Professional Documents

Culture Documents

Alquitran de Hulla Articulo - Ingles

Alquitran de Hulla Articulo - Ingles

Uploaded by

George Esteban Obeso PeñaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alquitran de Hulla Articulo - Ingles

Alquitran de Hulla Articulo - Ingles

Uploaded by

George Esteban Obeso PeñaCopyright:

Available Formats

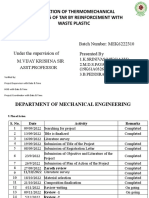

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/327430548

Validación del polígono de vacíos en el diseño de mezclas bituminosas con

alquitrán de hulla como ligante

Article in Revista Ingenieria de Construccion · August 2018

DOI: 10.4067/S0718-50732018000200137

CITATIONS READS

0 117

2 authors:

Ricardo Ochoa Gloria Grimaldo

Universidad Pedagógica y Tecnológica de Colombia University of Boyaca

9 PUBLICATIONS 15 CITATIONS 12 PUBLICATIONS 14 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Analysis of the use of coal tar as a binder in bituminous mixtures, using Marshall and Ramcodes methodologies View project

All content following this page was uploaded by Gloria Grimaldo on 27 March 2019.

The user has requested enhancement of the downloaded file.

Revista Ingeniería de Construcción RIC

Vol 33 Nº2 2018 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Validation of the polyvoids in the design of bituminous

mixtures with coal tar as a binder

Validación del polígono de vacíos en el diseño de mezclas

bituminosas con alquitrán de hulla como ligante

1

R. Ochoa *, G. Grimaldo **

* Universidad Pedagógica y Tecnológica de Colombia, Tunja. COLOMBIA

** Universidad de Boyacá, Tunja. COLOMBIA

Fecha de Recepción: 19/02/2018

Fecha de Aceptación: 06/06/2018

PAG 137-146

Abstract

The world has developed different methodologies for the design of asphalt mixtures; each of which is intended to optimise and find the optimal combination of

materials that allow them to be resistant under specific travel, climate and structural support conditions. This article presents the results of an investigation which

utilised coal tar as a binding agent for road surface mixtures and carried out a comparison of results of the physical and mechanical properties of sample bituminous

mixtures produced by two distinct methodologies, Marshall and Ramcodes. Finally, an analysis was carried out on the suitability of tar as a binding agent and on

utilising the Ramcodes methodology when designing mixtures.

Keywords: Coal tar, Marshall, Ramcodes, bituminous mixture

Resumen

En el mundo se han desarrollado diferentes metodologías para el diseño de mezclas asfálticas; cada una procura optimizar y encontrar la combinación óptima de

materiales que permita ser resistente bajo unas condiciones determinadas de tránsito, clima y apoyo estructural. En este artículo se muestran los resultados de una

investigación donde se utilizó el alquitrán de hulla como ligante en mezclas para pavimentos y se realiza una comparación de los resultados de las propiedades

físicas y mecánicas de probetas con mezcla bituminosa elaboradas por dos metodologías distintas, la Marshall y la Ramcodes. Por último, se realiza el análisis de la

conveniencia de utilizar el alquitrán como ligante y de utilizar la metodología Ramcodes para el diseño de mezclas.

Palabras clave: Alquitrán de hulla, Marshall, Ramcodes, mezcla bituminosa

1. Introduction

Since the beginning of time, man has endeavoured to Furthermore, with comparisons to the Marshall

develop activities to allow survival and evolution. In principle, methodology, this investigation aims to analyse the benefits of

these activities were limited to the direct consumption of using the Ramcodes methodology in the design of bituminous

resources that nature provided, with the improvement of mixtures and which out of these is most used in our

industrial activities increasing the presence of residues that environment.

were no longer bearable for the natural environment. In order to verify previous findings, with help from the

Road construction is an activity that implies a SPSS programme, statistical analysis was performed with the

significant consumption of natural resources, during which results obtained by the two methodologies, to determine

the production of bituminous mixtures involves using great whether these results differ and whether the use of this

quantities of aggregate and asphalt; the majority of these methodology is advisable.

coming from quarrying and oil exploitation. Taking into

account the politics of sustainability, this investigation aims to

contribute towards the development in the use of by-products

in the iron and steel industry.

2. Materials used

2.1 Tar as a binding agent

Tar, as shown in Figure 1, is a semi-solid or liquid

bituminous product that is obtained as a residue of

distillation, in the absence of air, organic substances that

contain volatile materials such as coal or wood. It is a cold

1 binding agent, resistant to water, insoluble in lubricating oils

Corresponding Author:

and petroleum fuels, soluble in ether, benzene, carbon

Professor from the Transportation and Public Works Department and active

Investigator for GRINFRAVIAL. Tunja, Colombia.

disulphide, chloroform and quinoline. The tar consists of

E-mail: ricardo.ochoa@uptc.edu.co

Revista Ingeniería de Construcción Vol 33 Nº2 Agosto de 2018 www.ricuc.cl 137

aliphatic and naphthenic components containing hydrogen, whose carried out the process at 1000°C (Gómez, 2002).

oxygen, nitrogen and sulphur. Table 1 shows the physicochemical properties of this material.

The tar utilised in this study is produced in a Coking

plant of the iron and steel company Acerías Paz del Río S.A.,

Figure 1. Tar produced by Acerías Paz del Río S.A

Table 1. Physicochemical properties of tar. Source: Departamento Laboratorio Acerías Paz del Río

S.A., 2015

Parameter Unit Average

Humidity % 7

Ashes % 0.10

Insoluble in Quinoline % 4

Insoluble in Toluene % 3

Calorific value kcal/kg 8900

2.2 Aggregate conducting tests in order to know the characteristics of the

The materials utilised in a bituminous mixture must be materials used in the design of the bituminous mixtures; the

subjected to rigorous studies to establish the possibility of second stage regards carrying out necessary tests to obtain

their use. For this, since coarse aggregate uses a crushed type the working formula of the bituminous mixture for the

of gravel, this was subjected to the following tests: erosion in Marshall methodology modified by University of Illinois, and

the Los Angeles abrasion testing machine, percentage of for the Ramcodes methodology, and the third, with regard to

fractures, extension rate and flattening rate. the comparison of the results from both methodologies and

In addition, tests were carried out to determine the the analysis in the advantage of using tar as a binding agent

specific gravity and the percentage of absorption. As fine and the implementation of the Ramcodes methodology.

aggregate used sand and, as a filler mineral, it used Portland

cement and grains of sand passed through sieve #200, their 3.1 Marshall Method

specific gravities were determined. All the tests were made The purpose of this method is to determine the

taking into account the testing standards for road materials set optimum binding content for a specific aggregate mixture and

by INVÍAS and ASTM. to provide information on the physical and mechanical

The type of mixture selected whilst carrying out this properties of hot bituminous mixture, so that it is possible to

study was a dense mixture in type 19 heat (MDC-19) in establish if they meet the parameters of densities and optimal

accordance with Article 450-13, of the general road content vacuum during the construction of the pavement

construction specifications by INVÍAS (2013a). layer.

The overall objective of the design process involves

determining a combination and economic intensity of

aggregate and binding agents that produce a mixture with:

3. Methodology sufficient binding agent to guarantee a durable pavement;

adequate stability to meet traffic demands without causing

The methodology used in the development of this any deformation or displacement; a vacuum content high

investigation was considered in three stages: the first was enough to allow a slight amount of additional compaction

under heavy, without any bleeding or loss of stability and

Revista Ingeniería de Construcción Vol 31 Nº3 Diciembre de 2016 www.ricuc.cl

138

Revista Ingeniería de Construcción RIC

Vol 33 Nº2 2018 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

enough workability to allow for efficient placement without aggregates. Verify that Gsa>Gse>Gsb, according

segregation (Hosseinzadeh et al., 2016). to theoretical definitions.

• Mathematically obtain, from the polyvoids, the

3.2 Ramcodes Method optimum binding content, considering the

The Ramcodes method (Ochoa-Díaz, 2013; Sánchez specifications and specific gravities of the

et al., 2002), an acronym for RAtional Methodology for combination of aggregates.

COmpacted geomaterial’s DEnsification and Strength analysis • Following Marshall test regulations, mix the

developed by F.J. Sánchez-Leal, is a methodology based on combination of aggregates with the optimum

factorial experiments and the practical experience in design binding content and condense three specimens to

and control, for an analysis of densification and compacted determine the vacuums and try them to

geomaterial resistance. determine their stability and flow. Work out the

The Marshall accelerated by Ramcodes is an average of the results.

application developed for the quick design of traditional • Verify if the average of the binding content and

Marshall procedure, which rationally binds the design the Bulk density enters into the polyvoids. If not,

specifications with the field control criteria, by implementing then the attempt failed. Select another

the “polyvoids” which defines an area which meets all combination of aggregates and return to the first

vacuum specifications (VAM, VAF y VA) (Sánchez-Leal et al., step.

2011). These vacuums are based according to the binding • Verify if the average of stability and flow of the

content (%CA) and Bulk density (Gmb) and are indicated on specimens comply with the specification. If not,

maps as isolines, for the allowed values, the intersection of then the attempt failed. Select another

these lines produce a graphic construction of space %CA – combination of aggregates and return to the first

Gmb, which results in a polygon, in which, through its step.

centroid, is mathematically possible to obtain an asphalt

content that meets all vacuum specifications for the mixture

(Delgado et al., 2006).

The following steps have been proposed to modify or

4. Experimental design

accelerate the original Marshall design process (Sánchez-Leal,

In Table 2, six granulometric distributions of the

2009):

material use are shown, with their respective dosages

(Sánchez-Leal, 2007); the particle sizes were adjusted so that,

• Determine the specific effective gravity (Gse), the

in a strip of the MDC-19 mixture, they were exactly in the

specific Bulk gravity of a combination of

centre, on the thin side and on the thick side of this strip,

aggregates (Gsb) and the apparent specific

Figure 2, in order to evaluate the impact of the particle size in

gravity (Gsa) of the combination of selected

the mixture’s performance.

Figure 2. The Granulometric Distribution of the Mixtures

temperate of the aggregates and the binding agent was 40°C

The variable is the type of mineral filler (cement or with a constant compaction of 75 shocks per side (traffic level

sand), adjusted to the granulometric strip of the mixture. The NT-2) (INVIAS, 2013b), making a factorial experiment

laboratory testing process for the Marshall and Ramcodes varying in two factors, the binding content variable by 0.5%

methodologies was developed in two stages. for each mixture and variable gradation according to the

In the first stage, six Marshall designs were carried out position on the granulometric strip. The former, with the

for experimental development, three with cement as a filler objective of finding the working formula for the Marshall

and three with sand passed through sieve #200. The heating design, followed by the compaction process and outcomes of

the mechanical performance of the mixtures.

Revista Ingeniería de Construcción Vol 33 Nº2 Agosto de 2018 www.ricuc.cl 139

In the second part, six Ramcodes were developed the compaction process and outcomes of the mixtures

(identical particle sizes to those used with Marshall), with stability and flow. Once the samples were compressed, they

constant binding percentages for each particle size, with a were left to cool for 15 minutes, before removing the mould.

constant compaction of 75 shocks per side and a mixing Once out of the mould, they were allowed to cool and cure

temperature of 40°C. These percentages were obtained at room temperature for eight days, so that the mixtures

according to the use of the RAMSOFT program based on the solvents evaporated. Following this, the test was continued to

Ramcodes methodology, which generated the work formula determine the stability and flow in the Marshall plan.

(optimum binding percentage) for each mixture, followed by

Table 2. Mixture particle distributions and aggregate type

Mixture Aggregate Material Percentage Distribution

Coarse Gravel 41

The fine side of the

M-1 Fine Sand 52

granulometric strip

Filler Cement 7

Coarse Gravel 46

Centre of the

M-2 Fine Sand 49 granulometric strip

Filler Cement 5

Coarse Gravel 50

The coarse side of the

M-3 Fine Sand 46

granulometric strip

Filler Cement 4

Coarse Gravel 40

The fine side of the

M-4 Fine Sand 54

granulometric strip

Filler Sand passing #200 6

Coarse Gravel 44

Centre of the

M-5 Fine Sand 51 granulometric strip

Filler Sand passing #200 5

Coarse Gravel 47

The coarse side of the

M-6 Fine Sand 49

granulometric strip

Filler Sand passing #200 4

4.1 Results of the tests carried out with both methodologies level of transit NT-1; However, the flow is above the range of

The following Table 3 and Table 4 present the results 2-4mm.

obtained from the mixtures designed through both In the observed results of the mixtures prepared with

methodologies. sand passing the sieve #200 as a filler, some parameters

Regarding the obtained results and taking into account achieve the specifications for a level of transit NT-1, although

the specifications of Table 450.4 from article 450-07 of the the flow resulted remotely from the specified range. The

general specifications of the construction of highways, the results of the Marshall Method for the Mixture M-2 fulfil all the

mixtures prepared with Portland cement as a filler achieve a specifications for the level of transit NT-2, to which this work

is the formula that best presents mechanical behaviour.

Revista Ingeniería de Construcción Vol 31 Nº3 Diciembre de 2016 www.ricuc.cl

140

Revista Ingeniería de Construcción RIC

Vol 33 Nº2 2018 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Table 3. Results of the Designed Mixtures with Cement as a Filler

Designed mixtures with gravel, sand, and cement

M-1 M-2 M-3

Parameter Request NT-2

Marshall Ramcodes Marshall Ramcodes Marshall Ramcodes

Bitumen (%) 7.40 7.13 6.50 6.87 6.42 6.63 -

3

Gmb (gr/cm ) 2.13 2.14 2.14 2.13 2.13 2.13 -

Stability (Kg) 734 793 792 755 668 688 >750

Flow (mm) 4.13 4.03 3.88 4.13 4.26 4.22 2-4

Vv (%) 4.0 3.86 4.0 3.88 4.0 3.88 3-5

VAM (%) 16.37 15.78 15.22 15.80 15.53 15.81 > 15

VFA (%) 75.70 75.51 73.90 75.43 74.30 75.43 65 - 78

Table 4. Results of the Designed Mixtures with Sand as a Filler

Designed mixtures with gravel, sand, and sand passing sieve #200

M-4 M-5 M-6

Request NT-2

Marshall Ramcodes Marshall Ramcodes Marshall Ramcodes

Parámetro

Bitumen (%) 6.60 6.80 6.60 6.70 6.20 6.70 -

3

Gmb (gr/cm ) 2.18 2.18 2.17 2.17 2.18 2.17 -

Stability (Kg) 527 472 702 643 665 588 >750

Flow (mm) 8.0 10.1 9.2 10.0 8.6 9.8 2-4

Vv (%) 4.0 3.9 4.0 3.9 4.0 3.9 3-5

VAM (%) 15.6 15.8 15.8 15.8 15.0 15.8 > 15

VFA (%) 73.7 75.5 74.0 75.5 73.0 75.5 65 - 78

4.2 Sensibility Analysis for Mixture M-2 that is an image of the response surface for each selected

For this mixture, the study of sensibility was achieved mechanical parameter.

based on statistical techniques of the analysis of factorial Ramcodes are based on a two-level factorial

experiments according to Ramcodes. Furthermore, the experiment–the binding content (%Pb) and the specific bulk

behaviour of the two most influential factors in the weight (Gmb). The usage of maps permits a vision of variation

bituminous mixtures (Gmb y %Pb) was studied. This analysis of the mechanical properties inside the area where the space

has great advantages in controlling the compact mixtures. specifications are achieved. In Figure 3, the behaviour of

Besides the vacant requisites, the bituminous mixture stability is shown, while in Figure 4, the behaviour of flow is

has to achieve the mechanical property’s requirements such demonstrated. This mixture has high or low performance

as stability and flow. The graphic representation of the depending on where status is established.

response values under Gmb and %Pb generate a contour plot

Revista Ingeniería de Construcción Vol 33 Nº2 Agosto de 2018 www.ricuc.cl 141

Figure 3. Behaviour of Stability

Figure 4. Behaviour of Flow

4.3 Statistical Analysis population, the corresponding points for each part are

In order to do the comparison of stability in relation to clustered around the diagonal represented in the diagram.

the used methodologies, the box diagram, Figure 5, is initially The diversions in the diagonal indicate deviations in

verified. It shows a small difference between the values of normality.

stability and the variability of similar data. Figure 6 shows the diagram Q-Q Normal for the data

In order to confirm if a significant difference exists established and obtained by the Marshall Method. Figure 7

between the results of stability for the two methodologies, it is presents the diagram Q-Q Normal for the data established

necessary to verify the assumption of normality, for which the and obtained by RAMCODES method. The above information

results of the test of normality are shown in Table 5. verifies that the normal distribution adequately traces the data

In a diagram or graph Q-Q Normal, every value of stability by methodology.

observed (Yi) is compared to the typical score NZi that Furthermore, the Shapiro-Wilk Test in Table 5 confirms

theoretically corresponded to that value in the normal this behaviour at a level of confidence of 95% (α=0.05)

standardised distribution. On the X-axis, the values observed

are represented and ordered from least to greatest (stability Marshall Method: p-value = 0.532>0.05

and flow); in such an order, the typical, normal scores are

represented (NZi). When a sample precedes a normal RAMCODES Method: p-value=0.101>0.05

Revista Ingeniería de Construcción Vol 31 Nº3 Diciembre de 2016 www.ricuc.cl

142

Revista Ingeniería de Construcción RIC

Vol 33 Nº2 2018 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Figure 5. Box Diagram regarding Stability

Table 5. Normality Test Results

Kolmogorov-smirnova Shapiro-wilk

Method

Statistical Gl Sig. Statistical Gl Sig.

Ramcodes 0.228 15 0.034 0.902 15 0.101

Stability

Marshall 0.144 15 0.200* 0.950 15 0.532

a. Correction of the significance of Lilliefors

*. This is an inferior limit of true significance

With this information, the statistical inference To compare the flow in respect to the two applied

developed relating the difference in the average value of methodologies, the box diagram in Figure 8 is initially verified.

stability for both methodologies. The results obtained in the Figure 8 shows a similar behaviour for the data of flow for

SPSS software for this test is presented in Table 6. both methodologies.

With the assumption of equal variances, these results Using the Mann-Whitney Test (Table 7) for the

lead to the conclusion that no significant difference exists in independents samples, that which is observed in Figure 8 can

the values of stability (p-value = 0.856>0.05). This implies be confirmed.

that the use of any method does not generate a significant Regarding the confidence level of 95%, p-value

difference in the values of stability. =0.299>0.05, no significant difference between the values of

flow can be concluded by using either methodologies.

Revista Ingeniería de Construcción Vol 33 Nº2 Agosto de 2018 www.ricuc.cl 143

Figure 6. Diagram Q-Q Normal, Stability regarding the Marshall Method

Figure 7. Diagram Q-Q Normal, Stability regarding the Ramcodes Method

Table 6. Test Results of Independent Samples regarding Stability

Levene’s test

Equal Test t for the equality of the median

Variances

95% confidence interval

Sig. Dif. in Tip.

F Sig. t gl

(bilateral) median Error Inferior Superior

Equal

0.018 0.894 -0.183 28 0.856 -9.133 49.978 -111.508 93.242

Variances

STB.

Different

-0.183 0.856 -9.133 49.978 -111.544 93.277

Variances

Revista Ingeniería de Construcción Vol 31 Nº3 Diciembre de 2016 www.ricuc.cl

144

Revista Ingeniería de Construcción RIC

Vol 33 Nº2 2018 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Figure 8. Box Diagram regarding Flow

Table 7. Results of the Mann-Whitney Test

Statistics of Contrast b

Flow

U for Mann-Whitney 87.500

W for Wilcoxon 207.500

Z -1.039

Asymptotic Sig. (bilateral) 0.299

Exact Sig. [2*(unilateral Sig.)] 0.305a

a. No corrections for the ties.

b. Group Variable: Method

5. Conclusions Method and the Ramcodes Method–being that the usage of

the Ramcodes Method is valid in the design of the bituminous

It is not intended to replace asphalt for pavement in mixtures of pavements.

the preparation of mixtures. Instead, the intention is to seek The mixture that best presents the behaviour and best

alternatives that permit the selection of product that adjust to adjusts to the required technical requests by INVIAS norms

the needs of every specific project. was the preparation with gravel as a course aggregate, sand

Ramcodes is a methodology of great usefulness for its as a fine aggregate, and cement as a filler. However, one must

design, production and quality control of bituminous continue with this investigation in order to find the best way

mixtures, provided that it guarantees the compliance of the to utilise this bind and thereby contribute to the environment.

volumetric parameters demanded by the specifications. Given the thermal susceptibility of bitumen and,

Furthermore, there exists various benefits to using this therefore, of the asphalt mix, it is determined that this type of

methodology as it saves times, resources and money. mixture can be used in cold to temperate climates. Under

Thankfully, it is only necessary to make three briquettes in these conditions, the behaviour of the mixture will be

comparison to 15 briquettes in the Marshall Method. acceptable under the action of burdens imposed by traffic.

Amongst the inconsistent observations in the If some mixtures did not fulfil the INVIAS requirements

development of this investigation and keeping the statistical for the wearing layer of the roadway, it would be possible to

analysis in mind, it was demonstrated that no significant use them as enhanced base or sub-base layers.

difference exists between the results obtained by the Marshall To guarantee an acceptable behaviour of this type of

mixture requires a strict control of quality in the minimum

Revista Ingeniería de Construcción Vol 33 Nº2 Agosto de 2018 www.ricuc.cl 145

requirements of the aggregates just like the usage of cement time, transportation to the work site, placement and

as a filler. This quality control must be done in each phase of compaction of the mixture.

the project: in the design, development of the mixture, curing

6. References

Delgado H., Garnica P., Villatoro G. M., Rodríguez G. (2006), Influencia de la granulometría en las propiedades volumétricas de la mezcla

asfáltica. Sanfandila, Querétaro. Retrieved from https://imt.mx/archivos/Publicaciones/PublicacionTecnica/pt299.pdf

Gómez A. (2002), Procesos siderúrgico – Planta Belencito, Acerías Paz del Río S.A. Belencito, Colombia, Tech. Rep., enero, 2002.

Hosseinzadeh N., Rezaei M. J., Hosseini S. M. (2016), Investigation and performance improvement of hot mix asphalt concrete containing EAF

slag. International Journal of Engineering and Technology, 8(4), 260–264. https://doi.org/10.7763/IJET.2016.V8.895

INVIAS. (2013a), Artículo 450-13 Mezclas asfálticas en caliente de gradación continua. Bogotá.

INVIAS. (2013b), Normas para ensayos de materiales para carreteras. Bogotá.

Ochoa-Díaz R. (2013), Analysis of the use of coal tar as a binder in bituminous mixtures, using Marshall and Ramcodes methodologies. Journal

of Physics: Conference Series, 466(1). https://doi.org/10.1088/1742-6596/466/1/012034

Sánchez-Leal F. J. (2007), Gradation Chart for Asphalt Mixes : Development. Journal of Materials in Civil Engineering in Civil Engineering, 19(2),

185–197. https://doi.org/10.1061/?ASCE?0899-1561?2007?19:2?185?

Sánchez-Leal F. J. (2009), Manual de Aplicación - Metodología de Analísis y Diseño de Geomateriales Compactados. (Ramcodes, Ed.).

Sánchez-Leal F. J., Anguas P. G., Larreal M., Valdés D. B. L. (2011), Polyvoids : Analytical Tool for Superpave HMA Design. Journal of Materials

in Civil Engineering, 23(8), 1129–1137. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000275.

Sánchez F., Garnica P., Gómez J., Pérez N. (2002), Ramcodes: Metodología racional para el análisis de densificación de geomateriales

compactados.200. Sanfandila, Querétaro. Retrieved from https://imt.mx/archivos/Publicaciones/PublicacionTecnica/pt200.pdf

Revista Ingeniería de Construcción Vol 31 Nº3 Diciembre de 2016 www.ricuc.cl

146

View publication stats

You might also like

- FrigioneAguiar Materials 13 05448Document5 pagesFrigioneAguiar Materials 13 05448samiha.ramdaniNo ratings yet

- Performance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsDocument6 pagesPerformance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsEditor IJTSRDNo ratings yet

- Indian Cement Industry On Path of Environment Sustainability Through Innovation and Resource OptimizationDocument10 pagesIndian Cement Industry On Path of Environment Sustainability Through Innovation and Resource OptimizationVeena PasumarthyNo ratings yet

- A Review On Modification of Bitumen For Flexible Pavement: March 2018Document7 pagesA Review On Modification of Bitumen For Flexible Pavement: March 2018isaac MbiawaNo ratings yet

- Effectiveness of Waste Polythene Bags Modified Bitumen Mixes and Their Comparative Economical AnalysisDocument8 pagesEffectiveness of Waste Polythene Bags Modified Bitumen Mixes and Their Comparative Economical AnalysisFajuyigbeNo ratings yet

- Int J Ceramic Engine Sci - 2021 - Scaratti - Conceptual Design and Cost Analysis of A Large Scale Plant For ConvertingDocument8 pagesInt J Ceramic Engine Sci - 2021 - Scaratti - Conceptual Design and Cost Analysis of A Large Scale Plant For ConvertingSourabh SharmaNo ratings yet

- A Study On Evolution of Geopolymer ConcreteDocument5 pagesA Study On Evolution of Geopolymer ConcreteMahmoud HakimNo ratings yet

- A Study On Recycling of Crumb Rubber and Low Density Polyethylene Blend On Stone Matrix AsphaltDocument17 pagesA Study On Recycling of Crumb Rubber and Low Density Polyethylene Blend On Stone Matrix AsphaltSyedBaqirNo ratings yet

- Español Peru2018Document10 pagesEspañol Peru2018Edwin RodríguezNo ratings yet

- JTTE WastePlasticintheLaboratory PRE PUBLICATIONDocument20 pagesJTTE WastePlasticintheLaboratory PRE PUBLICATIONZuri GarricksNo ratings yet

- Grindability and Abrasive Behavior of Coal Blends: Analysis and PredictionDocument29 pagesGrindability and Abrasive Behavior of Coal Blends: Analysis and PredictionsvvsnrajuNo ratings yet

- Final Na Inin Jama Sa Feasibility StudyDocument8 pagesFinal Na Inin Jama Sa Feasibility StudyEstiven GierNo ratings yet

- Production and Optimization of Eco-Efficient Self Compacting Concrete SCC With Limestone and PETDocument13 pagesProduction and Optimization of Eco-Efficient Self Compacting Concrete SCC With Limestone and PETYosseline Vargas MezaNo ratings yet

- JINDALDocument7 pagesJINDALDivya SharmaNo ratings yet

- Methods of Analysis of PolymersDocument20 pagesMethods of Analysis of PolymersTUF GAMINGNo ratings yet

- Irjet V5i1240Document8 pagesIrjet V5i1240Aman raj singhNo ratings yet

- 6 - Review - Avances en Tipos de Hidrogeles y Remoción de ColorantesDocument27 pages6 - Review - Avances en Tipos de Hidrogeles y Remoción de ColorantesAlejandro PérezNo ratings yet

- d6 PDFDocument15 pagesd6 PDFKaushik RokkamNo ratings yet

- Petrochemical Projects in Indonesia in The Pipeline - Fluid Handling MagazineDocument1 pagePetrochemical Projects in Indonesia in The Pipeline - Fluid Handling MagazineDennis Koay GMNo ratings yet

- Gautam2018 PDFDocument15 pagesGautam2018 PDFShubham SharmaNo ratings yet

- Construction and Building Materials: Hamid Maljaee, Rozita Madadi, Helena Paiva, Luis Tarelho, Victor M. FerreiraDocument18 pagesConstruction and Building Materials: Hamid Maljaee, Rozita Madadi, Helena Paiva, Luis Tarelho, Victor M. Ferreiramohamme.arif63No ratings yet

- Mix Design of DBM With Rap Aggregates Construction Materials IJERTCONV11IS02019Document9 pagesMix Design of DBM With Rap Aggregates Construction Materials IJERTCONV11IS02019bineetmishra1990No ratings yet

- Experimental Test and Analytical Modeling of Mechanical Properties of Graphene-Oxide Cement CompositesDocument12 pagesExperimental Test and Analytical Modeling of Mechanical Properties of Graphene-Oxide Cement CompositesBuddhika AbeysekaraNo ratings yet

- Journal of Environmental Management: Tholiso Ngulube, Jabulani Ray Gumbo, Vhahangwele Masindi, Arjun MaityDocument23 pagesJournal of Environmental Management: Tholiso Ngulube, Jabulani Ray Gumbo, Vhahangwele Masindi, Arjun MaityibrahimNo ratings yet

- DE Sem 5Document24 pagesDE Sem 5Yamin Devgadhwala100% (1)

- My ReviewDocument14 pagesMy Reviewemmanferrer482No ratings yet

- 1 s2.0 S0959652622036083 MainDocument29 pages1 s2.0 S0959652622036083 MainesoubihNo ratings yet

- Solventes Separacion 2018Document15 pagesSolventes Separacion 2018Paula Isabella LancherosNo ratings yet

- Alasan Suhu Curing Konsentrasi NaOh Dan Rasio Si Dan AlDocument34 pagesAlasan Suhu Curing Konsentrasi NaOh Dan Rasio Si Dan AlfansberatsotongNo ratings yet

- 10 1108 - Ijlm 02 2022 0086Document36 pages10 1108 - Ijlm 02 2022 0086mikay.112621No ratings yet

- Sustainability 15 14178 v2Document21 pagesSustainability 15 14178 v2Yogesh DewangNo ratings yet

- New MortarDocument7 pagesNew MortarAndrea C.No ratings yet

- Sustainability Evaluation of Concretes With Mixed Recycled AggregateDocument11 pagesSustainability Evaluation of Concretes With Mixed Recycled AggregateOmar TurkNo ratings yet

- Sustainability 14 15820Document8 pagesSustainability 14 15820imranasaif.aercNo ratings yet

- Polypropylene Resins - Chemical Economics Handbook (CEH) - IHS MarkitDocument8 pagesPolypropylene Resins - Chemical Economics Handbook (CEH) - IHS Markitarman0% (1)

- Sustainable Applications of Asphalt Mixes With Reclaimed Asphalt Pavement (RAP) Materials: Innovative and New Building BrickDocument11 pagesSustainable Applications of Asphalt Mixes With Reclaimed Asphalt Pavement (RAP) Materials: Innovative and New Building BrickPl TorrNo ratings yet

- CDW - Strategy - Draft Final - 011118 PDFDocument40 pagesCDW - Strategy - Draft Final - 011118 PDFKRISHNA KANTNo ratings yet

- A Mix Design Procedure For Geopolymer Concrete With Fly Ash (21.02.2023)Document10 pagesA Mix Design Procedure For Geopolymer Concrete With Fly Ash (21.02.2023)Velchuri SairamNo ratings yet

- Transportation Applications of Recycled Concrete Aggregate: FHWA State of The Practice National Review September 2004Document47 pagesTransportation Applications of Recycled Concrete Aggregate: FHWA State of The Practice National Review September 2004hieputcNo ratings yet

- Water ResearchDocument12 pagesWater ResearchRajnish SingalNo ratings yet

- Agro WasteDocument25 pagesAgro WastehemanthreddyNo ratings yet

- Materials 15 01883Document5 pagesMaterials 15 01883ing.mtorresgNo ratings yet

- ICEEE12716 Radzuan JuninDocument10 pagesICEEE12716 Radzuan JuninAhmad AmirhilmiNo ratings yet

- Termolisis PDFDocument16 pagesTermolisis PDFGaby Taipe AndaguaNo ratings yet

- RPT 22 18Document266 pagesRPT 22 18Paco MorenoNo ratings yet

- Improvement of High Modulus Asphalt Mixtures With Average Quality Aggregate and Bitumen by Application of Polymeric AdditivesDocument12 pagesImprovement of High Modulus Asphalt Mixtures With Average Quality Aggregate and Bitumen by Application of Polymeric AdditivesAnaMariaDiazLasprillaNo ratings yet

- Current Developments and Future Trends in Photocatalytic Glycerol - Karimiestahbanati - 2021Document23 pagesCurrent Developments and Future Trends in Photocatalytic Glycerol - Karimiestahbanati - 2021leonardoNo ratings yet

- 1 s2.0 S2542504822000549 MainDocument9 pages1 s2.0 S2542504822000549 MainJasna San MartínNo ratings yet

- Cleantechnology Thermochemical Recy TiresDocument16 pagesCleantechnology Thermochemical Recy TiresmmmeuropeNo ratings yet

- Mek6222310 - 1Document14 pagesMek6222310 - 1Srinivas KosuriNo ratings yet

- Polymers 15 02337Document21 pagesPolymers 15 02337hàNo ratings yet

- In Uence of 2D rGO Nanosheets On The Properties of OPC PasteDocument13 pagesIn Uence of 2D rGO Nanosheets On The Properties of OPC PasterusnaNo ratings yet

- Nikhil Pal Project Mba1Document44 pagesNikhil Pal Project Mba1nikhilpal89233No ratings yet

- Sustainability-15-07232-V2 1Document18 pagesSustainability-15-07232-V2 1Sara Pierina Santos DiazNo ratings yet

- Rubberized Geopolymer Composites A Comprehensive ReviewDocument26 pagesRubberized Geopolymer Composites A Comprehensive ReviewShaker QaidiNo ratings yet

- MEK6222310Document14 pagesMEK6222310Srinivas KosuriNo ratings yet

- 40296-Article Text-172956-1-10-20220428Document11 pages40296-Article Text-172956-1-10-20220428alphana fitrohNo ratings yet

- Operational Analysis of Green Batching Plant Using Dmaic Tools To Improve Company PerformanceDocument5 pagesOperational Analysis of Green Batching Plant Using Dmaic Tools To Improve Company PerformanceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- Circular Economy: Assessment and Case StudiesFrom EverandCircular Economy: Assessment and Case StudiesNo ratings yet

- TWT M50 Mix DesignDocument6 pagesTWT M50 Mix DesignStupidity TalksNo ratings yet

- List of Business Establishment in Talisay City, CebuDocument255 pagesList of Business Establishment in Talisay City, Cebutisay12100% (2)

- Quality Control Manual For Hma Using SPFDocument68 pagesQuality Control Manual For Hma Using SPFDilhara WickramaarachchiNo ratings yet

- Niyobuhungiro DominiqueDocument70 pagesNiyobuhungiro DominiqueNiyobuhungiro DominiqueNo ratings yet

- Eco-Friendly Concrete With Waste Tyre AggregateDocument14 pagesEco-Friendly Concrete With Waste Tyre AggregateMukaila SanniNo ratings yet

- FR 521Document132 pagesFR 521anant11235No ratings yet

- Design of New Interlocking Bricks Making MachineDocument20 pagesDesign of New Interlocking Bricks Making MachineRAZAFIMAHEFA Tsivalalaina DavidNo ratings yet

- Trial Mix DesignsDocument4 pagesTrial Mix DesignsEngineeri TadiyosNo ratings yet

- Screening Machines and Process Equipment 01Document16 pagesScreening Machines and Process Equipment 01tafakorNo ratings yet

- Innovative Study On Reusing Demolished WasteDocument3 pagesInnovative Study On Reusing Demolished Wastehasnath kpNo ratings yet

- STRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS IeeeDocument3 pagesSTRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS Ieeettk qsNo ratings yet

- Local Industry Project: " Study of Pavement Tiles & Concrete Block Industry in Jodhpur "Document20 pagesLocal Industry Project: " Study of Pavement Tiles & Concrete Block Industry in Jodhpur "YogendraNo ratings yet

- La Abrasion TestDocument3 pagesLa Abrasion TestHahahahahahahahahahaNo ratings yet

- CE414L Activity1 Group2Document12 pagesCE414L Activity1 Group2MARK RENIELLE BAUTISTANo ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Document11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Ono SoeratnoNo ratings yet

- D1241-07 Standard Specification For Materials For Soil-Aggregate Subbase, Base, and Surface CoursesDocument3 pagesD1241-07 Standard Specification For Materials For Soil-Aggregate Subbase, Base, and Surface CoursesAlabbas FadhelNo ratings yet

- Plumbing Boq PDFDocument6 pagesPlumbing Boq PDFNPNo ratings yet

- Aggregates For Concrete DR Mwasha Abrahams Extn: 3434 Aggregates Are Used in Concrete For The Following ReasonsDocument12 pagesAggregates For Concrete DR Mwasha Abrahams Extn: 3434 Aggregates Are Used in Concrete For The Following ReasonsSanjay MaharajNo ratings yet

- Final Schedule of Rates 2016-17Document174 pagesFinal Schedule of Rates 2016-17tendersNo ratings yet

- Investigation of Hydrophilic and Hydrophobic Properties of DifferentDocument6 pagesInvestigation of Hydrophilic and Hydrophobic Properties of DifferentChainun TaidamrongNo ratings yet

- Visveswaraya Technological University: Centre For Post Graduate Studies V.T.U Regional Centre, MysuruDocument46 pagesVisveswaraya Technological University: Centre For Post Graduate Studies V.T.U Regional Centre, MysuruSunil KumarNo ratings yet

- IRC 19-2005 STANDARD SPECIFICATIONS AND CODE OF PRACTICE FOR WATER BOUND MACADAM (Third Revision) PDFDocument24 pagesIRC 19-2005 STANDARD SPECIFICATIONS AND CODE OF PRACTICE FOR WATER BOUND MACADAM (Third Revision) PDFJitendraceNo ratings yet

- Characterizing The Environmental Effects of The Quarrying Industry 1325661770 PDFDocument13 pagesCharacterizing The Environmental Effects of The Quarrying Industry 1325661770 PDFYvonne Angelyn Ramilo-AliasNo ratings yet

- Final Yuksom Revised Estimate PDFDocument394 pagesFinal Yuksom Revised Estimate PDFSunny LakhotraNo ratings yet

- OPSS 1010 Nov03Document15 pagesOPSS 1010 Nov03Jonathan Enrique Canales SanchezNo ratings yet

- Total Moisture Content 100Document5 pagesTotal Moisture Content 100Tyrone PaulinoNo ratings yet

- Rate Analyze PDFDocument13 pagesRate Analyze PDFmohamedNo ratings yet

- 11 - Construction Quality Assurance Plan R1Document55 pages11 - Construction Quality Assurance Plan R1olegNo ratings yet

- Strength Properties of Polypropylene Fiber Reinforced ConcreteDocument5 pagesStrength Properties of Polypropylene Fiber Reinforced ConcreteVarun ChandraNo ratings yet

- Aggregates: Essential QuestionsDocument10 pagesAggregates: Essential QuestionsDiane de OcampoNo ratings yet