Professional Documents

Culture Documents

Product: Chocking & Anchor Bolt Setting Compound

Product: Chocking & Anchor Bolt Setting Compound

Uploaded by

Fajri AnnamlaCopyright:

Available Formats

You might also like

- Shell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsMiguel ArizaNo ratings yet

- ASTM D2196 - 15 Standard Test MethodDocument2 pagesASTM D2196 - 15 Standard Test MethodRenzo PONo ratings yet

- 116-117 Grade BeamDocument2 pages116-117 Grade Beamlala lalaNo ratings yet

- 04 HT - Chockfast OrangeDocument2 pages04 HT - Chockfast OrangeGESTION Y CONTROL DE PROYECTOS IngeminNo ratings yet

- Chock FastDocument2 pagesChock FastredsilverNo ratings yet

- Chockfast Orange PDFDocument2 pagesChockfast Orange PDFKaharul AfandiNo ratings yet

- Chockfast Orange DataDocument2 pagesChockfast Orange DataDilnesa EjiguNo ratings yet

- Datasheet Chockfast RedDocument2 pagesDatasheet Chockfast RedAlexander0% (1)

- Data Sheet Mortero (Grout) Epóxico Chockfast Red PDFDocument2 pagesData Sheet Mortero (Grout) Epóxico Chockfast Red PDFDaniel Puello RodeloNo ratings yet

- Datasheet Chockfast OrangeDocument2 pagesDatasheet Chockfast OrangeOdlanier José MendozaNo ratings yet

- 659H-Chockfast-Orange-TDS Web A4 6 2021Document2 pages659H-Chockfast-Orange-TDS Web A4 6 2021febriNo ratings yet

- Datasheet Chockfast BlackDocument2 pagesDatasheet Chockfast BlackOdlanier José MendozaNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- Mobilgrease 28Document2 pagesMobilgrease 28Jeef100% (1)

- Duraplate Uhs EnglishDocument4 pagesDuraplate Uhs EnglishLuis JaraNo ratings yet

- 7-1881 TDS Blue LP Liquid EpoxyDocument2 pages7-1881 TDS Blue LP Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- Sikadur 42 Gorut Palk LE - CaDocument2 pagesSikadur 42 Gorut Palk LE - Carobert benavidesNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed Nouzer100% (1)

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Chock FastDocument25 pagesChock FastBrajko NikolaNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- 3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Document2 pages3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Massimiliano VolaNo ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enAndres Rodriguez HerreraNo ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- 21.00078 Classic - TDS - CA - v6Document2 pages21.00078 Classic - TDS - CA - v6beattiecNo ratings yet

- InstructionsDocument2 pagesInstructionsmithuntcvNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- SikaAnchorFix2Arctic PdsDocument4 pagesSikaAnchorFix2Arctic PdsDragoș SturzoiuNo ratings yet

- Product Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichDocument2 pagesProduct Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichJORGE HOLGUINNo ratings yet

- Hips 8350Document2 pagesHips 8350mohamad mostafaviNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- PDS-PITTWRAP CF Jacket-EnDocument9 pagesPDS-PITTWRAP CF Jacket-EnChristian DoriaNo ratings yet

- ABS Cycolac X37Document3 pagesABS Cycolac X37countzeroaslNo ratings yet

- Five Star Rapid Epoxy GroutDocument2 pagesFive Star Rapid Epoxy GroutJohnprasannaNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Sikagrout - 528 SFDocument4 pagesSikagrout - 528 SFManuel CardosoNo ratings yet

- Datasheet CG60Document3 pagesDatasheet CG60ouss oussNo ratings yet

- Gac 244Document2 pagesGac 244mohamad mostafaviNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Gac 250Document2 pagesGac 250mohamad mostafaviNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- 7-1883 TDS Grey Liquid EpoxyDocument2 pages7-1883 TDS Grey Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- Duralprep A.C.: Bonding Agent and Anti-Corrosion CoatingDocument2 pagesDuralprep A.C.: Bonding Agent and Anti-Corrosion Coatingaandueza_1No ratings yet

- Pds CPD Sikadur55SLV UsDocument2 pagesPds CPD Sikadur55SLV UsMikeNo ratings yet

- 6210GCFNC1 英文物性表 20161122Document1 page6210GCFNC1 英文物性表 20161122Sơn Nguyễn ĐắcNo ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- Raychem Shrink SleevesDocument12 pagesRaychem Shrink SleevesislamakthamNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- Abs 250Document2 pagesAbs 250mohamad mostafaviNo ratings yet

- 3C Phet Projectiles Lab WKSHT DraftDocument2 pages3C Phet Projectiles Lab WKSHT Draftmaemma olivarNo ratings yet

- TAC Xenta 411/412: Digital Input ModuleDocument3 pagesTAC Xenta 411/412: Digital Input ModuleTeddy HariyantoNo ratings yet

- 1972 PHD HooftDocument134 pages1972 PHD HooftolgerrenekoopNo ratings yet

- Connection Design ManualDocument34 pagesConnection Design ManualAlaa AssiNo ratings yet

- 11.stresses in Soil Mass 16-9Document23 pages11.stresses in Soil Mass 16-9Samirsinh ParmarNo ratings yet

- HydrualicsDocument6 pagesHydrualicsShahd ElfkiNo ratings yet

- Paraffin WaxDocument5 pagesParaffin WaxJoseph0% (1)

- Photochemistry and SpectrosDocument41 pagesPhotochemistry and Spectrosyt HehkkeNo ratings yet

- Cladding of Low-Carbon Steel To Austenitic Stainless Steel by Hot-Roll Bonding: Microstructure and Mechanical Properties..Document13 pagesCladding of Low-Carbon Steel To Austenitic Stainless Steel by Hot-Roll Bonding: Microstructure and Mechanical Properties..Rami GhorbelNo ratings yet

- Hydrovane. Compresor A Paletas.Document24 pagesHydrovane. Compresor A Paletas.Juan M Flores MNo ratings yet

- Pointer Thermometer Messko MT-ST Compact / Messko MT-ST Compact RMDocument92 pagesPointer Thermometer Messko MT-ST Compact / Messko MT-ST Compact RMfreescalerNo ratings yet

- Multiferroic Materials: Shruti K.J Sanskrita M.Tech (Im) ROLL NO-185503Document27 pagesMultiferroic Materials: Shruti K.J Sanskrita M.Tech (Im) ROLL NO-185503ShrutiNo ratings yet

- Quotation: Home Automation Price ListDocument2 pagesQuotation: Home Automation Price ListUsman khanNo ratings yet

- Experiment 6Document3 pagesExperiment 6Subhasis BiswalNo ratings yet

- PT Acceptance CriteriaDocument8 pagesPT Acceptance Criteriaankit7588No ratings yet

- Voltage Regulation of 3 WFG TransformerDocument6 pagesVoltage Regulation of 3 WFG TransformerSKS_2014No ratings yet

- Physics O LevelDocument32 pagesPhysics O LevelCollins JimNo ratings yet

- Well Integrity Logs: Downhole Casing InspectionDocument10 pagesWell Integrity Logs: Downhole Casing InspectionAG YNo ratings yet

- (Main) : Computer Based Test (CBT)Document9 pages(Main) : Computer Based Test (CBT)Resonance EduventuresNo ratings yet

- Hvac Schematic DiagramDocument2 pagesHvac Schematic DiagramSuan, Mike E.No ratings yet

- Partial DischargeDocument11 pagesPartial DischargeDavid_Allen_007100% (1)

- Evaluation of The NATM Tunnel Load On Concrete Lining Using The Ground Lining Interaction ModelDocument11 pagesEvaluation of The NATM Tunnel Load On Concrete Lining Using The Ground Lining Interaction ModelRAJAT PURWARNo ratings yet

- 04Document1 page04Christine AnunciadoNo ratings yet

- Question # (1) Los: Course Name: Design and Drawing EngineeringDocument1 pageQuestion # (1) Los: Course Name: Design and Drawing EngineeringMohamed TamerNo ratings yet

- Simulation Models For Wind Parks With Variable Speed Wind Turbines in EmtpDocument58 pagesSimulation Models For Wind Parks With Variable Speed Wind Turbines in EmtpDes LawlessNo ratings yet

- Sernak - Geomembrane Hdpe-EngDocument2 pagesSernak - Geomembrane Hdpe-EngmablataNo ratings yet

- MAGWAVE Literature - ServiceDocument3 pagesMAGWAVE Literature - Servicejesus cesar tiburcio pelaezNo ratings yet

- MWA Question Set 1Document2 pagesMWA Question Set 1Mahesh PatelNo ratings yet

Product: Chocking & Anchor Bolt Setting Compound

Product: Chocking & Anchor Bolt Setting Compound

Uploaded by

Fajri AnnamlaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product: Chocking & Anchor Bolt Setting Compound

Product: Chocking & Anchor Bolt Setting Compound

Uploaded by

Fajri AnnamlaCopyright:

Available Formats

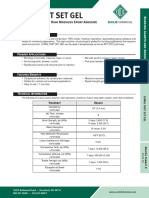

CHOCKFAST Gray

Chocking & Anchor Bolt Setting Compound

Technical Bulletin # 656H

Product Description

CHOCKFAST Gray (PR-610FR) is a specially formulated 100% solids, two component, inert filled

compound developed for use in chocking non-precisely aligned equipment or in setting anchor bolts in

concrete. The compound is designed to withstand severe marine and industrial environments involving a

high degree of both physical and thermal shock. The compound is non-shrinking, non-burning and has a

very high impact and compressive strength. Years of successful experience have shown the use of PR-

610FR to be a far superior yet less expensive method of establishing and retaining equipment alignment

under extreme conditions. When poured as a continuous chock under deck equipment, CHOCKFAST

Gray provides a corrosion proof moisture seal. PR-610FR is approved or accepted for marine use by

A.B.S., Coast Guard, Lloyd's Register and other regulatory agencies.

Use & Benefits

CHOCKFAST GRAY was developed as a chocking compound for use under marine deck machinery,

pumps, generators and steering gears. Industrially, the compound is used under diesel engines,

generators, compressors, pumps, turbines, bearing blocks, crane rails and numerous other applications.

It is also used extensively in the setting of anchor bolts into concrete.

When used as a chocking compound for machinery, the CHOCKFAST Gray provides perfectly even

support without the tedious hand packing associated with conventional cement grouts. Because the

compound flows readily, much thinner cross sections can be used. The compound is also completely

chemical and oil resistant, will not powder or crack with age, weathering, or freeze-thaw cycling, and will

seal the mounting surfaces protecting them from deterioration. Steel soleplates and rails between the

machinery and the concrete foundations are not necessary with CHOCKFAST Gray.

Other successful applications of CHOCKFAST GRAY include mounting of crane rails, chocking of crane

bull gears, chocking of machine shop machinery, sealing of cable penetrations, and as a filler to dampen

machinery vibrations.

Design Considerations

CHOCKFAST Gray may be used where equipment alignment does NOT have to be maintained precisely

o o

AND the equipment’s normal operating temperature is below 125 F (52 C). Examples of this class of

machinery include winches, pumps, skid mounted diesel generators and other self-contained equipment.

CHOCKFAST Gray works best when poured at a depth of between ½” to 2” (12 mm to 50 mm). Please

consult your CHOCKFAST distributor or ITW Philadelphia Resins if you need to pour CHOCKFAST Gray

outside of these limits.

Application Instructions

CHOCKFAST Gray requires no special tools or special skills as does chocking with steel. When cast,

CHOCKFAST GRAY flows readily into chock area filling all voids and conforming to all irregularities. This

eliminates the machining of base plates or foundations for a perfectly fitted chock.

o o o o

To facilitate mixing and pouring, store CHOCKFAST Gray at 68 to 77 F (20 to 25 C) for 12 to 24 hours

prior to mixing. Pour the entire contents of the hardener container into the resin container and power mix

using a Jiffy Mixing blade at 250 to 450 RPM for 3 to 5 minutes. Scrape the side and bottom of the

container with the mixing blade. Do not allow air to be drawn into the mixture.

o o

Precondition the surrounding metal and/or concrete surfaces to at least 55 F (13 C). Pour the mixed

CHOCKFAST Gray into the overpour area of one end of a prepared mold. Allow the epoxy to flow under

the mounting foot, pushing the air out ahead of it. Fill the overpour to at least 1/2” (12mm) above the

mounting foot at the highest point in the chock. Do not scrape epoxy from the sides or bottom of the

container when pouring.

ITW POLYMER TECHNOLOGIES

130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688

CHOCKFAST Gray

Bulletin No. 656H Page 2

Physical Properties

2

COMPRESSIVE STRENGTH 16,000 psi (1,125 kg/cm ) ASTM C-695

2

COMPRESSIVE MODULUS OF ELASTICITY 520,000 psi (36,568 kg/cm ) ASTM C-695

LINEAR SHRINKAGE 0.0003 in/in (0.0003 mm/mm) ASTM D-2566

-6

COEFFICIENT OF LINEAR THERMAL 16.8 x 10 /F° @ 32°F to 140°F ASTM D-696

-6

EXPANSION (30.3 x 10 /C° @ 0°C to 60°C)

FLEXURAL STRENGTH ASTM C-582

FLEXURAL MODULUS OF ELASTICITY ASTM C-582

2

TENSILE STRENGTH 4,000 psi (281 kg/cm ) ASTM D-638

IZOD IMPACT STRENGTH 7.2 in.lbs./in. (0.32 N-m/cm) ASTM D-256

FIRE RESISTANCE Self-extinguishing ASTM D-635

o o

SERVICE TEMPERATURE Up to 52 C (125 F)

VIBRATION RESISTANCE Pass 33 cps @ 0.02 in. (0.51mm) amplitude

Total cycles 237,600

THERMAL SHOCK RESISTANCE Pass 20°F to 200°F (– 6.5°C to + 93°C)

CORROSION RESISTANCE Pass FTM 151A @ 96 hrs.

0.5% NaC1 96°F (35°C) Fog

SPECIFIC GRAVITY 1.82

HARDNESS 35-40 ASTM D-2583

Product Information

UNIT COVERAGE:

Small Unit - 187 cu.in. (3.06 liters)

Large Unit - 816 cu.in. (13.37 liters)

o o o o

APPLICATION TEMPERATURE 55 F (13 C) to 95 F (35 C)

UNIT WEIGHT: Small Unit: Resin (NH) – 12.5 lbs. (5.6 kg), 0.76 gal

(2.9 L) in a 1 gal can, Hardener (H) – 0.6 lbs., (0.3

kg), 0.3 L (9 oz) in an 8 oz plastic bottle

Large Unit: Resin (NH) – 53.5 lbs. (24.3 kg), 3.2 gal

(12 L) in a 5 gal bucket, Hardener (H) – 2.6 lbs. (1.2

kg), 40 oz (1.2 L) in a ½ gal can

UNIT SHIPPING WEIGHT Small Unit: 5.9 kg (13 lbs), Large Unit: 56 lbs. (25.5 kg)

CURE TIME (approximate): 18 hrs. @ 85°F (30°C)

24 hrs. @ 65°F (18°C)

POT LIFE: 30-40 mins. @ 70F (21C)

SHELF LIFE: 2 Years

CLEAN UP: IMPAX IXT-59 Solvent or equal

Reference For design considerations and application details please request Bulletin No. 692 or

contact ITW Philadelphia Resins' Engineering Services Department.

Date 01/2012

General: Every reasonable effort is made to insure the technical Suggestions concerning the use of products are not warranties.

information and recommendations on these data pages are true and The purchaser assumes the responsibility for determining

accurate to the best of our knowledge at the date of issuance. suitability of products and appropriate use. ITW Philadelphia

However, this information is subject to change without notice. Prior Resins’ sole liability, for breach of warranty, negligence or

versions of this publication are invalid with the release of this version. otherwise, shall be the replacement of product or refund of the

Products and information are intended for use by qualified applicators purchase price, at ITW Philadelphia Resins’ election. Under no

that have the required background, technical knowledge, and circumstances shall ITW Philadelphia Resins be liable for any

equipment to perform said tasks in a satisfactory manner. Consult indirect, incidental or consequential damages.

your local distributor for product availability, additional product Modification of Warranty: No distributor or sales representative

information, and technical support. has the authority to change the above provisions. No change in

Warranty: ITW Philadelphia Resins, a division of Illinois Tool Works the above provisions will be valid unless in writing and signed by an

Inc., warrants that its products meet their printed specifications. This officer or the Technical Director of ITW Philadelphia Resins. No

is the sole warranty. This warranty expires one year after product term of any purchase order shall serve to modify any provision of

shipment. this document.

Warranty Claims: If any product fails to meet the above, ITW Mediation and Arbitration: If any dispute arises relating to

Philadelphia Resins will, at its option, either replace the product or products or product warranties, either the purchaser or ITW

refund the purchase price. ITW Philadelphia Resins will have no other Philadelphia Resins may a) initiate mediation under the then

liability for breach of warranty, negligence, or otherwise. All warranty current Center for Public Resources (CPR) Model Procedure for

claims must be made in writing within one year of the date of shipment. Mediation of Business Disputes, or b) initiate a non-binding

No other claims will be considered. arbitration under the rules of the American Arbitration

Disclaimer: ITW Philadelphia Resins makes no other warranty, Association for the resolution of commercial disputes.

expressed or implied, and specifically disclaims any warranty of

merchantability or fitness for a particular purpose.

You might also like

- Shell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsMiguel ArizaNo ratings yet

- ASTM D2196 - 15 Standard Test MethodDocument2 pagesASTM D2196 - 15 Standard Test MethodRenzo PONo ratings yet

- 116-117 Grade BeamDocument2 pages116-117 Grade Beamlala lalaNo ratings yet

- 04 HT - Chockfast OrangeDocument2 pages04 HT - Chockfast OrangeGESTION Y CONTROL DE PROYECTOS IngeminNo ratings yet

- Chock FastDocument2 pagesChock FastredsilverNo ratings yet

- Chockfast Orange PDFDocument2 pagesChockfast Orange PDFKaharul AfandiNo ratings yet

- Chockfast Orange DataDocument2 pagesChockfast Orange DataDilnesa EjiguNo ratings yet

- Datasheet Chockfast RedDocument2 pagesDatasheet Chockfast RedAlexander0% (1)

- Data Sheet Mortero (Grout) Epóxico Chockfast Red PDFDocument2 pagesData Sheet Mortero (Grout) Epóxico Chockfast Red PDFDaniel Puello RodeloNo ratings yet

- Datasheet Chockfast OrangeDocument2 pagesDatasheet Chockfast OrangeOdlanier José MendozaNo ratings yet

- 659H-Chockfast-Orange-TDS Web A4 6 2021Document2 pages659H-Chockfast-Orange-TDS Web A4 6 2021febriNo ratings yet

- Datasheet Chockfast BlackDocument2 pagesDatasheet Chockfast BlackOdlanier José MendozaNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- Mobilgrease 28Document2 pagesMobilgrease 28Jeef100% (1)

- Duraplate Uhs EnglishDocument4 pagesDuraplate Uhs EnglishLuis JaraNo ratings yet

- 7-1881 TDS Blue LP Liquid EpoxyDocument2 pages7-1881 TDS Blue LP Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- Sikadur 42 Gorut Palk LE - CaDocument2 pagesSikadur 42 Gorut Palk LE - Carobert benavidesNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed Nouzer100% (1)

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Chock FastDocument25 pagesChock FastBrajko NikolaNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- 3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Document2 pages3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Massimiliano VolaNo ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enAndres Rodriguez HerreraNo ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- 21.00078 Classic - TDS - CA - v6Document2 pages21.00078 Classic - TDS - CA - v6beattiecNo ratings yet

- InstructionsDocument2 pagesInstructionsmithuntcvNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- SikaAnchorFix2Arctic PdsDocument4 pagesSikaAnchorFix2Arctic PdsDragoș SturzoiuNo ratings yet

- Product Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichDocument2 pagesProduct Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichJORGE HOLGUINNo ratings yet

- Hips 8350Document2 pagesHips 8350mohamad mostafaviNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- PDS-PITTWRAP CF Jacket-EnDocument9 pagesPDS-PITTWRAP CF Jacket-EnChristian DoriaNo ratings yet

- ABS Cycolac X37Document3 pagesABS Cycolac X37countzeroaslNo ratings yet

- Five Star Rapid Epoxy GroutDocument2 pagesFive Star Rapid Epoxy GroutJohnprasannaNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Sikagrout - 528 SFDocument4 pagesSikagrout - 528 SFManuel CardosoNo ratings yet

- Datasheet CG60Document3 pagesDatasheet CG60ouss oussNo ratings yet

- Gac 244Document2 pagesGac 244mohamad mostafaviNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Gac 250Document2 pagesGac 250mohamad mostafaviNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- 7-1883 TDS Grey Liquid EpoxyDocument2 pages7-1883 TDS Grey Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- Duralprep A.C.: Bonding Agent and Anti-Corrosion CoatingDocument2 pagesDuralprep A.C.: Bonding Agent and Anti-Corrosion Coatingaandueza_1No ratings yet

- Pds CPD Sikadur55SLV UsDocument2 pagesPds CPD Sikadur55SLV UsMikeNo ratings yet

- 6210GCFNC1 英文物性表 20161122Document1 page6210GCFNC1 英文物性表 20161122Sơn Nguyễn ĐắcNo ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- Raychem Shrink SleevesDocument12 pagesRaychem Shrink SleevesislamakthamNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- Abs 250Document2 pagesAbs 250mohamad mostafaviNo ratings yet

- 3C Phet Projectiles Lab WKSHT DraftDocument2 pages3C Phet Projectiles Lab WKSHT Draftmaemma olivarNo ratings yet

- TAC Xenta 411/412: Digital Input ModuleDocument3 pagesTAC Xenta 411/412: Digital Input ModuleTeddy HariyantoNo ratings yet

- 1972 PHD HooftDocument134 pages1972 PHD HooftolgerrenekoopNo ratings yet

- Connection Design ManualDocument34 pagesConnection Design ManualAlaa AssiNo ratings yet

- 11.stresses in Soil Mass 16-9Document23 pages11.stresses in Soil Mass 16-9Samirsinh ParmarNo ratings yet

- HydrualicsDocument6 pagesHydrualicsShahd ElfkiNo ratings yet

- Paraffin WaxDocument5 pagesParaffin WaxJoseph0% (1)

- Photochemistry and SpectrosDocument41 pagesPhotochemistry and Spectrosyt HehkkeNo ratings yet

- Cladding of Low-Carbon Steel To Austenitic Stainless Steel by Hot-Roll Bonding: Microstructure and Mechanical Properties..Document13 pagesCladding of Low-Carbon Steel To Austenitic Stainless Steel by Hot-Roll Bonding: Microstructure and Mechanical Properties..Rami GhorbelNo ratings yet

- Hydrovane. Compresor A Paletas.Document24 pagesHydrovane. Compresor A Paletas.Juan M Flores MNo ratings yet

- Pointer Thermometer Messko MT-ST Compact / Messko MT-ST Compact RMDocument92 pagesPointer Thermometer Messko MT-ST Compact / Messko MT-ST Compact RMfreescalerNo ratings yet

- Multiferroic Materials: Shruti K.J Sanskrita M.Tech (Im) ROLL NO-185503Document27 pagesMultiferroic Materials: Shruti K.J Sanskrita M.Tech (Im) ROLL NO-185503ShrutiNo ratings yet

- Quotation: Home Automation Price ListDocument2 pagesQuotation: Home Automation Price ListUsman khanNo ratings yet

- Experiment 6Document3 pagesExperiment 6Subhasis BiswalNo ratings yet

- PT Acceptance CriteriaDocument8 pagesPT Acceptance Criteriaankit7588No ratings yet

- Voltage Regulation of 3 WFG TransformerDocument6 pagesVoltage Regulation of 3 WFG TransformerSKS_2014No ratings yet

- Physics O LevelDocument32 pagesPhysics O LevelCollins JimNo ratings yet

- Well Integrity Logs: Downhole Casing InspectionDocument10 pagesWell Integrity Logs: Downhole Casing InspectionAG YNo ratings yet

- (Main) : Computer Based Test (CBT)Document9 pages(Main) : Computer Based Test (CBT)Resonance EduventuresNo ratings yet

- Hvac Schematic DiagramDocument2 pagesHvac Schematic DiagramSuan, Mike E.No ratings yet

- Partial DischargeDocument11 pagesPartial DischargeDavid_Allen_007100% (1)

- Evaluation of The NATM Tunnel Load On Concrete Lining Using The Ground Lining Interaction ModelDocument11 pagesEvaluation of The NATM Tunnel Load On Concrete Lining Using The Ground Lining Interaction ModelRAJAT PURWARNo ratings yet

- 04Document1 page04Christine AnunciadoNo ratings yet

- Question # (1) Los: Course Name: Design and Drawing EngineeringDocument1 pageQuestion # (1) Los: Course Name: Design and Drawing EngineeringMohamed TamerNo ratings yet

- Simulation Models For Wind Parks With Variable Speed Wind Turbines in EmtpDocument58 pagesSimulation Models For Wind Parks With Variable Speed Wind Turbines in EmtpDes LawlessNo ratings yet

- Sernak - Geomembrane Hdpe-EngDocument2 pagesSernak - Geomembrane Hdpe-EngmablataNo ratings yet

- MAGWAVE Literature - ServiceDocument3 pagesMAGWAVE Literature - Servicejesus cesar tiburcio pelaezNo ratings yet

- MWA Question Set 1Document2 pagesMWA Question Set 1Mahesh PatelNo ratings yet