Professional Documents

Culture Documents

Home Built 4x8ft CNC Plasma Metal Cutting System: Instructables

Home Built 4x8ft CNC Plasma Metal Cutting System: Instructables

Uploaded by

Fauzi Ma'arifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Home Built 4x8ft CNC Plasma Metal Cutting System: Instructables

Home Built 4x8ft CNC Plasma Metal Cutting System: Instructables

Uploaded by

Fauzi Ma'arifCopyright:

Available Formats

instructables

Home Built 4x8ft CNC Plasma Metal Cutting System

by Customfabricated

What is a CNC Plasma Cutting System? These are I designed and built this system in my personal shop

computer controlled machines that can cut through utilizing several o -the-shelf components along with

any electrically conductive material (steel / stainless / some custom fabricated assemblies.

aluminum / copper). The machine takes a 2D

computer generated sketch and translates it to a Check out the following steps for a detailed overview

computer numerical control (CNC) system that is of my custom CNC Plasma build!

coupled with a Plasma Cutter. The Plasma Cutter uses

an electrical arc and compressed air to cut through

the conductive material.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 1

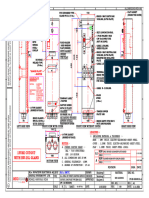

Step 1: Planning and Components

Pla nning

Before beginning, I had to answer a couple key questions:

How large of a CNC table do I want to make?

What is the max thickness of material that I need to cut?

These two questions will drive the rest of your project. For me, I decided to build a table that can accommodate a

4x8ft sheet of material (4x8ft is one of the most common sizes for raw steel plate). Based on what I typically

fabricate, I wanted the ability to cut through 1/4in thick steel at a minimum.

I also included a few unique aspects into the design:

Drop down casters for easy mobility

Down draft system for drawing out dust and smoke

Nozzle point suction system and water trap for drawing out ne particles near the cutting tip

Removable cutting surface - allows me to lift o the cutting surface and insert a water pan for an

alternate method of smoke and dust control

Co m po ne nt s inv o lv e d

Below is a general list of the main components of a CNC plasma cutting system:

Pla s m a cut t e r - I elected to purchase a Hypertherm Powermax 65 plasma cutter for this build. This

machine is capable of cutting 1in thick steel.

Air co m pre s s o r - Plasma cutters require an air supply to operate and cut through materials. I

chose an Ingersoll 80 gallon air compressor which should have no issues keeping up with the air

supply demands from the system.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 2

CNC M o t o r Co nt ro l Pa cka g e - These are the drivers and motors that control the movement of

the Plasma Cutting torch. I purchased my system from a company called CandCNC. This system

included all 4 stepper motors and motor drivers in one complete package.

Ta ble B a s e - I custom fabricated my table base using raw materials. The main frame is built from

2in x 11ga square tubing.

G a nt ry As s e m bly - this includes all of the bearings, gears, gear tracks, and structural

components that make up the moving gantry on top of the table. You can source these parts

individually or purchase a full gantry kit. I elected to purchase my gantry from Precision Plasma.

S o f t w a re - a few di erent types of software are required:

CAD Design Software - Computer Aided Design software allows you to sketch and

design your parts before cutting them out. AutoCad or Fusion 360 are great options for

CAD design programs.

Plasma CAM Software - Computer Aided Manufacturing software will convert your CAD

sketch into a coding language (typically 'G-Code') that the CNC plasma system can read

and interpret. I run SheetCAM on my system.

CNC Control Software - this software reads G-Code and sends it to the motors on the

CNC table. My system uses Mach3 CNC control software

Co m put e r - a basic computer is required to run your CNC Control Software and hook up to your

motor control box

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 3

Step 2: Fabricating the Table Base

I began by building the main frame using 2x2x11ga square tubing and 2x3x11ga rectangular tubing. I included

drop down casters that pin in place for easy mobility. I also extended my gantry rails such that the gantry will roll

completely o the 4x8ft area to allow for easy loading of steel sheets. The dimensions of the gantry drove the width

of the table base.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 4

Step 3: Fabricating the Cutting Surface

I designed the cutting surface as a removable assembly. This allows me to lift the surface up and insert a water pan

as an option for dust and smoke control. This cutting surface uses 2x1/8in sacri cial slats and was built using the

following materials:

2x3x11ga rect. tube

2x2x11ga square tube

1x1x14ga square tube

2x.25in at bar

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 5

Step 4: Assembling the Table Base and Cutting Surface

The cutting surface drops into place on the table base. A set of 3in wide by 3/8in thick cold rolled at bars serve as

the rails for the gantry. Cold rolled materials maintain a higher dimensional tolerance than hot rolled. These rails

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 6

bolt to the top of the main frame.

Step 5: Bench Testing the Motor Control System

Before attaching your motors and wiring, it is prudent At this stage, I also wired up my Hypertherm Plasma

to bench test the system. This will ensure all your cutter so it will auto-start using a signal from the

motors and connections are fully operational and pre- CandCNC control box. The CancCNC instructions

programmed to turn in the correct directions. The walked me through this connection process.

instructions included with my CandCNC motor control

kit helped make this a straightforward process.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 7

Step 6: Assembling the Gantry

After fabricating the table base and cutting surface, speci ed distance even if the material being cut

the next step was to assemble and t check the begins to warp. Without THC, you run the risk of your

gantry. My gantry system from Precision Plasma was torch running into the work piece. A THC system also

built with extruded aluminum. prolongs the life of the plasma cutter consumables

(electrode / tip / nozzle).

This gantry incorporates a Z-axis allowing for torch

height control (THC). Torch height control is a highly I also opted to use belt reduction drive assemblies for

desirable feature on CNC plasma tables. This allows each motor. This helped to smooth out the operation

for active and automatic control of the distance and movement of the gantry.

between the torch tip and the material being cut. A

voltage feedback system automatically maintains a

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 8

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 9

Step 7: Building a Desk / Control Center

I fabricated a desk out of 1.5in square tube to house my computer and monitor. Some folks mount their computers

directly to the CNC base. I opted to keep this as a separate assembly. My computer is kept underneath the desk top.

I subsequently added some sheet metal around the desk to protect the computer from dust.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 10

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 11

Step 8: Adding a Downdraft System

An e cient means to draw out fumes and dust while of a removable cutting surface. I started by enclosing

running a CNC plasma system is highly necessary. the table base using aluminum sheet metal. I

There are two common methods for this: a water table plumbed in qty 4 suction points using 10in HVAC duct

or a down draft. Each has its own set of advantages work. Each suction point has a slider window that

and disadvantages allows me to direct maximum amounts of suction to

certain quadrants of the table. To power my

W a t e r Ta ble - this type involves a reservoir of water downdraft, I used two commercial grade kitchen

(often times treated with a corrosion and bacteria exhaust fans. These fans are typically mounted on a

inhibitor) that sits just under the material being cut. roof or wall and expel air radially in all directions. I

The water traps a large majority of the cutting dust modi ed the fans to expel air in a single direction

and helps to keep the material cool. However, water using some custom built duct work. My fans blow all

often times splashes around while cutting and will dust and fumes to the outside of my shop. Tip: nd

require constant maintenance to keep your gantry yourself a local HVAC wholesale company to purchase

system dry and clean your downdraft ductwork - this will be signi cantly

cheaper than the local big box home improvement

Do w ndra f t - this type uses mechanically driven air stores.

ow to suck the dust and fumes down into the table

and out to a desired location. With the right fans and I subsequently also added a nozzle point suction

enough air ow, this method works very well. system. I used 1.5in sump pump drain hose and

However, it does not provide the material cooling routed it from the cutting tip, through my gantry

capabilities that a water pan does. Keeping the cable tracks, and down to a 5 gallon bucket which is

material cool is bene cial to reduce warping especially also connected to a shop vac. By partially lling the 5

when cutting thin materials. gal bucket with water, I created a makeshift water

trap that helps to capture ne dust and particles.

I opted to incorporate a downdraft onto my table but

left the option open for a water table through the use

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 12

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 13

Step 9: Calibrating and Squaring the Gantry

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 14

This is a critical step to ensure your system produces table to ensure it remains even and true throughout

accurate and true cuts. By physically measuring the it's full range of motion. The 'limits' for the table are

movements of the gantry and making slight controlled by microswitches. My CandCNC control

adjustments in the control system, you can dial in system user manual walked me through the

your table ensuring a perfect 90 degrees between the integration of the switches.

X-axis and Y-axis. I ran my gantry up and down the

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 15

Step 10: Test Cuts

After squaring up the system and completing all set-up steps from the CancCNC user manual, I was ready for some

test cuts. I followed the instructions from my control system manual and got to cutting. This system was ready to

work right from the get go. The rst cuts were crisp and clean.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 16

Step 11: Examples of CNC Plasma Projects

This table has changed the way I fabricate. Projects that would typically take days or weeks were cut down to a

matter of hours. Anytime I tackle something new, I rst consider how I can utilize the CNC table to build it quickly

and e ciently.

Here are a few projects I completed for myself and a few of my friends using this table.

See the next step for a video of the table in action.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 17

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 18

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 19

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 20

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 21

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 22

Step 12: Video of the Table in Action

Thanks for checking out my build and please feel free to ask questions in the comments section!

https://youtu.be/nrYRxeJ61gU

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 23

If you are happy with Mach3 then fair enough, but I would like to point out that LinuxCNC now has

very good integration of Plasma, so that things like automatic torch-height correction (cut

corrugated iron...) and gantry squaring are fairly seamless.

Lots of info here: http://linuxcnc.org/docs/2.8/html/plasma/plasma-cn...

And here: http://linuxcnc.org/docs/2.8/html/plasma/plasmac-user-guide.html#cha:plasmac-user-

guide

I agree, linuxcnc is free (GNU) and it's realy good software.

For CAD I wood recomend FreeCad ( https://www.freecadweb.org/ ). It's good 3D software and

free (GNU) and it has it's own CAM module.

For orcanic moddeling (non-technical shapes) I would recomend Blender 3d

https://www.blender.org/ , also free (GNU).

Can we say that working on Linux is a better

Wicked! I build my own router CNC (as I mostly work with wood) but absolutely love what is done

with metal!

Thanks!

Good description. We built a 4x8 plasma table a couple of years ago. We only have a HyperTherm

45. If we need to cut thicker, we have an oxy/acetylene machine torch to put on it. We also

mounted a chuck that can turn up to 6" tubing/pipe so we can CNC cut it too. We enclosed the

electronics in a box about 20x20x20 and have two 150 cfm fans pulling air through a 1970s Ford

air cleaner for a 460 cid engine. We also used the CandCNC controls and stepper motors.

Could you give me an approximate cost of what it was to construct your plasma table?

I would say around $7000, which included $2000 HyperTherm 45, $2500 CandCNC controls and

motors, and a $700 machine torch. The rotary capability added about $600. We used (4) 24' pieces

of 2x3 rectangular tubing for the frame.

Love it. That's great stuff. Send some pics, would love to see it

Adding a CNC table to your shop is great, I have built a few tables from scratch and the cost is not

that bad, abut ($1500.) plus the Plasma unit. I have added optional attachments to mine to route

wood, drag knife sign vinyl and diamond etch metal. I have sold plans to over 14 countries.

//www.youtube.com/embed/fErYc7Wi1ps

Impressive work. Well done. Nice job. Look professional. I am surprised by how fast it is.

Thanks as you know you can have fun building one, and more fun with what you can do with it

after that. Adding a table is more possible than many think. The pink one was built for a lady doing

router work.

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 24

This build is so helpful.

To paraphrase Robin Williams " God gave me a massive table and a box full of electronics, but not

enough Brains to get them to run at the same time". I think this instructable will get this project

back on the front burner for me.

Thanks! I had this on my to do list for years. I eventually decided one day that the only way to finish

it is to start it. I googled some info and starting buying parts. Before I knew it, I had a running

machine that completely changed my fabrication capabilities

This is a phenomenal piece of work, I must say. Not' like I don't have enough machines in the

garage, but but is brilliant, thanks for sharing it

thanks!

I used to work for a small company that built CNC cutting machines. I think the largest one we ever

built had a 20'+ gantry with a half dozen plasma torches. One of the smallest machines was for

cutting sheet metal and was about the size of yours. I did most of the design work and fabrication

(it was a very small company - about 4 of us plus the owner). I think your design is brilliant and

looks every bit as good as the ones we sold. There is one small difference that other builders might

consider. It won't improve functionality, but it might make it a bit easier to build. We used 80/20

aluminum extrusion for the side rails as well as the gantry which avoided the problem of cold rolled

steel often having warp and twist

You have built an incredibly versatile and useful machine. I hope you have fun using it.

thanks! I actually have a lot of scrap 80/20 that purchased from a friend and I am planning to use it

for a CNC router build

Could this be built to accommodate a wood cutting router?

Yes it can. The particular motor control system, gantry, and software I used is actually fully capable

of cnc router operations

Awesome! Have you tried putting plexiglass or lexan underneath a thin sheet of sacrificial metal for

spark? Then assemble in layers in bass relief for contouring? Always wanted to try it with led light

strips for accenting.

the sparks from the metal may get embedded in the plexyglass

Several advantages with building your own instead of buying one:

- Lower cost than retail purchase price.

- You can diagnose an issue without having to call in a service.

- Repair costs are lower.

Very good. In the 70's, I worked in a Colorado machine tool manufacturer (Heath Engineering) that

built oxy-fuel, optical tracing, shape cutters. In the 80's, the company started adding plasma

cutters, by the time ESAB bought us, we were working on a line of smaller "garage scale"

machines very similar to your idea. Having built quite a few of these, although many years ago and

quite different technology, I can say with some experience that this is a great tool, built right, and I

admire your work.

Really great project build & 'ible! Glad to see you've monetized it as well - paid for itself yet?

Ah, the beauty of instructables! :D

I enjoy seeing simple I-might-do-this-sometime projects, and in the next moment seeing insanely

complicated never-gonna-do-it projects, too!

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 25

While I may never build anything like this, seeing your various techniques and final result are both

educational and inspirational. Well done all around, thank you for sharing this!

I feel the same way you do. From simple to complex, the creativity on display through Instructables

is amazing.

Thanks for the kind words! Glad to share! I too enjoy seeing the wide range of projects and

techniques posted here. Browsing through the projects always stirs up ideas for me!

I am a teacher at a Senior High School. We have a new Head of Department now, who is very

keen too 'drag our department into the 21st century.'

This idea of yours is awesome. I will let you know how I/we get on.

Thanks for this,

Domo Arigato,

Hitrd

(Heading in the right direction)

This would be an excellent project for a set of high school students to tackle. Let me know if you

have any questions along the way. Happy to help! Thanks

Nice. I bet it cost a small fortune though even with you doing the labour.

Thanks! In total (not including the plasma cutter and air compressor) I spent about 7k on

components and materials

Wow. Not bad. Cheaper than I thought. Out of curiosity how do you set z height on it? It must be a

certain distance for it to work, so is it set manually or? Just wondering.

This system has z-axis torch height control that automatically maintains a specified distance

between the tip and work piece. Prior to cutting, I set a THC voltage value in the control system

that is based on material type, thickness, and cutting amperage. This is a must have feature in my

opinion

Wow wow wow! Amazing work.

Thanks!

Home Built 4x8ft CNC Plasma Metal Cutting System: Page 26

You might also like

- 2430 & TB2448 ComarisionDocument6 pages2430 & TB2448 ComarisionpiyushNo ratings yet

- (Byoung K. Choi, Robert B. Jerard (Auth.) ) Sculptu (B-Ok - Xyz) PDFDocument376 pages(Byoung K. Choi, Robert B. Jerard (Auth.) ) Sculptu (B-Ok - Xyz) PDFgande10No ratings yet

- Catalogue For C6236 PDFDocument2 pagesCatalogue For C6236 PDFSomasekhar Koushik AyalasomayajulaNo ratings yet

- Mill Certification: Other Test ResultsDocument1 pageMill Certification: Other Test ResultsAlonso FraireNo ratings yet

- Introduction CNC PlasmaDocument2 pagesIntroduction CNC PlasmaHaziq PazliNo ratings yet

- Hot Wire CNC Foam CutterDocument12 pagesHot Wire CNC Foam CutterrevildaNo ratings yet

- CNC and Part ProgramDocument54 pagesCNC and Part ProgramAkatew Haile Mebrahtu100% (1)

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDocument43 pagesComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiNo ratings yet

- Implementation of A Low Cost CNC Machine With A DCM Based Servo-Motor For Router MovementDocument62 pagesImplementation of A Low Cost CNC Machine With A DCM Based Servo-Motor For Router Movementakisseh soneNo ratings yet

- AXBB E ManualDocument29 pagesAXBB E ManualKenny HebertNo ratings yet

- ME2252 MT2 Lecture Notes PDFDocument237 pagesME2252 MT2 Lecture Notes PDFnallsrajjNo ratings yet

- Chapter 6 High Speed MachiningDocument31 pagesChapter 6 High Speed Machiningmuhamadsaidi100% (5)

- CNC SoftwareDocument11 pagesCNC SoftwareTegoeh SankenryokuNo ratings yet

- High Speed Machining (HSM) : Seminar OnDocument26 pagesHigh Speed Machining (HSM) : Seminar OnAnonymous LFgO4WbID100% (2)

- 802600r4 Lift PDFDocument20 pages802600r4 Lift PDFEliane SouzaNo ratings yet

- Tronxy x1 Assembly GuideDocument26 pagesTronxy x1 Assembly GuideВайсер Евгений100% (1)

- CNC MachineDocument24 pagesCNC MachinePatel Nikhil0% (1)

- Plastic Molding MachineDocument46 pagesPlastic Molding Machinenthung114No ratings yet

- Experiment No: 3: AIM: To Study About Flexible Manufacturing SystemDocument17 pagesExperiment No: 3: AIM: To Study About Flexible Manufacturing SystemHarshal HodarNo ratings yet

- CNC MachineDocument70 pagesCNC Machinejacky hansdah100% (1)

- Eng - DNM Ii - 1401 - Su - E20Document20 pagesEng - DNM Ii - 1401 - Su - E20Nikolat840% (1)

- Recent Trends in ManufacturingDocument13 pagesRecent Trends in ManufacturingAmbarish100% (2)

- Abdul Azwan Abdol ZaharDocument24 pagesAbdul Azwan Abdol ZaharthuongviedamNo ratings yet

- Cncpresentation PDFDocument37 pagesCncpresentation PDFCorey YoungNo ratings yet

- NC Machining Technique01Document112 pagesNC Machining Technique01Dark ShadowNo ratings yet

- Manual Contorl CNCDocument89 pagesManual Contorl CNCSebastian Almaraz UnzuetaNo ratings yet

- 5 Axis MachineDocument13 pages5 Axis Machinesteel6000100% (2)

- What Is Milling MachineDocument6 pagesWhat Is Milling MachineGlenn VergaraNo ratings yet

- LinuxCNC IntegratorDocument21 pagesLinuxCNC IntegratormilknaniNo ratings yet

- Mayank Jain: - Elex InternationalDocument26 pagesMayank Jain: - Elex InternationalMayank JainNo ratings yet

- Computer Numerical Control (CNC) Machine: Industrial Oriented Mini Project Report ONDocument46 pagesComputer Numerical Control (CNC) Machine: Industrial Oriented Mini Project Report ONMechanical 2-1No ratings yet

- CNC WorkDocument8 pagesCNC Workyeng botzNo ratings yet

- Introduction To CNC ProgrammingDocument28 pagesIntroduction To CNC ProgrammingDIPAK VINAYAK SHIRBHATENo ratings yet

- Axes Design Basics-Apr2018Document76 pagesAxes Design Basics-Apr2018Srinivas MurthyNo ratings yet

- CNC MillingDocument18 pagesCNC MillingShegs Jefferson JosephNo ratings yet

- Incremental Sheet Metal Forming On CNC Milling Machine-ToolDocument4 pagesIncremental Sheet Metal Forming On CNC Milling Machine-ToolDionysius WahyoeNo ratings yet

- CNC and NC MachineDocument36 pagesCNC and NC MachineShaaf AmjadNo ratings yet

- Soft Limit ProcedureDocument11 pagesSoft Limit Procedureradio-chaserNo ratings yet

- Cam Lab ManualDocument14 pagesCam Lab Manualelangandhi0% (1)

- Training Programme On CNC LatheDocument33 pagesTraining Programme On CNC Lathesharafudheen_sNo ratings yet

- Tool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesDocument7 pagesTool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesseventhsensegroupNo ratings yet

- Century Star CNC System Programming Guide For Milling Machines PDFDocument147 pagesCentury Star CNC System Programming Guide For Milling Machines PDFDiego Steven Pulido AriasNo ratings yet

- Comparative Study of CNC Controllers Used in CNC Milling MachineDocument9 pagesComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALNo ratings yet

- Elements of CNC MachineDocument40 pagesElements of CNC MachineAmit Vijhani100% (2)

- CNC PDFDocument99 pagesCNC PDFAdrianNo ratings yet

- Numerical ControllerDocument157 pagesNumerical ControllerDhaval PatelNo ratings yet

- Tools & Work Holding Devices in CNC MachinesDocument17 pagesTools & Work Holding Devices in CNC MachinesAhtisham AmjadNo ratings yet

- CNC Plasma TableDocument37 pagesCNC Plasma Tablenjsoffice100% (1)

- Injection Mold DesignDocument23 pagesInjection Mold DesignernestomucardoNo ratings yet

- CNC Programming & Application: Federal TVET Institute Manufacturing Technology Department Addis Abeba EthiopiaDocument58 pagesCNC Programming & Application: Federal TVET Institute Manufacturing Technology Department Addis Abeba EthiopiaGezae MebrahtuNo ratings yet

- Jdsw51a Usb Mach3 (Blue) - 5aixsDocument36 pagesJdsw51a Usb Mach3 (Blue) - 5aixsabelmil123No ratings yet

- 12 Different Types of CNC Machine (Complete Guide) & PDFDocument16 pages12 Different Types of CNC Machine (Complete Guide) & PDFAK KHANNo ratings yet

- Sprintcut PDFDocument5 pagesSprintcut PDFpruthiviraj13100% (1)

- Semi Automatic Lathe Machine Using ARM ProcessorDocument7 pagesSemi Automatic Lathe Machine Using ARM ProcessorIRJIENo ratings yet

- Home Built 4x8ft CNC Plasma Cutting System: InstructablesDocument24 pagesHome Built 4x8ft CNC Plasma Cutting System: Instructablesanwar ap100% (2)

- Internship ReportDocument12 pagesInternship ReportNirav100% (1)

- Building A CNC RouterDocument42 pagesBuilding A CNC RouterPheetonks HadiwijotoNo ratings yet

- Building A 40 Ton Hydraulic Press Brake MachineDocument28 pagesBuilding A 40 Ton Hydraulic Press Brake MachineIfeanyi ObuaNo ratings yet

- Madde Welabu University School of EngineeringDocument6 pagesMadde Welabu University School of Engineeringzelalem wegayehuNo ratings yet

- Machine Shop Tools and Shop Practice 1911Document564 pagesMachine Shop Tools and Shop Practice 1911john silver100% (1)

- Friedensreich Hundertwasser Graphic Works: Pucker Gallery BostonDocument30 pagesFriedensreich Hundertwasser Graphic Works: Pucker Gallery BostonLaura LandazábalNo ratings yet

- Alwyn Chandler MOS 5301 Fire Protection Technology Dr. MosesDocument4 pagesAlwyn Chandler MOS 5301 Fire Protection Technology Dr. MosesYogo Otieno CamlusNo ratings yet

- 3.1 1P SL CutoutDocument1 page3.1 1P SL CutoutSalman AlyazouriNo ratings yet

- Casting, Welding, Machine Tools, Material SCDocument240 pagesCasting, Welding, Machine Tools, Material SCPrabhat YadavNo ratings yet

- Rotational MouldingDocument42 pagesRotational MouldingMercyJatindroNo ratings yet

- American Woodworker - 123 (September 2006)Document65 pagesAmerican Woodworker - 123 (September 2006)Emilian Baluta100% (3)

- Exp 4Document11 pagesExp 4masuma lovelyNo ratings yet

- Electrochemistry: Exercise 1 Rusting of MetalDocument5 pagesElectrochemistry: Exercise 1 Rusting of MetalSansen Diamante Colipano Jr.No ratings yet

- VLÄTKRIG InstructionsDocument2 pagesVLÄTKRIG InstructionsEscargotNo ratings yet

- PTA Welding and HardfacingDocument16 pagesPTA Welding and Hardfacingpavi32No ratings yet

- BASIC MACHINE TOOL OPERATIONS QuestionsDocument9 pagesBASIC MACHINE TOOL OPERATIONS QuestionsMeir Gavinson Seroy NamocoNo ratings yet

- Starting Woodturning A Beginners GuideDocument15 pagesStarting Woodturning A Beginners GuideSameh_Abd_Aziz75% (4)

- STP 494-1971Document32 pagesSTP 494-1971ahmadmubarakaliasNo ratings yet

- BS 970 Part 2 PDFDocument16 pagesBS 970 Part 2 PDFJoe AggarwalNo ratings yet

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Document36 pages'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Veeralekshmanan KumarNo ratings yet

- Mix Design For Segments of 80 MPaDocument4 pagesMix Design For Segments of 80 MPaForood TorabianNo ratings yet

- TD If 9009ltDocument4 pagesTD If 9009ltbehzadNo ratings yet

- Brown Staining Galvanized CoatingsDocument1 pageBrown Staining Galvanized CoatingspennacchiettiNo ratings yet

- Biofuels Bioprod Bioref - 2009 - LarsonDocument21 pagesBiofuels Bioprod Bioref - 2009 - LarsonNamrah ShumailNo ratings yet

- Esab Ferroweld1Document1 pageEsab Ferroweld1Gokul RajanNo ratings yet

- Drying EquipmentDocument9 pagesDrying EquipmentEngr Saad AhmedNo ratings yet

- 2.AquaArm SBS 3000XDocument3 pages2.AquaArm SBS 3000XBijaya RaulaNo ratings yet

- Proofex GPE: Cold Applied Polymer Modified Bitumen Waterproofing Sheet MembraneDocument3 pagesProofex GPE: Cold Applied Polymer Modified Bitumen Waterproofing Sheet Membranemarzuki0202No ratings yet

- FINAL SMAW-12-Quarter-3-module 3 PDFDocument20 pagesFINAL SMAW-12-Quarter-3-module 3 PDFRandy Sacatani100% (1)

- BOSTIK Boscoprime 1 Rev1-MinDocument2 pagesBOSTIK Boscoprime 1 Rev1-MinBuana Paksa OfficialNo ratings yet

- The New Generation of Thin-Slab Casting and Rolling Plant For No Production and Market LimitationsDocument6 pagesThe New Generation of Thin-Slab Casting and Rolling Plant For No Production and Market LimitationsJJNo ratings yet