Professional Documents

Culture Documents

Weld in G P Ro Cedu Re SP Ecifica Tio N (WP S)

Weld in G P Ro Cedu Re SP Ecifica Tio N (WP S)

Uploaded by

almasrizal0 ratings0% found this document useful (0 votes)

46 views2 pages(1) This Welding Procedure Specification document outlines the welding process, materials, and parameters for a single V-groove butt joint configuration using SMAW and GMAW welding.

(2) The base material is ASTM ST 37 Gr.B steel with a 12mm groove and the filler metals are ER70S-6 for GMAW and E7016 for SMAW.

(3) Key welding parameters include a root pass with SMAW using E7016 filler at 70-90A and 20-30V, followed by hot and cap passes with GMAW using ER70

Original Description:

Original Title

WPS 3G

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document(1) This Welding Procedure Specification document outlines the welding process, materials, and parameters for a single V-groove butt joint configuration using SMAW and GMAW welding.

(2) The base material is ASTM ST 37 Gr.B steel with a 12mm groove and the filler metals are ER70S-6 for GMAW and E7016 for SMAW.

(3) Key welding parameters include a root pass with SMAW using E7016 filler at 70-90A and 20-30V, followed by hot and cap passes with GMAW using ER70

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

46 views2 pagesWeld in G P Ro Cedu Re SP Ecifica Tio N (WP S)

Weld in G P Ro Cedu Re SP Ecifica Tio N (WP S)

Uploaded by

almasrizal(1) This Welding Procedure Specification document outlines the welding process, materials, and parameters for a single V-groove butt joint configuration using SMAW and GMAW welding.

(2) The base material is ASTM ST 37 Gr.B steel with a 12mm groove and the filler metals are ER70S-6 for GMAW and E7016 for SMAW.

(3) Key welding parameters include a root pass with SMAW using E7016 filler at 70-90A and 20-30V, followed by hot and cap passes with GMAW using ER70

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

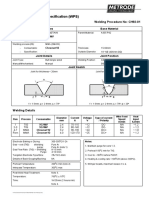

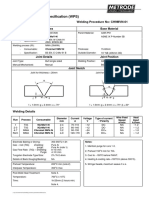

Welding Procedure Specification (WPS)

No. : 1/wps/lsp-welding/2019

Revision :2

Welding Process : SMAW - GMAW

Ref Code : ASME sect IX

Joint Design Base Material

1

ASTM ST 37 Gr.B P No:1 Group No : 1

SMAW Base material groove : 12 mm

GMAW

2-3 Filler : ER70S-6

Pipe Diameter Range :-

60o-70o

Joint Design Filler Metal

Groove Design : V But Joint SMAW GMAW

Backing (Yes/No) : No AWS No : A5.1 E7016 ER70S-6

Backing material (Type) : N/A E7018

Others : Plate F No 4 N/A A

No 1 N/A Size

2,6 mm 1,2 mm SFA No

- - Weld Metal Range -

-

Other / Brand :

Position Post weld head treatment

Position (s) of groove : 3G Temperature range : None

Welding progression : Combination - Multi layer Time range : None

Preheat Gas

Preheat temp. minimum (OC) : N/A Shielding : CO2

Interpass temp. maximum (OC) : N/A Flow rate : 10 L/min s/d 15 L/min

Preheat maintenance (minutes) : N/A Gas backing : None

Electrical Characteristic Technique

Process SMAW GMAW String or weaving bead : Both

Current DC DC Gas cup size :-

Polarity EN EP Method of back gouging : N/A

EP Initial and interpass cleaning : brushing & grinding

Ampere range 70-90 90-120 Multiple or single pass (per side) : multiple / single

90-120 For (GMAW) thickness pass max :1

Volt range 10 – 30 20 – 30

Head input max - -

Tungsten electrode Size :-

Type :-

Filler Metal Current Travel

Weld Speed

Process Diameter Type of Ampere Volt Range Others

(Layers) Class Range

(mm) Polarity Range

(cm/min)

Root SMAW E7016 2,6 DCEN 70-90 4 – 14 20 – 30

Hot GMAW ER70S-6 1,2 DCEP 90 – 120 4 – 14 20 – 30

Cap GMAW ER70S-6 1,2 DCEP 90 – 120 4 – 14 20 – 30

Prepared By : Checked By : Verified By :

Asesor Asessor Lead Asessor

Sign Sign Sign

Name : Name : Name :

Date : Date : Date :

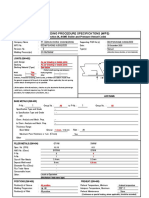

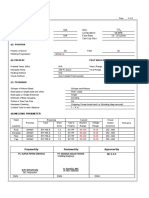

Lembar pemeriksaan hasil (visual test)

Posisi : 3 G

Nilai

No Pemeriksaan Standar

1 2

1 Perubahan bentuk / distorsi Max 3O

2 Goresan busur las Tidak ada

3 Misalignment Max 0,5mm

4 Tinggi reinforcement 1-3 mm

5 Lebar reinforcement + 2 mm dari lebar kampuh

las

6 Kerataan reinforcement 90% rata

7 Kelurusan jalur las 90% lurus

8 Sambungan jalur las Sama tinggi dan berpadu,

toleransi beda ketinggian

0,5mm

9 Undercut Kedalaman max 0,5mm,

panjang max 10% panjang

benda

10 Overlap Tidak ada overlap

11 Porosity Max 5 buah, total diameter

2mm

12 Slag inclusions Max 2mm2

13 Incomplete fusion Tidak ada

14 Spatter/percikan terak Max 2 buah

15 Bekas gerinda Tidak ada

16 Bekas pukulan Tidak ada

Total Nilai

You might also like

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- WPS For P1 MaterialDocument1 pageWPS For P1 Materialasirul_meNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Foam Concrete Mix DesignDocument1 pageFoam Concrete Mix DesignJuzar Matin78% (9)

- Unimech PDFDocument2 pagesUnimech PDFSAMPATHUNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocument2 pagesNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)tebetupar.ttNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Wps-01 C.S. GtawDocument2 pagesWps-01 C.S. GtawMohamed Tarek HamamNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- WPS (Gtaw)Document2 pagesWPS (Gtaw)Ramadhan AdityaNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- PQR 3G Fcaw SF71Document3 pagesPQR 3G Fcaw SF71long phamNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)Mohamad Marwan HamwiNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- P91 ProfileDocument6 pagesP91 ProfilesrinivasanNo ratings yet

- Pt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Document1 pagePt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Ilham PaneNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobini100% (1)

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Crouse Hint PDFDocument180 pagesCrouse Hint PDFJEFFERSON ALEJANDRO MURILLO CAPERANo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Media Book EnglishDocument48 pagesMedia Book Englishtmangat100% (1)

- Course Outline Djj1043Document4 pagesCourse Outline Djj1043mohdazizeeNo ratings yet

- Complete RCC ProjectDocument51 pagesComplete RCC ProjectRezwanullah KhpelwakNo ratings yet

- CSC Portal FrameDocument11 pagesCSC Portal FramePhilip AmankwahNo ratings yet

- GAs MedisDocument1 pageGAs MedissyafrijalNo ratings yet

- Henament Physics Exercise Young ModulisDocument2 pagesHenament Physics Exercise Young ModulisMohamed JameelNo ratings yet

- WDocument11 pagesWShrey PandeyNo ratings yet

- ISO Valve StandardsDocument3 pagesISO Valve StandardsFacundo ArgüelloNo ratings yet

- Js-Kamyotra Aida DSWDocument52 pagesJs-Kamyotra Aida DSWnuti_srinivasNo ratings yet

- Science Q1 W5 D2Document66 pagesScience Q1 W5 D2marilou sorianoNo ratings yet

- The Use of Ultrasound To Mitigate Membrane Fouling in Desalination and Water TreatmentDocument61 pagesThe Use of Ultrasound To Mitigate Membrane Fouling in Desalination and Water TreatmentFatma Al BelushiNo ratings yet

- KERTASIVE E-Catalogue (March 2022)Document30 pagesKERTASIVE E-Catalogue (March 2022)Winadi KurniawanNo ratings yet

- Hydrogen Homogeneous Charge Compression Ignition (HCCI) Engine With DME As An Ignition PromoterDocument10 pagesHydrogen Homogeneous Charge Compression Ignition (HCCI) Engine With DME As An Ignition PromoterenjpetNo ratings yet

- Malcolm WilliamsDocument3 pagesMalcolm WilliamsDigital MediaNo ratings yet

- Crane Katalog-RS AngDocument29 pagesCrane Katalog-RS AngNNNo ratings yet

- Thermowood HandbookDocument66 pagesThermowood HandbookAdam LewisNo ratings yet

- Solid Liquid GAS: Class 4 Unit 5: ASM 2 EVSDocument3 pagesSolid Liquid GAS: Class 4 Unit 5: ASM 2 EVSOM GARGNo ratings yet

- Momente Strangere Suruburi Americane - ASTM A574Document1 pageMomente Strangere Suruburi Americane - ASTM A574tracam500No ratings yet

- Ua2 5NJDocument12 pagesUa2 5NJvaleluxosNo ratings yet

- ABS Rule Part4 Chapter6 Section1Document8 pagesABS Rule Part4 Chapter6 Section1Kamil AdliNo ratings yet

- Chemical Reactiochemical - Reactionsstoichiometry NsstoichiometryDocument16 pagesChemical Reactiochemical - Reactionsstoichiometry NsstoichiometryOuryhell ArevaloNo ratings yet

- Application of Line Pipe and Hot Induction Bends in Hydrogen Gas PDFDocument6 pagesApplication of Line Pipe and Hot Induction Bends in Hydrogen Gas PDFgagodoy20No ratings yet

- Firewalls To NBCC 2010Document34 pagesFirewalls To NBCC 2010BeammanNo ratings yet

- New York State Plastic Bag Task Force ReportDocument88 pagesNew York State Plastic Bag Task Force ReportMatthew Hamilton100% (1)

- Added Photos-Final PROJECT REPOR 8sem (1) PDFDocument50 pagesAdded Photos-Final PROJECT REPOR 8sem (1) PDFravi singhNo ratings yet

- RODocument7 pagesROdalton2004No ratings yet