Professional Documents

Culture Documents

SKH Metals LTD.: Process Control Standerd

SKH Metals LTD.: Process Control Standerd

Uploaded by

shinuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SKH Metals LTD.: Process Control Standerd

SKH Metals LTD.: Process Control Standerd

Uploaded by

shinuCopyright:

Available Formats

Page 1 of 2

-

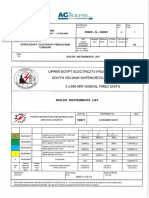

SKH METALS LTD.

- PROCESS CONTROL STANDERD

-

- TYPES: PROTOTYPE PRELAUNCH PRODUCTION

-

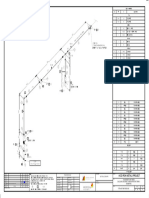

PART ASSY 85611-62S00 CUSTOMER KML DOC NO CP / Y1K- 85611-62S00

-

NAME INDV. PART Riser Fr cush Outside L MODEL Y1K KEY /ORIG. DATE Tuesday, May 14, 2019

- ASSY Riser Fr cush Outside L SUPPLIER NAME SKH Metals Ltd- Manesar

PART NO REV. NO. / DATE -

- INDV. PART 85611-62S00 SUPPLIER CODE

CORE

- PROCESS RESPONSIBILITY :-

TEAM

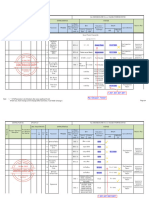

- CHARACTERISTICS (SPECIAL & OTHER) - SPECIFICATION / TOLERANCES METHODS

PART PROCESS M/C TOOL &

MISP REACTION

CLASS

PROCESS OPERATION JIG USED SAMPLE INSPECT CONTROL

- NO. REF. PRODUCT PROCESS PRODUCT PROCESS EVALUTION FREQUENCY RECORDING PLAN

STEP NO. DESCRIPTION FOR MFG. SIZE ION BY METHOD

NO

SUPPLIER TEST

- CERTIFICATE COMPARE n=1, EACH LOT YES I MTC

1 MATERIAL C JSC590 RN WITH STANDARD

3rd PARTY MECHANICAL ONCE IN 6 3rd PARTY

n=1, YES E HOLD THE

STORAGE OF TESTING MONTHS REPORT

LOT&INFORM

0 RAW MATERIAL -

L= 1360 +1.0/-0.0 VISUAL VERIFICATION OF SUPPLIER TO STORE

(LOCAL) BLANK/STRIP

2 C W= 475 +1.0/-0.0 SUPPLIER IDENTIFICATION n=1, Each Packet YES I IDENTIFICATIO SUPERVISOR

THICKNESS

T=1.2 ± 0.08 TAG N TAG

VISUAL VERIFICATION OF SUPPLIER

NO DAMAGE, RUST ,PITTING &

- 3 APPEARANCE C SUPPLIER IDENTIFICATION n=1, Each Packet NO I IDENTIFICATIO

DENT ON RAW MATERIAL.

TAG N TAG

NO CRACK, RUSTY SHEET,

DENT, DEFORMATION, START, MID & FOA,MOA &

1 APPEARANCE C VISUAL n=1, YES R

SCRATCH, WRINKLE,THINNING, END OF LOT LOA

HARD MARK, OVERLAPPING

PRESS START, MID & FOA,MOA & STOP

BLANKING - MACHINE 2 SHEET THICKNESS C 1.2 ± 0.10 mm MICROMETER n=1, YES R PRODUCTION &

10 END OF LOT LOA

OP10 INFORM TO

( 315T ) DEAD STROKE CHECK BY OIL DROP ON SUPERVISOR

3 SHUT HEIGHT M n=1, DIE SET UP YES R FOA

TO BE DONE SETTING BLOCK

START, MID & FOA,MOA &

4 HOLE 2 C Only for locationg purpose VISUAL n=1, YES R

END OF LOT LOA

NO CRACK, DENT,

DEFORMATION, SCRATCH, START, MID & FOA,MOA &

1 APPEARANCE C VISUAL n=1, YES R

WRINKLE,THINNING, HARD END OF LOT LOA

MARK, OVERLAPPING

START, MID & FOA,MOA &

PRESS 2 SHEET THICKNESS C 1.2 ± 0.10 mm MICROMETER n=1, YES R

END OF LOT LOA STOP

MACHINE

FORMING - CHECK BY OIL PRODUCTION &

10 CHECK BY OIL DROP ON

OP20 3 SHUT HEIGHT M DEAD STOPPER TO BE DONE DROP ON n=1, DIE SET UP YES R FOA INFORM TO

( 500/800T ) SETTING BLOCK

SETTING BLOCK SUPERVISOR

MAX. 20% OF SHEET VISUAL / POINT START, MID & FOA,MOA &

4 THINNING S n=1, YES R

THICKNESS MICROMETER END OF LOT LOA

SHOULD BE AVAILABLE- START, MID & FOA,MOA &

5 BOTTOMING MARK S VISUAL n=1, YES R

2 NOS END OF LOT LOA

NO CRACK, DENT,

DEFORMATION, SCRATCH, START, MID & FOA,MOA &

- 1 APPEARANCE S VISUAL n=1, YES R

WRINKLE,THINNING, HARD END OF LOT LOA

PRESS MARK, OVERLAPPING

STOP

RESTRIKE MACHINE

START, MID & FOA,MOA & PRODUCTION &

20 - OP 2 ID MARK S L VISUAL n=1, YES R

END OF LOT LOA INFORM TO

30 ( 315/500T )

SUPERVISOR

CHECK BY OIL

CHECK BY OIL DROP ON

3 SHUT HEIGHT S DEAD STOPPER TO BE DONE DROP ON n=1, DIE SET UP YES R FOA

SETTING / DEAD BLOCK

SETTING BLOCK

NO CRACK, DENT,

DEFORMATION, SCRATCH, START, MID & FOA,MOA &

1 APPEARANCE S VISUAL n=1, YES R

WRINKLE,THINNING, HARD END OF LOT LOA

PRESS MARK, OVERLAPPING STOP

CAM BENDING MACHINE MAX. 20% OF SHEET VISUAL / POINT START, MID & FOA,MOA & PRODUCTION &

30 2 THINNING S n=1, YES R

- OP 40 (315/500-T ) THICKNESS MICROMETER END OF LOT LOA INFORM TO

SUPERVISOR

CHECK BY OIL

CHECK BY OIL DROP ON

3 SHUT HEIGHT M DEAD STROKE TO BE DONE DROP ON n=1, DIE SET UP YES R FOA

SETTING / DEAD BLOCK

SETTING BLOCK

Page 2 of 2

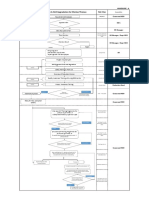

NO HOLE BURR, NO HOLE OVAL , NO

HOLE MISS , NO HOLE UNDER SIZE START, MID & END

1 APPEARANCE S VISUAL n=1, YES R FOA,MOA & LOA

OVER SIZE, NO HOLE SHIFT, NO HOLE OF LOT

DENT

START, MID & END

2 NO OF PIERCING C 15 Nos. Visual Count n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

3 TOTAL NO OF PIERCING C 21 Nos Visual Count n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

4 D1 C Ø16.2+0.2/-0.0 MM VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

5 D2 C Ø16.2 +0.2/-0.0MM VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

6 H1 C Ø10.7 +0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

7 H2 C Ø8.5 +0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

8 H3 C Ø10.5 +0.2/-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

9 H4 C Ø6.5 +0.2/-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

10 H5 C Ø22.5+0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

11 H6 C Ø10.5 +0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

12 H7 C 10.0 +0.5-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

13 H8 C Ø8.5 +0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

STOP

PRESS

CAM PI +PI START, MID & END PRODUCTION &

40 MACHINE 14 H9 C Ø12.0 +0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

- OP50 OF LOT INFORM TO

( 315/500-T )

SUPERVISOR

START, MID & END

15 H10 C Ø8.5 +0.2/-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

16 H11 C Ø25.7 +0.2/-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

17 H12 C Ø12.0 +0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

18 H13 C Ø11.0 +0.2/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

19 S1 C 10X20+0.5/-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

20 S2 C 10X20+0.5/-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

21 S3 C 20X20+0.5/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

22 S4 C 10X20+0.5/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

23 S5 C 10X20+0.5/-0.0 VERNIER n=1,

OF LOT

YES R FOA,MOA & LOA

START, MID & END

24 S6 C 10X20+0.5/-0.0 VERNIER n=1, YES R FOA,MOA & LOA

OF LOT

START, MID & END

25 PERPENDICULARITY C 1 MM PANNEL CHECKER n=1, YES R FOA,MOA & LOA

OF LOT

CHECK BY OIL DROP CHECK BY OIL DROP ON SETTING START, MID & END

26 SHUT HEIGHT C DEAD STROKE TO BE DONE n=1, YES R FOA,MOA & LOA

ON SETTING BLOCK BLOCK OF LOT

-

C-Critical

- S-Significant

W - Operator PREPARED BY VERIFY BY APPROVED BY

Legend For

I - Inspector

- Control In - ISSUE BY

E - Supervisor

charge

P-Process Approval

- COPY STATUS ISSUE DATE

R-Patrol Inspection

AM- Automatic Measurement

- REV. NO DATE DESCRIPTION REASON FOR CHANGE ISSUE NO

You might also like

- (Chemical Injection System) - Operation and Maintenance ManualDocument19 pages(Chemical Injection System) - Operation and Maintenance Manualasri elektronikNo ratings yet

- FANUC Series 0+-PF: Operator'S ManualDocument1,182 pagesFANUC Series 0+-PF: Operator'S ManualYogendra SaxenaNo ratings yet

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- NO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionDocument123 pagesNO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionYoseph Maulana0% (1)

- Plating PQCS Bolt Flange SH M6X16 - OLDDocument5 pagesPlating PQCS Bolt Flange SH M6X16 - OLDPrakash kumarTripathiNo ratings yet

- SFT 0090 Control PlanDocument24 pagesSFT 0090 Control PlanspdhimanNo ratings yet

- Standard Quality Plan: Conforming To Code: Is 8183Document4 pagesStandard Quality Plan: Conforming To Code: Is 8183jagan100% (1)

- QW-QAL-626 - (Rev-00) - Prod. and QC Process Flow Chart - Ventura Motor No. 13 (35804)Document6 pagesQW-QAL-626 - (Rev-00) - Prod. and QC Process Flow Chart - Ventura Motor No. 13 (35804)Toso BatamNo ratings yet

- Process Control Plan FormatDocument1 pageProcess Control Plan FormatSanchit SoniNo ratings yet

- Journey Management Plan (Code-A)Document27 pagesJourney Management Plan (Code-A)jaydyishiah1234No ratings yet

- Lifting Equipment Thorough Examination Register: Almansoori Inspection ServicesDocument1 pageLifting Equipment Thorough Examination Register: Almansoori Inspection ServicesRanjithNo ratings yet

- Plating PQCS Bolt Flange SH M6X16 - NEWDocument6 pagesPlating PQCS Bolt Flange SH M6X16 - NEWPrakash kumarTripathiNo ratings yet

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- 1778-4307-MP-DWG-042 - 0 Line 4307-015-LCC-80-HDPE-2-ModelDocument1 page1778-4307-MP-DWG-042 - 0 Line 4307-015-LCC-80-HDPE-2-ModellewihonawiNo ratings yet

- TVS Jupiter RMC - 19.3.19Document60 pagesTVS Jupiter RMC - 19.3.19vinodNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- Heat Stress Management PlanDocument18 pagesHeat Stress Management Planjaydyishiah1234No ratings yet

- S.P. Engineering Works: Part Inspection ReportDocument1 pageS.P. Engineering Works: Part Inspection ReportshalinmishraNo ratings yet

- 0169-013-SHS-200-20G-H80 Sheet 1-ModelDocument1 page0169-013-SHS-200-20G-H80 Sheet 1-ModellewihonawiNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- Heat Exchanger QAPDocument3 pagesHeat Exchanger QAPRajnikant PatelNo ratings yet

- QAP (Honeycomb Fabric)Document4 pagesQAP (Honeycomb Fabric)Ahamed UmarNo ratings yet

- 4M Change Tracking SheetDocument1 page4M Change Tracking SheetKanaiya Jha83% (6)

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Sahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportDocument3 pagesSahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportPrakash kumarTripathiNo ratings yet

- Line List: System 60 - Firewater SystemDocument20 pagesLine List: System 60 - Firewater SystemDaoued HaouesNo ratings yet

- Appendix 5 - Control and Alarm SetpointsDocument20 pagesAppendix 5 - Control and Alarm SetpointsCù Xuân HuyNo ratings yet

- Mpi Report Jvs FormatDocument2 pagesMpi Report Jvs FormatGauravNo ratings yet

- 447 Final Inspn Edited PDFDocument3 pages447 Final Inspn Edited PDFATHIBAN VNo ratings yet

- QA-R-05 - Weld Traceability RecordDocument1 pageQA-R-05 - Weld Traceability RecordvinothNo ratings yet

- Hydraulic Seal Catalogue PDFDocument322 pagesHydraulic Seal Catalogue PDFQuang Nhật100% (1)

- 1778-4711-WD-DWG-006I - Line 4711-105-WCS-15-Q235A - CommentDocument6 pages1778-4711-WD-DWG-006I - Line 4711-105-WCS-15-Q235A - CommentAsyifa AldanaNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Task Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Faizan ShabbirNo ratings yet

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- SOS4575991Document19 pagesSOS4575991Vivek JainNo ratings yet

- Itp - Spool FabricationDocument1 pageItp - Spool FabricationjaseelNo ratings yet

- CPF2-PAUT For Heat Medium Heater A (H-25630A)Document10 pagesCPF2-PAUT For Heat Medium Heater A (H-25630A)Yasir MohammedNo ratings yet

- Weld MapDocument1 pageWeld MapFerdie OS100% (1)

- RT Report Format Rev.1 17-3-19Document6 pagesRT Report Format Rev.1 17-3-19mohd as shahiddin jafriNo ratings yet

- C05-Uu00-Q-7856 - 1 - PS1, Emg-Ff Building, Lighting Layout and Lighting Fixture Schedule, SHT 2of2Document1 pageC05-Uu00-Q-7856 - 1 - PS1, Emg-Ff Building, Lighting Layout and Lighting Fixture Schedule, SHT 2of2sartajNo ratings yet

- Client: Aramco Overseas Company B.V. & Sumitomo Chemical Co., LTDDocument1 pageClient: Aramco Overseas Company B.V. & Sumitomo Chemical Co., LTDJaime FlaminianoNo ratings yet

- 30600-G-G0002 4 Instr ListDocument58 pages30600-G-G0002 4 Instr Listmohamed abourayaNo ratings yet

- 5W SheetDocument1 page5W Sheetgagandeep isherNo ratings yet

- Crompton - Qap-Rev-0Document6 pagesCrompton - Qap-Rev-0gulatimanish1985No ratings yet

- Magnetic Particle Test Record Truck Crane Articulating Boom (Gb-La03)Document2 pagesMagnetic Particle Test Record Truck Crane Articulating Boom (Gb-La03)Hario PramuditoNo ratings yet

- Process FMEADocument14 pagesProcess FMEAPranjal JangidNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- LOCK ROD Chamfer NG Counter Measure Report - Cop121yDocument3 pagesLOCK ROD Chamfer NG Counter Measure Report - Cop121yMohit SinghNo ratings yet

- Me-Ff-03 - Standard Details-2 Fire Fighting SystemDocument1 pageMe-Ff-03 - Standard Details-2 Fire Fighting SystemEng Qais ShamikhNo ratings yet

- 18.00 X 16.00 UT Rej Micro Analysis ReportDocument1 page18.00 X 16.00 UT Rej Micro Analysis Report33 Nivetha . VNo ratings yet

- Request For Inspection: Rfi No: Abis-Mech-Yr/72Document7 pagesRequest For Inspection: Rfi No: Abis-Mech-Yr/72Richard PeriyanayagamNo ratings yet

- 01.SOP - Center BezelDocument2 pages01.SOP - Center BezelRS MANIKANDANNo ratings yet

- 506-Ppa.4711-Iso-070 - 0 - 4508-087-HML-80-Q235Document1 page506-Ppa.4711-Iso-070 - 0 - 4508-087-HML-80-Q235lewihonawiNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Group-A Credit Based Grading SystemDocument1 pageRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Group-A Credit Based Grading Systemकिशोरी जूNo ratings yet

- GIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Document1 pageGIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Kacip BolaNo ratings yet

- Updated Standard Qap 14.07.22Document6 pagesUpdated Standard Qap 14.07.22Karna Satish KumarNo ratings yet

- III - ITP - Site Piping Installation - STSSB-QAC-ITP-TA14-002Document9 pagesIII - ITP - Site Piping Installation - STSSB-QAC-ITP-TA14-002mohd as shahiddin jafriNo ratings yet

- BP-5.2.3B Job Observance For Regular OperatorsDocument1 pageBP-5.2.3B Job Observance For Regular OperatorsshinuNo ratings yet

- BP-5.1.2D OJT Effectiveness SHEET - Level-2Document1 pageBP-5.1.2D OJT Effectiveness SHEET - Level-2shinuNo ratings yet

- Die Assessment Check Sheet-Plate Type - For Physical AssessmentDocument2 pagesDie Assessment Check Sheet-Plate Type - For Physical AssessmentshinuNo ratings yet

- BP-5.1.2B Operator TRG Annexure - BDocument1 pageBP-5.1.2B Operator TRG Annexure - BshinuNo ratings yet

- BP-5.1.2A Operator TRG Annexure - ADocument1 pageBP-5.1.2A Operator TRG Annexure - AshinuNo ratings yet

- Plant Monitoring ChecksheetDocument7 pagesPlant Monitoring ChecksheetshinuNo ratings yet

- MACE Green Activity Timing PlanDocument1 pageMACE Green Activity Timing PlanshinuNo ratings yet

- Job Responsibilities For AllDocument6 pagesJob Responsibilities For AllshinuNo ratings yet

- Pfmea 85611-611-62S00Document3 pagesPfmea 85611-611-62S00shinuNo ratings yet

- Queue (First in First Out) FifoDocument16 pagesQueue (First in First Out) FifoMamta BhattaraiNo ratings yet

- ControllingDocument31 pagesControllingshadmanNo ratings yet

- Basic Clarity DemoDocument28 pagesBasic Clarity Demoamir loloNo ratings yet

- HP Corrosion Mitigation Program Update April2012 v5Document52 pagesHP Corrosion Mitigation Program Update April2012 v5feni4kaNo ratings yet

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDocument2 pagesPradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalNo ratings yet

- Ericsson Uplink Booster BrochureDocument9 pagesEricsson Uplink Booster Brochurejdklfgs aiodsNo ratings yet

- API TestingDocument13 pagesAPI Testingwaqar khalidNo ratings yet

- Alimoradi Ber45900 - 221202 - 203039Document3 pagesAlimoradi Ber45900 - 221202 - 203039rasool mehrjoo100% (2)

- Cambridge: Computer Science Tripos Part IbDocument82 pagesCambridge: Computer Science Tripos Part IbSheilaNo ratings yet

- MIS Chapter-7Document45 pagesMIS Chapter-7Lovely Ann De GuzmanNo ratings yet

- Topway Smart LCD SGTools HandbookDocument99 pagesTopway Smart LCD SGTools Handbooksherwin53No ratings yet

- Vistatec - XTM - Accepting and Finishing Tasks in XTM For Linguists - V2.0Document15 pagesVistatec - XTM - Accepting and Finishing Tasks in XTM For Linguists - V2.0kamarajme2006No ratings yet

- Genex PHU Site ProjectDocument13 pagesGenex PHU Site ProjectJesusmar Rafael Pèrez RamosNo ratings yet

- All - Linux - Iptables at Master K00lith - All GitHubDocument3 pagesAll - Linux - Iptables at Master K00lith - All GitHubDoru Ciprian MuresanNo ratings yet

- Mod 2 Notes CryptoDocument66 pagesMod 2 Notes CryptoMahalaxmi GinnamNo ratings yet

- New Open Elective IoTDocument1 pageNew Open Elective IoTManikanta RobbiNo ratings yet

- IBM Personal ComputerDocument16 pagesIBM Personal Computerahmed youssefNo ratings yet

- IEEE 802.11g-2003 - Wikipedia, The Free EncyclopediaDocument3 pagesIEEE 802.11g-2003 - Wikipedia, The Free Encyclopediajei liNo ratings yet

- Question Bdgo4103 Introductory Organisational BehaviourDocument8 pagesQuestion Bdgo4103 Introductory Organisational Behaviourdicky chongNo ratings yet

- Webbing eSIM End User Activation - Home-Country Use CaseDocument5 pagesWebbing eSIM End User Activation - Home-Country Use CaseKamito YloverNo ratings yet

- Exit Model 3rd Round Exam For H.DINODocument66 pagesExit Model 3rd Round Exam For H.DINOsuraasefa5No ratings yet

- Coc 3 (Procedural) 1. Peer To PeerDocument4 pagesCoc 3 (Procedural) 1. Peer To PeerHenry De los ReyesNo ratings yet

- 1MRS756064 - MS X - Substation Automation - Web PDFDocument8 pages1MRS756064 - MS X - Substation Automation - Web PDFdavidNo ratings yet

- Quotation For 42U RACK SIDocument7 pagesQuotation For 42U RACK SIarjun singhNo ratings yet

- Micro Niches You Can Work On - Sheet1Document1 pageMicro Niches You Can Work On - Sheet1zuneraNo ratings yet

- Automata Homework SolutionsDocument5 pagesAutomata Homework Solutionsafmsxeghf100% (1)

- Chapter4 - CH - 07-Time and Territory ManagementDocument38 pagesChapter4 - CH - 07-Time and Territory ManagementHuỳnh Tâm NhưNo ratings yet

- HPCA - Recap and Moving Forward: Soumyajit Dey, Assistant Professor, CSE, IIT KharagpurDocument23 pagesHPCA - Recap and Moving Forward: Soumyajit Dey, Assistant Professor, CSE, IIT KharagpurSunil MishraNo ratings yet

- Add Standalone NIM ClientsDocument3 pagesAdd Standalone NIM ClientsSandria MiguelNo ratings yet