Professional Documents

Culture Documents

HC IFI: Hindustan Chemicals G.T.Road, Opp. RR Auto Petrol

HC IFI: Hindustan Chemicals G.T.Road, Opp. RR Auto Petrol

Uploaded by

Karna Satish KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HC IFI: Hindustan Chemicals G.T.Road, Opp. RR Auto Petrol

HC IFI: Hindustan Chemicals G.T.Road, Opp. RR Auto Petrol

Uploaded by

Karna Satish KumarCopyright:

Available Formats

MANUFACTURE'S NAME & ADDRESS:

HC

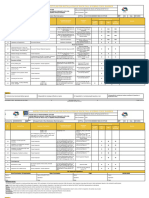

MANUFACTURING QUALITY PLAN

HINDUSTAN CHEMICALS G.T.ROAD, OPP. RR AUTO PETROL

ITEM: COACH SCREW INSULATOR QP NO:HC/AEPL/QA&I/01 L&T Doc Ref No:

PUMP, KHURJA- 203131-INDIA REV.NO:00 Project:

SUPPLIER NAME & ADDRESS : Arvensis Enrgy Pvt. Ltd. -

DATE: 04.01.2022 Client:

IFI Hyderabad No. of Page: 05

Contractor :

Component & Reference Format of

Sl.No Characteristics Class Type of Check Quantum of Check Acceptance Norms Agency Remarks

operation Document Records

1 2 3 4 5 6 7 8 9 10 11

M C N

SECTION: 1.1 RAW MATERIAL FOR BODY

1 Kg/10 MT part QC

a) Inspection / colour Major Visual Plant Std. White V V V

thereof Report

b) Residue retained on 200 QC

Major Test Do Plant Std. 3.0% Max. P V V

mesh Report

Quartz Snow white, white or off white color QC

1 c) fired colour Major Visual Do Plant Std. V V V

Powder free from any inclusions Report

As per HC Plant Standard

QC

f) Moisture Content Major Visual Do Plant Std. nil V V V

Report

h) Chemical analysis Sampling Once in 3 Supplier

Major Test Plant Std. SiO2 > 98% P V V

month/ 300 MT TC/ QC

1 Kg/10 MT part QC

a) Inspection / colour Major Visual Plant Std. White Pinkis Powder V V V

thereof Report

b) Residue retained on 200 QC

Major Test Do Plant Std. < 1.5% max. P V V

mesh Report

Feldspar QC

2 e) Moisture Content Major Visual Do Plant Std. Nil V V V As per HC Plant Standard

powder Report

f) fired behavior/Sintering Transparent or transparent QC

Major Visual Do Plant Std. V V V

(Button Test) Felspathic glass Report

g) Chemical analysis Once in 3 Alumina < 60%, Potash 10% Min & Supplier

Major Test Plant Std. P V V

month/100MT Soda 3% Max. TC/ QC

The clay shall be free from any QC

a) Inspection Major Visual 1 Kg/10 MT Plant Std. V V V

impurities & any be off white, Report

b) Residue retained on 200 QC

Major Test Do Plant Std. 2% Max. P V V

mesh Report

QC

c) Fired colour Major Visual Do Plant Std. Off white to light cream V V V

Report

QC

3 China clays d) Dry shrinkage Major Test Do Plant Std. 8% Max. P V V

Report

QC

e) Total shrinkage Major Test Do Plant Std. 18% Max. P V V

Report

QC

f) Grain Size Major Visual Do Plant Std. Less then 5 Micron 60% Min. V V V

Report

h) Chemical analysis Once in 3 10 % Min. Of LOI SiO2 48 to 50 %, Supplier

Major Test Plant Std. P V V

month/100MT Alo3 32% Min, Fe2O3 2.0% Max. TC/ QC

The clay shall be free from any

QC

a) Inspection/ colour Major Visual 1 Kg/10 MT Plant Std. impurities & will be dark creimies & P V V

Report

dark brownies colour

b) Residue retained on 200 QC

Major Test Do Plant Std. 3% Max. P V V

mesh Report

QC

c) Fired colour Major Visual Do Plant Std. Biscuit Colour V V V

Report

QC

d) Dry shrinkage Major Test Do Plant Std. 4 to 6% P V V

4 Ball clay Report As per HC Plant Standard

# Sensitivity: LNT Construction Internal Use

QC

e) Grain Size Major Visual Do Plant Std. Less then 5 Micron 60% Min. V V V

Report

QC

g) Moisture Content Major Visual Do Plant Std. 5 to 10 % V V V

Report

QC

h) Total shrinkage Major Test Do Plant Std. 12 to 16 % P V V

Report

i) Chemical analysis Once in 3 8 % Min. Of LOI SiO2 60 % Max., Supplier

Major Test Plant Std. P V V

month/300MT Alo3 25% Min, Fe2O3 1.5% Max. TC/ QC

SECTION: 1.2 RAW MATERIAL FOR GLAZE

1 Kg/05 MT or part QC

a) Inspection/ colour Major Visual Plant Std. Red Colour Powder V V V

thereof Report

b) Residue retained on 200 QC

Major Test Do Plant Std. 2% Max. P V V

mesh Report

5 Iron oxide As per HC Plant Standard

c) Fired colour of 1% iron oxide Black coloured QC

Major Visual Do Plant Std. V V V

in feldspar powder Report

d) Chemical analysis Sampling Once in 6 Supplier

Major Test Plant Std. 96% min. P V V

Fe2O3 content month/10 MT TC/ QC

Black coloured QC

a) Inspection/ colour Major Visual 1 Kg/05 MT or Plant Std. V V V

powder Report

b) Residue retained on 200 QC

Major Test Do Plant Std. 10% Max P V V

Manganese di- mesh Report

6 As per HC Plant Standard

oxide c) Fired colour of 2% Black coloured QC

Major Visual Do Plant Std. V V V

manganese dioxide in feldspar Report

d) Chemical analysis Sampling Once in 6 Supplier

Major Test Plant Std. 80% Min. P V V

MnO2 content month/ 10 MT TC/ QC

1 Kg/05 MT or part Green coloured QC

a) Inspection/ colour Major Visual Plant Std. V V V

thereof powder Report

b) Residue retained on 200 QC

Major Test Do Plant Std. 2% Max P V V

Chromium mesh Report

7 As per HC Plant Standard

oxide c) Fired colour of 3% chromium QC

Major Visual Do Plant Std. Greenies Color V V V

oxide in feldspar powder Report

d) Chemical analysis Sampling Once in 6 Supplier

Major Test Plant Std. 90% Min. P V V

Cr2O3 content month/ 10 MT TC/ QC

1 Kg/05 MT or part QC

a) Inspection/ colour Major Visual Plant Std. Off or dull white V V V

thereof Report

b) Residue retained on 200 the residue shall be free from iron QC

Major Test Do Plant Std. P V V

Calcite mesh particles and magnetic impurities Report

8 As per HC Plant Standard

powder QC

c) Fired characteristic Major Visual Do Plant Std. Free from ferrous/ferric impurities V V V

Report

d) Chemical analysis Sampling Once in 6 Vendor's test certificate Supplier

Major Test Plant Std. P V V

month/ 10 MT TC/ QC

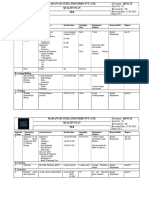

SECTION:2 ASSEMBLY MATERIALS INSPECTION

IS 12269 & Plant Sample of cement taken out the

0.01% of total quantity QC

a) Inspection Major Visual Std bag at should be free from lumps & V V V

received Report Cement shall not give rise

dark grey in color

9 Cement to chemical reaction with

IS 12269 & Plant metal fittings

QC

b) Compressive strength Major Test Do Std Min. 4% kg after 7 days P V V

Report

SECTION: 4 IN PROCESS INSPECTION

QC

a) Inspection Major Visual Each charge Plant Std. Plant Std. V V V

Report

Wet grinding

b) Residue retained on 200 QC

13 of ceramic Major Test Do Plant Std. Plant Std. P V V

mesh Report

body

QC

c) Litre Weight Major Test Do Plant Std. Plant Std. P V V

Report

# Sensitivity: LNT Construction Internal Use

a) Residue retained on 300 QC

Major Test Each charge Plant Std. 0.4% Max. P V V

Glaze mesh Report

14

Preparation QC

Major Test Do Plant Std. Plant Std. P V V

b) Litre Weight Report

Pug mill's clay QC

15 a) De airing checking Major Test Every 30 Mins Plant Std. Plant Std. P V V

blank Report

Sampling Once in 3 2 QC

Properties of a) Dry MOR Major Test Plant Std. 28 Kgs/cm Min P V V

month Report

16 unfired

Sampling Once in QC

porcelain b) Linear shrinkage Major Test Plant Std. Max. 14% P V V

month Report

a) Making cavity check ( QC

Major Measurement Once in every shift As per Drawing As per Drawing P V V

Dimension) Report

QC

17 Shaping b) Finishing dimension Major Measurement Do Do Do P V V

Report

QC

c) Moisture Major Test Once daily Plant Std. Plant Std. P V V

Report

o QC

a) Hot rooms temperature Major Visual Once in a day Plant Std. 50-80 C V V V

Report

18 Drying

QC

b) moisture content Major Test 3 samples per day Plant Std. 1.5% Max P V V

Report

Sampling Once in 3 Unglazed 750 kg/cm2 Min QC

a) Fired M.O.R Major Test Plant Std. P V V

month glazed 850 kg/cm2 Min Report

Properties of

19 All cars of every shuttle As per ANSI:C29- QC

fired porcelain b) porosity Major Test As per ANSI:C29-4 P V V

kiln & any one 4 & 29-3 Report

QC

c) Bulk density/Water absorption Major Test daily & each kiln Plant Std. 2.38 Min / 0.2% P V V

Report

QC

a) Inspection Major Visual 100% Plant Std. Plant Std. V V V

Report

Glazing QC

20 b) Sp.gravity Major Test Every hour Plant Std. 1.49-1.51 P V V

(Brown glaze) Report

QC

c) Moisture % Major Test 3 samples per day Plant Std. 2.5% Max P V V

Report

Temperature QC

21 Major Visual Every hour Plant Std. Plant Std. V V V

during firing Report

QC Coach Screw Insulator

22 Packing a) Inspection Major Visual 100% Plant Std. Plant Std. V W W

Report shall be packed in Pallet

SECTION:5 FINAL INSPECTION: Coach Screw Insulator

a) Dimensional & Visual QC

23 Routine Test Major Visual 100% AS Per IS: 1445 P V V

Verification Report

Surface shall be smooth, free from,

FAT

a) Visual Verification Major Measurement AS Per IS: 1445 AS Per IS: 1445 breakage chips, noulding defect, P W W

Report

cracks & having uniform glazing

Acceptance b) Dimensional Verification

24 tests on FAT

(Creepage, groove height, Major Measurement AS Per IS: 1445 AS Per IS: 1445 As per approved Drawing P W W

Insulators Report

diameter, insulator height etc)

Shall withstood rared KV for 1 FAT

c) Power Frequency Test Major Test AS Per IS: 1445 AS Per IS: 1445 P W W

minutes Report

FAT

d) Porosity Test Major Test AS Per IS: 1445 AS Per IS: 1445 No Dye Panetration P W W

Report

DOC NO REV………….. CAT………………

LEGEND : "RECORDS IDENTIFIED WITH "TICK" SHALL BE ESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTION

M - MANUFACTURER/SUBSUPPLIER

Manufacturer/ Sub Supplier MAIN SUPPLIER

C - MAIN SUPPLER

# Sensitivity: LNT Construction Internal Use

N - SGS

P - PERFORM

SIGNATURE

V- VERIFICATION AS APPROPRIATE

REVIEW APPROVAL SEAL

# Sensitivity: LNT Construction Internal Use

You might also like

- QAP FormatDocument3 pagesQAP FormatSaravana Kumar100% (2)

- ITP For CivilDocument85 pagesITP For CivilBilibili weekly TOP 10 videos100% (7)

- Inspection and Test Plan (ITP) WeldingDocument3 pagesInspection and Test Plan (ITP) WeldingMuhammed Abo-Fandood100% (5)

- FRP ItpDocument2 pagesFRP ItpHrishikesan100% (2)

- Itp For Fitp For Hdpe Pipes InstallationDocument3 pagesItp For Fitp For Hdpe Pipes InstallationBleep NewsNo ratings yet

- Dispensing Lab - RX 1-13 NotesDocument7 pagesDispensing Lab - RX 1-13 NotesEdrick Ramoran50% (4)

- Epoxidation of CholesterolDocument8 pagesEpoxidation of CholesterolKeithen Cast100% (1)

- Receipt Inspection Quality PlanDocument1 pageReceipt Inspection Quality Plankulkarnimegha87No ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Qap TataDocument5 pagesQap TataDesign VardhNo ratings yet

- Bird Guard MQP RGTLDocument3 pagesBird Guard MQP RGTLKumara SubramanianNo ratings yet

- Rock Fall Barrier ITPDocument2 pagesRock Fall Barrier ITPVishnudas MgNo ratings yet

- Kundalia RB Project - Cage Ladder QAPDocument2 pagesKundalia RB Project - Cage Ladder QAPHarshit AdwaniNo ratings yet

- YzcvfDocument2 pagesYzcvfCheeragNo ratings yet

- Kundalia RB Project - Cage Ladder QAPDocument2 pagesKundalia RB Project - Cage Ladder QAPHarshit AdwaniNo ratings yet

- 9 ITP GypsumboardDocument1 page9 ITP Gypsumboardahmsami91No ratings yet

- Table-A: Summary of Materials / Products Specification and QA/QC Test RequirementsDocument42 pagesTable-A: Summary of Materials / Products Specification and QA/QC Test RequirementsVictor VargheseNo ratings yet

- Itp-22!11!1 Rev.0 en 10219-Bare Pipe Somatm SaDocument12 pagesItp-22!11!1 Rev.0 en 10219-Bare Pipe Somatm Samahmut gelNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- Quality Assurance Standard Quality Plan Column and Ceiling GirderDocument9 pagesQuality Assurance Standard Quality Plan Column and Ceiling Girdertalk2dilpreetNo ratings yet

- QAPDocument10 pagesQAPsheikmoinNo ratings yet

- No.-QC/202D/2022/276250 Wearing Course: 3approved Revised Not Updated. Organization Chart To Be UpdatedDocument2 pagesNo.-QC/202D/2022/276250 Wearing Course: 3approved Revised Not Updated. Organization Chart To Be UpdatedAtulNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- Saatvik QAP-72 Cell Full CellDocument4 pagesSaatvik QAP-72 Cell Full Cellvenkatraman JNo ratings yet

- QAP N2 Generator & N2 VesselDocument2 pagesQAP N2 Generator & N2 VesselVijay - Spantech EngineersNo ratings yet

- Rock Dowels & Rock Nails ITPDocument7 pagesRock Dowels & Rock Nails ITPVishnudas MgNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- Qap - NRLDocument1 pageQap - NRLStructures ProductionNo ratings yet

- Protection Wire Mesh ITPDocument3 pagesProtection Wire Mesh ITPVishnudas MgNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Itp-Internals R2Document2 pagesItp-Internals R2Delta akathehuskyNo ratings yet

- Nit 2800 3 PDFDocument7 pagesNit 2800 3 PDFAnonymous uXdS9Y7No ratings yet

- 18.9 ITP SUB BASE Rev01Document2 pages18.9 ITP SUB BASE Rev01YEHIA100% (1)

- QAP For FlangesDocument2 pagesQAP For FlangesGOPINATH KRISHNAN NAIRNo ratings yet

- Quality Assurance Plan: Raw Material ProcurmentDocument2 pagesQuality Assurance Plan: Raw Material ProcurmentHuỳnh Ngọc HiệpNo ratings yet

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Quality Assurance Plan For PEBDocument2 pagesQuality Assurance Plan For PEBBipin Vihari DasNo ratings yet

- TRN-334-DG SetDocument1 pageTRN-334-DG Setcontracts1.delhiNo ratings yet

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- Book 1Document2 pagesBook 1srinivasu.k2009No ratings yet

- ITP For BuildingDocument57 pagesITP For BuildingBilibili weekly TOP 10 videos100% (1)

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- QCP For StructureDocument4 pagesQCP For StructureHema Nandh100% (1)

- ITP WeldingDocument49 pagesITP WeldingBinu SulochananNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Material Inspection SheetDocument3 pagesMaterial Inspection Sheetrahid iqubalNo ratings yet

- 08.QA-NPD-08 - Sani Mold - Cover Timer Side - 32981-EDocument6 pages08.QA-NPD-08 - Sani Mold - Cover Timer Side - 32981-EdelightplasticsNo ratings yet

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- Icl Condensate TrapDocument5 pagesIcl Condensate TrapAlberto CamposNo ratings yet

- ITP For Earth FillingDocument1 pageITP For Earth FillingRICPL - Quality Management Department- HONo ratings yet

- Final Dimension Control Procedure - Flare KOD Rev ADocument9 pagesFinal Dimension Control Procedure - Flare KOD Rev ARajesh K Pillai100% (1)

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- 04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTADocument4 pages04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTAjay2kay5793No ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- TTD Seva ReceiptDocument1 pageTTD Seva ReceiptKarna Satish KumarNo ratings yet

- IRCTC Retiring Room09Document1 pageIRCTC Retiring Room09Karna Satish KumarNo ratings yet

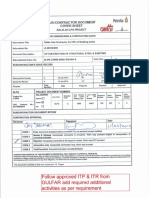

- Witnessed Factory Acceptance ReportDocument4 pagesWitnessed Factory Acceptance ReportKarna Satish KumarNo ratings yet

- Ban HydDocument1 pageBan HydKarna Satish KumarNo ratings yet

- Factory Visit RequirementsDocument2 pagesFactory Visit RequirementsKarna Satish KumarNo ratings yet

- SATISHDocument2 pagesSATISHKarna Satish KumarNo ratings yet

- DPR - (18-July-2022)Document332 pagesDPR - (18-July-2022)Karna Satish KumarNo ratings yet

- MOM ParamountDocument1 pageMOM ParamountKarna Satish KumarNo ratings yet

- Pmu Segaluid Substation Structures Packing ListDocument9 pagesPmu Segaluid Substation Structures Packing ListKarna Satish KumarNo ratings yet

- Hyd To BanDocument1 pageHyd To BanKarna Satish KumarNo ratings yet

- Polutry Sheds - DWGSDocument4 pagesPolutry Sheds - DWGSKarna Satish KumarNo ratings yet

- Conductor Technical CatalogDocument22 pagesConductor Technical CatalogKarna Satish KumarNo ratings yet

- Prepared By: Julkarnain Ahemad. L&T-QA/QC-DDIP-SambalpurDocument26 pagesPrepared By: Julkarnain Ahemad. L&T-QA/QC-DDIP-SambalpurKarna Satish KumarNo ratings yet

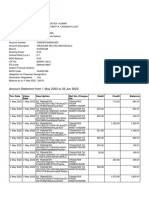

- SGS ReportDocument4 pagesSGS ReportKarna Satish KumarNo ratings yet

- A JXi 60 LWZ YV2 P OC4Document15 pagesA JXi 60 LWZ YV2 P OC4Karna Satish KumarNo ratings yet

- Updated Standard Qap 14.07.22Document6 pagesUpdated Standard Qap 14.07.22Karna Satish KumarNo ratings yet

- Redgear PDFDocument47 pagesRedgear PDFKarna Satish KumarNo ratings yet

- Approved Drawing Kotsons 100KVA TFDocument3 pagesApproved Drawing Kotsons 100KVA TFKarna Satish KumarNo ratings yet

- Project: Supply of Jasikan 33Kv Switching Station Control Relay Panel. Enpro Job Ref: Eia-979Document3 pagesProject: Supply of Jasikan 33Kv Switching Station Control Relay Panel. Enpro Job Ref: Eia-979Karna Satish KumarNo ratings yet

- Government of India Ministry of RailwaysDocument31 pagesGovernment of India Ministry of RailwaysKarna Satish KumarNo ratings yet

- 161Kv - YY Modification For TestingDocument6 pages161Kv - YY Modification For TestingKarna Satish KumarNo ratings yet

- Eia-979 CRP QCPDocument5 pagesEia-979 CRP QCPKarna Satish KumarNo ratings yet

- IP Rating Chart 4Document1 pageIP Rating Chart 4Karna Satish KumarNo ratings yet

- Repair Estiamte CR Channel CHN 21-22 0308Document2 pagesRepair Estiamte CR Channel CHN 21-22 0308Karna Satish KumarNo ratings yet

- XX StubDocument1 pageXX StubKarna Satish KumarNo ratings yet

- 11KV Stay Insulator - DWNG - 001Document1 page11KV Stay Insulator - DWNG - 001Karna Satish KumarNo ratings yet

- HFC Digital TechnologiesDocument1 pageHFC Digital TechnologiesKarna Satish KumarNo ratings yet

- Fuse CutoutsDocument10 pagesFuse CutoutsKarna Satish KumarNo ratings yet

- Type Tests Connducted by ArvensisDocument2 pagesType Tests Connducted by ArvensisKarna Satish KumarNo ratings yet

- Towhomsoever It May ConcernDocument2 pagesTowhomsoever It May ConcernKarna Satish KumarNo ratings yet

- Heavy Metals and Its Impact in Vegetable CropsDocument10 pagesHeavy Metals and Its Impact in Vegetable CropsSandeep GunalanNo ratings yet

- 339-3778 NGEC Heavy Duty Cooling System FluidDocument3 pages339-3778 NGEC Heavy Duty Cooling System Fluidchristian ivan castro canoNo ratings yet

- Investigation On The Effect of Nano Zeolite and Potassium Permanganate On The Shelf Life Extending and Quality of Red Delicious AppleDocument7 pagesInvestigation On The Effect of Nano Zeolite and Potassium Permanganate On The Shelf Life Extending and Quality of Red Delicious AppleInternational Network For Natural SciencesNo ratings yet

- Suzuki CouplingDocument63 pagesSuzuki CouplingVirendra RautNo ratings yet

- Slags in Ferroalloys ProductionDocument10 pagesSlags in Ferroalloys ProductionQuinton Dean ChingokaNo ratings yet

- 50 Polimeros NanocompuestosDocument35 pages50 Polimeros NanocompuestosMONICA XIMENA ERAS VARGASNo ratings yet

- AcetobacterDocument11 pagesAcetobacterdiantinurwindaNo ratings yet

- Bio-024-Lab-Activity-2 Navarro, Mia Grace G.Document3 pagesBio-024-Lab-Activity-2 Navarro, Mia Grace G.Mia NavarroNo ratings yet

- Detergent Ingredient Database Final Report (DID-list) PDFDocument13 pagesDetergent Ingredient Database Final Report (DID-list) PDFherrumbeNo ratings yet

- Gypsum Plaster: Product Description Physical PropertiesDocument1 pageGypsum Plaster: Product Description Physical PropertiesImtiyazNo ratings yet

- Full Factorial DesignDocument6 pagesFull Factorial DesignterNo ratings yet

- Sulfur PDFDocument21 pagesSulfur PDFjjtpiNo ratings yet

- 4 Growth & DevelopmentDocument7 pages4 Growth & Developmentphoenix eastwoodNo ratings yet

- Crude Oil CharacterizationDocument51 pagesCrude Oil CharacterizationVenkatesh Kumar Ramanujam67% (3)

- 05 Arcel EvacleanDocument3 pages05 Arcel EvacleanKemas RamaNo ratings yet

- Ni - AISI - 9013 - Amonia ProductionDocument23 pagesNi - AISI - 9013 - Amonia ProductionBaher ElsheikhNo ratings yet

- PDF 2D Metal Carbides and Nitrides Mxenes Structure Properties and Applications Babak Anasori Ebook Full ChapterDocument53 pagesPDF 2D Metal Carbides and Nitrides Mxenes Structure Properties and Applications Babak Anasori Ebook Full Chapterpaul.popp121100% (8)

- Sour WaterDocument6 pagesSour Waterrasnowmah2012No ratings yet

- GF-304CR Dossier.Document35 pagesGF-304CR Dossier.suria qaqcNo ratings yet

- USP-NF Acetaminophen and Codeine Phosphate TabletsDocument3 pagesUSP-NF Acetaminophen and Codeine Phosphate TabletsStalin VacaNo ratings yet

- Project On Green ChemistryDocument39 pagesProject On Green ChemistryHardik Shukla86% (7)

- 107th AgendaDocument123 pages107th Agendakinanantha100% (1)

- PQR 005-50-NLG PWHT (Icas)Document2 pagesPQR 005-50-NLG PWHT (Icas)Atilio BarriosNo ratings yet

- 14 32302rsj090817 94 100Document8 pages14 32302rsj090817 94 100EnaPetrovskaNo ratings yet

- Polyphosphoric Acid (PPA) in Road Asphalts ModificationDocument3 pagesPolyphosphoric Acid (PPA) in Road Asphalts ModificationTarak PatelNo ratings yet

- Fusion Behavior of Plastisols of PVC Studied by ATR FTIRDocument5 pagesFusion Behavior of Plastisols of PVC Studied by ATR FTIRFilthynotesNo ratings yet

- Aws A5.1 (1991) PDFDocument57 pagesAws A5.1 (1991) PDFRenier KoenNo ratings yet

- Washing Principle Denim DystarDocument80 pagesWashing Principle Denim DystarLieven Verraest100% (4)