Professional Documents

Culture Documents

Fixed Temperature Thermostats: - 1Nt Series

Fixed Temperature Thermostats: - 1Nt Series

Uploaded by

chouaib kennicheCopyright:

Available Formats

You might also like

- Third Periodical Test in Math 5Document8 pagesThird Periodical Test in Math 5fritz78% (9)

- 3 DOF Helicopter - User ManualDocument23 pages3 DOF Helicopter - User ManualMurilloMaganNo ratings yet

- He Weiling - Flatness TransformedDocument360 pagesHe Weiling - Flatness TransformedArturo TorresNo ratings yet

- Edi 300 PDFDocument98 pagesEdi 300 PDFLuis Mesones RamirezNo ratings yet

- BEL8 S (3x1.5'') 450 3MDocument1 pageBEL8 S (3x1.5'') 450 3MSergio Espinosa EscobarNo ratings yet

- 4AEF8B53.catalog SQ-M BSQ-MDocument12 pages4AEF8B53.catalog SQ-M BSQ-Mtaher shaikNo ratings yet

- BEL8 S (3x2'') 450 5MDocument1 pageBEL8 S (3x2'') 450 5MSergio Espinosa EscobarNo ratings yet

- SP Loss WorksheetDocument9 pagesSP Loss WorksheetJojo FernandezNo ratings yet

- DAIKIN VRV Systems Comparison (May-15)Document1 pageDAIKIN VRV Systems Comparison (May-15)zafar.ucNo ratings yet

- Stadium Auto Stair InfoDocument1 pageStadium Auto Stair Infokatar kumarNo ratings yet

- MBBR FabricationDocument1 pageMBBR Fabricationvikraman_sNo ratings yet

- SP - LOSS - WORKSHEET DuctingDocument9 pagesSP - LOSS - WORKSHEET DuctingAzrinshah Abu BakarNo ratings yet

- Type 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Document3 pagesType 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Tien Nguyen TatNo ratings yet

- Cables and AccessoriesDocument1 pageCables and Accessoriesrajkumar222No ratings yet

- Shiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Document2 pagesShiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Kyaw Win TunNo ratings yet

- BEL8-S - (1x3'' 2x2'') - 450-3MDocument1 pageBEL8-S - (1x3'' 2x2'') - 450-3MSergio Espinosa EscobarNo ratings yet

- Bertyl-10 PDFDocument1 pageBertyl-10 PDFKripa SriramNo ratings yet

- Section ProjectDocument2 pagesSection Projectapi-592003671No ratings yet

- Deepborewell - Ishwar House - Kichto PanchayatDocument13 pagesDeepborewell - Ishwar House - Kichto PanchayatShubham SinghNo ratings yet

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- WW Linear Veneered Planks Master SheetDocument2 pagesWW Linear Veneered Planks Master SheetChiara NaderNo ratings yet

- Codeline Drawing 80H45Document3 pagesCodeline Drawing 80H45kunjansutharNo ratings yet

- HF1113Z0005 ReceiverDocument1 pageHF1113Z0005 ReceivergianninacostaNo ratings yet

- 2 Upper Level-Wall FinishesDocument1 page2 Upper Level-Wall FinishesHoracio Rodriguez SanchezNo ratings yet

- 97 GP Trim Tabs CADDocument2 pages97 GP Trim Tabs CADMike SNo ratings yet

- First FloorDocument2 pagesFirst FloorOsama al kojaNo ratings yet

- BEL8-S - (1x2'' 2x1.5'') - 450-3MDocument1 pageBEL8-S - (1x2'' 2x1.5'') - 450-3MSergio Espinosa EscobarNo ratings yet

- Fci - Hermosa: Previous Accomplishment Report 75.92%Document1 pageFci - Hermosa: Previous Accomplishment Report 75.92%Jhn Cbllr BqngNo ratings yet

- Pin-Assignment: USB 2.0 Type A Female/Female AdaptorDocument1 pagePin-Assignment: USB 2.0 Type A Female/Female AdaptorJBertrandNo ratings yet

- 09 Street and Drainage DetailsDocument1 page09 Street and Drainage Detailsapi-355743719No ratings yet

- 09 Street and Drainage DetailsDocument1 page09 Street and Drainage Detailsapi-355743719No ratings yet

- MS 13 66Document2 pagesMS 13 66nurockNo ratings yet

- InfinityFA7i FlyerDocument4 pagesInfinityFA7i FlyerjassimNo ratings yet

- Top View: Resultant Consulting EnginersDocument1 pageTop View: Resultant Consulting EnginersEnrique RafaelNo ratings yet

- BbomercitoDocument5 pagesBbomercitoOmar Espinoza sanchezNo ratings yet

- Manifold ValveDocument2 pagesManifold ValveShakir AnsariNo ratings yet

- Series C World Class Circuit Breakers K-FrameDocument4 pagesSeries C World Class Circuit Breakers K-Framebaskaranjay5502No ratings yet

- STRUCTURALDocument4 pagesSTRUCTURALJerico NamucoNo ratings yet

- 23 07 2018 - DAY-Inspection Log SheetDocument1 page23 07 2018 - DAY-Inspection Log SheetArunNo ratings yet

- Jhust GeneratorDocument1 pageJhust GeneratorKovács TamásNo ratings yet

- Bonkuri Ramulu 01 PlanDocument1 pageBonkuri Ramulu 01 Planshiva007KNo ratings yet

- Series C World Class Circuit Breakers F-Frame 10-225 AmperesDocument8 pagesSeries C World Class Circuit Breakers F-Frame 10-225 Amperesbaskaranjay5502No ratings yet

- A-2 - Existing and Proposed ElevationsDocument1 pageA-2 - Existing and Proposed ElevationsЈована ДимевскаNo ratings yet

- Area of The Site Area of The Pro.G.F.Building Area of The Open SpaceDocument1 pageArea of The Site Area of The Pro.G.F.Building Area of The Open SpaceAsr FlowerNo ratings yet

- VENGALA NEERAJA DEVI SULBD-ModelDocument1 pageVENGALA NEERAJA DEVI SULBD-Modelarun kumarNo ratings yet

- A Bru140032 140513 TSC/RP Tsc/Va: 4812315771-Reva-Ver1 PDFDocument16 pagesA Bru140032 140513 TSC/RP Tsc/Va: 4812315771-Reva-Ver1 PDFjunior Oliveira100% (1)

- APE Core Group 1 Sell SheetDocument1 pageAPE Core Group 1 Sell Sheetbig2yaNo ratings yet

- Model Jockey Pump Controller:JP3: Wiring SchematicDocument2 pagesModel Jockey Pump Controller:JP3: Wiring SchematicUmair BaBer100% (1)

- Construction Issue: General NotesDocument1 pageConstruction Issue: General NotesShokry AlkissyNo ratings yet

- BR124-04A Construction Section & SpecificationsDocument1 pageBR124-04A Construction Section & SpecificationsLaurentiu NaeNo ratings yet

- R70pf0027ed1800 AutomotiveDocument6 pagesR70pf0027ed1800 AutomotiveSelva Prem KumarNo ratings yet

- MoBo SchematicDocument3 pagesMoBo SchematicAbd Al-KhataibNo ratings yet

- SBFC-JT: Low-Amperage Plug-In Type FuseDocument1 pageSBFC-JT: Low-Amperage Plug-In Type Fuseoom_tgwNo ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- Audi 80 2.0 16V 92 96Document1 pageAudi 80 2.0 16V 92 96Ronaldo SilvaNo ratings yet

- 13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Document1 page13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Anonymous BZQOJwWIh6No ratings yet

- 2ND KeypadDocument1 page2ND KeypadFerdion AbsariNo ratings yet

- TF20G 2000GPM DieselDocument1 pageTF20G 2000GPM DieselKarim Tarek100% (1)

- Lsmim: Lahore-Sialkot Motorway (B.O.T.)Document1 pageLsmim: Lahore-Sialkot Motorway (B.O.T.)husnain aliNo ratings yet

- Product Manual - R 3EL 125 - PO 8584Document71 pagesProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNo ratings yet

- Swiftwater - Lane-Drainage Plan1Document1 pageSwiftwater - Lane-Drainage Plan1chrisNo ratings yet

- TravelMate 8473 Wistron BAD40 - 50-HRDocument109 pagesTravelMate 8473 Wistron BAD40 - 50-HRMicropc Technology SolutionNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- MC083V RC Spec 2021.06.08Document10 pagesMC083V RC Spec 2021.06.08chouaib kennicheNo ratings yet

- lmh5485 SepDocument30 pageslmh5485 Sepchouaib kennicheNo ratings yet

- 26 Flyer Visor-Guided-Robotics en 06 2023 SmallDocument26 pages26 Flyer Visor-Guided-Robotics en 06 2023 Smallchouaib kennicheNo ratings yet

- Early Journal Content On JSTOR, Free To Anyone in The WorldDocument29 pagesEarly Journal Content On JSTOR, Free To Anyone in The Worldchouaib kennicheNo ratings yet

- DocumentationDocument1 pageDocumentationchouaib kennicheNo ratings yet

- Machine Learning Techniques To PerceiveDocument4 pagesMachine Learning Techniques To Perceivechouaib kennicheNo ratings yet

- User Manual: All Rights Reserved. Version 2019-11-13Document46 pagesUser Manual: All Rights Reserved. Version 2019-11-13chouaib kennicheNo ratings yet

- Saraswati English School (S.S.C Board) : SMT. S. D. S. S'sDocument2 pagesSaraswati English School (S.S.C Board) : SMT. S. D. S. S'sSahadev KadlagNo ratings yet

- Kulkarni 2010Document7 pagesKulkarni 2010Jesus JeronimoNo ratings yet

- 3rd Assessment Mathematics 5Document5 pages3rd Assessment Mathematics 5Raselle Alfonso Palisoc100% (1)

- Moisture Particle SizeDocument6 pagesMoisture Particle SizejayaNo ratings yet

- Scada Course Outline PDFDocument2 pagesScada Course Outline PDFpfalencar100% (1)

- Education: A315/5, IIT Kanpur - India (+91) 9660998600 - Yashbth@iitk - Ac.in - /in/yashbth - /yashbthDocument2 pagesEducation: A315/5, IIT Kanpur - India (+91) 9660998600 - Yashbth@iitk - Ac.in - /in/yashbth - /yashbthVikas SrivastavNo ratings yet

- DPS 2100 Engine Safety System User Manual Doc. No. 921.450.021Document84 pagesDPS 2100 Engine Safety System User Manual Doc. No. 921.450.021_Avek_89% (9)

- Earth Mat Sizing Calculations - 22 MW - Azure Rev 03Document31 pagesEarth Mat Sizing Calculations - 22 MW - Azure Rev 03Mohdsalauddin HabeebNo ratings yet

- All Wheel Steering Project 22Document3 pagesAll Wheel Steering Project 22Snev EvansNo ratings yet

- Boeing B737Document96 pagesBoeing B737Amjad Baig100% (6)

- Seismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterDocument16 pagesSeismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterAlNo ratings yet

- Report 8 HydroDocument13 pagesReport 8 HydroAbdallah AlhasanNo ratings yet

- Grout Cubes Versus Cylinders TestsDocument20 pagesGrout Cubes Versus Cylinders TestsMustufa F KanjetaNo ratings yet

- SECOM 737: User ManualDocument133 pagesSECOM 737: User Manualdinojr2010No ratings yet

- patent-US2629213-Crankshaft Grinding DeviceDocument9 pagespatent-US2629213-Crankshaft Grinding DeviceMahnooshNo ratings yet

- A Fast Settling Slew Rate Enhancement Technique For Operational AmplifiersDocument4 pagesA Fast Settling Slew Rate Enhancement Technique For Operational AmplifiersShubham SharmaNo ratings yet

- Oracle DataGuard Documentation PDFDocument45 pagesOracle DataGuard Documentation PDFLuis Alberto MadridNo ratings yet

- Set 01Document161 pagesSet 01ashishjakateNo ratings yet

- MGMT2023 Lecture 4 & 5 TVM Slides - Parts I, II IIIDocument91 pagesMGMT2023 Lecture 4 & 5 TVM Slides - Parts I, II IIIIsmadth2918388No ratings yet

- Bulletin Mechanical Engineering Modeling 2016 BMEDocument39 pagesBulletin Mechanical Engineering Modeling 2016 BMEBálint Vincze100% (1)

- Geom Trig Packet of WorksheetsDocument10 pagesGeom Trig Packet of Worksheetssherdan0% (1)

- Elektor Electronics July-August 2007Document152 pagesElektor Electronics July-August 2007carl12No ratings yet

- Class 6 Maths Set I Sample PapersDocument4 pagesClass 6 Maths Set I Sample PapersChetan RamtekeNo ratings yet

- Assessment 2 Stat20053 Descriptive Statistics - CompressDocument2 pagesAssessment 2 Stat20053 Descriptive Statistics - CompressDon RatbuNo ratings yet

- Block Diagram of Satellite Communication System 1nm82cvDocument1 pageBlock Diagram of Satellite Communication System 1nm82cvAbdou Gaye80% (5)

- Accelerate EducationDocument11 pagesAccelerate EducationThomas DyeNo ratings yet

Fixed Temperature Thermostats: - 1Nt Series

Fixed Temperature Thermostats: - 1Nt Series

Uploaded by

chouaib kennicheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixed Temperature Thermostats: - 1Nt Series

Fixed Temperature Thermostats: - 1Nt Series

Uploaded by

chouaib kennicheCopyright:

Available Formats

SAIL

SMALL APPLIANCES INDUSTRIAL & LIGHTING

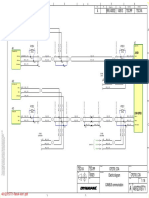

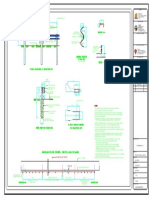

| 1NT SERIES Fixed Available Constructions

Available Constructions

Temperature Thermostats High Profile Construction

Options shown: 90˚– 1/4” Q.C. terminals

Low Profile Construction

4 Post

Manual Reset Construction

Options shown: Flat 1/4” Q.C. terminals

with Surface mount flange Options shown: 45˚ – 1/4” Q.C. terminals with Airstream mount cup

with 4 post and flat Al cup

ø3.72

(.147)

Ref. 2.6

23.8 (.102)

30.0 Max.

(.937) Ref. (1.181)

Max.

16.6 Max.

(.654) 30.2

(1.189) 23.8

(.937) Ref.

Key Features • Product innovations include: ø19.4 ø16.0

Max.

(.630) Max.

• ISO9001: 2000 certification - Solid metal-to-metal terminal (.764) Max.

6.5 12.52

• Factory inspected for continuity and construction (.256)

Max.

(.493)

ø3.7 (.146) Ref.

WORLD CLASS contact resistance - Current free spring

Max.

ø14.7

34.2 (1.346) Max. 5.6

PERFORMANCE • Global sales and technical support - One piece transfer mechanism ø14.7 6.65

(.579) Max.

(.220) Max.

(.579) ø14.7

(.262)

• Ambient temperature rating from • Switch actions: Max. Min.

(.579)

Max.

-40ºC to 240ºC (-40ºF to 464ºF) - Automatic reset: Available with 20.9 ø14.6 12.5

(.492) Max.

The 1NT has been designed to • 1NT base provides: both normally open and normally (.823)

Max.

(.575) Max.

ø16.0

- Low cost closed switch logic ø16.0

(.630)

(.630)

Max. 4.4

be applied for use in many - High temperature capability - Manual reset: Mechanical reset Max.

12.9

20.8

(.819)

(.173)

30.4 12.5 Max.

(1.197) (.508) Max.

HVAC and appliance products - Clean processing device 4.3

(.170) Max.

(.492) Max.

max.

- High impact strength - Trip free manual reset: UL M2 Max.

as either a regulating or over- - Low static generation class rating that resists consumer

Part Types by Construction

temperature safety switch. • Bi-metal disc is factory pre-set to tampering

achieve: - One shot: meets agency 1NT01 Auto Reset / Silver Contacts 1NT02 Auto Reset / Silver Contacts 1NT08 Manual Reset / Silver Contacts

1NT11 Auto Reset / Gold Contacts 1NT02TL Low Profile / One Shot 1NT12 Manual Reset / Gold Contacts

- Operation at requested requirements for single operation 1NT09 One Shot: -35˚C (-31˚F) Reset 1NT20 Auto Reset / Gold Contacts 1NT15 Trip Free MR / Silver Contacts

The 1NT uses Klixon® temperatures device 1NT10 One Shot: 0˚C (32˚F) Reset 1NT19 Trip Free MR / Gold Contacts

- Tamperproof settings

technology and is available in All dimensions mm (in.)

several mounting options.

Numbering

NumberingSystem

System

Sensata Technologies has been

a leading global supplier of Part Number

1NTXX E L XXXX

pressure sensors and switches Applications

for over 50 years. • Microwave ovens • Vacuum cleaners

• Sandwich makers • Gas / electric furnaces Part Type Special Processing Switch Type ID Number

• Rice cookers • Espresso machines Consult A Wire Lead Assy L Limit* Unique,

Customer

• Hair dryers • Tea makers Table E Exposed Disc F Fan**

Above Specific

• Fan heaters • Automotive / truck

Temperature Code

L 150 F 30

Switch Type Operating Temp. Temp. Scale Differential

L Limit* Nominal ## Nom. Open to

Open C Celcius Nom. Close

F Fan** Temperature MR Manual Reset

* Limit switch opens on temperature rise

** fan switch closes on temperature rise

43 Klixon is a registered trademark of Sensata Technologies © Copyright Sensata Technologies 2013 44

SAIL

SMALL APPLIANCES INDUSTRIAL & LIGHTING

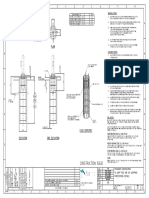

1NT Series Electrical Ratings

Accessories

Accessoriesand

andOptions

Options

The 1NT series of thermostats has been recognized by safety agencies, including UL, of the product to confirm that the thermostat

Cup Styles

Canadian–UL and KEMA. Agency ratings are presented below as a general guide. However, selected will operate as intended over the

the temperature settings, mechanical, electrical, thermal and environmental conditions of the useful design life of the user’s applications. Airstream Mount Integral Cup Flat Cup 3NT Flange Cup Airstream Mount Integral Cup

57611 73926 57366 27185

specific application may differ significantly from agency test conditions. Therefore, the user Materials: Aluminum, Stainless Steel Material: Aluminum or Copper

Material: Stainless Steel

Material: Aluminum Available mounting rotation relative

must not rely solely on the agency ratings presented here, but must perform its own testing Available mounting rotation or Copper Closed Bottom Only to terminals

relative to terminals – O ˚or 90˚ 0˚, 45˚ or 90˚ with Closed Bottom

Closed Bottom Only 0˚ or 90˚ with Open Bottom

UL

ULand

andC–UL

C—UL KEMA

KEMA 23.8

ø3.7 23.8 See Note:. (.937) Ref.

(.146) Ref. (.937) Ref.

Type Max. Temp. Type Max. Temp. Cycles (X 1000) Electrical

Cycles Electrical Rating (unless otherwise

˚C ˚F (X 1000) ˚C specified) (Rating)* 19.7 20.8

20.8 16.26 (.776) (.819)

(.819) (.640) Max. Max. Max.

NT01, 02 204 400 100 120 Vac 0 - 9 amps 1NT01, 02 240 Vac 0 - 5 amps (1.66)A Max. Hole

100 6 - 13.5 amps (1.66)A** 5.5 Optional

10 - 17 amps* 204 (.217) 30.2

3.94 Max.

240 Vac 0 - 5 amps 30 240 Vac 16(5)A

30.2 0.30

(.155) Max. (1.189) Max.

(1.189) Max. (.012) Ref.

6 - 17 amps* 30 400 Vac 4(1)A 0.25 (.010) Ref.

277 Vac 7.2 amps 0.34 (.013) Ref.

1NT02TL 204 1 cycle 240 Vac 16(5)A 4.4 (.173) Max.

1NT08, 15, 08E** 204 400 1+5 240 Vac 25 amps

1NT08 204 10 240 Vac 16(5)A 0.5 (.020) 16.0

240 Vac 25 amps 10 400 Vac 4(1)A 16.0 16.0 Ref. 16.5 (.630) Max.

1NT09, 10 204 400 1-Shot (.630) (.650) Note:

277 Vac 7.2 amps (.630) 4.5 Max. Available Diameter Mounting Holes

1NT09 204 1 cycle 240 Vac 16(5)A Max. (.177) Max. Max. with open bottom: 3.7 (.146)

125 VA 1 amp with closed bottom: 3.7(.146) / 4.2(.165) or none

1NT11, 20 204 400 100 1NT11 204 100 30 Vdc1A

30 Vdc

Airstream Mount Integral Cup Wide-Eared Integral Cup “Tear-Drop” Integral Cup Large Oval Integral Cup

1NT12, 19 204 400 1+5 125 VA 1NT15 204 10 240 Vac 16(5)A (slotted mounting holes) 57608 57609 59122

57367 Material: Stainless Steel Material: Stainless Steel Material: Aluminum

1NT01E, 02E** 204 400 100 120 Vac 10 amps 1NT20 204 100 30 Vdc1A Material: Aluminum Available mounting rotation Available mounting rotation

Available mounting rotation

Available mounting rotation relative to terminals - 0˚ or 90˚ relative to terminals -

relative to terminals - 0˚ or 90˚ Closed Bottom Only 0˚ or 90˚ with Open Bottom

* UL rated at these current levels at specific open/close temperatures. When applying to * Parenthesis indicate inductive load ratings. relative to terminals - 0˚ or 90˚

Closed Bottom Only Closed Bottom Only 0˚, 45˚ or 90˚ with Closed Bottom

these electrical levels, nominal open/close temperatures must be considered to determine ** KEMA rated at these current levels at specific open/close temperatures. When applying to

if the thermostat selected will operate as intended in the user’s application. Please consult 43.28 15.87

these electrical levels, nominal open/close temperatures must be considered to determine 39.67

24.5 (1.704) Max. (.625)

a Sensata Engineer for additional clarification. if the thermostat selected will operate as intended in the user’s application. Please consult 4.5 Ref. 1.57 (1.562) Ref.

(.965) Ref.

** “E” means exposed disc. a Sensata Engineer for additional clarification. (.177) (.062) Ref.

Ref.

20.15 22.50

22.50 (.886)

(.793) (.886) 38.3

Max.

Standard

Standard Temperatures,

Temperatures,Tolerances

Tolerancesand

andDifferential

Differential

3.4

Max. Max. (1.508)

Max.

Manual Reset and One-Shot (.134) ø.475 .475 21.72 11.3 HOLE

31.75 (.855) (.445) OPT.

Automatic Reset Thermostats Thermostats Ref. 32.15 (1.250) Ref.

(.187) (.187)

Ref. Max. Max.

(1.266) Ref.

Standard Tolerances Max. .438 51.1

Nominal Top Min. Bottom Nominal Top Open (.173) (2.010) Max. . 0.33

Temperature Temperature Differential Open Close Temperature Tolerances 0.25 Ref. (.013) Max.

(.010) Ref. 16.0

16.0 (.630)

˚C ˚F ˚C ˚F ˚C ˚F ˚C ˚F ˚C ˚F ˚C ˚F ˚C ˚F 0.5 16.5 (.630) Note: Max. 4.6

0.25 (.181) 16.0

(.020) (.650) 5.5 (.010) Ref. Max. 90 o mounting option is also available .33

<60 <140 ±4.0 ±7.5 Ref. (.217) Max. 4.6 (.181) Max. (.013) (.630)

11 to 16 20 to 29 ±3.0 ±5.5 ±4.0 ±7.5 Max.

Max.

with 57612 teardrop shaped stiffening

flange upon customer request. Ref. Max. 5.3 (.209) Max.

18 to 27 65 to 80 -33 -26 17 to 21 30 to 38 ±3.0 ±5.5 ±4.5 ±8.5 61 TO 160 141 to 320 ±5.0 ±9.0

22 to 33 39 to 59 ±3.0 ±5.5 ±5.5 ±10.0

161 TO 204 321 to 399 ±6.0 ±11.0 Flanges Bolt On Assembly

73972

28 to 80 81 to 176 -33 -26 11 to 13 20 to 23 ±3.0 ±5.5 ±4.0 ±7.5 Thread Specs:

Loose Ear Wide Eared – Fixed Rotation Metric: M4 x 0.7 - 6G

and and 14 to 16 24 to 29 ±3.0 ±5.5 ±4.5 ±8.5 Fixed Rotation

M5 x 0.8 - 6G

Surface Mount Flange Surface Mount Flange Mounting Flange

*81 to 93 177 to 199 50 122 17 to 33 30 to 59 ±3.0 ±5.5 ±5.0 ±9.0 CUP 57336 27183 57337 Stud Length:

Material: Nickel Plated Steel Metric: 6.15, 7.00, 8.00, 9.00 (with M4)

Available mounting rotation relative Material: Aluminum 8.00 (with M5)

Available mounting rotation

11 to 16 20 to 29 ±3.5 ±6.5 ±4.5 ±8.5 to terminals - 90˚ with Aluminum – relative to terminals - 45˚ CCW English: 6 x 32 - 1⁄2“ Long

*94 to 121 *200 to 249 50 122 30 to 38 ±3.5 ±6.5 ±5.5 ±10.0 0˚, 90˚ / or 57˚, 127˚, 135˚ CCW 8 x 32 - 1⁄4” Long

17 to 21

BIMETALLIC with Nickel Plated Steel Material:

22 to 33 39 to 59 ±3.5 ±6.5 ±6.5 ±12.0 ø 14.9 Hole Stud: Zinc Plated Steel

34 to 55 60 to 99 ±5.5 ±10.0 ±10.0 ±20.0 DISC (.587) Ref. 22.5 2.95 Cap: Aluminum

KAPTON 6.5 19.4

(.886) Max. (.116) Ref.

(.256) Max. 6.5

14 to 21 24 to 38 ±4.0 ±7.5 ±5.5 ±10.0 INSULATOR (.764)

(.256) Max. Max.

122 to 149 50 ±8.0 13.74

250 to 300 122 21 to 33 39 to 59 ±4.0 ±7.5 ±14.5 (.541) Max.

MOVABLE 19.4 4.75.

34 to 55 60 to 99 ±5.5 ±10.0 ±11.0 ±20.0 (.764)

ARM 31.75 (.187)

Max. Max.

(1.250) Ref.

22 to 33 39 to 59 ±5.0 ±9.0 ±9.0 ±16.5 23.8 23.8 (.937) 15.90

Ref. 3.72 (.626) Max.

150 to 177 301 to 399 50 122 34 to 44 60 to 79 ±5.5 ±10.0 ±11.0 ±20.0 SPRING (.937)

ø3.72 18.4 (.146) Ref. 43.28 (1.704) Max.

Ref.

45 to 55 80 to 99 ±5.5 ±10.0 ±11.0 ±20.0 18.4 (.147) (.724)

18.4 (.724) Max. 3.81(.150)

Max.

(.724) Max. Ref. Max.

22 to 33* 39 to 59 ±5.0 ±9.0 ±9.0 ±16.5 3.81 0.38

178-204** 351 to 399 50 122 34 to 44 60 to 79 ±5.5 ±10.0 ±10.0 ±20.0 0.38 (.150) Lgth. Varies

(.015) Ref.

45 to 55 80 to 99 ±5.5 ±10.0 ±10.0 ±20.0 METAL TO METAL (.015) Ref. Max.

TERMINAL JOINT 0.38 3.51

* Not valid for Fan Devices (.015) Ref. (.139) Max.

** Top Temp for Fan Devices cannot exceed 380˚F (193˚C) THERMOPLASTIC BASE All dimensions mm (in.)

45 Klixon is a registered trademark of Sensata Technologies © Copyright Sensata Technologies 2013 46

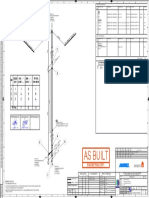

SAIL

SMALL APPLIANCES INDUSTRIAL & LIGHTING

Accessories and

Accessories and Options

Options (cont.)

(cont.) Sample Order Placement

To enable Sensata Technologies to serve you in a quicker, more efficient manner,

Quick Connects

Terminals 27132 27162* 27163 please be prepared to provide the following information when requesting samples:

Thickness (A): 0.8(.031) 0.5(.020) 0.8(.031) 1. Detailed application description

Solder Terminal Crimp Terminal Width (B): 6.3(.250) 4.8(.187) 4.8(.187)

27182* 27184* Materials: Brass - Solid, Ni, Ag, or Tin Plated 2. Estimated yearly usage.

Material: Tin Plated Brass Material: Tin Plated Brass Steel - Nickel Plated

3. Opening and closing temperatures

4. Max. temperature tolerances allowable

5.7 15.62

3.5 5. Switch type

(.224) (.138) (.615)

Max. Max.

2.8

Ref. 6. Mounting style desired

(.110) Ref. 2.6

(.102) 7. Terminal orientation and material

Ref. “B” 8. Electrical load

Positions

Other conditions which are likely to affect the 1NT operation should also be

ø 3.22 (.127) Ref.

90 o described. These include:

45 o

1. Maximum temperature exposure

2. Location with respect to heat source

0.50 “A”

(.020) 3. Temperature transfer medium (air, metal surface, etc)

Ref. Flat

0.50 4. Possible contamination sources (lint, chemical fumes, liquid, condensation,

(.020)

Ref. humidity, etc.)

Screw Terminal Weld Terminal Weld Terminal When ordering thermocouple samples, specify whether J, K, or T type and the lead

57200 57201 57312*

Material: Nickel Plated Steel Material: Nickel Plated Steel Material: Nickel Plated Steel length desired. Standard wire size is 30 Ga..

M3 x 0.5 Class 6H Thread

.396

Narrow (.156) Ref. Wide Thermostat Handling Tips

5.6

Tab Tab

3.55 (.220) Ref. 1. Exposed disc devices should be kept free of dust and particulates, liquid and

(.140) Ref. 4.45

(.175) Max. condensation. The face of the disc should never be snapped.

2. Mounting screws and drivers for use with smaller integral cups and

0.8 flanges should be sized to provide adequate clearance to the thermostat body.

(.032) .254 6.35

Ref. (.100) (.250) 3. The installation force applied to the cup face should not exceed 66.7N

Ref. Ref.

6.42

(.253) Max.

(15 lbs.)

4. The maximum reset force on the manual reset and trip free button is

22.2N (5 lbs.).

.071

(.028) 0.50 5.6 0.50

Ref. (.020) Ref. (.220) Max. (.020) Ref.

*10A Max. on all terminals 0.51 (.020) thick

All dimensions mm (in.)

Series Agency

1NT Series Agency Listings

Listings Important Notice

Users are solely responsible for design application and function of the

Agency end use product. Users must evaluate the suitability of these devices to

Region their application with respect to temperature settings, mechanical cycle

Type life, electrical loading and environmental conditions. These devices are

UL /C-UL KEMA METI

N. America Europe Japan not environmentally sealed and have exposed electrical components.

They are not intended for use in applications where exposure to con-

1NT01, 02 • • • densed or dripping liquids, immersion in liquid, or exposure to other

1NT08 • • • environmental contaminants may occur. In such cases, use of environ-

1NT09, 10 • • • mentally sealed devices such as the 3NT is recommended. Excessive

1NT11, 12, 19, 20 • • •

mechanical cycling, high electrical loading or exposure to liquids or

1NT15 • • •

1NT01E, 02E • • • environmental contaminants as noted above can compromise electrical

insulating properties of the device. Such conditions may result in insula-

Reference Numbers File: E9977 KEMA cert #

tion breakdown and accompanying localized electrical heating. The

Category: XAPX2 EN2014531.16

device may remain permanently closed or open as a result of these

XAPX8

conditions, as well as at normal end-of-life.

47 Klixon is a registered trademark of Sensata Technologies © Copyright Sensata Technologies 2013 48

You might also like

- Third Periodical Test in Math 5Document8 pagesThird Periodical Test in Math 5fritz78% (9)

- 3 DOF Helicopter - User ManualDocument23 pages3 DOF Helicopter - User ManualMurilloMaganNo ratings yet

- He Weiling - Flatness TransformedDocument360 pagesHe Weiling - Flatness TransformedArturo TorresNo ratings yet

- Edi 300 PDFDocument98 pagesEdi 300 PDFLuis Mesones RamirezNo ratings yet

- BEL8 S (3x1.5'') 450 3MDocument1 pageBEL8 S (3x1.5'') 450 3MSergio Espinosa EscobarNo ratings yet

- 4AEF8B53.catalog SQ-M BSQ-MDocument12 pages4AEF8B53.catalog SQ-M BSQ-Mtaher shaikNo ratings yet

- BEL8 S (3x2'') 450 5MDocument1 pageBEL8 S (3x2'') 450 5MSergio Espinosa EscobarNo ratings yet

- SP Loss WorksheetDocument9 pagesSP Loss WorksheetJojo FernandezNo ratings yet

- DAIKIN VRV Systems Comparison (May-15)Document1 pageDAIKIN VRV Systems Comparison (May-15)zafar.ucNo ratings yet

- Stadium Auto Stair InfoDocument1 pageStadium Auto Stair Infokatar kumarNo ratings yet

- MBBR FabricationDocument1 pageMBBR Fabricationvikraman_sNo ratings yet

- SP - LOSS - WORKSHEET DuctingDocument9 pagesSP - LOSS - WORKSHEET DuctingAzrinshah Abu BakarNo ratings yet

- Type 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Document3 pagesType 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Tien Nguyen TatNo ratings yet

- Cables and AccessoriesDocument1 pageCables and Accessoriesrajkumar222No ratings yet

- Shiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Document2 pagesShiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Kyaw Win TunNo ratings yet

- BEL8-S - (1x3'' 2x2'') - 450-3MDocument1 pageBEL8-S - (1x3'' 2x2'') - 450-3MSergio Espinosa EscobarNo ratings yet

- Bertyl-10 PDFDocument1 pageBertyl-10 PDFKripa SriramNo ratings yet

- Section ProjectDocument2 pagesSection Projectapi-592003671No ratings yet

- Deepborewell - Ishwar House - Kichto PanchayatDocument13 pagesDeepborewell - Ishwar House - Kichto PanchayatShubham SinghNo ratings yet

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- WW Linear Veneered Planks Master SheetDocument2 pagesWW Linear Veneered Planks Master SheetChiara NaderNo ratings yet

- Codeline Drawing 80H45Document3 pagesCodeline Drawing 80H45kunjansutharNo ratings yet

- HF1113Z0005 ReceiverDocument1 pageHF1113Z0005 ReceivergianninacostaNo ratings yet

- 2 Upper Level-Wall FinishesDocument1 page2 Upper Level-Wall FinishesHoracio Rodriguez SanchezNo ratings yet

- 97 GP Trim Tabs CADDocument2 pages97 GP Trim Tabs CADMike SNo ratings yet

- First FloorDocument2 pagesFirst FloorOsama al kojaNo ratings yet

- BEL8-S - (1x2'' 2x1.5'') - 450-3MDocument1 pageBEL8-S - (1x2'' 2x1.5'') - 450-3MSergio Espinosa EscobarNo ratings yet

- Fci - Hermosa: Previous Accomplishment Report 75.92%Document1 pageFci - Hermosa: Previous Accomplishment Report 75.92%Jhn Cbllr BqngNo ratings yet

- Pin-Assignment: USB 2.0 Type A Female/Female AdaptorDocument1 pagePin-Assignment: USB 2.0 Type A Female/Female AdaptorJBertrandNo ratings yet

- 09 Street and Drainage DetailsDocument1 page09 Street and Drainage Detailsapi-355743719No ratings yet

- 09 Street and Drainage DetailsDocument1 page09 Street and Drainage Detailsapi-355743719No ratings yet

- MS 13 66Document2 pagesMS 13 66nurockNo ratings yet

- InfinityFA7i FlyerDocument4 pagesInfinityFA7i FlyerjassimNo ratings yet

- Top View: Resultant Consulting EnginersDocument1 pageTop View: Resultant Consulting EnginersEnrique RafaelNo ratings yet

- BbomercitoDocument5 pagesBbomercitoOmar Espinoza sanchezNo ratings yet

- Manifold ValveDocument2 pagesManifold ValveShakir AnsariNo ratings yet

- Series C World Class Circuit Breakers K-FrameDocument4 pagesSeries C World Class Circuit Breakers K-Framebaskaranjay5502No ratings yet

- STRUCTURALDocument4 pagesSTRUCTURALJerico NamucoNo ratings yet

- 23 07 2018 - DAY-Inspection Log SheetDocument1 page23 07 2018 - DAY-Inspection Log SheetArunNo ratings yet

- Jhust GeneratorDocument1 pageJhust GeneratorKovács TamásNo ratings yet

- Bonkuri Ramulu 01 PlanDocument1 pageBonkuri Ramulu 01 Planshiva007KNo ratings yet

- Series C World Class Circuit Breakers F-Frame 10-225 AmperesDocument8 pagesSeries C World Class Circuit Breakers F-Frame 10-225 Amperesbaskaranjay5502No ratings yet

- A-2 - Existing and Proposed ElevationsDocument1 pageA-2 - Existing and Proposed ElevationsЈована ДимевскаNo ratings yet

- Area of The Site Area of The Pro.G.F.Building Area of The Open SpaceDocument1 pageArea of The Site Area of The Pro.G.F.Building Area of The Open SpaceAsr FlowerNo ratings yet

- VENGALA NEERAJA DEVI SULBD-ModelDocument1 pageVENGALA NEERAJA DEVI SULBD-Modelarun kumarNo ratings yet

- A Bru140032 140513 TSC/RP Tsc/Va: 4812315771-Reva-Ver1 PDFDocument16 pagesA Bru140032 140513 TSC/RP Tsc/Va: 4812315771-Reva-Ver1 PDFjunior Oliveira100% (1)

- APE Core Group 1 Sell SheetDocument1 pageAPE Core Group 1 Sell Sheetbig2yaNo ratings yet

- Model Jockey Pump Controller:JP3: Wiring SchematicDocument2 pagesModel Jockey Pump Controller:JP3: Wiring SchematicUmair BaBer100% (1)

- Construction Issue: General NotesDocument1 pageConstruction Issue: General NotesShokry AlkissyNo ratings yet

- BR124-04A Construction Section & SpecificationsDocument1 pageBR124-04A Construction Section & SpecificationsLaurentiu NaeNo ratings yet

- R70pf0027ed1800 AutomotiveDocument6 pagesR70pf0027ed1800 AutomotiveSelva Prem KumarNo ratings yet

- MoBo SchematicDocument3 pagesMoBo SchematicAbd Al-KhataibNo ratings yet

- SBFC-JT: Low-Amperage Plug-In Type FuseDocument1 pageSBFC-JT: Low-Amperage Plug-In Type Fuseoom_tgwNo ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- Audi 80 2.0 16V 92 96Document1 pageAudi 80 2.0 16V 92 96Ronaldo SilvaNo ratings yet

- 13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Document1 page13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Anonymous BZQOJwWIh6No ratings yet

- 2ND KeypadDocument1 page2ND KeypadFerdion AbsariNo ratings yet

- TF20G 2000GPM DieselDocument1 pageTF20G 2000GPM DieselKarim Tarek100% (1)

- Lsmim: Lahore-Sialkot Motorway (B.O.T.)Document1 pageLsmim: Lahore-Sialkot Motorway (B.O.T.)husnain aliNo ratings yet

- Product Manual - R 3EL 125 - PO 8584Document71 pagesProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNo ratings yet

- Swiftwater - Lane-Drainage Plan1Document1 pageSwiftwater - Lane-Drainage Plan1chrisNo ratings yet

- TravelMate 8473 Wistron BAD40 - 50-HRDocument109 pagesTravelMate 8473 Wistron BAD40 - 50-HRMicropc Technology SolutionNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- MC083V RC Spec 2021.06.08Document10 pagesMC083V RC Spec 2021.06.08chouaib kennicheNo ratings yet

- lmh5485 SepDocument30 pageslmh5485 Sepchouaib kennicheNo ratings yet

- 26 Flyer Visor-Guided-Robotics en 06 2023 SmallDocument26 pages26 Flyer Visor-Guided-Robotics en 06 2023 Smallchouaib kennicheNo ratings yet

- Early Journal Content On JSTOR, Free To Anyone in The WorldDocument29 pagesEarly Journal Content On JSTOR, Free To Anyone in The Worldchouaib kennicheNo ratings yet

- DocumentationDocument1 pageDocumentationchouaib kennicheNo ratings yet

- Machine Learning Techniques To PerceiveDocument4 pagesMachine Learning Techniques To Perceivechouaib kennicheNo ratings yet

- User Manual: All Rights Reserved. Version 2019-11-13Document46 pagesUser Manual: All Rights Reserved. Version 2019-11-13chouaib kennicheNo ratings yet

- Saraswati English School (S.S.C Board) : SMT. S. D. S. S'sDocument2 pagesSaraswati English School (S.S.C Board) : SMT. S. D. S. S'sSahadev KadlagNo ratings yet

- Kulkarni 2010Document7 pagesKulkarni 2010Jesus JeronimoNo ratings yet

- 3rd Assessment Mathematics 5Document5 pages3rd Assessment Mathematics 5Raselle Alfonso Palisoc100% (1)

- Moisture Particle SizeDocument6 pagesMoisture Particle SizejayaNo ratings yet

- Scada Course Outline PDFDocument2 pagesScada Course Outline PDFpfalencar100% (1)

- Education: A315/5, IIT Kanpur - India (+91) 9660998600 - Yashbth@iitk - Ac.in - /in/yashbth - /yashbthDocument2 pagesEducation: A315/5, IIT Kanpur - India (+91) 9660998600 - Yashbth@iitk - Ac.in - /in/yashbth - /yashbthVikas SrivastavNo ratings yet

- DPS 2100 Engine Safety System User Manual Doc. No. 921.450.021Document84 pagesDPS 2100 Engine Safety System User Manual Doc. No. 921.450.021_Avek_89% (9)

- Earth Mat Sizing Calculations - 22 MW - Azure Rev 03Document31 pagesEarth Mat Sizing Calculations - 22 MW - Azure Rev 03Mohdsalauddin HabeebNo ratings yet

- All Wheel Steering Project 22Document3 pagesAll Wheel Steering Project 22Snev EvansNo ratings yet

- Boeing B737Document96 pagesBoeing B737Amjad Baig100% (6)

- Seismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterDocument16 pagesSeismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterAlNo ratings yet

- Report 8 HydroDocument13 pagesReport 8 HydroAbdallah AlhasanNo ratings yet

- Grout Cubes Versus Cylinders TestsDocument20 pagesGrout Cubes Versus Cylinders TestsMustufa F KanjetaNo ratings yet

- SECOM 737: User ManualDocument133 pagesSECOM 737: User Manualdinojr2010No ratings yet

- patent-US2629213-Crankshaft Grinding DeviceDocument9 pagespatent-US2629213-Crankshaft Grinding DeviceMahnooshNo ratings yet

- A Fast Settling Slew Rate Enhancement Technique For Operational AmplifiersDocument4 pagesA Fast Settling Slew Rate Enhancement Technique For Operational AmplifiersShubham SharmaNo ratings yet

- Oracle DataGuard Documentation PDFDocument45 pagesOracle DataGuard Documentation PDFLuis Alberto MadridNo ratings yet

- Set 01Document161 pagesSet 01ashishjakateNo ratings yet

- MGMT2023 Lecture 4 & 5 TVM Slides - Parts I, II IIIDocument91 pagesMGMT2023 Lecture 4 & 5 TVM Slides - Parts I, II IIIIsmadth2918388No ratings yet

- Bulletin Mechanical Engineering Modeling 2016 BMEDocument39 pagesBulletin Mechanical Engineering Modeling 2016 BMEBálint Vincze100% (1)

- Geom Trig Packet of WorksheetsDocument10 pagesGeom Trig Packet of Worksheetssherdan0% (1)

- Elektor Electronics July-August 2007Document152 pagesElektor Electronics July-August 2007carl12No ratings yet

- Class 6 Maths Set I Sample PapersDocument4 pagesClass 6 Maths Set I Sample PapersChetan RamtekeNo ratings yet

- Assessment 2 Stat20053 Descriptive Statistics - CompressDocument2 pagesAssessment 2 Stat20053 Descriptive Statistics - CompressDon RatbuNo ratings yet

- Block Diagram of Satellite Communication System 1nm82cvDocument1 pageBlock Diagram of Satellite Communication System 1nm82cvAbdou Gaye80% (5)

- Accelerate EducationDocument11 pagesAccelerate EducationThomas DyeNo ratings yet