Professional Documents

Culture Documents

PRIMER COAT-Zinc Anode 304 MZV - PDS

PRIMER COAT-Zinc Anode 304 MZV - PDS

Uploaded by

MANIMARAN QCCopyright:

Available Formats

You might also like

- Position Paper For Plaintiff (Ejectment Case)Document8 pagesPosition Paper For Plaintiff (Ejectment Case)Aldrin Loyola100% (9)

- The Forrester Wave™ - Digital Business Transformation Services, Q4 2020Document15 pagesThe Forrester Wave™ - Digital Business Transformation Services, Q4 2020divider100% (1)

- Grade 1 Class Program 2022-2023Document1 pageGrade 1 Class Program 2022-2023Geoff Rey100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Karumel Ex4412: KCC CorporationDocument4 pagesKarumel Ex4412: KCC CorporationABAID ULLAHNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- Sikaproof Membrane: Safety Data SheetDocument6 pagesSikaproof Membrane: Safety Data SheetSamuel CastilloNo ratings yet

- F 2 Pentathane 4510Document3 pagesF 2 Pentathane 4510Gunjan GaganNo ratings yet

- D 1331 - 89 R01 - RdezmzeDocument3 pagesD 1331 - 89 R01 - Rdezmzejamaljamal20No ratings yet

- Monash Debaters HandbookDocument79 pagesMonash Debaters HandbookGusva HavitaNo ratings yet

- License KeyDocument1 pageLicense KeyLolobau50% (10)

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Astm D2584-18 - LoiDocument3 pagesAstm D2584-18 - LoiSaravanan JNo ratings yet

- Prebond 220 Acid Resistant PaintDocument4 pagesPrebond 220 Acid Resistant Paintsudhir64No ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- Mandolite 550 DSDocument4 pagesMandolite 550 DSnrd9771No ratings yet

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- ASTM D2624 - Jtvo9242Document8 pagesASTM D2624 - Jtvo9242Nayth Andres GalazNo ratings yet

- Astm A668Document10 pagesAstm A668Hussain AliNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- Pentadur Glass Flake Epoxy 3580 PDFDocument2 pagesPentadur Glass Flake Epoxy 3580 PDFChoice Organo100% (1)

- Astm D2621 2005Document26 pagesAstm D2621 2005Marc Padu100% (1)

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDocument2 pagesExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNo ratings yet

- Thermaline Heat Shield PDSDocument2 pagesThermaline Heat Shield PDSKhemaraj Path100% (1)

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Sigmashield 880 GF - ISO 23040-1Document1 pageSigmashield 880 GF - ISO 23040-1Saravan KumarNo ratings yet

- Inspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationDocument17 pagesInspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationPrakash SIngh Rawal100% (1)

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- Nitocote ET402: Constructive SolutionsDocument3 pagesNitocote ET402: Constructive SolutionsGavriel Ng100% (1)

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- Mar Resistance of Organic Coatings: Standard Test Method ForDocument3 pagesMar Resistance of Organic Coatings: Standard Test Method Formit uotNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- 355 SaDocument2 pages355 Sakhalid764100% (1)

- TFR CommissioningDocument24 pagesTFR CommissioningKrishna DNo ratings yet

- 19-19 Tightness Test PDFDocument31 pages19-19 Tightness Test PDFJoyNo ratings yet

- Preservation Program Works For Outages From One Month To Several YearsDocument4 pagesPreservation Program Works For Outages From One Month To Several Yearse.vicente.caballeroNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data Sheetapply19842371No ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972No ratings yet

- OTS60PBDocument4 pagesOTS60PBLiza Taguines VillegasNo ratings yet

- Specifications of Painting WorksDocument7 pagesSpecifications of Painting WorksSiddharth Gamare100% (1)

- Bond Strength of Mortar To Masonry Units: Standard Test Method ForDocument8 pagesBond Strength of Mortar To Masonry Units: Standard Test Method Foranon_694321072100% (1)

- Wimpey Laboratories DUBAI AccreditationDocument49 pagesWimpey Laboratories DUBAI AccreditationomerNo ratings yet

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- Is2720 Part09Document6 pagesIs2720 Part09anvesh_kumar_16No ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Paint Certificate 80A45-1Document1 pagePaint Certificate 80A45-1Shyam_Nair_9667No ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Asian Paints PuDocument2 pagesAsian Paints PuAkash BadwaikNo ratings yet

- SSPC SP 1Document2 pagesSSPC SP 1romdhan88No ratings yet

- QAP - Gate Valve - NPCILDocument6 pagesQAP - Gate Valve - NPCILkaustavNo ratings yet

- PDS - EP-10 Etch PrimerDocument2 pagesPDS - EP-10 Etch Primercarlogeretto2No ratings yet

- Astm D578@578M-05 (R2011) E1Document19 pagesAstm D578@578M-05 (R2011) E1Doulat RamNo ratings yet

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinNo ratings yet

- 5.2.3.1equipment For High Voltage Spark TestingDocument5 pages5.2.3.1equipment For High Voltage Spark TestingManriquez AndresNo ratings yet

- Uphill Versus Downhill Welding PDFDocument4 pagesUphill Versus Downhill Welding PDFPatrick DominguezNo ratings yet

- Testing of Non - Metallic Materials For Use With Drinking WATER (BS 6920: 2000)Document8 pagesTesting of Non - Metallic Materials For Use With Drinking WATER (BS 6920: 2000)whwy99No ratings yet

- SS621 TUV Testing Report (Full Permission)Document5 pagesSS621 TUV Testing Report (Full Permission)Christiano RodriguezNo ratings yet

- Apcs 17a 85710Document2 pagesApcs 17a 85710jojo_323No ratings yet

- Contractor IOT Infrastructure & Energy Services LTDDocument38 pagesContractor IOT Infrastructure & Energy Services LTDNaveen KurupNo ratings yet

- Interzinc 52 TDSDocument4 pagesInterzinc 52 TDSDele TedNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZvkvc soodNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZsojeckNo ratings yet

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDocument2 pagesDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckNo ratings yet

- WPS DP ReportsDocument8 pagesWPS DP ReportsMANIMARAN QCNo ratings yet

- Pressure Test REPORTDocument6 pagesPressure Test REPORTMANIMARAN QCNo ratings yet

- Raw Material - E-023-22Document2 pagesRaw Material - E-023-22MANIMARAN QCNo ratings yet

- FINISH COAT-Bergerthane PU CoatingDocument2 pagesFINISH COAT-Bergerthane PU CoatingMANIMARAN QCNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Dimension RFPDocument3 pagesDimension RFPMANIMARAN QCNo ratings yet

- DPT ReportDocument3 pagesDPT ReportMANIMARAN QCNo ratings yet

- N Murthy Report On Corporate GovernanceDocument8 pagesN Murthy Report On Corporate GovernanceShrishtiNarayaniNo ratings yet

- Annual Report 2017 18Document122 pagesAnnual Report 2017 18Ali AhmedNo ratings yet

- Bitera M3W2Document9 pagesBitera M3W2Chelsea NicoleNo ratings yet

- A5 - Fringe Benefit TaxationDocument3 pagesA5 - Fringe Benefit TaxationJomer FernandezNo ratings yet

- Government Finance: Taxation in The United States United States Federal BudgetDocument7 pagesGovernment Finance: Taxation in The United States United States Federal BudgetKatt RinaNo ratings yet

- New Final Updated IFRS 16Document98 pagesNew Final Updated IFRS 16murshidalbimaanyNo ratings yet

- Personal Profile For Jco & Jnco - NewDocument3 pagesPersonal Profile For Jco & Jnco - NewMed Cabojoc Jr.No ratings yet

- 3210Q011 04gb PDFDocument2 pages3210Q011 04gb PDFrpicho100% (1)

- M-40k Notice of Denial of Expedited FS or Inability To Issue FSDocument1 pageM-40k Notice of Denial of Expedited FS or Inability To Issue FShooNo ratings yet

- Jail Officer Up To The Rank of Jail Superintendent and Other Law Enforcement Agencies, and Agencies Under The Criminal Justice SystemDocument3 pagesJail Officer Up To The Rank of Jail Superintendent and Other Law Enforcement Agencies, and Agencies Under The Criminal Justice SystembogartsidoNo ratings yet

- Offer Letter SathwikDocument3 pagesOffer Letter SathwikRaviteja PavanNo ratings yet

- Limkhawpui: N. Hlimen Huan Neitu Pawl HriattirnaDocument2 pagesLimkhawpui: N. Hlimen Huan Neitu Pawl HriattirnaJC LalthanfalaNo ratings yet

- CHPL Management AgreementDocument39 pagesCHPL Management AgreementRaghvendra AgarwalNo ratings yet

- Htg-S510 User Manual: Hitech Global Stratix V Pci Express Ethernet Networking Development PlatformDocument43 pagesHtg-S510 User Manual: Hitech Global Stratix V Pci Express Ethernet Networking Development PlatformlitoduterNo ratings yet

- Evolution of The Indian Insolvency and Bankruptcy CodeDocument22 pagesEvolution of The Indian Insolvency and Bankruptcy CodeSid KaulNo ratings yet

- Provide Monthly Seo Service Onpage and Offpage Optimization by Saifullah937 - FiverrDocument1 pageProvide Monthly Seo Service Onpage and Offpage Optimization by Saifullah937 - FiverrAbdul Latif0% (1)

- Provisions of ESOP in Companies ActDocument6 pagesProvisions of ESOP in Companies ActshanikaNo ratings yet

- Rabusa 2005Document8 pagesRabusa 2005Desiree GuaschNo ratings yet

- NIBIN Fact SheetDocument2 pagesNIBIN Fact Sheet13WMAZNo ratings yet

- Full Text Set 3 - TaxDocument33 pagesFull Text Set 3 - TaxulticonNo ratings yet

- Ncnda & Imfpa (Icc1)Document6 pagesNcnda & Imfpa (Icc1)King RoodNo ratings yet

- 8 Steps For Ethical Decision Making - HalfmantrDocument3 pages8 Steps For Ethical Decision Making - HalfmantrJai Dev100% (2)

- As 3519-2005 Timber - Machine Proof GradingDocument8 pagesAs 3519-2005 Timber - Machine Proof GradingSAI Global - APACNo ratings yet

- NMH Doc Issue PlanDocument5 pagesNMH Doc Issue PlanJustin MusopoleNo ratings yet

- Important Facts of Indian HistoryDocument5 pagesImportant Facts of Indian HistoryKabeer PallikkalNo ratings yet

PRIMER COAT-Zinc Anode 304 MZV - PDS

PRIMER COAT-Zinc Anode 304 MZV - PDS

Uploaded by

MANIMARAN QCOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRIMER COAT-Zinc Anode 304 MZV - PDS

PRIMER COAT-Zinc Anode 304 MZV - PDS

Uploaded by

MANIMARAN QCCopyright:

Available Formats

BERdc

BERGER

Scope

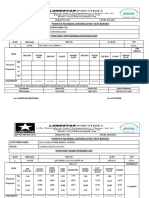

Zinc Anode 304 MZV

Inorganic Zinc Silicate Coating

Protecton

A two pack Solventless Epoxy Finish designed

Scope Uses

A two pack solvent based inorganic zinc silicate primer for

application on blasted steel surface. Suitable for use on steel structures,

exterior of storage tanks, infrastructure

It provides outstanding cathodic protection and protects steel facilities, equipments, pipelines, etc.

against severe corrosion. It is however, not recommended for

contacts with strong acids or alkalis of pH below 5 or

exceeding 10.

The coatings attains water resistance within 30 minutes of

application and is unaffected by rain, condensation or dew.

Product Data

Resistance Guide

Type: Two pack self cured

Chemical Resistance (with proper top coat)

Composition: Ethyl Silicate / Metallic Zinc

Mixing Ratio: Part A & Part B when mixed will give

20 Ltr paint.

Exposures Splash Mild Fumes /

Pot Life: 3-5 hours and spillage outdoor

Application: conventional and airless spray. Brush Resistance

for small areas. Acids Very Good Excellent

Recommended DFT: 65-75 microns per coat Alkalis Very Good Excellent

Corresponding WFT: 108-125 Microns per coat____ Solvent Excellent Excellent

Salt Excellent Excellent

Theoretical Spreading Rate: 8.0 -9.2 Sq. Mtr/Ltr

__________________________________________ Water Excellent Excellent

Drying time:

Temperature Resistance:

TOUCH: 30 minutes

HANDLE: 2-4 hours

HARD: Overnight Continuous: 400 degree C

Intermittent: 426 degree C

Curing Time: 6-7 days

Weatherability : Excellent

Overcoating Interval: Min: Overnight

Max:Indefinite

Flexibility: Fair

Flash Point: Below 22 degree C

Colour: Grey Abrasion Resistance: Excellent

Finish: Matt - Increases with age

Packing: 20 Ltrs.

Thinner / Cleaner: Thinner 870

Storage Life: Up to six months as long as the sealed

containers are kept under cover in a dry place under Date Sheet No. 137

normal temperature conditions.

Surface Preparation

Remove grease, oil and other contaminants preferably by using Bison Degreasing Solvent. Blast clean to a minimum Sa 2 ½ Swedish

Standards SIS 05 5900 with a surface profile not exceeding 50 microns. The surface should be clean and dry before application of Zinc

Anode 304 MZV.

Application

Stir Part A and Part B thoroughly to uniform consistency. Mix the components in the recommended proportion with constant stirring -

preferably with a mechanical stirrer. Continue stirring until the components are thoroughly mixed. Strain the mixture through a 80 mesh

sieve. Allow the mixture to mature for 15-20 minutes before application. Stir again before use and from time to time during application.

Conventional Spray: Add upto 5% Thinner 870 depending on conditions. Use any standard equipment at an atomizing pressure of

3..5-4.4 Kg/cm2 .

Airless spray: Apply preferably without thinning. Use any standard equipment having pump ratio 30:1. Tip size 0..38-0.48 mm. Tip

pressure 110-160 Kg/cm2

Typical Painting Specifications

Surface 1st coat 2nd coat 3rd coat 4th coat

-----------------------------------------------------------------------------------------------------------------------------------

Steel Zinc Anode 304 Epilux 4 HB MIO Epilux 4 Enl or Epilux Epilux 4 Enl or Epilux 155 HB

MZV 155 HB or Epilux 89 Fsg or Epilux 89 Fsg

-do- -do- Epilux 5 CTE or Epilux 5 CTE or

Epilux 555 CTE Epilux 555 CTE HB

-do- -do- Epithane or Epithane or Bergerthane

Bergerthane Enl Enl

-do- -do- Lumeros HR/47 Lumeros HR/47 OR

or Silicone Silicone Acrylic HR

Acrylic HR Ctg Ctg.

Overcoating of Zinc Anode 304 MZV

It must be fully cured and free from residual solvent before overcoating. This normally takes 10-12 hours but time may be

extended under conditions of humidity below 80%.

While overcoating a mist coat should first applied to avoid bubbling which appears due to air entrapment.

Notes:

1. Use off the mixed paint within the stipulated pot life period

Berger Paints India Ltd

2. Both components available in liquid form also for ease of

application. BERGERHOUSE

3. It cures by reaction with moisture and may be applied at high 129 Park Street

humidity provided the blasted surface itself is free from Calcutta – 700 017

condensation and meets the requirement of Sa 2.5 Swedish Tel: (033) 2299724 (5 lines)

Standard 2499754 (4 lines)

4. Application equipment should be cleaned with Thinner 870 Fax: 91-33-2499729/9009

otherwise they are liable to be damaged. Telex: 021-5482/5791

5. At lower relative humidity, drying and curing are likely to be

extended.

6. Damaged areas can be touched up with Epilux 4 Zinc Rich

Primer.

Health & Safety - Please refer to the separate safety data sheet

available with detailed information.

Disclaimer

The information contained herein within this data sheet is based on information

Data Sheet No.137

believed to be reliable at the time of its preparation. The Company will not be

liable for loss or damage howsoever caused including liability for negligence,

which may be suffered by the user of the data contained herein. It is the users’

Issue Date : Dec’2001

responsibility to conduct all necessary tests to confirm the suitability of any

product or system for their intended use. No guarantee of results is implied since

conditions of use are beyond our control.

You might also like

- Position Paper For Plaintiff (Ejectment Case)Document8 pagesPosition Paper For Plaintiff (Ejectment Case)Aldrin Loyola100% (9)

- The Forrester Wave™ - Digital Business Transformation Services, Q4 2020Document15 pagesThe Forrester Wave™ - Digital Business Transformation Services, Q4 2020divider100% (1)

- Grade 1 Class Program 2022-2023Document1 pageGrade 1 Class Program 2022-2023Geoff Rey100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Karumel Ex4412: KCC CorporationDocument4 pagesKarumel Ex4412: KCC CorporationABAID ULLAHNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- Sikaproof Membrane: Safety Data SheetDocument6 pagesSikaproof Membrane: Safety Data SheetSamuel CastilloNo ratings yet

- F 2 Pentathane 4510Document3 pagesF 2 Pentathane 4510Gunjan GaganNo ratings yet

- D 1331 - 89 R01 - RdezmzeDocument3 pagesD 1331 - 89 R01 - Rdezmzejamaljamal20No ratings yet

- Monash Debaters HandbookDocument79 pagesMonash Debaters HandbookGusva HavitaNo ratings yet

- License KeyDocument1 pageLicense KeyLolobau50% (10)

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Astm D2584-18 - LoiDocument3 pagesAstm D2584-18 - LoiSaravanan JNo ratings yet

- Prebond 220 Acid Resistant PaintDocument4 pagesPrebond 220 Acid Resistant Paintsudhir64No ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- Mandolite 550 DSDocument4 pagesMandolite 550 DSnrd9771No ratings yet

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- ASTM D2624 - Jtvo9242Document8 pagesASTM D2624 - Jtvo9242Nayth Andres GalazNo ratings yet

- Astm A668Document10 pagesAstm A668Hussain AliNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- Pentadur Glass Flake Epoxy 3580 PDFDocument2 pagesPentadur Glass Flake Epoxy 3580 PDFChoice Organo100% (1)

- Astm D2621 2005Document26 pagesAstm D2621 2005Marc Padu100% (1)

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDocument2 pagesExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNo ratings yet

- Thermaline Heat Shield PDSDocument2 pagesThermaline Heat Shield PDSKhemaraj Path100% (1)

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Sigmashield 880 GF - ISO 23040-1Document1 pageSigmashield 880 GF - ISO 23040-1Saravan KumarNo ratings yet

- Inspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationDocument17 pagesInspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationPrakash SIngh Rawal100% (1)

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- Nitocote ET402: Constructive SolutionsDocument3 pagesNitocote ET402: Constructive SolutionsGavriel Ng100% (1)

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- Mar Resistance of Organic Coatings: Standard Test Method ForDocument3 pagesMar Resistance of Organic Coatings: Standard Test Method Formit uotNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- 355 SaDocument2 pages355 Sakhalid764100% (1)

- TFR CommissioningDocument24 pagesTFR CommissioningKrishna DNo ratings yet

- 19-19 Tightness Test PDFDocument31 pages19-19 Tightness Test PDFJoyNo ratings yet

- Preservation Program Works For Outages From One Month To Several YearsDocument4 pagesPreservation Program Works For Outages From One Month To Several Yearse.vicente.caballeroNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data Sheetapply19842371No ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972No ratings yet

- OTS60PBDocument4 pagesOTS60PBLiza Taguines VillegasNo ratings yet

- Specifications of Painting WorksDocument7 pagesSpecifications of Painting WorksSiddharth Gamare100% (1)

- Bond Strength of Mortar To Masonry Units: Standard Test Method ForDocument8 pagesBond Strength of Mortar To Masonry Units: Standard Test Method Foranon_694321072100% (1)

- Wimpey Laboratories DUBAI AccreditationDocument49 pagesWimpey Laboratories DUBAI AccreditationomerNo ratings yet

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- Is2720 Part09Document6 pagesIs2720 Part09anvesh_kumar_16No ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Paint Certificate 80A45-1Document1 pagePaint Certificate 80A45-1Shyam_Nair_9667No ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Asian Paints PuDocument2 pagesAsian Paints PuAkash BadwaikNo ratings yet

- SSPC SP 1Document2 pagesSSPC SP 1romdhan88No ratings yet

- QAP - Gate Valve - NPCILDocument6 pagesQAP - Gate Valve - NPCILkaustavNo ratings yet

- PDS - EP-10 Etch PrimerDocument2 pagesPDS - EP-10 Etch Primercarlogeretto2No ratings yet

- Astm D578@578M-05 (R2011) E1Document19 pagesAstm D578@578M-05 (R2011) E1Doulat RamNo ratings yet

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinNo ratings yet

- 5.2.3.1equipment For High Voltage Spark TestingDocument5 pages5.2.3.1equipment For High Voltage Spark TestingManriquez AndresNo ratings yet

- Uphill Versus Downhill Welding PDFDocument4 pagesUphill Versus Downhill Welding PDFPatrick DominguezNo ratings yet

- Testing of Non - Metallic Materials For Use With Drinking WATER (BS 6920: 2000)Document8 pagesTesting of Non - Metallic Materials For Use With Drinking WATER (BS 6920: 2000)whwy99No ratings yet

- SS621 TUV Testing Report (Full Permission)Document5 pagesSS621 TUV Testing Report (Full Permission)Christiano RodriguezNo ratings yet

- Apcs 17a 85710Document2 pagesApcs 17a 85710jojo_323No ratings yet

- Contractor IOT Infrastructure & Energy Services LTDDocument38 pagesContractor IOT Infrastructure & Energy Services LTDNaveen KurupNo ratings yet

- Interzinc 52 TDSDocument4 pagesInterzinc 52 TDSDele TedNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZvkvc soodNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZsojeckNo ratings yet

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDocument2 pagesDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckNo ratings yet

- WPS DP ReportsDocument8 pagesWPS DP ReportsMANIMARAN QCNo ratings yet

- Pressure Test REPORTDocument6 pagesPressure Test REPORTMANIMARAN QCNo ratings yet

- Raw Material - E-023-22Document2 pagesRaw Material - E-023-22MANIMARAN QCNo ratings yet

- FINISH COAT-Bergerthane PU CoatingDocument2 pagesFINISH COAT-Bergerthane PU CoatingMANIMARAN QCNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Dimension RFPDocument3 pagesDimension RFPMANIMARAN QCNo ratings yet

- DPT ReportDocument3 pagesDPT ReportMANIMARAN QCNo ratings yet

- N Murthy Report On Corporate GovernanceDocument8 pagesN Murthy Report On Corporate GovernanceShrishtiNarayaniNo ratings yet

- Annual Report 2017 18Document122 pagesAnnual Report 2017 18Ali AhmedNo ratings yet

- Bitera M3W2Document9 pagesBitera M3W2Chelsea NicoleNo ratings yet

- A5 - Fringe Benefit TaxationDocument3 pagesA5 - Fringe Benefit TaxationJomer FernandezNo ratings yet

- Government Finance: Taxation in The United States United States Federal BudgetDocument7 pagesGovernment Finance: Taxation in The United States United States Federal BudgetKatt RinaNo ratings yet

- New Final Updated IFRS 16Document98 pagesNew Final Updated IFRS 16murshidalbimaanyNo ratings yet

- Personal Profile For Jco & Jnco - NewDocument3 pagesPersonal Profile For Jco & Jnco - NewMed Cabojoc Jr.No ratings yet

- 3210Q011 04gb PDFDocument2 pages3210Q011 04gb PDFrpicho100% (1)

- M-40k Notice of Denial of Expedited FS or Inability To Issue FSDocument1 pageM-40k Notice of Denial of Expedited FS or Inability To Issue FShooNo ratings yet

- Jail Officer Up To The Rank of Jail Superintendent and Other Law Enforcement Agencies, and Agencies Under The Criminal Justice SystemDocument3 pagesJail Officer Up To The Rank of Jail Superintendent and Other Law Enforcement Agencies, and Agencies Under The Criminal Justice SystembogartsidoNo ratings yet

- Offer Letter SathwikDocument3 pagesOffer Letter SathwikRaviteja PavanNo ratings yet

- Limkhawpui: N. Hlimen Huan Neitu Pawl HriattirnaDocument2 pagesLimkhawpui: N. Hlimen Huan Neitu Pawl HriattirnaJC LalthanfalaNo ratings yet

- CHPL Management AgreementDocument39 pagesCHPL Management AgreementRaghvendra AgarwalNo ratings yet

- Htg-S510 User Manual: Hitech Global Stratix V Pci Express Ethernet Networking Development PlatformDocument43 pagesHtg-S510 User Manual: Hitech Global Stratix V Pci Express Ethernet Networking Development PlatformlitoduterNo ratings yet

- Evolution of The Indian Insolvency and Bankruptcy CodeDocument22 pagesEvolution of The Indian Insolvency and Bankruptcy CodeSid KaulNo ratings yet

- Provide Monthly Seo Service Onpage and Offpage Optimization by Saifullah937 - FiverrDocument1 pageProvide Monthly Seo Service Onpage and Offpage Optimization by Saifullah937 - FiverrAbdul Latif0% (1)

- Provisions of ESOP in Companies ActDocument6 pagesProvisions of ESOP in Companies ActshanikaNo ratings yet

- Rabusa 2005Document8 pagesRabusa 2005Desiree GuaschNo ratings yet

- NIBIN Fact SheetDocument2 pagesNIBIN Fact Sheet13WMAZNo ratings yet

- Full Text Set 3 - TaxDocument33 pagesFull Text Set 3 - TaxulticonNo ratings yet

- Ncnda & Imfpa (Icc1)Document6 pagesNcnda & Imfpa (Icc1)King RoodNo ratings yet

- 8 Steps For Ethical Decision Making - HalfmantrDocument3 pages8 Steps For Ethical Decision Making - HalfmantrJai Dev100% (2)

- As 3519-2005 Timber - Machine Proof GradingDocument8 pagesAs 3519-2005 Timber - Machine Proof GradingSAI Global - APACNo ratings yet

- NMH Doc Issue PlanDocument5 pagesNMH Doc Issue PlanJustin MusopoleNo ratings yet

- Important Facts of Indian HistoryDocument5 pagesImportant Facts of Indian HistoryKabeer PallikkalNo ratings yet