Professional Documents

Culture Documents

LSS Blackbelt Curriculum

LSS Blackbelt Curriculum

Uploaded by

Azalea IYOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LSS Blackbelt Curriculum

LSS Blackbelt Curriculum

Uploaded by

Azalea IYCopyright:

Available Formats

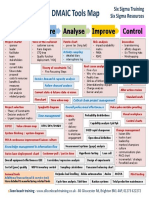

LEAN SIX SIGMA BLACKBELT CURRICULUM

Activities

• Review Project Charter • Value Stream Map for Deeper • Identify Potential Root • Develop Potential Solutions • Implement Mistake Proofing

• Validate Problem Statement Understanding and Focus Causes • Evaluate, Select, and Optimize • Develop SOP’s, Training Plan

and Goals • Identify Key Input, Process and • Reduce List of Potential Best Solutions & Process Controls

• Validate Voice of the Customer Output Metrics Root Causes • Develop ‘To-Be’ Value Stream • Implement Solution and

& Voice of the Business • Develop Operational Definitions • Confirm Root Cause to Map(s) Ongoing Process

• Validate Financial Benefits • Develop Data Collection Plan Output Relationship • Develop and Implement Pilot Measurements

• Validate High-Level Value • Validate Measurement System • Estimate Impact of Root Solution • Identify Project Replication

Stream Map and Scope • Collect Baseline Data Causes on Key Outputs • Confirm Attainment of Project Opportunities

• Create Communication Plan • Determine Process Capability • Prioritize Root Causes Goals • Complete Control Gate

• Select and Launch Team • Complete Measure Gate • Complete Analyze Gate • Develop Full Scale • Transition Project to Process

• Develop Project Schedule Implementation Plan Owner

• Complete Define Gate • Complete Improve Gate

Identify and Implement Quick Improvements with Kaizen

Tools

• Project Charter • Value Stream Mapping • Process Constraint ID and Takt Kaizen, 5S, NVA Analysis, • Mistake-Proofing/

• Voice of the Customer and • Value of Speed (Process Cycle Time Analysis Generic Pull Systems, Zero Defects

Kano Analysis Efficiency / Little’s Law) • Cause & Effect Analysis Four Step Rapid Setup Method • Standard Operating

• SIPOC Map • Operational Definitions • FMEA Procedures (SOP’s)

• Replenishment Pull/Kanban

• Project Valuation / EVA • Data Collection Plan • Hypothesis Tests/Conf. Intervals • Process Control Plans

• Stocking Strategy

Analysis Tools • Statistical Sampling • Simple & Multiple Regression • Visual Process Control Tools

• Process Flow Improvement

• RACI and Quad Charts • Measurement System Analysis • ANOVA • Statistical Process Controls

• Process Balancing

• Stakeholder Analysis (MSA) • Components of Variation (SPC)

• Analytical Batch Sizing

• Communication Plan • Gage R&R • Conquering Product and • Solution Replication

• Maintenance Excellence

• Effective Meeting Tools • Kappa Studies Process Complexity • Project Transition Model

• Design of Experiments (DOE)

• Inquiry and Advocacy Skills • Control Charts • Queuing Theory • Team Feedback Session

• Solution Selection Matrix

• Time Lines, Milestones, • Histograms

• Piloting and Simulation

and Gantt Charting • Normality Test

• Pareto Analysis • Process Capability Analysis

• Belbin Analysis Slide 1

You might also like

- Mine Managers' HandbookDocument572 pagesMine Managers' HandbookAraceli Rodriguez96% (25)

- QUIZ 1 - Preparation of Financial StatementsDocument3 pagesQUIZ 1 - Preparation of Financial StatementsDorothy Romagos100% (7)

- E-Book - Retail Marketing Management - Principles & Practice-Pearson (2015) - Helen Goworek PDFDocument369 pagesE-Book - Retail Marketing Management - Principles & Practice-Pearson (2015) - Helen Goworek PDFJerrielle CastroNo ratings yet

- APQP Process Flow MapDocument13 pagesAPQP Process Flow Mapjohnoo70% (1)

- Irish Spring ReportDocument11 pagesIrish Spring ReportAri EngberNo ratings yet

- Double Double Cameron Herold Chpt1Document22 pagesDouble Double Cameron Herold Chpt1Lucxon Riodin100% (1)

- Case AnalysisDocument5 pagesCase AnalysisShrijaSrivNo ratings yet

- Lean Six Sigma RoadmapDocument16 pagesLean Six Sigma RoadmapSteven Bonacorsi100% (11)

- APQP Training MaterialDocument13 pagesAPQP Training Materialsuresh kumar100% (3)

- APQP Training MaterialDocument13 pagesAPQP Training Materialsuresh kumar100% (1)

- The Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICFrom EverandThe Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICRating: 4.5 out of 5 stars4.5/5 (7)

- CH 10Document22 pagesCH 10Shayne0% (1)

- DMAIC Tools & DeliverablesDocument27 pagesDMAIC Tools & DeliverablessalvaNo ratings yet

- Bonacorsi Consulting Master DMAIC RoadmapDocument7 pagesBonacorsi Consulting Master DMAIC Roadmapaminos85No ratings yet

- Control PhaseDocument24 pagesControl Phasehaidar khadourNo ratings yet

- An Overview of Six SigmaDocument9 pagesAn Overview of Six SigmaReza GanNo ratings yet

- Lean Six Sigma Asq Road MapDocument2 pagesLean Six Sigma Asq Road Maphj100% (4)

- BAE - 06 Pull System Analytics v1Document33 pagesBAE - 06 Pull System Analytics v1lrff1950No ratings yet

- 6 SigmaDocument2 pages6 SigmaLorenzo CarmeniNo ratings yet

- DMAIC Tools Map: Measure Analyse Improve Define ControlDocument1 pageDMAIC Tools Map: Measure Analyse Improve Define Controlhafsa bassemNo ratings yet

- 14056132-Six Sigma DMAIC Project TemplateDocument14 pages14056132-Six Sigma DMAIC Project TemplateSAMHO DigitalNo ratings yet

- L16 Control GB Six SigmaDocument24 pagesL16 Control GB Six Sigmahaidar khadourNo ratings yet

- Control GB Six SigmaDocument24 pagesControl GB Six Sigmarobyn100No ratings yet

- Tnt21 Advance Define PhaseDocument43 pagesTnt21 Advance Define PhaseRosario LopezNo ratings yet

- Six Sigma Process MapDocument1 pageSix Sigma Process MapIndra burnamaNo ratings yet

- MRII Lean 6 Sigma WorkshopDocument191 pagesMRII Lean 6 Sigma WorkshopDonna CincoNo ratings yet

- CIStandards Steps1 10 V2rev08302016 2Document2 pagesCIStandards Steps1 10 V2rev08302016 2Are Em GeeNo ratings yet

- Introduction To Screening Tools: Grow & InnovateDocument71 pagesIntroduction To Screening Tools: Grow & InnovateGowtham GanesanNo ratings yet

- Statistical Process Control SPC BrochureDocument1 pageStatistical Process Control SPC BrochureexamplecgNo ratings yet

- Resume Toolkit Cantilever LabsDocument9 pagesResume Toolkit Cantilever Labsd nNo ratings yet

- FI - Chapter 4 - Improvement ToolkitDocument161 pagesFI - Chapter 4 - Improvement Toolkitgilson.fernandesNo ratings yet

- Introduction To Lean Six SigmaDocument19 pagesIntroduction To Lean Six SigmaSanketNo ratings yet

- Session 9 10Document50 pagesSession 9 10NK SanNo ratings yet

- APQP Phases & Elements of APQPDocument6 pagesAPQP Phases & Elements of APQPSachin Ramdurg100% (1)

- Value Engineering POMDocument16 pagesValue Engineering POMnabendu4u100% (1)

- Managemen Mutu (Presentasi)Document123 pagesManagemen Mutu (Presentasi)Ucu SuratmanNo ratings yet

- Design For Six Sigma Training BrochureDocument1 pageDesign For Six Sigma Training Brochureexamplecg100% (2)

- MeasurementDocument105 pagesMeasurementshoumikraihan71No ratings yet

- Week 2Document31 pagesWeek 2mexiweNo ratings yet

- Inception Cheat SheetDocument1 pageInception Cheat SheetAntonny JaramilloNo ratings yet

- Session 5 LectureDocument55 pagesSession 5 Lecturesymbianmark9No ratings yet

- TransformYourHabits EditedDocument60 pagesTransformYourHabits EditedGowtham GanesanNo ratings yet

- Strat Epm RoadmapDocument26 pagesStrat Epm RoadmapabacusdotcomNo ratings yet

- Module 39. Improve RoadmapDocument4 pagesModule 39. Improve Roadmaptaghavi1347No ratings yet

- A Guide To Project ManagementDocument60 pagesA Guide To Project ManagementPrashant ThawariNo ratings yet

- Lean Six SigmaDocument14 pagesLean Six Sigmababudukku100% (10)

- Process Groups Mapping With ColoursDocument41 pagesProcess Groups Mapping With ColoursbhartiaNo ratings yet

- Reverse Engineering Process Flow ChartDocument3 pagesReverse Engineering Process Flow Chartpradeep k100% (1)

- DMAIC Process Storyboard: Team Formation Define MeasureDocument14 pagesDMAIC Process Storyboard: Team Formation Define MeasureEric AlvarezNo ratings yet

- How To Perform Risk Assessment According To IATF 16949 Webinar Presentation DeckDocument18 pagesHow To Perform Risk Assessment According To IATF 16949 Webinar Presentation Deckfrancisco.delgadoNo ratings yet

- Value Engineering POMDocument16 pagesValue Engineering POMnabendu4u100% (1)

- Project Details - Indira IIBM 7 DMTIMS - Operations PDFDocument5 pagesProject Details - Indira IIBM 7 DMTIMS - Operations PDFDr. Vishal GhagNo ratings yet

- Process Improvement Methodology and Tools - Define Phase OverviewDocument1 pageProcess Improvement Methodology and Tools - Define Phase OverviewKapil MohanNo ratings yet

- Driving Synergy Across Innovation, Process and Execution: An IVTREE ProductDocument4 pagesDriving Synergy Across Innovation, Process and Execution: An IVTREE ProductManju JosephNo ratings yet

- Process Improvement Methodology and Tools - Measure Phase OverviewDocument1 pageProcess Improvement Methodology and Tools - Measure Phase OverviewKapil MohanNo ratings yet

- PS-GPD - ProjSys - GPD - Cost - Workshop - KickoffDocument12 pagesPS-GPD - ProjSys - GPD - Cost - Workshop - KickoffKhaoula EL EDRISSINo ratings yet

- ISQA 572/ 449 Models For Quality Control/ Process Control and Improvement ISQA 572/ 449 Models For Quality Control/ Process Control and ImprovementDocument69 pagesISQA 572/ 449 Models For Quality Control/ Process Control and Improvement ISQA 572/ 449 Models For Quality Control/ Process Control and ImprovementhamedNo ratings yet

- Benchmark IT Solutions LLC Service Offering PresentationDocument7 pagesBenchmark IT Solutions LLC Service Offering Presentationganesh01021648No ratings yet

- APQP Process FlowDocument13 pagesAPQP Process Flowkaca82No ratings yet

- Sample Process MatrixDocument3 pagesSample Process Matrixchris_gray1980No ratings yet

- IT Quality Session 1Document64 pagesIT Quality Session 1Madhur GuptaNo ratings yet

- Pdca ConceptDocument16 pagesPdca ConceptVardhan ShahNo ratings yet

- B Plan Handout 9Document30 pagesB Plan Handout 9SmayandasNo ratings yet

- Implementing the Stakeholder Based Goal-Question-Metric (Gqm) Measurement Model for Software ProjectsFrom EverandImplementing the Stakeholder Based Goal-Question-Metric (Gqm) Measurement Model for Software ProjectsNo ratings yet

- Arba Minch Univeristy School of Business and Economics: ID PRBE/075/13Document8 pagesArba Minch Univeristy School of Business and Economics: ID PRBE/075/13Wara GobeNo ratings yet

- Value Added TaxASDASDocument7 pagesValue Added TaxASDASJohn Lester LantinNo ratings yet

- PackagingDocument11 pagesPackagingFariyal ZohaNo ratings yet

- Portfolio Theory and Investment AnalysisDocument19 pagesPortfolio Theory and Investment AnalysisAfdal SyarifNo ratings yet

- Capital Market PDFDocument13 pagesCapital Market PDFSameer OmlesNo ratings yet

- Aker Horizons IPO ProspectusDocument80 pagesAker Horizons IPO ProspectusMartin Duy NguyenNo ratings yet

- Prelim Rem9Document3 pagesPrelim Rem9Josue Sandigan Biolon SecorinNo ratings yet

- BCG The Bionic Company June 2019 - tcm9 223779 PDFDocument8 pagesBCG The Bionic Company June 2019 - tcm9 223779 PDFNatalia LopezNo ratings yet

- ESS FS DetailsDocument8 pagesESS FS DetailskkumartamanamNo ratings yet

- Availability CheckDocument41 pagesAvailability CheckTek's Notani50% (2)

- Quantitative MethodsDocument19 pagesQuantitative MethodsSerena Van der WoodsenNo ratings yet

- Meetings of Board and Its PowersDocument60 pagesMeetings of Board and Its PowersPalashJainNo ratings yet

- Implementation of Business Marketing StrategyDocument43 pagesImplementation of Business Marketing StrategyMubashir Ali BeighNo ratings yet

- Tendernotice 1 PDFDocument81 pagesTendernotice 1 PDFRamesh KumarNo ratings yet

- Banking Practice For Actuaries - How It All Happened in SADocument6 pagesBanking Practice For Actuaries - How It All Happened in SAChirikure PanasheNo ratings yet

- Syndicate Assignment: Case Study: Letting Go of Lehman BrothersDocument6 pagesSyndicate Assignment: Case Study: Letting Go of Lehman BrothersJane Tito100% (1)

- National Contexts, Incubator Families and Trends in Incubation - Views From Four CountriesDocument23 pagesNational Contexts, Incubator Families and Trends in Incubation - Views From Four CountriesscribdoibNo ratings yet

- Jindal Saw-AR-2017-18-NET PDFDocument274 pagesJindal Saw-AR-2017-18-NET PDFshahavNo ratings yet

- Theodore Levitt's Marketing Myopia: Colin GrantDocument2 pagesTheodore Levitt's Marketing Myopia: Colin GrantSauravSNo ratings yet

- Treatment of Reserves Arising On Amalgama-Tion in The Nature of MergerDocument2 pagesTreatment of Reserves Arising On Amalgama-Tion in The Nature of MergerDaniel AggarwalNo ratings yet

- Reg Section 1.861-4Document13 pagesReg Section 1.861-4EDC AdminNo ratings yet

- Round PDFDocument2 pagesRound PDFmnrcavNo ratings yet

- FIN111 Spring2015 Tutorials Tutorial 5 Week 6 QuestionsDocument3 pagesFIN111 Spring2015 Tutorials Tutorial 5 Week 6 QuestionshaelstoneNo ratings yet