MeterRam KumarNo ratings yet

- RUH Umpen: Ruhrpumpen GMBHDocument40 pagesRUH Umpen: Ruhrpumpen GMBHjacobo nasimbaNo ratings yet

- Pressure Relief ValvesDocument4 pagesPressure Relief ValvesHassanNo ratings yet

- WDR 01Document1 pageWDR 01carlos.nunez.t.ingNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Acids Bases and SaltsDocument55 pagesAcids Bases and Saltsgeorgy shibuNo ratings yet

- Astronomy - February 2019 USA PDFDocument80 pagesAstronomy - February 2019 USA PDFRaluca Roxana RujaNo ratings yet

- Paper ChromatographyDocument5 pagesPaper ChromatographyChelsea MartinezNo ratings yet

- Mathematical Model of A Direct Methanol Fuel Cell: DMFC023Document6 pagesMathematical Model of A Direct Methanol Fuel Cell: DMFC023KaustubhNo ratings yet

- Dattaproject DONEDocument25 pagesDattaproject DONEsumit potdarNo ratings yet

- Iron Removal From A Kaolinitic Clay by Leaching To Obtain High Whiteness IndexDocument5 pagesIron Removal From A Kaolinitic Clay by Leaching To Obtain High Whiteness IndexromanangelhernandezNo ratings yet

- 5991-4687en - APP Pesticide in Difficult FoodDocument8 pages5991-4687en - APP Pesticide in Difficult FoodBogdan CioroiuNo ratings yet

- Hsslive-Xi-Chemistry-11. The P-Block Elements-Anil-SirDocument7 pagesHsslive-Xi-Chemistry-11. The P-Block Elements-Anil-SirKrishnendu NairNo ratings yet

- WaterAnalyses PDFDocument2 pagesWaterAnalyses PDFZenga Harsya PrakarsaNo ratings yet

- Lecture 5, 6 Chapter 3 - Equilibrium 2D, 3DDocument52 pagesLecture 5, 6 Chapter 3 - Equilibrium 2D, 3Drobel metikuNo ratings yet

- An Ultimate Guide To Transistor PinoutsDocument15 pagesAn Ultimate Guide To Transistor PinoutsjackNo ratings yet

- SolutionDocument3 pagesSolutionbahast faiqNo ratings yet

- Null 27Document5 pagesNull 27BTS ArmyNo ratings yet

- Skin Effect and Skin DepthDocument2 pagesSkin Effect and Skin DepthUdit SharmaNo ratings yet

- DTD Handbook: Section 2.2.6.3. Crack Opening DisplacementDocument4 pagesDTD Handbook: Section 2.2.6.3. Crack Opening Displacementpouya_msNo ratings yet

- Magnetism For JEEDocument15 pagesMagnetism For JEEJatin SonwalNo ratings yet

- Electroplating of Cu-Sn Alloys andDocument81 pagesElectroplating of Cu-Sn Alloys andcicerojoiasNo ratings yet

- Gravitation: Very Short Answer Type Questions-Pg-100Document53 pagesGravitation: Very Short Answer Type Questions-Pg-100DX GamingNo ratings yet

- 253TAIYO ASC 32 V2.0.0.0 Appendix V1.1 ENDocument8 pages253TAIYO ASC 32 V2.0.0.0 Appendix V1.1 ENhmhaidarNo ratings yet

- The Copernican RevolutionDocument41 pagesThe Copernican RevolutionRhea Jane Dela CruzNo ratings yet

- 7 CarbohydratesDocument18 pages7 CarbohydratesBhanuPrasannaNo ratings yet

- 10 Chemistry Guess by MNA Ghumman Smart SyllabusDocument5 pages10 Chemistry Guess by MNA Ghumman Smart SyllabusSania Ashir0% (2)

- Borophene Paper: by Raghisa KhalidDocument22 pagesBorophene Paper: by Raghisa KhalidRAghixa KhAlidNo ratings yet

- C R Robertson Fundamental Electrical and ElectroBookZZ - Org 31Document4 pagesC R Robertson Fundamental Electrical and ElectroBookZZ - Org 31Salmarianto AntoNo ratings yet

- HPMC Viscosity GradesDocument10 pagesHPMC Viscosity GradesKhoa Duy100% (1)

- Lec#03. Special Types of ConcretesDocument24 pagesLec#03. Special Types of ConcretesThe GLOBENo ratings yet

- Magnesium & Aluminum in Water FuelsDocument10 pagesMagnesium & Aluminum in Water FuelsCliff ThriveNo ratings yet

- Physics Education Vol 2Document60 pagesPhysics Education Vol 2Arindam Kumar ChatterjeeNo ratings yet

- MetabolomicsDocument12 pagesMetabolomicswatson191No ratings yet

CPU Trip Limit 1

CPU Trip Limit 1

Uploaded by

Bikash Kumar SahooOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CPU Trip Limit 1

CPU Trip Limit 1

Uploaded by

Bikash Kumar SahooCopyright:

Available Formats

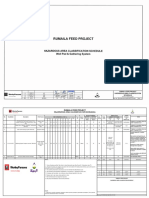

Annexure II control Write-up

Project Code :331

Project : IB Thermal Power Station, Banharpali (2 x 660 MW) Units3 & 4

Title : Impoprtant Process Interlock

Reference Alaram/Trip set Audio Visual

SL No Tag No. Service / Fumnction Interlock / Trip Action

P&ID Point Alarm on TFT

1 TAH-100 Condensate Inlet Header Temp High 60° ●

Inlet/ Outlet Header By-Pass Valve- PCV-109 to

open for full by-pass

2 AAH-100 Condensate Inlet Header Conductivity High 2 µs/cm ●

Cation Conductivity Exit Service Vessel R-1a

3 AAH-101a

High

0.1 µs/cm ●

D.P. Across Service Vessel R-1a including

4 DPAH-104a

resin trap High

3.5 Kg/cm2 ●

For any of 5 Conditions, R1-a will be isolated from

service operation and the auto-isolation valves at

Silica content service vessel R-1a exist High inlet R1a-KV101 and Outlet R1a-KV102 will close

5 AAH-104a

(Channel-I)

5 ppb ● and the Condensate inlet /Outlet Header By-Pass

control valve PCV-109 will open to the extent to By-

Pass Service Vessel R-1a flow.

6 FQA-101a Totalized flow inlet Service Vessel R-1a High 1,30,872 M3 ●

Sodium containt service vessel R-1a outlet

7 AAH-1052a

High (Channel-I)

2 ppb ●

Cation Conductivity Exit Service Vessel R-1b

8 AAH-105b

High

0.1 µs/cm ●

DO3-C-331-83-PL-00025-A001

D.P. Across Service Vessel R-1b including

9 DPAH-104b

resin trap High

3.5 Kg/cm2 ●

For any of 5 Conditions, R1-b will be isolated from

service operation and the auto-isolation valves at

Silica content service vessel R-1b exist High inlet R1b-KV101 and Outlet R1b-KV102 will close

10 AAH-104b

(Channel-II)

5 ppb ● and the Condensate inlet /Outlet Header By-Pass

control valve PCV-109 will open to the extent to By-

Pass Service Vessel R-1b flow.

11 FQA-101b Totalized flow inlet Service Vessel R-1b High 1,30,872 M3 ●

Sodium containt service vessel R-1b outlet

12 AAH-105b

High (Channel-II)

2 ppb ●

Cation Conductivity Exit Service Vessel R-1c

13 AAH-101c

High

0.1 µs/cm ●

D.P. Across Service Vessel R-1c including

14 DPAH-103c

resin trap High

3.5 Kg/cm2 ●

For any of 5 Conditions, R1-c will be isolated from

service operation and the auto-isolation valves at

inlet R1c-KV101 and Outlet R1c-KV102 will close

15 AAH-104c Silica content service vessel R-1c exist High 5 ppb ● and the Condensate inlet /Outlet Header By-Pass

control valve PCV-109 will open to the extent to By-

Pass Service Vessel R-1c flow.

16 FQA-101c Totalized flow inlet Service Vessel R-1c High 1,30,872 M3 ●

Sodium containt service vessel R-1c outlet

17 AAH-105c

High

2 ppb ●

Service Vessel Blower Discharge Pressure

18 PAH-112

High

> 0.5 Kg/cm2 ● To Trip the Running Air Blower

19 AAL-602 ARU Rinse Outlet Conductivity Low < 5 µs/cm ●

DO3-C-331-83-PL-00025-A002

20 AAH-603 CRU Rinse Outlet Conductivity Low < 5 µs/cm ●

Resin Transfer from ARU to CRU - Outlet

21 AAH-601

Conductivity High (Interface detection)

< 70 ●

regeneration Air Blower Discharge Pressure

22 PT-606

high

> 0.6 Kg/cm2 ● To Trip the Running Air Blower

Annexure II control Write-up

Project Code :331

Project : IB Thermal Power Station, Banharpali (2 x 660 MW) Units3 & 4

Title : Impoprtant Process Interlock

Reference Alaram/Trip set Audio Visual

SL No Tag No. Service / Fumnction Interlock / Trip Action

P&ID Point Alarm on TFT

Alkali Solution Preparition Tank T-2 Lavel

23 LAL-706(L)

Low 30% ● To Close Alkali Outlet Valvle of T-2, i.e, T4-KV701

24 LAH-708(H) Alkali Measuring Tank T-4 Lavel High 75% ● To Close Alkali Inlet Valvle of T-2, i.e, T4-KV701

To Close Alkali Outlet & Common O/L valve from

25 LAL-708(L) Alkali Measuring Tank T-4 Lavel Low 30% ● Tank T-4, i.e,T4-KV702 & MT1-KV701

To Close Acid Inlet Valve T5-KV701 to Stop acid

26 LAH-714(H) Acid Measuring Tank T-5 Lavel High 75% ● filling of T5

To Close Acid Inlet ValvemT2-KV701 to stop acid

27 LAL-714(L) Acid Measuring Tank T-5 Lavel Low 30% ● injection Operation.

28 PHAH-701(L) Neutralized Effluent pH- High 7.5 ●

To close Effluent Disposal Valve P5-KV701 and open

Effluent Recirculation Valve (Selected) i.e, either C1a-

KV701 or C1b-KV701

29 6.5

DO3-C-331-83-PL-00025-A003

LALL-716 Neutralized Effluent pH- Low ●

1. To cut-off Heater-1 & 2

30 TAHH-702 Hot Water Tank R-6 Water Temp.-Low 20% ● 2. To Stop the Running alkali dosing pump.

31 LAHH-702 Hot Water Tank R-6 Water Temp.-High 80% ● To cut-Off Heater-1 & 2

To Trip DM Water Regen. & Resin Transfer Pumps

32 LALL-(ClientScope) Dm Water Storage Tank Level-Low 20% ● P1a, P1b

33 LAL-711 Bulk Acid Storage tank T7 Level - Low 30% ● To Close Acid Outlet Valves T7-KV701

To trip the Running Acid Unloading Pump P4a Or

34 LAH-711 Bulk Acid Storage tank T7 Level - High 75% ● 4b

To trip the Running Alkali Unloading Pump P3a Or

35 LAL-704 Bulk Alkali Storage Tank T6 Level - High 75% ● 3b

To trip the Running Alkali Transfer Pump cum

36 LAH-704 Bulk Alkali Storage Tank T6 Level - Low 30% ● Recirculation Pump P2a Or 2b

37 LAL-717 Alkali Measuring Tank Level-Low 75% ● To trip the running Agitator

NOTE :- The alaram/trip set points indicated above are tentative and they may so slightly under change during Pre- commissioning /

Commissioning as per Plant Operation Requirement.

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- 000 5Document185 pages000 5fahad jamilNo ratings yet

- B C N (None) : C-Spool H-SpoolDocument2 pagesB C N (None) : C-Spool H-SpoolPasqualeNo ratings yet

- Attachment C - HAZOP WorksheetDocument18 pagesAttachment C - HAZOP Worksheetwibowo wibowo50% (2)

- PCV Data Sheet PDFDocument5 pagesPCV Data Sheet PDFveenaNo ratings yet

- Relays Selection Chart: FeaturesDocument8 pagesRelays Selection Chart: FeaturesNoCopyrightMusicsNo ratings yet

- Pipeline Capacity IncreaseDocument8 pagesPipeline Capacity IncreaseElendu Emmanuel ChigozieNo ratings yet

- Watts by Dixon R119 06C Specification SheetDocument2 pagesWatts by Dixon R119 06C Specification SheetGIANNo ratings yet

- hdm18 - 200 P 991210 enDocument19 pageshdm18 - 200 P 991210 enAlejandro NavaNo ratings yet

- r119 16j Parker Air Regulator DatasheetDocument2 pagesr119 16j Parker Air Regulator DatasheetGIANNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- KA3511BS: Intelligent Voltage Mode PWM ICDocument20 pagesKA3511BS: Intelligent Voltage Mode PWM ICPlamenPetrovNo ratings yet

- Song - Chuan 845HN 1C C 24VDC DatasheetDocument7 pagesSong - Chuan 845HN 1C C 24VDC DatasheetYul GoncalvesNo ratings yet

- Bucher Vent IlDocument16 pagesBucher Vent IlOl WebNo ratings yet

- Electric Amplifiers VT-VRPA2 RE30048 01.09Document8 pagesElectric Amplifiers VT-VRPA2 RE30048 01.09cnidstpsNo ratings yet

- 24.operation of SSDocument2 pages24.operation of SSNishantNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit Agarwal100% (1)

- Mill Reject System NTPC FarakkaDocument26 pagesMill Reject System NTPC FarakkapntripathiNo ratings yet

- Deliver The Well: Rodney Howard Halliburton, AberdeenDocument100 pagesDeliver The Well: Rodney Howard Halliburton, AberdeenЮрий Усков100% (1)

- m16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedDocument54 pagesm16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedsfssullconnectNo ratings yet

- MT28JE5PVEDocument5 pagesMT28JE5PVEJo PastorNo ratings yet

- FRDALAN Es Us LetterDocument1 pageFRDALAN Es Us LetterIsaac Ticona MenesesNo ratings yet

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- AnnexureDocument391 pagesAnnexureTommy ArjanggiNo ratings yet

- 55 50 SN Diagnosis Valve BodyDocument29 pages55 50 SN Diagnosis Valve BodyPatricio ArredondoNo ratings yet

- Valvula de DiluvioDocument4 pagesValvula de DiluvioJJ GOLE PRECIOS UNITARIOSNo ratings yet

- B757 36 B757 Pneumatics T S Job AidDocument19 pagesB757 36 B757 Pneumatics T S Job Aidprzytul2007No ratings yet

- NCP1396A, NCP1396B Controller, High Performance Resonant Mode, With High and Low Side DriversDocument26 pagesNCP1396A, NCP1396B Controller, High Performance Resonant Mode, With High and Low Side DriversMaria VaccarielloNo ratings yet

- Ut 1201Document2 pagesUt 1201pathivadasirishNo ratings yet

- RECLOSER-FARADAY-33KV Auto Recloser BrochureDocument9 pagesRECLOSER-FARADAY-33KV Auto Recloser BrochureJoel Alevxandr OsorttoNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- DatasheetDocument25 pagesDatasheetDaniel LeinadNo ratings yet

- 16.04.2022 - Description of CSSDocument2 pages16.04.2022 - Description of CSSYazhisai SelviNo ratings yet

- Vt-Vrpa2-5 - 1XRTPDocument8 pagesVt-Vrpa2-5 - 1XRTPPanca AriefNo ratings yet

- P6SD Series: Technical Specifications Features and BenefitsDocument8 pagesP6SD Series: Technical Specifications Features and BenefitsEduardo Rogelio Prado LevanoNo ratings yet

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- Cable Schedule (FF.17001)Document51 pagesCable Schedule (FF.17001)josejohn1No ratings yet

- 59 270001 Relay 793Document5 pages59 270001 Relay 793Ethan JanusNo ratings yet

- Liq ProdData 71-385Document4 pagesLiq ProdData 71-385mohan.tijare.mtNo ratings yet

- Model RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)Document4 pagesModel RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)asimnaqvi2008No ratings yet

- DMDAMAN Full en Us LetterDocument3 pagesDMDAMAN Full en Us LetterjmmcaptainNo ratings yet

- 00100W N G0 G020 SR LST 0001 0 - 76029Document2 pages00100W N G0 G020 SR LST 0001 0 - 76029Jalal AlbadriNo ratings yet

- SECTION 3.3.8 PAGE 114 OF 172: Section 3.3.8 - Protection Indication System R4Document21 pagesSECTION 3.3.8 PAGE 114 OF 172: Section 3.3.8 - Protection Indication System R4ramNo ratings yet

- Updated Cable Schedule (FF (12-04-17)Document58 pagesUpdated Cable Schedule (FF (12-04-17)josejohn1No ratings yet

- Gruas KrancoDocument13 pagesGruas KrancoYorchOwnsNo ratings yet

- A XW-118 A XW-128 Ami-926lw/rwDocument34 pagesA XW-118 A XW-128 Ami-926lw/rwpata saladaNo ratings yet

- Peak 3A Bus Termination RegulatorDocument12 pagesPeak 3A Bus Termination RegulatormkubawatNo ratings yet

- FAN7380 Half-Bridge Gate Driver: Features DescriptionDocument12 pagesFAN7380 Half-Bridge Gate Driver: Features Descriptionflo72afNo ratings yet

- RS 210 RS 210: Sectional Directional Control Valve Control ValveDocument20 pagesRS 210 RS 210: Sectional Directional Control Valve Control ValveAnemNo ratings yet

- Fuse, Bussman Time Delay FNQ-RDocument3 pagesFuse, Bussman Time Delay FNQ-RSerNo ratings yet

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- Model 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotDocument2 pagesModel 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotVignesh PandiyanNo ratings yet

- Ut-1201 Flow MeterDocument12 pagesUt-1201 Flow MeterRam KumarNo ratings yet

- RUH Umpen: Ruhrpumpen GMBHDocument40 pagesRUH Umpen: Ruhrpumpen GMBHjacobo nasimbaNo ratings yet

- Pressure Relief ValvesDocument4 pagesPressure Relief ValvesHassanNo ratings yet

- WDR 01Document1 pageWDR 01carlos.nunez.t.ingNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Acids Bases and SaltsDocument55 pagesAcids Bases and Saltsgeorgy shibuNo ratings yet

- Astronomy - February 2019 USA PDFDocument80 pagesAstronomy - February 2019 USA PDFRaluca Roxana RujaNo ratings yet

- Paper ChromatographyDocument5 pagesPaper ChromatographyChelsea MartinezNo ratings yet

- Mathematical Model of A Direct Methanol Fuel Cell: DMFC023Document6 pagesMathematical Model of A Direct Methanol Fuel Cell: DMFC023KaustubhNo ratings yet

- Dattaproject DONEDocument25 pagesDattaproject DONEsumit potdarNo ratings yet

- Iron Removal From A Kaolinitic Clay by Leaching To Obtain High Whiteness IndexDocument5 pagesIron Removal From A Kaolinitic Clay by Leaching To Obtain High Whiteness IndexromanangelhernandezNo ratings yet

- 5991-4687en - APP Pesticide in Difficult FoodDocument8 pages5991-4687en - APP Pesticide in Difficult FoodBogdan CioroiuNo ratings yet

- Hsslive-Xi-Chemistry-11. The P-Block Elements-Anil-SirDocument7 pagesHsslive-Xi-Chemistry-11. The P-Block Elements-Anil-SirKrishnendu NairNo ratings yet

- WaterAnalyses PDFDocument2 pagesWaterAnalyses PDFZenga Harsya PrakarsaNo ratings yet

- Lecture 5, 6 Chapter 3 - Equilibrium 2D, 3DDocument52 pagesLecture 5, 6 Chapter 3 - Equilibrium 2D, 3Drobel metikuNo ratings yet

- An Ultimate Guide To Transistor PinoutsDocument15 pagesAn Ultimate Guide To Transistor PinoutsjackNo ratings yet

- SolutionDocument3 pagesSolutionbahast faiqNo ratings yet

- Null 27Document5 pagesNull 27BTS ArmyNo ratings yet

- Skin Effect and Skin DepthDocument2 pagesSkin Effect and Skin DepthUdit SharmaNo ratings yet

- DTD Handbook: Section 2.2.6.3. Crack Opening DisplacementDocument4 pagesDTD Handbook: Section 2.2.6.3. Crack Opening Displacementpouya_msNo ratings yet

- Magnetism For JEEDocument15 pagesMagnetism For JEEJatin SonwalNo ratings yet

- Electroplating of Cu-Sn Alloys andDocument81 pagesElectroplating of Cu-Sn Alloys andcicerojoiasNo ratings yet

- Gravitation: Very Short Answer Type Questions-Pg-100Document53 pagesGravitation: Very Short Answer Type Questions-Pg-100DX GamingNo ratings yet

- 253TAIYO ASC 32 V2.0.0.0 Appendix V1.1 ENDocument8 pages253TAIYO ASC 32 V2.0.0.0 Appendix V1.1 ENhmhaidarNo ratings yet

- The Copernican RevolutionDocument41 pagesThe Copernican RevolutionRhea Jane Dela CruzNo ratings yet

- 7 CarbohydratesDocument18 pages7 CarbohydratesBhanuPrasannaNo ratings yet

- 10 Chemistry Guess by MNA Ghumman Smart SyllabusDocument5 pages10 Chemistry Guess by MNA Ghumman Smart SyllabusSania Ashir0% (2)

- Borophene Paper: by Raghisa KhalidDocument22 pagesBorophene Paper: by Raghisa KhalidRAghixa KhAlidNo ratings yet

- C R Robertson Fundamental Electrical and ElectroBookZZ - Org 31Document4 pagesC R Robertson Fundamental Electrical and ElectroBookZZ - Org 31Salmarianto AntoNo ratings yet

- HPMC Viscosity GradesDocument10 pagesHPMC Viscosity GradesKhoa Duy100% (1)

- Lec#03. Special Types of ConcretesDocument24 pagesLec#03. Special Types of ConcretesThe GLOBENo ratings yet

- Magnesium & Aluminum in Water FuelsDocument10 pagesMagnesium & Aluminum in Water FuelsCliff ThriveNo ratings yet

- Physics Education Vol 2Document60 pagesPhysics Education Vol 2Arindam Kumar ChatterjeeNo ratings yet

- MetabolomicsDocument12 pagesMetabolomicswatson191No ratings yet