Professional Documents

Culture Documents

CHIEF 3000 PSI Welded Pin Eye 2013 WP

CHIEF 3000 PSI Welded Pin Eye 2013 WP

Uploaded by

Omar De La GarzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHIEF 3000 PSI Welded Pin Eye 2013 WP

CHIEF 3000 PSI Welded Pin Eye 2013 WP

Uploaded by

Omar De La GarzaCopyright:

Available Formats

WP

®

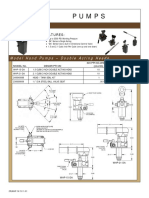

Hydraulic Cylinders by Bailey

Our Most Versatile Medium-Duty Welded Cylinder

The Chief WP is a high quality welded and very versatile cylinder. The rod end comes eye drilled and can easily be cus-

tomized by cutting and welding to fit your rod end choice. Base end has a strong cross tube with grease zerk. Ideal for con-

struction and agricultural applications as well as other industries like trailers, metal fabricating, forestry, material handling,

mining, demolition, waste/recycling and more. SAE O-ring ports for easy hookup.

Each and every Chief WP cylinder is functionally tested and pressurized to 1.5 times the normal working pressure to

insure performance reliability. The Chief WP is available in bore sizes from 1-1/2” to 4” and strokes from 4” to 72”. It has a

3,000 PSI operating range and 3 year limited warranty. Cylinder can be customized to meet OEM requirements on large

orders. Painted black, available in custom colors.

• Hard Chrome Plated Rod

• Ductile Iron Piston with Wear Ring

• Hallite 755 Piston Seal

• SAE 8 O-ring Ports (SAE 6 O-rings on 1 1/2” bore)

• Cross Tube Base End with Grease Zerk

• 3000 PSI Working Pressure

• Eye Drilled Rod End

3000 PSI Imported Chief cylinders are manufactured at ISO 9001:2000 Certified Facilities

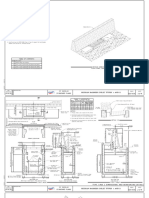

Chief WP Welded Cylinder Bore Sizes 1 1/2” to 4” Strokes from 4” to 72”

Intended Use: Double-acting applications • Piston: Ductile iron • Gland: Ductile iron • Tube: Precision honed steel for extended seal life

• Rod: Hard chrome plated • Rod End Mount: Rod eye drilled • Base End Mount: Cross tube C-1026 with grease zerk • Tube Seal: Buna

O-ring with Polytemp hytrel backup • Rod Seal: Deep polypak with B lip design • Rod Wiper: Urethane, snap-in • Piston Seal: Hallite 755

provides prolonged wear resistance • All Seals: Manufactured to US specifications • Paint: Red. Custom colors are available

• Packaging: Individually poly bagged

A + STROKE

C (Typ.)

s

N M K J L

B (Wall)

s

s

s

s

s

s

s

s

R R

s

F (Typ.)

s

E D

s

s

s s

s

s

s

S

s

s

Dimensional Data in Inches (Millimeters)

BORE A B C D E F J K L M N R S

4.000 9.000 0.25 SAE 8 2.000 4.625 2.937 3.002 2.185 1.250 1.613 1.000 1.265 2.000

(101.6) (228.6) (6.4) (50.8) (117.5) (74.60) (76.25) (55.50) (31.8) (40.97) (25.4) (32.1) (50.80)

You might also like

- Viva La VidaDocument1 pageViva La VidaAndrew Davis0% (1)

- The Book Block O Miolo Do Livro SampleDocument10 pagesThe Book Block O Miolo Do Livro Samplebisturbio7480No ratings yet

- Bs en 14901Document20 pagesBs en 14901khai rule100% (1)

- S788 ManualDocument248 pagesS788 ManualPerry BettertonNo ratings yet

- Danau: Kampus Stie Dwi MulyaDocument1 pageDanau: Kampus Stie Dwi MulyaUseless YouthNo ratings yet

- 08 - Switch Plan Lantai 2Document1 page08 - Switch Plan Lantai 2Sugianto KusumaNo ratings yet

- Digital Voltmeter Schematic 1Document1 pageDigital Voltmeter Schematic 1Yasir AmmarNo ratings yet

- Continut Portofoliu Fata VersoDocument71 pagesContinut Portofoliu Fata VersoAlexandra UngureanuNo ratings yet

- Absen Sholat Jama'AhDocument4 pagesAbsen Sholat Jama'Ahsa.afuzuNo ratings yet

- Jaz TT Cup Knotted BrushDocument9 pagesJaz TT Cup Knotted BrushGianfranco CopelloNo ratings yet

- Sprinkler PBXDocument1 pageSprinkler PBXTHEBLUE-REINo ratings yet

- Town Homes Electrical 12 21 10 E 04 3Document1 pageTown Homes Electrical 12 21 10 E 04 3kimNo ratings yet

- Here We Come A Wassailing Flute Sheet Music Christmas (SheetMusic Free Com)Document2 pagesHere We Come A Wassailing Flute Sheet Music Christmas (SheetMusic Free Com)anna niederleimbacherNo ratings yet

- Technological Institute of The Philippines: CEC41S5 1 CEC41S5Document1 pageTechnological Institute of The Philippines: CEC41S5 1 CEC41S5Julius Caesar FelixNo ratings yet

- Ferreria Eplan2 e 2Document1 pageFerreria Eplan2 e 2Ezekiel A. NavarroNo ratings yet

- Flagstaff Fabulous Plants BroshureDocument2 pagesFlagstaff Fabulous Plants Broshurelenny mcreadyNo ratings yet

- Palmolein Oil TankDocument1 pagePalmolein Oil TankProchem ECNo ratings yet

- Palm Oil TankDocument1 pagePalm Oil TankProchem ECNo ratings yet

- PDF Ekinerja 2022 Bagus MiftakhuddinDocument19 pagesPDF Ekinerja 2022 Bagus Miftakhuddinrisang642No ratings yet

- Ti-E Kohler Setup BFDocument7 pagesTi-E Kohler Setup BFMitchell SunNo ratings yet

- Ultimate Guide To SSC Combined Graduate Level - CGL (Tier I & Tier II) Exam 5th Edition PDFDocument728 pagesUltimate Guide To SSC Combined Graduate Level - CGL (Tier I & Tier II) Exam 5th Edition PDFsdasd100% (2)

- Din 1592Document1 pageDin 1592Sudarshan KaragudariNo ratings yet

- 2014 Sac Me Spec Ver105Document61 pages2014 Sac Me Spec Ver105Lawrence Anthony BenitezNo ratings yet

- RCP ModelDocument1 pageRCP ModelLyndryl ProvidoNo ratings yet

- Asme-B 1825 MDocument20 pagesAsme-B 1825 MGyan Ka Data PackNo ratings yet

- Sni 01 2780 1992 Susu EvaporasiDocument10 pagesSni 01 2780 1992 Susu EvaporasiRizka AdindaNo ratings yet

- Mining 1Document17 pagesMining 1mallikNo ratings yet

- Ground Floor Lighting Layout Second Floor Lighting Layout Rooftop Lighting LayoutDocument1 pageGround Floor Lighting Layout Second Floor Lighting Layout Rooftop Lighting LayoutMark Allan RojoNo ratings yet

- 230 Link Bait IdeasDocument1 page230 Link Bait IdeasCiprian TimofteNo ratings yet

- HydrocarbonDocument8 pagesHydrocarbonPutri Nur SyafieqahNo ratings yet

- Form Order General Tool: Drawer 1Document2 pagesForm Order General Tool: Drawer 1yonefi utariNo ratings yet

- Peta Dunia (Fizikal)Document2 pagesPeta Dunia (Fizikal)Oboi Mw Blajar UdaNo ratings yet

- 1c Excel Nomina 03Document1 page1c Excel Nomina 03DaseNo ratings yet

- VW 01103Document9 pagesVW 01103Alexandre GoulartNo ratings yet

- Khufa Buc Musarat ChalanDocument8 pagesKhufa Buc Musarat ChalanRiaz AhmedNo ratings yet

- Lalaland SomeoneInTheCrowd ScoreDocument9 pagesLalaland SomeoneInTheCrowd ScoreMichaël OrandNo ratings yet

- Zoning Design Review 2017Document1 pageZoning Design Review 2017dealsforrishiNo ratings yet

- ATCM44 Att032 e PDFDocument1 pageATCM44 Att032 e PDFrogonpouNo ratings yet

- Petrified Forest NPDocument1 pagePetrified Forest NPapi-19487128No ratings yet

- Carlos Goes To SchoolDocument7 pagesCarlos Goes To SchoolSandy StormNo ratings yet

- Altered ScaleDocument3 pagesAltered ScalesophochaNo ratings yet

- RNA y Origenes de La VidaDocument4 pagesRNA y Origenes de La VidaLuciana ColqueNo ratings yet

- Amca 500 D 07 Damper TestingDocument74 pagesAmca 500 D 07 Damper TestingLê Viết HàNo ratings yet

- Academic CalendarDocument2 pagesAcademic CalendarSAURABH KUMARNo ratings yet

- Printable Dotted Letter S Tracing PDF WorksheetDocument1 pagePrintable Dotted Letter S Tracing PDF WorksheetFariha Muhammad AliNo ratings yet

- Ejemplo de SubterraneaDocument1 pageEjemplo de SubterranearcorreaingeomegaNo ratings yet

- New Wiring Diagram Electric Ems2 Tad1640gepdfDocument2 pagesNew Wiring Diagram Electric Ems2 Tad1640gepdfSai R-JAgNo ratings yet

- General Notes:: of 4 1 425-030 Median Barrier Inlet Types 1 and 2Document4 pagesGeneral Notes:: of 4 1 425-030 Median Barrier Inlet Types 1 and 2VinceNo ratings yet

- IB SL AI Unit 07 Quantifying UncertaintyDocument6 pagesIB SL AI Unit 07 Quantifying UncertaintyLorraine SabbaghNo ratings yet

- 大众标准PV3909-伸长率Document3 pages大众标准PV3909-伸长率zz576614No ratings yet

- 7S11LEN00138: SartoriusDocument4 pages7S11LEN00138: SartoriusDen TseNo ratings yet

- Application Form For Height Limitaion Rev 032013 PDFDocument1 pageApplication Form For Height Limitaion Rev 032013 PDFLouie Zavalla LeyvaNo ratings yet

- Long HillDocument1 pageLong HillmbrackenburyNo ratings yet

- RSG D Adt 180506 Rev7Document2 pagesRSG D Adt 180506 Rev7Stefan TrollipNo ratings yet

- Polyhex Tree of Life Wall-ChartsDocument2 pagesPolyhex Tree of Life Wall-ChartsPatrick Mulcahy100% (14)

- Qdoc - Tips Transformer Foundation DesignDocument13 pagesQdoc - Tips Transformer Foundation DesignabguyNo ratings yet

- Proposed Two - Storey Residence: Load ScheduleDocument1 pageProposed Two - Storey Residence: Load Scheduleqfg2qqcf42No ratings yet

- Feed Water DP-uploadDocument2 pagesFeed Water DP-uploadmyungkwan haNo ratings yet

- Trail/Beaver Valley/Rossland Pennywise June 6, 2017Document40 pagesTrail/Beaver Valley/Rossland Pennywise June 6, 2017Pennywise PublishingNo ratings yet

- 302 ParkerDocument1 page302 ParkerOmar De La GarzaNo ratings yet

- Manual Explosion Proof Pressure Transmitter Kp46Document2 pagesManual Explosion Proof Pressure Transmitter Kp46Omar De La GarzaNo ratings yet

- Pump Motor5 HP 230 V (EJMM3613T)Document3 pagesPump Motor5 HP 230 V (EJMM3613T)Omar De La GarzaNo ratings yet

- Wolverine Hand PumpDocument3 pagesWolverine Hand PumpOmar De La GarzaNo ratings yet

- Coal - WikipediaDocument1 pageCoal - WikipediaZalanda NisarNo ratings yet

- Gate 2000 CyDocument9 pagesGate 2000 CyYocobSamandrewsNo ratings yet

- BiochemistryDocument68 pagesBiochemistry20AR018 HARIHARA SUBRAMANIANNo ratings yet

- Human TraffickingDocument26 pagesHuman TraffickingNiyoga Singarimbun100% (3)

- Pathfit 2Document18 pagesPathfit 2Pam LlanetaNo ratings yet

- Master Circular 16 Compassionate GroundDocument13 pagesMaster Circular 16 Compassionate GroundSHANMUGA VADIVEL SUNDARARAJANNo ratings yet

- Communication and Ethics in Pharmacy Practice: What Is To BeDocument23 pagesCommunication and Ethics in Pharmacy Practice: What Is To BeMuhammad RezaNo ratings yet

- Fluor CarbonDocument3 pagesFluor CarbonHrishikesh DhawadshikarNo ratings yet

- Nurse-Patient Interaction Process Recording: College of NursingDocument3 pagesNurse-Patient Interaction Process Recording: College of NursingBianx Flores DosdosNo ratings yet

- 2022 Tucson Plug in Hybrid Emergency Response Quick Reference GuideDocument2 pages2022 Tucson Plug in Hybrid Emergency Response Quick Reference GuideForum PompieriiNo ratings yet

- Working Principle of Earth Leakage Circuit Breaker (ELCB), RCD PDFDocument6 pagesWorking Principle of Earth Leakage Circuit Breaker (ELCB), RCD PDFjobpei260% (5)

- 27-07-2021 HMB EnglishDocument12 pages27-07-2021 HMB EnglishGyan PrakashNo ratings yet

- Fundamentals of Urban and Regional Planning: Theories and PracticeDocument7 pagesFundamentals of Urban and Regional Planning: Theories and PracticeMaru PabloNo ratings yet

- Horrocks Et Al. 2018. Demonstrating An Integrated Pest Management PDFDocument9 pagesHorrocks Et Al. 2018. Demonstrating An Integrated Pest Management PDFEdna SuárezNo ratings yet

- BM 4 - Bricks & BlocksDocument30 pagesBM 4 - Bricks & BlocksArch Reem AlzyoudNo ratings yet

- Hemodialysis Patients' Perceptions of Home Hemodialysis and Self-CareDocument13 pagesHemodialysis Patients' Perceptions of Home Hemodialysis and Self-CareRandee BoiiNo ratings yet

- Effective Assessment of Crude Oil Sourness For The MaterialDocument7 pagesEffective Assessment of Crude Oil Sourness For The MaterialRenanLacanaNo ratings yet

- Definition of Terms Mine SurveyingDocument2 pagesDefinition of Terms Mine Surveyingaquariuspj25100% (3)

- Orthopaedic Study Guide 2014Document126 pagesOrthopaedic Study Guide 2014Yip Kar Jun100% (1)

- D154-85 (2009) Standard Guide For Testing VarnishesDocument4 pagesD154-85 (2009) Standard Guide For Testing VarnishesRonny100% (1)

- Tecan Sunrise Absorbance Reader Analyser - User ManualDocument74 pagesTecan Sunrise Absorbance Reader Analyser - User Manualomer oartbNo ratings yet

- Bosch ManualDocument56 pagesBosch Manualjhon manuel de jesus100% (1)

- Gen 017 - Sas Lesson #4Document5 pagesGen 017 - Sas Lesson #4ABM - Villanueva, Jaimee Lyn C.No ratings yet

- Bacteria ProfileDocument18 pagesBacteria ProfileNOR-FATIMAH BARATNo ratings yet

- DRRR2324 Q4 DRRDocument7 pagesDRRR2324 Q4 DRRh4gtg7n55gNo ratings yet

- 04-Analysis of FS With Developed ChecklistDocument32 pages04-Analysis of FS With Developed Checklistyeddy andriansyahNo ratings yet

- Zoology Mammals (Rabbit)Document3 pagesZoology Mammals (Rabbit)PerrieNo ratings yet

- Switchgear CBM ActivitiesDocument62 pagesSwitchgear CBM ActivitiesHelmyNo ratings yet