Professional Documents

Culture Documents

Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING STABILITY" Boca Raton: CRC Press LLC, 2000

Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING STABILITY" Boca Raton: CRC Press LLC, 2000

Uploaded by

obricenoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING STABILITY" Boca Raton: CRC Press LLC, 2000

Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING STABILITY" Boca Raton: CRC Press LLC, 2000

Uploaded by

obricenoCopyright:

Available Formats

Anderson, Loren Runar et al "RING STABILITY"

Structural Mechanics of Buried Pipes

Boca Raton: CRC Press LLC,2000

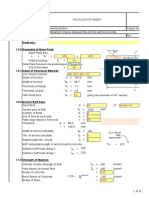

Figure 10-1 Top — Elliptical ring with uniform radial pressure P acting on it.

Bottom — Free-body-diagram of half of the elliptical ring showing approximate ring compression thrust in

the walls due to pressure P.

©2000 CRC Press LLC

CHAPTER 10 RING STABILITY

The performance limit of ring stability is instability. Performance limit is wall crushing. The ring

Ring instability is a spontaneous deformation that deformation collapse equation is a function of ring

progresses toward inversion (reversal of curvature). stiffness, EI/r3. Performance limit is inversion. Ring

At worst, instability is ring collapse. Buried pipes stiffness is related to pipe stiffness; i.e., F/∆ =

can invert only if the ring deflects and the soil slips 53.77EI/D3. Pipe stiffness can be measured by a

at the same time. Instability of buried pipes is parallel plate test or three-edge-bearing test. The

analyzed as a soil-structure interaction. The ring deformation collapse equation is based on

stiffness of the ring resists inversion. Soil supports assumptions that the ring is elastic, and that the pipe

the ring by holding it in a stable (near circular) is restrained longitudinally. Longitudinal restraint

shape. Soil resists inversion of the ring. results in a plane stress analysis. The Poisson ratio

is not included.

Two basic modes of ring instability are: 1. ring

compression, i.e., wall crushing or buckling at yield In a plane strain analysis, longitudinal stress is zero,

stress; and 2. ring deformation. See Figure 10-1. the Poisson ratio is included, and the pressure at

Each is analyzed separately. Instabilities of buried collapse is,

and unburied rings are also analyzed separately.

Pcr = 3EI/r3(1-ν2),

UNBURIED RING COLLAPSE where

Pcr = critical pressure, i.e., P at collapse,

From Chapters 2 and 5, external pressure at collapse ν = Poisson ratio = 0.27 for steel,

of an unburied thin-walled, circular, elastic ring is EI/r3 = ring stiffness.

found from the equations:

The difference in fluid pressures between top and

Pr/A = σf RING COMPRESSION COLLAPSE bottom of the pipe is usually ignored, but may be

significant. For plane stress analysis of critical

Pr3/EI = 3 RING DEFORMATION pressure at collapse of circular, unburied pipes,

COLLAPSE

where Pcr = 3EI/r3 . . . . . (10.1)

P = external pressure at collapse,

r = mean circular radius of ring, For plain pipes (not coated, lined, rib stiffened, or

A = wall area per unit length, corrugated), critical pressure at collapse is,

t = wall thickness of plain pipe,

m = r/t = ring flexibility, Pcr = E/4m3 . . . . . (10.2)

do = initial ring deflection (ellipse),

E = modulus of elasticity,

I = moment of inertia of the cross-sectional Moment of Inertia, I

area of the wall per unit length,

σf = yield strength, In order to evaluate ring stiffness, EI/r3, the moment

Pcr = critical pressure on the circular ring. of inertia, I, must be known. For plain pipes, I =

t3/12. For corrugated pipes, tables of values for I

The ring compression collapse equation is a function are found in the manuals provided by manufacturers.

of ring flexibility and yield strength. For steel pipes with lining and coating, consider

©2000 CRC Press LLC

Figure 10-2 Transformed section of a unit slice of mortar-lined and coated steel pipe wall, transformed into

its equivalent section in mortar, for evaluating moment of inertia. Shown on the right is the elastic stress

distribution.

Figure 10-3 Effective T-section , comprising stiffener ring and an effective width of pipe wall — often

assumed to be 50t in steel pipes.

©2000 CRC Press LLC

a unit slice of the wall. See Figure 10-2. Example 1

Discounting conservatively the bond between mortar

and steel, moment of inertia, I, is the sum of the A plain 18-inch high-density polyethylene pipe is

separate moments of inertia of steel, lining, and out-of-round (elliptical) by five percent. It is

coating. Because the mortar is the critical material, unburied. What is the internal vacuum at collapse?

steel is transformed into its equivalent width, n, in

mortar. n = Es /Em . For the layers, ID = 16.217 and t = 0.857,

DR = 21 = OD/t = 2m+1,

Ic = tc 3/12 m = 10 = r/t,

Is = nts3/12 σf = 3.2 ksi = yield strength',

Il = tl3/12, E = 110 ksi = modulus of elasticity,

Pcr = 27.5 psi = E/4m3 from Equation 10.2,

and I = Ic + Is + Il do = 0.05 = initial ring deflection.

For pipes with stiffener rings welded to the pipe, the Substituting into Equation 10.3a, internal vacuum at

moment of inertia is found from the effective T- collapse is, P = 21.5 psi. From Equation 10.3b, P =

s ection. See Figure 10-3. The procedure is 9.2 psi with ample safety factor included.

described in texts on mechanics of solids. For steel

pipes, the T-section comprises the stiffener ring and Example 2

an effective width of pipe wall — in steel usually

assumed to be 50t. The pipe wall between effective Calculate the vacuum at collapse of a mortar-lined

T-sections is ignored in calculating I. and coated steel pipe, for which:

r = 25.5 inch (D = 51 inch for steel),

Elliptical Ring Instability tc = 0.75 inch, Ic = 0.03516 (cr)

ts = 0.175 inch, nIs = 0.00335

Instability of non-circular, unburied rings is difficult tl = 0.5 inch, Il = 0.01042

to analyze. However, analysis is available from Em = 4(106) psi,

texts on mechanics of solids for one important case Es = 30(106) psi,

— a ring that is initially elliptical with ring deflection n = 7.5 = Es /Em ,

d o . Vacuum increases ring deflection. Stress is σf = 10 ksi for mortar (critical),

c ritical at the spring lines, B, where the ring is I = 0.04893 in 3,

subjected to both maximum ring compression stress d = 0 = ring deflection (negligible).

and maximum flexural stress. See Figure 10-1.

Vacuum, P, at collapse is found from: From Equation 10.1, Pcr = 3Σ (Em I/r3). Assuming the

mean radius of the steel is,

P2 - [σf /m + (1+6mdo)Pcr] P + σ f Pcr /m = 0 rs = 25.5, then rc = 25.9625 and rl = 25.1625.

. . . . . (10.3a) Substituting values, Pcr = 32 psi.

Equation 10.3a is applied by plotting values of P as Example 3

a function of m for given values of do and for a

constant σf. For design, a simplification is proposed What does Equation 10.3a reduce to if Pcr = P? It is

by Murphy and Langner (1985), easily shown that all of the terms cancel except

6mdoP, which must be zero. The only way this term

P = Pcr /(1+40d) . . . . . (10.3b) can be zero is if initial ring deflection is do = 0. As

expected, for a circular ring, P = Pcr.

©2000 CRC Press LLC

BURIED RING COLLAPSE plastics (metals), for which wall crushing can occur

only after ring compression stress (not flexural

Stress Analysis of Elliptical Ring stress) reaches yield strength. See Chapter 5.

Therefore, Equation 10-7 is limited. Initial ring

Figure 10-1 is a half ring free-body-diagram. At B deflection, do, depends upon compression of sidefill

the ring compression stress is, which requires analysis of pipe-soil interaction.

σc = P(OD)(1+d)/2A . . . . . (10.4) Equations 10.4 to 10.7 are based on elastic theory.

Under some circumstances, plastic theory is

and the ring deformation stress (flexural stress) is, justified. For plain pipes and corrugated pipes, the

plastic moment (at plastic hinging) is 3/2 times the

σd = Ec(1/r'x - 1/rx) . . . . . (10.5) moment at yield stress by elastic theory.

Notation:

P = vertical external pressure, Ring Deformation Collapse of Buried Pipes

OD = outside diameter of the circular ring,

do = initial ring deflection, For the following analyses, vacuum is negative

d = ring deflection after P is applied, pressure, p, inside the pipe plus positive external

r'x = radius of curvature at B due to initial ring hydrostatic pressure, u. Both affect ring collapse.

deflection do,

rx = radius of curvature at B after vacuum P is Rigid Pipes

applied,

E = modulus of elasticity, Because ring deflection of rigid pipes is negligible,

c = distance from the neutral surface of the rigid pipes are analyzed by ring compression except

wall to the most remote fiber (t/2 for a that vertical pressure on the pipe is P+p

.

plain pipe), Ring compression stress is,

σd = flexural stress caused by ring deformation. σ = (P+p)(OD)/2A . . . . . (10.8)

where

Substituting in values of radii of curvature for the

σ = ring compression stress in the pipe wall,

ellipse from Chapter 3, the equation for flexural (ring

P = total soil pressure at the top of the pipe,

deflection) stress becomes:

including water pressure, u,

p = internal vacuum,

σd = (Ec/r) 3(d-do) / (1-2d-2do) . . . . . (10.6)

OD = outside diameter of the pipe,

A = wall area per unit length of pipe.

The maximum stress is the sum of Equations 10.4

and 10.6; i.e., σ= σ c + σ f. The maximum stress at B

Area A is a transformed section if the wall is

in a buried plain pipe is,

composite such as concrete reinforced with steel

bars. For design, the ring compression stress, σ ,

σ = Pm(1+d) + (E/2m)3(d-do) / (1-2d-2d

. .o). . . (10.7)

from Equation 10.8 is equated to the strength of the

pipe wall, σf, reduced by a safety factor.

where m = r/t = ring flexibility of a plain pipe.

Equation 10.7 can be solved to find vacuum P at

In the case of a very large diameter pipe, it may be

yield stress for brittle (rigid) pipes.

necessary to consider the change in pressure of

liquids (both inside and outside) throughout the depth

But yield stress is not failure for plastics or elasto-

©2000 CRC Press LLC

of the pipe. For example, if the pipe is empty, but σf = (P+p)(1+d)OD/2A . . . . . (10.9)

the water table is above the top of the pipe, it may COLLAPSE BY WALL CRUSHING

be prudent to apply Equation 10.8 to the bottom of where

the pipe where total pressure P, acting up on the σf = ring compression stress at yield stress in

bottom, is greater than prismatic soil pressure on top the pipe wall at B,

by the increase in hydrostatic pressure between the A = wall area per unit length of pipe,

top and bottom. Of course, water inside the pipe will t = wall thickness = A for plain pipes,

negate any increase in external hydrostatic pressure. OD = outside diameter,

It is noteworthy that internal vacuum and external P = external pressure at top of pipe,

hydrostatic pressure have little effect on the opening p = internal vacuum,

of cracks in rigid pipes. The 0.01-inch crack is not d = ∆ D = ring deflection.

a suitable performance limit.

Area, A, is used for transformed composite sections,

or ribbed, or ring-stiffened or corrugated.

Flexible Pipes

At ring deformation collapse the soil must slip in

Collapse of buried flexible pipes is either: 1. wall order for the ring to deflect. See Figure 10-4. In the

crushing (ring compression) or 2. inversion (ring left sketch, the vertical pressure includes soil

deformation). Collapse due to longitudinal bending pressure and vacuum; i.e. PA = P+p. Before it is

is not included in this analysis. Bending deforms the buried, the ring is circular, but as backfill is placed,

pipe cross section into an ellipse with the short the ring deflects into an ellipse.

diameter in the plane of the bend. Bending strength

is decreased. Bending failure is collapse. Following If the ring is flexible, and if shearing stresses

are procedures for evaluating the vacuum at which between pipe and soil are neligible, vertical and

a buried flexible ring collapses. horizontal soil pressures are related as follows:

If the ring could be held circular, analysis would be PArA = PBrB = Pr = constant

simple ring compression — the same as for a rigid

pipe. But flexible ring analysis anticipates ring where Pr is the product of pressure and radius of

deflection, do, before the vacuum is applied. Ring curvature at any point on the circumference of the

deflection depends upon ring stiffness and stiffness ring. For an ellipse,

of the embedment soil. It is assumed that pipes are

initially circular and empty, and that coefficient of rA /rB = (1+d)3/(1-d)3.

friction between the pipe and the backfill is zero

because of the inevitable breakdown of shearing Therefore,

stresses due to earth tremors and changes in

temperature, moisture, and pressures. The PB = PA(1+d)3/(1-d)3 = PAr r . . . . . (10.10)

embedment is assumed to be granular. The flexible

pipe is often assumed to be thin-walled; i.e., OD = where

ID = D = mean diameter of the pipe. rA = mean radius of curvature at the top A,

rB = mean radius of curvature at the side B,

Performance limit is collapse which occurs if the PA = pressure on the pipe at A,

ring either crushes due to ring compression, or PB = pressure on the pipe at B,

inverts due to sidefill soil slip at B. See Figure 10-4. d = /D = initial ring deflection,

rr = (1+d)3/(1-d)3 = ratio of radii.

©2000 CRC Press LLC

p

Figure 10-4 UNSATURATED SOIL — (left) Free-body-diagram of an infinitesimal cube at spring line, B,

showing the stresses at incipient soil slip. (right) Vertical soil pressure, Po, supported by the pipe due to ring

stiffness.

Figure 10-5 Free-body-diagrams for finding the vertical deflection of point B by means of the Castigliano

theorem.

©2000 CRC Press LLC

But for any pipe stiffness, F/∆ (or equivalent ring PB = (PA+p-Po)rr - p

stiffness, 53.77 EI/D3), the ring itself is able to

support part of the vertical pressure as it deflects. See Figure 10-6 for free-body-diagram and

That part of the vertical pressure supported by ring assumptions. For a plain pipe, substituting in Po,

stiffness is Po shown in the sketch on the right of

Figure 10-4. For a given ring deflection, Po can be PB = (PA+uA+p-Ed/m3)rr - p . . . . . (10.11)

calculated by the Castigliano theorem from the free-

body-diagram in Figure 10-5. From the sketch on where

the left, the moment M at point B can be evaluated PB = horizontal pressure of pipe on soil,

by noting that the slope at B does not change during PA = vertical external soil pressure at A,

deflection. θ BA = 0. Knowing M, Castigliano can be p = internal vacuum,

applied again using the sketch on the right from EI/D3 = ring stiffness,

which the vertical deflection, YB, is evaluated for the F/ = 53.77(EI/D3) = pipe stiffness,

virtual load p due to the forces on the ring quadrant. D = mean diameter of the circular ring,

Knowing YB, the ring deflection, d, can be found as r = mean radius of the circular ring = D/2,

a function of EI and Po, and from this relationship, Po t = thickness of the plain pipe wall,

can be found as a function of d. The result is: m = r/t = ring flexibility,

d = ∆ /D = initial ring deflection,

Po = 96(EI/D3)d/(1-2d) rr = (1+d) 3 /(1-d)3 = ratio of vertical and

horizontal radii (maximum and minimum

For small ring deflections, it is conservative to radii of the ellipse).

disregard 2d in the denominator; whereupon, µA = rwh for floods at level h.

Po = Ed/m3 = 96(EI/D3)d If soil at B does not have adequate strength, the soil

slips, and the ring inverts.

where

Po = vertical pressure on top of the pipe Strength of Soil at Spring Lines

that can be supported by ring

stiffness, Because most embedment is granular, the following

Ed/m3 = Po for a plain pipe, is analysis of strength for granular (cohesionless)

EI/D3 = ring stiffness = 0.0186 F/∆ , sidefill. See Figure 10-6. The horizontal strength of

F/∆ = pipe stiffness, soil at point B, at soil slip, is soil passive resistance,

I = moment of inertia of the pipe wall per

unit length of pipe = t3/12 for plain σx = Kσ y

pipe,

t = wall thickness for plain pipe, _where

D = mean diameter, σ = horizontal effective soil stress at B,

_x

r = mean radius of the circular pipe, σ y = vertical effective soil stress at B,

m = r/t = ring flexibility, K = ratio of horizontal to vertical effective

d = ring deflection. stresses at soil slip (ring collapse),

K = (1+sinφ)/(1-sinφ),

φ = friction angle of the embedment, for which

Pressure Against Soil at Spring Lines values can be obtained from tests.

_

The horizontal pressure of the pipe against the soil at σ y can be evaluated at the spring lines by methods

B is reduced by Po; i.e., of Chapter 4.

©2000 CRC Press LLC

x x

Figure 10-6 SATURATED SOIL — Free-body-diagram of an infinitesimal soil cube at B, showing the

stresses acting on it at incipient soil slip, and showing the shear planes at soil slip.

x +u+p

Figure 10-7 Pressure diagram for analyzing critical hydrostatic pressure on the bottom of the pipe at inversion

of the ring from the bottom. rr = ry /rx.

©2000 CRC Press LLC

Vacuum at Collapse of Buried Pipes From Equation 10.13, the vacuum at ring collapse

can be calculated. E/m 3 can be replaced by

The total horizontal soil pressure on the pipe at 96EI/D3, or 1.7856F/∆ for other-than-plain pipes.

spring lines B at soil slip is,

_

If the embedment is not cohesionless, as assumed

PB = Kσy + uB . . . . . (10.12) in the above analysis, the same procedure may be

used except that the relationship between horizontal

where and vertical stresses at soil slip must be evaluated

PB_ = total horizontal pressure on soil at B, for each particular _embedment. In the case of ideal

_

Kσ y = horizontal effective soil slip stress at B, cohesive soil, σ y - σ x = 2C, where C is the cohesion

uB = hydrostatic pressure in the soil at B. of the soil. See Chapter 4.

When the horizontal pressure PB from Equation Below a groundwater table, the hydrostatic pressure

10.11 is equal to PB from Equation 10.12, the soil is on the bottom of the pipe is greater than on top.

on the verge of slipping — instability. For plain Figure 10-7 shows buoyant pressure on the bottom,

pipes, including all of the pertinent variables, the γ w(h+H+D). An empty pipe tends to float, but in

equation of equilibrium of sidefill at soil slip is, this analysis, is assumed to be restrained by the

_ effective soil wedge on top. Collapse occurs from

p'(r r-1) = Kσ y + uB - (PA - Ed/m3)rr . . . . . (10.13) the bottom for large, empty, flexible pipes with a

COLLAPSE BY RING INVERSION water table above the pipe.

where Example 1

p' = vacuum at collapse, A thin-wall, welded steel penstock is 51 inches in

rr = (1+d)3/(1-d)3 = ratio of vertical to diameter with a wall thickness of 0.219 inch. It is

horizontal radii of elliptical pipe, buried in embedment of dry, uncompacted sand to a

m = r/t, height of two ft above the top of the pipe. Unit

r = mean radius of the circular pipe, weight of the sand is 102 pcf. The soil friction angle

t = wall thickness for plain pipe, is 25 o . Ring deflection was not controlled during

d = /D = initial ring deflection — usually due backfilling, so the average initial ring deflection is

to backfilling, 8%. What is the internal vacuum at collapse? The

K = (1+sinφ)/(1-sinφ) at passive resistance, pertinent data are:

φ = friction angle of the embedment, D = 2r = 51 inches,

σy = vertical effective soil stress at B, t = 0.219 inch = average wall thickness,

uB = hydrostatic pressure (pore water pressure) E = 30(106) psi = modulus of elasticity,

at B if a water table is above the pipe, I = 875(10-6) in3 = moment of inertia of

PA = soil and water pressure at A, the wall cross section per inch of

E = modulus of elasticity of pipe material, length of pipe.

I = moment of inertia of the wall cross section EI/D3 = 0.198 psi = ring stiffness,

per unit length of pipe, d = 0.08 = ∆/D = initial ring deflection

E/m = 96EI/D3 where,EI/D3

3

= ring stiffness, before vacuum is applied,

F/∆ = pipe stiffness = 53.77EI/D3.

©2000 CRC Press LLC

H = 2 ft = soil cover, carefully placed and compacted so that ring

γ = 102 pcf = unit weight of soil, deflection will not be excessive.

h = 0 — no water table,

uB = 0 — no hydrostatic pressure at B, Ring Compression:

ϕ = 25o = soil friction angle at the spring lines,

K = 2.464 = ratio of horizontal to vertical Ring compression stress must be less than short-

effective soil stresses at soil slip. term yield. Long-term yield strength does not apply

because, under constant deflection in select

Substituting values into Equation 10.13, p = 11.9 psi embedment, the plastic relaxes faster than the yield

= vacuum at collapse. Increasing ϕ by compacting strength regresses. See Chapter 20.

the soil greatly increases the vacuum at collapse.

Ring Inversion:

Example 2

In evaluating critical pres sure, P, it is assumed that:

Specifications for the penstock of Example 1 limit

ring deflection to 5%. Had ring deflection been 5%, 1. The basic deformation is from circle to ellipse.

what would be the internal vacuum at collapse? 2. Friction between soil and pipe is negligible.

From Equation 10.13, p = 18.7 psi. Because the 3. There is no vacuum in the pipe and no water

maximum vacuum (atmospheric pressure) is only table.

14.7 psi, the pipe would not collapse. This illustrates Equation 10.13 applies. p = 0; uB = 0; and, for high

the importance of limiting ring deflection by soil fills , σ y ≅ P A ≅ P. The critical pressure P is the

compaction if the pipe is to be subjected to vacuum. following in three different forms:

Example 3 P = 8Ed/(DR-1)3(1-K/rr)

Solve Example 1 if ring stiffness is neglected; i.e. the P = Ed/m3(1-K/rr)

pipe is so flexible that ring stiffness cannot be

depended upon to support any of the soil load. With P = 1.7854 (F/ )d/(1-K/rr) . . . . . (10.14)

8% ring deflection, what is the vacuum at collapse?

From Equation 10.13, neglecting the ring stiffness where K = (1+sinϕ)/(1-sinϕ), and r r = (1+d)3/(1-d)3.

term, Ed/m3, vacuum at collapse is, p = 8.0 psi. Ring From Equations 10.14, it is clear that if K > rr, there

stiffness does provide resistance to inversion in loose is no soil slip regardless of soil pressure P. In fact,

soil. P becomes negative.

Equation 10.14 is plotted in Figure 10-8. The vertical

STABILITY DESIGN AND ANALYSIS scale is dimensionless critical soil pressure term,

P/(EI/r3). The soil friction angle of the sidefill is ϕ.

Flexible Pipes Under High Fills With No Internal The horizontal scale is ring deflection d. If the

Vacuum and No Water Table critical soil pressure term, P/(EI/r3), and the ring

deflection term, d, locate a point below or to the left

One example of flexible pipes under high fills is drain of a soil friction curve (ϕ-curve), the buried pipe is

pipes under sanitary landfills. Some sanitary landfills stable. If the point falls above and to the right of a

reach heights of hundreds of feet. They require ϕ-curve, collapse is incipient — not imminent but

drainage by a system of pipes. The leachate may be possible. Collapse may progress over a period of

so corrosive that plastic pipes are specified. For time, due to soil dynamics such as earth tremors,

plastic pipes, the embedment must be select, and wetting and drying, etc.

©2000 CRC Press LLC

Compaction of the embedment has a significant pipe stiffness is F/ = 234 psi for E = 400,000 psi.

effect on stability. No safety factor is included, but From Equation 10.14 if P/(F/ ) = 600(75)/234(144)

soil arching action assures a margin of safety. If = 1.34, and ϕ = 15o, ring deflection at incipient

ring deflection is more than 20%, Equation 10.14 collapse is d = 11.4%.

(Figure 10-8) loses accuracy because of non-

elliptical ring deformation and ring stresses beyond Ring deflection can be controlled by the quality and

elastic limit. Collapse is not a problem if ring density of the sidefill. From laboratory tests, select

deflection is less than about 10% even for very loose crushed stone compacted to 95% density AASHTO

granular soil (ϕ = 15o). In fact, pipes with more than T99 (70% relative density) will hold ring deflection

10% ring deflection are usually rejected for reasons to less than d = 5% under 600 feet of cover at unit

other than structural instability. Including a safety weight of 75 pcf.

factor, if ring deflection is more than 10%, minimum

soil friction angle should be increased — say to ϕ =

30°. With Soil Support — No Water Table or Vacuum

The conditions for stability are assured if the sidefills Performance limit is soil slip of the sidefill. At soil

are good granular soil, carefully compacted, and if slip, the pressure of the pipe against the soil at spring

the ring deflection is less than 10%. Under line is equal to passive soil resistance.

conditions where mitigation is sought, live loads and

height of soil cover can be limited. Prr = Kσ y . . . . . (10.15)

Example P is soil pressure at the top of the pipe. rr =

(1+d)3/(1-d)3. From Equation 10.15, ring deflection,

PVC piping is proposed for drainage under a d, can be found at soil slip.

sanitary landfill that is to be 600 ft high. Unit weight

of the landfill is 75 pounds per cubic feet. Fifteen Example

years are anticipated to complete the landfill. The

piping is to serve for 100 years. What is the ring deflection of a flexible steel pipe at

sidefill soil slip if D = 72 inches and H = 4 ft?

1. What dimension ratio (DR) is required? DR is Embedment is poor, granular, loose soil. Unit weight

the ratio of outside pipe diameter to wall thickness. is γ = 100 pcf. The soil friction angle is assumed to

Assume a 15-year yield strength of 5000 psi for be ϕ = 15o from which, K = (1+sinϕ)/(1-sinϕ) = 1.7.

PVC. Safety factor is to be 1.5. From Equation P = γ H = 400 psf. σy = γ Z = (100pcf)(4ft+3ft) =

10.9, ring compression stress is, σ = 0.5γ H(1+d)DR. 700 psf. For the first trial, let Z = 7 ft. Substituting

For a long-term sanitary landfill, it is prudent, for these values into Equation 10.15,

cleaning the pipes, to hold ring deflection to nearly Prr = (400lb/ft2)(1+d)3/(1-d)3 = 1189 lb/ft2.

zero by compacted select sidefill. Solving Equation Solving, d = 18%. For a second trial, let Z =

10.14 with d = 0, and with a safety factor of 1.5; DR 4ft+2.5ft = 6.5 ft to account for the 18% reduction

= 21.3. Specify PVC pipe SDR 21(200) ASTM D- in vertical diameter of the deflected ring. This

2241. SDR is "standard dimension ratio." It is solution yields d = 17%.

defined the same as DR; i.e., SDR = OD/t. PVC

pipes are resistant to corrosive leachate. The above analysis is conservative because ring

stiffness is ignored. Ring stiffness is included in

2. What is the maximum allowable ring deflection if Figure 10-8 which comprises graphs at soil slip of

embedment is loose with soil friction angle ϕ = 15°? soil pressure as a function of ring deflection and

From the Uni-Bell Handbook, for SDR = 21, the sidefill soil friction angle. It is assumed that soil

©2000 CRC Press LLC

Figure 10-8 UNSATURATED SOIL — Soil pressure term at soil slip as a function of ring deflection and soil

friction angle. Empty steel pipes — no internal vacuum. When used for design, a safety factor should be

considered.

Liquefied Soil — Soil can liquefy if it is saturated,

and shaken, and if density is less than about 80%,

AASHTO T-180. The concept of liquefaction is as

follows. Pour loose dry sand into a quart jar to the

top. Carefully fill to the top with water. Replace

the lid. Shake the jar, remove the lid and turn the jar

upside down. Liquefied soil gushes out because the

sand is "shaken down." Repeat the experiment, but,

this time, densify (tamp) the sand in layers as it is

placed in the quart jar. Then fill to the top with

water, replace the lid, shake, remove the lid, and turn

upside down. The wet sand "hangs up" in the jar. It

has not liquefied. In fact, the soil strength has

increased because the sand is "shaken up."

Figure 10-9 Conditions for collapse of a flexible ring

in liquefied embedment.

©2000 CRC Press LLC

cover is high enough that H is essentially equal to Z. h = height of water table above invert,

Figure 10-9 shows interrelationships of the pertinent P = hγ

variables. Two important conclusions are:

Solving, h = 5.4 ft. This illustrates the importance of

1. Compaction of the embedment has a significant densifying embedment soil — including soil under

effect on pressure, P, at soil slip. the haunches — if a water table could rise in the

embedment.

2. Soil does not slip if ring deflection is less than

about 10%. Therefore, maximum allowable ring

deflection is often limited by specification, to 5%, With Soil Support and Internal Vacuum

including safety factor — or less if other — No Water Table

performance limits prevail.

The performance limit for internal vacuum and/or

Example external soil pressure is ring inversion. Embedment

usually prevents total collapse. Critical vacuum, p,

If height of cover is H = 12 ft, what is the ring is sensitive to radius of curvature. Ring deflection

deflection of a steel pipe at soil slip? D = 72 inches reduces critical vacuum. Because vertical radius of

and t = 0.245 in. The embedment is poor, loose soil curvature, ry , is greater than r; ring stiffness, EI/ry 3,

for which γ = 100 pcf, and friction angle is φ = 15o. is less than EI/r3, and the vacuum at collapse is less

EI/r3 = 0.78 psi. P = 1200 psf = 8.33 psi. The for a deflected ring than for a circular ring.

pressure term is P/(EI/r3) = 10.7. From Figure 10-9,

d = 11%. No problem is anticipated if ring The stability analysis can include internal vacuum, p,

deflection is less than 5% — even in this poor soil. and the resistance of ring stiffness which, for a plain

pipe, is Ed/m3. The horizontal stresses on the

infinitesimal cube, B, of Figure 10-6 can be equated

Flexible Pipes in Liquefied Soil Embedment to passive soil resistance (soil slip). Solving for

vacuum, p, at soil slip,

If the embedment liquefies when a circular pipe is _

empty, the ring may be subjected to the hydrostatic p(rr-1) = Kσ y - (PA-Ed/m3)rr

pressures shown in Figure 10-8. If flotation is UNSATURATED SOIL . . . . . (10.16)

prevented, catastrophic collapse occurs from the

bottom according to the classical equation, For notation, see the more general form, Equation

10.17. Figure 10-10 shows graphs of Equation 10.16

Pr3/EI = 3; or h = (E/4γ )(t/r)3 for plain pipe. for a plain steel pipe with D/t = 288, and ring

deflection d = 10%, in granular embedment with two

Example feet of cover. It is noteworthy that critical vacuum

is increased significantly by compacting the

What is the height, h, of water table above the embedment (increased soil friction angle, φ). The

bottom of a steel pipe in embedment so loose that it effect of soil unit weight on critical vacuum is small.

can liquefy and cause catastrophic ring collapse?

Pipe: Example

D = 51 inches,

t = 0.219, A plain steel pipe is 51 inches in diameter with a

r/t = 117. 0.187 inch thick wall. D/t = 274.

Soil:

γ = 125 pcf, saturated,

©2000 CRC Press LLC

D/t = 288

Figure 10-10 UNSATURATED SOIL — Example of graphs constructed for the design and analysis of the

following buried steel pipe:

D = 48 inches

t = 0.167 inches

H = 2 ft

γ = 100 pcf = soil unit weight

©2000 CRC Press LLC

_

The height of soil cover is 2 ft. The soil is silty sand σy = effective vertical soil stress at B,

(SM) with soil friction angle φ = 25o (light PA = total vertical pressure at A,

compaction), and unit weight of about 100 pcf. If K = (1+sinφ)/(1-sinφ),

the buried ring deflection is discovered to be d = φ = soil friction angle,

10%, what is the internal vacuum at soil slip? uB = water pressure at B = (h+H+r)γ w,

Because D/t is close to 288, Figure 10-10 may be h = height of water table above ground surface,

used. p = 8 psi. Had the soil been compacted such γw = unit weight of water = 62.4 pcf,

that φ = 35o, all else unchanged, the pipe could have E = modulus of elasticity of steel = 30(10-6)psi,

withstood a vacuum of 12 psi. And had the ring d = ring deflection (ellipse) = ∆ /D,

deflection been only 5% in compacted soil, the pipe D = circular diameter of the pipe,

could have withstood a vacuum of 26 psi, which is m = r/t = ring flexibility,

above atmospheric pressure. By ring compression r = D/2 = radius of the circular pipe,

analysis, the critical vacuum would be increased t = wall thickness,

tenfold. rr = ry /rx.

For the design of pipes to withstand internal vacuum, The term, (πrγ w /2), is uplift pressure equivalent to

a safety factor of 1.5 is recommended. It is prudent buoyancy of the empty pipe. If the pipe is full of

to require that embedment soil be denser than water, this term is dropped from Equation 10.17.

critical. Critical density can be evaluated in the soils

laboratory. Even without a water table, percolating Noteworthy from Figure 10-11:

water and earth tremors tend to shake loose soil

down such that ring deflection could increase and 1. A water table reduces the critical vacuum.

reduce internal vacuum at collapse.

2. The effect of D/t on p is minor for values of D/t

greater than 240. Soil becomes the primary

With Soil Support — resistance to vacuum. The pipe is a lining.

With Water Table Above the Pipe:

3. The significant variables are ring deflection and

If the water table is above the top of the pipe, the soil density.

soil is in no danger of liquefaction if density of the

embedment is 90% Standard Proctor (ASTM D698 Example

or AASHTO T-99). The height of water table, h,

above ground surface, adds to the internal vacuum. A steel pipe of diameter D = 51 inches and wall

The worst case is an empty pipe with the water thickness t = 0.187 inch is buried under a soil cover

table above ground surface (flood level). See Figure of H = 4 ft. The embedment is loose granular soil

10-11. Critical vacuum includes water table above with saturated unit weight of 125 pcf and φ = 15o.

the pipe and effective soil pressure. Using the The water table is at ground surface. Ring

stability analysis of Figure 10-6, but including ring deflection happens to be 10%. What is the internal

stiffness and vacuum and water table, the equation vacuum at ring collapse? Substituting values into

of stability is, Equation 10.17, the critical vacuum is p' = 0.4 psi,

_ which leaves little margin of safety against collapse

p(rr-1) = Kσ y + uB - (PA + πrγ w/2 - Ed/m3)rr in a flood. If ring deflection had been held to 5%,

SATURATED SOIL . . . . . (10.17) even in this poor soil, the vacuum at collapse would

where: have been 3.8 psi which is equivalent to a flood 4.8

p = vacuum and/or pressure due to flood level h ft above ground surface. In the example above, if

above the pipe, embedment had been compacted such

©2000 CRC Press LLC

D/ t = 240

©2000 CRC Press LLC

that saturated unit weight was 130 pcf and φ = 35o, ring deflection at which collapse occurs? Specific

vacuum at collapse would be P' = 6.9 psi. If ring gravity of soil grains is 2.65. (6.1%)

deflection were 5% in this compacted embedment,

"vacuum" at collapse would exceed 20 psi. 10-5 In Problem 10-4 what is the internal vacuum at

collapse if the ring deflection. is 3%? (39 psi)

REFERENCES 10-6 In Problem 10-4, what pipe stiffness, F/∆,

would be needed to prevent collapse with a safety

Murphy, C.E. and Langner, C.G., (1985) Ultimate factor of 2 w.r.t. vacuum if ring deflection is 5% and

Pipe Strength Under Bending," Proceedings of vacuum is 11.4 psi? (24 psi)

ASME 4th International Offshore and Arctic

Engineering Symposium, New York, N.Y. 10-7 What is the allowable external hydrostatic

pressure plus internal vacuum on 150 class PVC

pipe of nominal 10 inch diameter? (818 psi)

PROBLEMS E = 400 ksi Assumptions:

σf = 7 ksi Temperature, 40ο F

10-1 What does Equation 10.3 reduce to if do = 0, ID = 9.82 in Safety factor = 2

and ring compression stress term, σy /m, is OD = 11.12 in No soil restraint

negligible? (P'r3/EI = 3) (Soil liquefies)

10-2 Derive Equation 10.6 for flexural stress: 10-8 If the pipe of Problem 10-7 is 10% out-of-

σf = (Et/D)(3do-3d)/(1-2do-2d). round (ellipse), what is the allowable external

hydrostatic pressure? (88 psi)

10-3 A 10-inch PVC pipe Schedule 80 is to serve as

a buried conduit for telephone cables under a river. 10-9 What is the external water head at collapse of

Suppose that for some reason the backfill is washed a 4D PVC pipe, SDR 26, if a sudden internal

off the pipe at one location. What is the head of vacuum of 12 psi occurs at the same time as the

water at which the pipe will collapse? From the external water head? D/t = 25. E = 400 ksi.

Uni-Bell Handbook, DR = 18.13, and (90.5 ft)

F/∆ = 370 psi. (380 ft)

10-10 What is the allowable external water head on

10-4 For a steel pipe penstock full of water, a 20D polyethylene pipe, DR 32.5, if the pipe is

D = 96 inches in diameter , unburied and has an initial ovality (ring deflection) of

t = 0.375 inch, 5%? From manufacturer's engineering data, short

m = 128 = r/t, term E = 115 ksi.

E = 30(106) psi,

The pipe is buried in an embedment of silt and fine 10-11 What horizontal soil-bearing capacity is

sand. The height of soil cover is 16 ft. At certain required for a 36D PVC pipe, SDR 41? Pipe

times during the year, the water table rises to 2 ft stiffness is F/∆ = 28 psi? Initial ring deflection due

below the ground surface. The pipe stiffness is F/∆ to careless installation is 15.9% and the vertical soil

= 5.5 psi. The dry unit weight of soil is 100 pcf. Soil load on top of the pipe is P = 1 ksf. The soil is dry.

friction angle is 15o. The maximum vacuum that can Safety factor is 1.0 at the point of collapse.

occur is 11.4 psi. What is the elliptical

©2000 CRC Press LLC

You might also like

- Strdes1 ModuleDocument150 pagesStrdes1 ModuleCharlene BalageoNo ratings yet

- Design of Anchor Bolt - Rev.ADocument8 pagesDesign of Anchor Bolt - Rev.AcivilaskarNo ratings yet

- CI/ASCE 38-02: Standard Guideline For The Collection and Depiction of Existing Subsurface Utility DataDocument20 pagesCI/ASCE 38-02: Standard Guideline For The Collection and Depiction of Existing Subsurface Utility DataBlakeNo ratings yet

- Static Load Testing of Truss Assemblies: Standard Practice ForDocument5 pagesStatic Load Testing of Truss Assemblies: Standard Practice FordgkmurtiNo ratings yet

- Guide For Maintenance of Concrete Bridge Members: ACI 345.1R-06Document2 pagesGuide For Maintenance of Concrete Bridge Members: ACI 345.1R-06Arqowi Pribadi100% (1)

- Solving Trusses Including InclinedDocument24 pagesSolving Trusses Including Inclinedjikijoker0% (2)

- Buckling of StrutsDocument11 pagesBuckling of StrutsIkhwan Z.91% (68)

- ANSYS NeoHook UsermatDocument15 pagesANSYS NeoHook UsermatRohan Nair100% (2)

- Civil Engineering, Water & Wastewater, Earthquake, Railways (3538 Titles) PDFDocument148 pagesCivil Engineering, Water & Wastewater, Earthquake, Railways (3538 Titles) PDFTomasz CzNo ratings yet

- Handbook For Drainage Design CriteriaDocument21 pagesHandbook For Drainage Design CriteriatranthanhquyenNo ratings yet

- Computer Assisted Hydraulic Design of Tyrolean WeirsDocument125 pagesComputer Assisted Hydraulic Design of Tyrolean WeirsbarabatinaNo ratings yet

- LTS 6 TableOfContents PDFDocument29 pagesLTS 6 TableOfContents PDFTAHANo ratings yet

- Scour CalDocument2 pagesScour CalAnonymous O404LiV4CNo ratings yet

- 2395 CH 15Document19 pages2395 CH 15abdülkadir cebeciNo ratings yet

- Bolted Field Splices For Steel Bridge Flexural MembersDocument76 pagesBolted Field Splices For Steel Bridge Flexural MembersMario Guevara Ubidia- IngenieroCivilNo ratings yet

- N Mean (x) yn Sn std. Deviation σ: Year Maximum flood discharge (m3/sec)Document4 pagesN Mean (x) yn Sn std. Deviation σ: Year Maximum flood discharge (m3/sec)SUDHIR GAYAKENo ratings yet

- Trash Racks and Safety GratesDocument4 pagesTrash Racks and Safety GratessanbarunNo ratings yet

- Topic 2: Flow in Pipes and Channels: ObjectivesDocument15 pagesTopic 2: Flow in Pipes and Channels: ObjectivesQi YeongNo ratings yet

- Specification For Civil/Structural General Requirements For Water WorksDocument34 pagesSpecification For Civil/Structural General Requirements For Water WorksALINo ratings yet

- Penstocks: Figure: Typical Installaion of PenstocksDocument6 pagesPenstocks: Figure: Typical Installaion of PenstocksTharindu Nuwan JayakodyNo ratings yet

- Water Hammer in Pumped Sewer MainsDocument45 pagesWater Hammer in Pumped Sewer MainsManikandanNo ratings yet

- ACI 350R Vs 318 - RevisedDocument76 pagesACI 350R Vs 318 - RevisedtroyscribdNo ratings yet

- CPAA Guidance Note NZ Loads On Circular Precast Concrete Manholes and MoreDocument8 pagesCPAA Guidance Note NZ Loads On Circular Precast Concrete Manholes and Morejunhe898No ratings yet

- Analysis On The Causes of Cracks in BridgesDocument14 pagesAnalysis On The Causes of Cracks in BridgesNguyễn Văn MinhNo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IIwooNo ratings yet

- Thrust Block ForceDocument3 pagesThrust Block ForceVincent HeraldNo ratings yet

- Design Guidelines For Bridge Size CulvertsDocument28 pagesDesign Guidelines For Bridge Size Culvertsعصام السامرائي100% (1)

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanNo ratings yet

- Determination of Pipe and Bedding Combinations For Drainage WorksDocument26 pagesDetermination of Pipe and Bedding Combinations For Drainage WorksFitriansyah Adi PutraNo ratings yet

- Crack Mitigation of Post Tensioned Floors TN454Document40 pagesCrack Mitigation of Post Tensioned Floors TN454kiranNo ratings yet

- Root Cause Analysis Guidelines - ISO 9001 2015Document2 pagesRoot Cause Analysis Guidelines - ISO 9001 2015OladimejiNo ratings yet

- Design of Non Erodible ChannelsDocument2 pagesDesign of Non Erodible Channelsveena sandheepNo ratings yet

- 2000 CALTRANS Bridge Design SpecificationsDocument14 pages2000 CALTRANS Bridge Design Specificationsrhonald2000No ratings yet

- MSB02 Concept Design 2010-03-12Document83 pagesMSB02 Concept Design 2010-03-12Vasil Georgiev Georgiev100% (1)

- Concrete Encasement of Flexible Pipes v20Document5 pagesConcrete Encasement of Flexible Pipes v20peterNo ratings yet

- Pipeline Selection ManualDocument63 pagesPipeline Selection ManualGirish Chandran100% (1)

- Design Analysis of Water Distribution Pipe Network of Royal Valley Housing Estate in Ilorin Using Arc-Gis and EpanetDocument13 pagesDesign Analysis of Water Distribution Pipe Network of Royal Valley Housing Estate in Ilorin Using Arc-Gis and Epanetvenkatesh19701No ratings yet

- Report DSO-11-06 - Seismic Induced Loads On Spillway Gates - Literature ReviewDocument40 pagesReport DSO-11-06 - Seismic Induced Loads On Spillway Gates - Literature Reviewchutton681No ratings yet

- Thailand Psha Pga s1 Ss MapDocument28 pagesThailand Psha Pga s1 Ss MapSudathipTangwongchaiNo ratings yet

- Standard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterDocument7 pagesStandard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterdrakenhavenNo ratings yet

- Wind Load On Porous MediaDocument11 pagesWind Load On Porous Mediamomo honeyNo ratings yet

- Ipc2022 - 87102 A Risk-Based Design Approach For Uncased Pipe Under Roads and RailwaysDocument10 pagesIpc2022 - 87102 A Risk-Based Design Approach For Uncased Pipe Under Roads and RailwaysOswaldo MontenegroNo ratings yet

- Khanki BarrageDocument10 pagesKhanki BarrageUmairmaqsood808No ratings yet

- Force at Pipe BendingDocument4 pagesForce at Pipe BendingPriyabrata Mahata100% (1)

- Rank PG Apr16 PDFDocument110 pagesRank PG Apr16 PDFCHRISTINo ratings yet

- UAE RainfallDocument11 pagesUAE RainfallraghuragooNo ratings yet

- Rational MethodDocument158 pagesRational MethodMilos Petrovic100% (2)

- Er - 1110 2 1806Document28 pagesEr - 1110 2 1806Ihab SorourNo ratings yet

- All Page PDFDocument24 pagesAll Page PDFsskamalakannanNo ratings yet

- CR17 2 PDFDocument0 pagesCR17 2 PDFDiego OrozcoNo ratings yet

- Properties of Soils: C.1 Soil TestsDocument4 pagesProperties of Soils: C.1 Soil TestsbarouniamineNo ratings yet

- Differences Between Working Stress Method and Limit State MethodDocument1 pageDifferences Between Working Stress Method and Limit State Methodaman rajNo ratings yet

- Chapter 19. Footing and Foundation 21.11.28Document51 pagesChapter 19. Footing and Foundation 21.11.28Hasanain GaltanNo ratings yet

- CulvertDocument340 pagesCulvertsorowareNo ratings yet

- Etl 1110-1-307Document16 pagesEtl 1110-1-307shahbazNo ratings yet

- Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "PIPE MECHANICS" Boca Raton: CRC Press LLC, 2000Document11 pagesStructural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "PIPE MECHANICS" Boca Raton: CRC Press LLC, 2000Sheikh Mizanur RahmanNo ratings yet

- Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "ENCASED FLEXIBLE PIPES" Boca Raton: CRC Press LLC, 2000Document19 pagesStructural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "ENCASED FLEXIBLE PIPES" Boca Raton: CRC Press LLC, 2000obricenoNo ratings yet

- Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING DEFORMATION" Boca Raton: CRC Press LLC, 2000Document9 pagesStructural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING DEFORMATION" Boca Raton: CRC Press LLC, 2000Sheikh Mizanur RahmanNo ratings yet

- Tranmission LengthDocument4 pagesTranmission LengthWole LabiranNo ratings yet

- Wire Springs, - Flat Springs, or - Special ShapedDocument25 pagesWire Springs, - Flat Springs, or - Special Shapedbiruk tolossaNo ratings yet

- LECTURE 4-PSC2b-prestress Loss - LatestDocument32 pagesLECTURE 4-PSC2b-prestress Loss - LatestAdam SalimiNo ratings yet

- Critical Buckling EquationDocument18 pagesCritical Buckling Equationxsi666No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Residual StressesDocument6 pagesResidual StressesSaad khanNo ratings yet

- Geotecnic Report Final 1 PDFDocument22 pagesGeotecnic Report Final 1 PDFyasir aliNo ratings yet

- Boos Ks For MEDocument5 pagesBoos Ks For MESuniljpatilNo ratings yet

- Btech Project Report Template-1Document38 pagesBtech Project Report Template-1OMShivRajaBabuNo ratings yet

- Vize - Bahar 2022Document6 pagesVize - Bahar 2022FrkanNo ratings yet

- Capstone Chapter 4Document108 pagesCapstone Chapter 4Calvin BaraquiaNo ratings yet

- Introduction To Instrumented IndentationDocument7 pagesIntroduction To Instrumented Indentationopvsj42No ratings yet

- Fracpro Course PresentationDocument111 pagesFracpro Course PresentationUmar Rasheed100% (1)

- Checks For CompactnessDocument15 pagesChecks For CompactnessjologscresenciaNo ratings yet

- SDM2-session3-crystal Plasticity-ReviewDocument31 pagesSDM2-session3-crystal Plasticity-ReviewPheng SeihaksethNo ratings yet

- Solution-ME F314Document3 pagesSolution-ME F314sai ramNo ratings yet

- Lug PaperDocument11 pagesLug PaperSrinivas PradhaanNo ratings yet

- Biaxial Bending EC2Document24 pagesBiaxial Bending EC2kissistvanNo ratings yet

- Settlements of Embankments in Soft SoilsDocument20 pagesSettlements of Embankments in Soft SoilsDavid HongNo ratings yet

- 22 - Fracture Toughness & Toughening MechDocument30 pages22 - Fracture Toughness & Toughening MechMd. Rafiqul IslamNo ratings yet

- Hardness Testing Lab ReportDocument8 pagesHardness Testing Lab Reportnit528No ratings yet

- AbaqusDocument1,535 pagesAbaqusKing1971100% (1)

- Iso Slope Ft1Document12 pagesIso Slope Ft1Bhavya PatelNo ratings yet

- Losses in PrestressDocument17 pagesLosses in PrestressSamanvay ChandnaoNo ratings yet

- Steel Anal For High Pressure H2Document13 pagesSteel Anal For High Pressure H2pec21102002No ratings yet

- Ubc 1994 Equivalent Static Lateral Force MethodDocument2 pagesUbc 1994 Equivalent Static Lateral Force MethodJonathan SantosNo ratings yet

- Tes SylineDocument40 pagesTes SylineBima SetiajiNo ratings yet

- Software Verification PDFDocument917 pagesSoftware Verification PDFPauccar Rhp Hp100% (2)

- Plate Buckling NotesDocument0 pagesPlate Buckling NotesSharyn PolleyNo ratings yet

- Cptu in Consolidating SoilsDocument29 pagesCptu in Consolidating SoilsRadekNo ratings yet

- Bearing Capacity of Strip and Circular Footings in Sand Using Finite ElementsDocument9 pagesBearing Capacity of Strip and Circular Footings in Sand Using Finite ElementsOum MahmdNo ratings yet