Professional Documents

Culture Documents

06 INTAKE & EXHAUST SYSTEM W3206L00BTM04A Rev 01

06 INTAKE & EXHAUST SYSTEM W3206L00BTM04A Rev 01

Uploaded by

John Earl TejamoCopyright:

Available Formats

You might also like

- d12d Fuel System Pv776-Tsp188406Document10 pagesd12d Fuel System Pv776-Tsp188406SlV40% (5)

- Mahindra XYLO MEagle Repair - Manual MAN 00052 Rev 1Document417 pagesMahindra XYLO MEagle Repair - Manual MAN 00052 Rev 1Nadeem Md100% (10)

- Man Diesel Engine D 2866 e D 2866 D 2866 Le D 2866 Lxe Operating InstructionsDocument6 pagesMan Diesel Engine D 2866 e D 2866 D 2866 Le D 2866 Lxe Operating InstructionsEstela100% (56)

- System Operation 3056 Fuel SystemDocument16 pagesSystem Operation 3056 Fuel SystemJosé LopezNo ratings yet

- Manual Vilter 440 and 450xlDocument41 pagesManual Vilter 440 and 450xlJose Antonio Yupa MedinaNo ratings yet

- Wartsila 8L32 Spare PartsDocument552 pagesWartsila 8L32 Spare PartsMick V90% (10)

- Scope: TIP Category: Data and CalculationsDocument11 pagesScope: TIP Category: Data and CalculationsManikandan Sigamani100% (2)

- 3126B Serial DCS02760 Arr 2077523 Repair ManualDocument1,196 pages3126B Serial DCS02760 Arr 2077523 Repair Manualviemey1952100% (4)

- D2866 - 76 - 191-338 KWDocument6 pagesD2866 - 76 - 191-338 KWMarko Bozic43% (7)

- Operation and Maintenance Manual of Holding Vacuum Pump-2BW4 252Document163 pagesOperation and Maintenance Manual of Holding Vacuum Pump-2BW4 252AhmadNo ratings yet

- Cooling Water System, V-EnginesDocument12 pagesCooling Water System, V-EnginesMuhammad Waleed Tariq100% (1)

- Dahatsu Terios CODocument19 pagesDahatsu Terios COJose M Chire0% (2)

- MM Dresser FinalDocument236 pagesMM Dresser FinalPriyabrat Mohanty100% (1)

- 1kz-Te Cooling System PDFDocument14 pages1kz-Te Cooling System PDFwill meridith100% (2)

- Workshop Manual: TID162AP, TD164KAE, TWD1620G/GH, TAD1630G/GE/P/V, TAD1631G/GE, TWD1630G/GE/P/VDocument164 pagesWorkshop Manual: TID162AP, TD164KAE, TWD1620G/GH, TAD1630G/GE/P/V, TAD1631G/GE, TWD1630G/GE/P/VNaing Min HtunNo ratings yet

- Cat EngineDocument145 pagesCat Enginenajafali83% (6)

- MCQ in Power Plant Engineering Part 1 ME Board ExamDocument15 pagesMCQ in Power Plant Engineering Part 1 ME Board ExamAaron Choco De GuzmanNo ratings yet

- 04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01Document14 pages04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01John Earl TejamoNo ratings yet

- 5-Coolin Water System PDFDocument11 pages5-Coolin Water System PDFKhizerMehmoodNo ratings yet

- Cooling Water SystemDocument11 pagesCooling Water SystemMuhammad Waleed TariqNo ratings yet

- 02 FUEL SYSTEM W3202L00BTM04A Rev 01Document64 pages02 FUEL SYSTEM W3202L00BTM04A Rev 01John Earl TejamoNo ratings yet

- Deutz Change From Tier II To Tier III TCD 2013 l06 2vDocument18 pagesDeutz Change From Tier II To Tier III TCD 2013 l06 2vduongpndngNo ratings yet

- Fig. 1 Cooling System Operation - 2.5L EngineDocument28 pagesFig. 1 Cooling System Operation - 2.5L Engineorangewedge32No ratings yet

- C15 Cooling System OperationDocument4 pagesC15 Cooling System OperationTakaNo ratings yet

- Cooling and InstrumentationDocument45 pagesCooling and InstrumentationTomislav BanićNo ratings yet

- 320 Shop Manual PDFDocument880 pages320 Shop Manual PDFThemune Azaa100% (4)

- Cooling System Cat C-15 & C-18Document5 pagesCooling System Cat C-15 & C-18Harzanyi MaldonadoNo ratings yet

- Cooling S Ystem PDFDocument2 pagesCooling S Ystem PDFFERDY zulfiarNo ratings yet

- Control and Istrumentazion System W3207L00BTM02C Rev 01Document45 pagesControl and Istrumentazion System W3207L00BTM02C Rev 01John Earl TejamoNo ratings yet

- Exhaust System and Intake Manifold: Exhaust Ball Joint CouplingDocument26 pagesExhaust System and Intake Manifold: Exhaust Ball Joint CouplingSry SantosNo ratings yet

- Additions, Revisions, or Updates: Subject DateDocument12 pagesAdditions, Revisions, or Updates: Subject Datecarlos maradiagaNo ratings yet

- SM Volvo Ew180d Wheeled Excavator Service Repair ManualDocument20 pagesSM Volvo Ew180d Wheeled Excavator Service Repair ManualJúnnior MendonçaNo ratings yet

- 12-10-01 (Printed Data Must Not Be Retained For Future Reference.)Document8 pages12-10-01 (Printed Data Must Not Be Retained For Future Reference.)Andres GuerreroNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Sistema de Enfriamiento C9Document5 pagesSistema de Enfriamiento C9GerardoNo ratings yet

- Kia Venga Audio Remote ControlDocument12 pagesKia Venga Audio Remote ControlffurlanutNo ratings yet

- DBAF396689Document562 pagesDBAF396689mahumedes jameahNo ratings yet

- Cooling System: Shutdown SIS Previous ScreenDocument3 pagesCooling System: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Zx200 5g Engine ManualDocument36 pagesZx200 5g Engine Manualeviton luisNo ratings yet

- Lide H16Document901 pagesLide H16Николай МозговNo ratings yet

- Md1 0 V 111-09-00008 A Extraction System RequirementsDocument29 pagesMd1 0 V 111-09-00008 A Extraction System RequirementsNguyễn ĐứcNo ratings yet

- Table of ContentDocument7 pagesTable of ContentAwliya TaqwaNo ratings yet

- Engine Air Intake Piping WG W/ 3306 CAT EnginesDocument2 pagesEngine Air Intake Piping WG W/ 3306 CAT EnginesHamilton MirandaNo ratings yet

- Acu - 02 Air Compressor Ingersoll Rand Xp-750 Wca Cap. 750 CFMDocument80 pagesAcu - 02 Air Compressor Ingersoll Rand Xp-750 Wca Cap. 750 CFMGanda SaputraNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Freelander - 1.8 Thermostat ModDocument3 pagesFreelander - 1.8 Thermostat ModMilan CvetkovicNo ratings yet

- XAAB145597 SpcenDocument600 pagesXAAB145597 Spcenufficio.tecnicoNo ratings yet

- Standard Erection Manual (Boiler Auxiliaries) PDFDocument222 pagesStandard Erection Manual (Boiler Auxiliaries) PDFharpreetresearchNo ratings yet

- Desmontaje de Culata-800240Document35 pagesDesmontaje de Culata-800240Juan Esteban Arango ArangoNo ratings yet

- Instrumentation Systems: Wärtsilä V50Df Standard EngineDocument30 pagesInstrumentation Systems: Wärtsilä V50Df Standard Enginelarina20049273100% (1)

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument55 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SECarlos VelázquezNo ratings yet

- Air Inlet and Exhaust System C9Document7 pagesAir Inlet and Exhaust System C9GerardoNo ratings yet

- Kaydon KC-30 Turbo-TOC® Turbine Oil Conditioning SystemDocument2 pagesKaydon KC-30 Turbo-TOC® Turbine Oil Conditioning Systemherysyam1980No ratings yet

- Standard Erection Manual (Boiler Auxiliaries)Document222 pagesStandard Erection Manual (Boiler Auxiliaries)sumit_anand97100% (4)

- Air Inlet and Exhaust System: Systems OperationDocument7 pagesAir Inlet and Exhaust System: Systems OperationMohammed KhalidNo ratings yet

- 2 Engine With Mounting and Equipment PDFDocument77 pages2 Engine With Mounting and Equipment PDFPorfidi FerrariNo ratings yet

- Cooling System Loader 988GDocument4 pagesCooling System Loader 988Gpurwa cuteNo ratings yet

- 02250209-254 (r01) SullairDocument178 pages02250209-254 (r01) SullairAnonymous ZtXb2RO100% (2)

- Service Bulletin Trucks: Turbocharger Air Intake Pipe ReplacementDocument3 pagesService Bulletin Trucks: Turbocharger Air Intake Pipe ReplacementCristhian Samuel Yacila OrdinolaNo ratings yet

- SM Volvo Ew180c Wheeled ExcavatorDocument22 pagesSM Volvo Ew180c Wheeled ExcavatorAl AminNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- English - No CorretteDocument9 pagesEnglish - No CorretteJohn Earl TejamoNo ratings yet

- Consulate General of Italy in London: PhotoDocument2 pagesConsulate General of Italy in London: PhotoJohn Earl TejamoNo ratings yet

- 04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01Document14 pages04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01John Earl TejamoNo ratings yet

- EMD00100EN 0702 Aut FilterDocument24 pagesEMD00100EN 0702 Aut FilterJohn Earl TejamoNo ratings yet

- Emergency Stop: Component DescriptionDocument10 pagesEmergency Stop: Component DescriptionJohn Earl TejamoNo ratings yet

- Solenoid Valve Block, Water: Component DescriptionDocument16 pagesSolenoid Valve Block, Water: Component DescriptionJohn Earl TejamoNo ratings yet

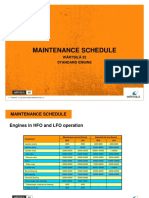

- MAINTENANCE SCHEDULE W32A4L00BTM01A Rev 01Document2 pagesMAINTENANCE SCHEDULE W32A4L00BTM01A Rev 01John Earl TejamoNo ratings yet

- 08 AUTOMATION SYSTEM W3208L00BTM10A Rev 01Document42 pages08 AUTOMATION SYSTEM W3208L00BTM10A Rev 01John Earl TejamoNo ratings yet

- Control and Istrumentazion System W3207L00BTM02C Rev 01Document45 pagesControl and Istrumentazion System W3207L00BTM02C Rev 01John Earl TejamoNo ratings yet

- Safety: Separation SystemDocument12 pagesSafety: Separation SystemJohn Earl TejamoNo ratings yet

- 02 FUEL SYSTEM W3202L00BTM04A Rev 01Document64 pages02 FUEL SYSTEM W3202L00BTM04A Rev 01John Earl TejamoNo ratings yet

- 03 LUBRICANT OIL SYSTEM W3203L00BTM08B Rev 01Document41 pages03 LUBRICANT OIL SYSTEM W3203L00BTM08B Rev 01John Earl TejamoNo ratings yet

- 21 - Starting Air SystemDocument11 pages21 - Starting Air SystemJohn Earl TejamoNo ratings yet

- 12 - Cylinder Head With ValvesDocument21 pages12 - Cylinder Head With ValvesJohn Earl TejamoNo ratings yet

- Engine Instruction ManualDocument3 pagesEngine Instruction ManualJohn Earl TejamoNo ratings yet

- Workshop Manual: Technical DataDocument36 pagesWorkshop Manual: Technical DataNaing Min HtunNo ratings yet

- Cat - G 3616Document6 pagesCat - G 3616aghakhanyNo ratings yet

- Turbo ChargerDocument23 pagesTurbo Chargerselvaraj9223100% (1)

- Cummins DGFA Data Sheet PDFDocument4 pagesCummins DGFA Data Sheet PDFSaqib iqbalNo ratings yet

- Plant Air BrochureDocument20 pagesPlant Air Brochure陳0鴻No ratings yet

- 3512 Engine OverhaulDocument7 pages3512 Engine OverhaulDarkman P and B75% (4)

- Optimization Problems Paper FinalDocument14 pagesOptimization Problems Paper FinalEnrique GalindoNo ratings yet

- ME22 ETH - GBDocument189 pagesME22 ETH - GBMUSTAFA0% (1)

- LS-16 Sullair ManualDocument112 pagesLS-16 Sullair Manualbinhleduc36100% (2)

- Operating Instructions: Diesel Engine 12 V 4000 M93 X 16 V 4000 M93 XDocument223 pagesOperating Instructions: Diesel Engine 12 V 4000 M93 X 16 V 4000 M93 XNaftal MassingueNo ratings yet

- Volkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolDocument128 pagesVolkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolAndres Jauregui Garcia100% (3)

- Sullair LS120Document172 pagesSullair LS120martin_jaitman100% (1)

- Assignment 1Document6 pagesAssignment 1kaushalshah28598No ratings yet

- Sperre Air Compressor HV2-200Document30 pagesSperre Air Compressor HV2-200Tomislav Korencic75% (4)

- MS150048 04e 20V4000M93Document200 pagesMS150048 04e 20V4000M93Giang DoNo ratings yet

- ZR - ZT 110-900 BrochureDocument24 pagesZR - ZT 110-900 BrochureSreenivasNo ratings yet

- System Practices For Ammonia and Carbon Dioxide RefrigerantsDocument27 pagesSystem Practices For Ammonia and Carbon Dioxide Refrigerants1940LaSalleNo ratings yet

- D-Line: Operation ManualDocument134 pagesD-Line: Operation Manualabduallah muhammadNo ratings yet

- Cat 3612leDocument4 pagesCat 3612letomjones77100% (1)

- Two Stage Air CompressorDocument7 pagesTwo Stage Air CompressormohammedNo ratings yet

- UntitledDocument1 pageUntitledJehana NaolNo ratings yet

- Moisture Separators enDocument4 pagesMoisture Separators enLa Ode AdhanNo ratings yet

- Operacion MotorDocument67 pagesOperacion Motorvictor100% (1)

- TE-I Lesson PlanDocument6 pagesTE-I Lesson PlanArunkumar MunimathanNo ratings yet

06 INTAKE & EXHAUST SYSTEM W3206L00BTM04A Rev 01

06 INTAKE & EXHAUST SYSTEM W3206L00BTM04A Rev 01

Uploaded by

John Earl TejamoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 INTAKE & EXHAUST SYSTEM W3206L00BTM04A Rev 01

06 INTAKE & EXHAUST SYSTEM W3206L00BTM04A Rev 01

Uploaded by

John Earl TejamoCopyright:

Available Formats

06 INTAKE & EXHAUST SYSTEMS

WÄRTSILÄ L32

TURBOCHARGER AT F.E.

2-STAGE CHARGE AIR COOLER

1 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Intake and exhaust system arrangement - internal

System components

01 Air filter

02 Compressor

03 Charge air cooler (HT)

04 Charge air cooler (LT)

05 Cylinders

06 Turbine

Pipe connections

501 Exhaust outlet

507 Cleaning water to turbine and compressor

601 Charge air inlet

Fig. name: Principal scheme of internal intake and exhaust system

2 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Intake and exhaust system on engine

The intake and exhaust system delivers compressed air to

the combustion chamber and channels the exhaust gases

out from the combustion chamber to exhaust manifold.

The intake and exhaust system can be split up into an

intake section and an exhaust section.

System components

01 Turbocharger

02 Charge air cooler

03 Charge air receiver

04 Charge air supply pipe (multiduct)

05 Exhaust manifold

06 Insulation for air inlet box and charge air cooler

07 Air inlet box

08 Insulation for exhaust manifold

09 Water cleaning system

Fig. name: Intake and exhaust system on engine

3 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Charge air system

Turbocharger

The turbocharger is driven by exhaust gases coming from

cylinders through opened exhaust valves. The compressor

is driven by the turbine. The energy of the exhaust gases

are used to compress the intake air of ambient pressure to

higher level. The charged air enlarges the air quantity fed

into the combustion space and thus makes it possible to

burn a bigger amount of fuel in the cylinder space.

The combustion air is taken outside of engine to the

compressor side of the turbocharger. Passing through the

compressor side, the air pressure and density are

increasing as well as the temperature. The heated air is

cooled down in the charge air cooler.

Components

01 Filter silencer 08 Nozzle ring

02 Radial plain bearing 09 Turbine wheel

03 Axial thrust bearing 10 Bearing casing

04 Bearing bush 11 Diffuser

05 Radial plain bearing 12 Compressor wheel

06 Gas outlet casing 13 Air outlet casing

07 Gas inlet casing

Fig. name: Principal view of turbocharger

4 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Charge air system

Basic settings of turbocharging

System components

01 Compressor

02 Charge air cooler

03 Turbine

System connections

A Air intake

B Exhaust outlet

Fig. name: Basic settings of turbocharging

5 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Charge air system

The engine is equipped with an air cooler to cool

down the compressed and thus heated air after

turbocharger. The outlet is connected to the charge

air receiver (06) through air inlet box (05).

The charge air cooler is of insert type and mounted

between air inlet boxes with screws.

System components

01 Bellows

02 Charge air pipe

03 Air inlet box

04 Charge air cooler

05 Air inlet box

06 Charge air receiver

07 Charge air supply pipe (multiduct)

System connections

A Ambient air

B Charge air to cooler

C Charge air to receiver

D Condensate water after charge air cooler

Fig. name: Charge air system

6 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Charge air system

Charge air cooler

The charge air temperature is kept at the correct level by

cooling water flows. The cooling water is circulated

through the tubes while the charge air passes between

the fins outside the tubes.

Components

01 Charge air cooler

Connections

A Air flow

B HT water inlet

C HT water outlet

D LT water inlet

E LT water outlet

Fig. name: Cooling water connections on charge air cooler

7 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Water cleaning system

Cleaning water dosing unit

The cleaning water dosing unit is located outside of the

engine. It consists of ball valve for water dosing, flow meter

and connection piping. Cleaning water for turbine and

compressor is led through cleaning water hose.

Components

01 Cleaning water pipe

02 Ball valve for water dosing

03 Cleaning water pipe

04 Flow meter

05 Cleaning water pipe

06 Reduction piece

07 Cleaning water hose

08 Bracket

Connections

A Cleaning water inlet

B Cleaning water to turbine and compressor

Fig. name: Cleaning water dosing unit

8 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Water cleaning system

Compressor side

The compressor cleaning system consists of a

pipeline (02) and a ball valve (01) for compressor

washing.

Deposits in the compressor stage (compressor

wheel and diffuser) and the deposit of dirt in the

flow ducts are cleaned up with an amount of clean

water which is injected with air pressure. The

cleaning water and air are provided from external

water and air systems.

The compressor washing is performed with the

highest engine load, i. e. at high compressor speed.

Components

01 Ball valve

02 Pipeline with flexible hose

Connections

C Cleaning water inlet

Fig. name: Water cleaning system for turbocharger compressor

9 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Water cleaning system

Turbine side

The exhaust gas inlet of the turbocharger is equipped

with a water cleaning system. Cleaning water to

turbine side is delivered through ball valve (01) and

pipeline (02).

Deposits on the turbine side can be reduced by

periodic washing during operation.

The turbine washing is performed with reduced engine

load.

Components

01 Ball valve

02 Pipeline

Connections

C Cleaning water inlet

Fig. name: Water cleaning system for turbocharger turbine

10 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Intake & Exhaust manifolds

The pulse converter type exhaust manifold consists

of exhaust and distance pipes with expansion

bellows connected to the cylinder head through a

multiduct (01).

The exhaust pipe sections are provided with flexible

expansion bellows (03 and 10) in order to eliminate

the forces caused by thermal deformations. The

bellows are fitted to the pipes with screws and

sealed with sealing rings.

Components

01 Multiduct

02 Exhaust pipe

03 Bellows

04 Sealing ring

05 Exhaust pipe, T-branch

06 Exhaust pipe

07 Sealing ring

08 Exhaust pipe

09 Sealing ring

10 Bellows

Fig. name: Principal view of exhaust system

11 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Intake & Exhaust manifolds

Charge air is delivered from charge air receiver (07) to

cylinder head through mutiduct (05).

The cylinder head in turn connects to exhaust manifold with

multiduct and exhaust pipe (03).

The exhaust manifold is covered with insulation box. The

exhaust manifold and insulations are supported with

multiducts.

Components

01 Exhaust pipe

02 Insulation box

03 Exhaust pipe, T-branch

04 Bracket

05 Multiduct

06 Engine block

07 Charge air receiver

08 Cylinder head

09 Cylinder liner

10 Cooling water

Connections

A Charge air flow to cylinder

B Exhaust gas flow from cylinder

Fig. name: Intake and exhaust manifolds

12 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Insulation

Turbochager

The turbocharger is insulated with insulation

covers for turbine (02) and compressor (03).

Exhaust connection from the manifold is also

protected with insulation box (01).

The insulation is for preventing injuries and thus

meet the SOLAS requirements (2).

Components

01 Insulation box for exhaust inlet

02 Insulation for turbine

03 Insulation for compressor

04 Insulation cover

Fig. name: Insulation for turbocharger

13 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Insulation

Exhaust manifold

The insulation for exhaust manifold is divided into

sections to facilitate easy maintenance. Each

section consists of an upper part insulation cover

and protecting bottom plate sealed with ceramic

fibre tape. The insulation sections are fastened to

each other with the cover profiles.

The insulation is for preventing injuries and thus

meet the SOLAS requirements (2).

Components

01 Insulation box section, 2 cyl.

011 Bottom plate section

012 Bracket

02 Insulation box section, 2 cyl.

021 Bottom plate section

03 Insulation box section, 2 cyl.

031 Bottom plate section

032 Insulation box cover profile

033 Bracket

034 Bracket

Fig. name: Insulation for exhaust manifold

14 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

06 INTAKE & EXHAUST SYSTEM

Insulation

Charge air pipes and cooler

The charge air pipe, air inlet box and cooler are

protected with insulation which is mounted with

screws.

The insulation is for preventing injuries and

thus meet the SOLAS requirements (2).

Components

01 Insulation cover

02 Support plate

Fig. name: Insulation for charge air pipes and cooler

15 © Wärtsilä 2 July 2008 W3206L00BTM04A Rev. 01

You might also like

- d12d Fuel System Pv776-Tsp188406Document10 pagesd12d Fuel System Pv776-Tsp188406SlV40% (5)

- Mahindra XYLO MEagle Repair - Manual MAN 00052 Rev 1Document417 pagesMahindra XYLO MEagle Repair - Manual MAN 00052 Rev 1Nadeem Md100% (10)

- Man Diesel Engine D 2866 e D 2866 D 2866 Le D 2866 Lxe Operating InstructionsDocument6 pagesMan Diesel Engine D 2866 e D 2866 D 2866 Le D 2866 Lxe Operating InstructionsEstela100% (56)

- System Operation 3056 Fuel SystemDocument16 pagesSystem Operation 3056 Fuel SystemJosé LopezNo ratings yet

- Manual Vilter 440 and 450xlDocument41 pagesManual Vilter 440 and 450xlJose Antonio Yupa MedinaNo ratings yet

- Wartsila 8L32 Spare PartsDocument552 pagesWartsila 8L32 Spare PartsMick V90% (10)

- Scope: TIP Category: Data and CalculationsDocument11 pagesScope: TIP Category: Data and CalculationsManikandan Sigamani100% (2)

- 3126B Serial DCS02760 Arr 2077523 Repair ManualDocument1,196 pages3126B Serial DCS02760 Arr 2077523 Repair Manualviemey1952100% (4)

- D2866 - 76 - 191-338 KWDocument6 pagesD2866 - 76 - 191-338 KWMarko Bozic43% (7)

- Operation and Maintenance Manual of Holding Vacuum Pump-2BW4 252Document163 pagesOperation and Maintenance Manual of Holding Vacuum Pump-2BW4 252AhmadNo ratings yet

- Cooling Water System, V-EnginesDocument12 pagesCooling Water System, V-EnginesMuhammad Waleed Tariq100% (1)

- Dahatsu Terios CODocument19 pagesDahatsu Terios COJose M Chire0% (2)

- MM Dresser FinalDocument236 pagesMM Dresser FinalPriyabrat Mohanty100% (1)

- 1kz-Te Cooling System PDFDocument14 pages1kz-Te Cooling System PDFwill meridith100% (2)

- Workshop Manual: TID162AP, TD164KAE, TWD1620G/GH, TAD1630G/GE/P/V, TAD1631G/GE, TWD1630G/GE/P/VDocument164 pagesWorkshop Manual: TID162AP, TD164KAE, TWD1620G/GH, TAD1630G/GE/P/V, TAD1631G/GE, TWD1630G/GE/P/VNaing Min HtunNo ratings yet

- Cat EngineDocument145 pagesCat Enginenajafali83% (6)

- MCQ in Power Plant Engineering Part 1 ME Board ExamDocument15 pagesMCQ in Power Plant Engineering Part 1 ME Board ExamAaron Choco De GuzmanNo ratings yet

- 04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01Document14 pages04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01John Earl TejamoNo ratings yet

- 5-Coolin Water System PDFDocument11 pages5-Coolin Water System PDFKhizerMehmoodNo ratings yet

- Cooling Water SystemDocument11 pagesCooling Water SystemMuhammad Waleed TariqNo ratings yet

- 02 FUEL SYSTEM W3202L00BTM04A Rev 01Document64 pages02 FUEL SYSTEM W3202L00BTM04A Rev 01John Earl TejamoNo ratings yet

- Deutz Change From Tier II To Tier III TCD 2013 l06 2vDocument18 pagesDeutz Change From Tier II To Tier III TCD 2013 l06 2vduongpndngNo ratings yet

- Fig. 1 Cooling System Operation - 2.5L EngineDocument28 pagesFig. 1 Cooling System Operation - 2.5L Engineorangewedge32No ratings yet

- C15 Cooling System OperationDocument4 pagesC15 Cooling System OperationTakaNo ratings yet

- Cooling and InstrumentationDocument45 pagesCooling and InstrumentationTomislav BanićNo ratings yet

- 320 Shop Manual PDFDocument880 pages320 Shop Manual PDFThemune Azaa100% (4)

- Cooling System Cat C-15 & C-18Document5 pagesCooling System Cat C-15 & C-18Harzanyi MaldonadoNo ratings yet

- Cooling S Ystem PDFDocument2 pagesCooling S Ystem PDFFERDY zulfiarNo ratings yet

- Control and Istrumentazion System W3207L00BTM02C Rev 01Document45 pagesControl and Istrumentazion System W3207L00BTM02C Rev 01John Earl TejamoNo ratings yet

- Exhaust System and Intake Manifold: Exhaust Ball Joint CouplingDocument26 pagesExhaust System and Intake Manifold: Exhaust Ball Joint CouplingSry SantosNo ratings yet

- Additions, Revisions, or Updates: Subject DateDocument12 pagesAdditions, Revisions, or Updates: Subject Datecarlos maradiagaNo ratings yet

- SM Volvo Ew180d Wheeled Excavator Service Repair ManualDocument20 pagesSM Volvo Ew180d Wheeled Excavator Service Repair ManualJúnnior MendonçaNo ratings yet

- 12-10-01 (Printed Data Must Not Be Retained For Future Reference.)Document8 pages12-10-01 (Printed Data Must Not Be Retained For Future Reference.)Andres GuerreroNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Sistema de Enfriamiento C9Document5 pagesSistema de Enfriamiento C9GerardoNo ratings yet

- Kia Venga Audio Remote ControlDocument12 pagesKia Venga Audio Remote ControlffurlanutNo ratings yet

- DBAF396689Document562 pagesDBAF396689mahumedes jameahNo ratings yet

- Cooling System: Shutdown SIS Previous ScreenDocument3 pagesCooling System: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Zx200 5g Engine ManualDocument36 pagesZx200 5g Engine Manualeviton luisNo ratings yet

- Lide H16Document901 pagesLide H16Николай МозговNo ratings yet

- Md1 0 V 111-09-00008 A Extraction System RequirementsDocument29 pagesMd1 0 V 111-09-00008 A Extraction System RequirementsNguyễn ĐứcNo ratings yet

- Table of ContentDocument7 pagesTable of ContentAwliya TaqwaNo ratings yet

- Engine Air Intake Piping WG W/ 3306 CAT EnginesDocument2 pagesEngine Air Intake Piping WG W/ 3306 CAT EnginesHamilton MirandaNo ratings yet

- Acu - 02 Air Compressor Ingersoll Rand Xp-750 Wca Cap. 750 CFMDocument80 pagesAcu - 02 Air Compressor Ingersoll Rand Xp-750 Wca Cap. 750 CFMGanda SaputraNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Freelander - 1.8 Thermostat ModDocument3 pagesFreelander - 1.8 Thermostat ModMilan CvetkovicNo ratings yet

- XAAB145597 SpcenDocument600 pagesXAAB145597 Spcenufficio.tecnicoNo ratings yet

- Standard Erection Manual (Boiler Auxiliaries) PDFDocument222 pagesStandard Erection Manual (Boiler Auxiliaries) PDFharpreetresearchNo ratings yet

- Desmontaje de Culata-800240Document35 pagesDesmontaje de Culata-800240Juan Esteban Arango ArangoNo ratings yet

- Instrumentation Systems: Wärtsilä V50Df Standard EngineDocument30 pagesInstrumentation Systems: Wärtsilä V50Df Standard Enginelarina20049273100% (1)

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument55 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SECarlos VelázquezNo ratings yet

- Air Inlet and Exhaust System C9Document7 pagesAir Inlet and Exhaust System C9GerardoNo ratings yet

- Kaydon KC-30 Turbo-TOC® Turbine Oil Conditioning SystemDocument2 pagesKaydon KC-30 Turbo-TOC® Turbine Oil Conditioning Systemherysyam1980No ratings yet

- Standard Erection Manual (Boiler Auxiliaries)Document222 pagesStandard Erection Manual (Boiler Auxiliaries)sumit_anand97100% (4)

- Air Inlet and Exhaust System: Systems OperationDocument7 pagesAir Inlet and Exhaust System: Systems OperationMohammed KhalidNo ratings yet

- 2 Engine With Mounting and Equipment PDFDocument77 pages2 Engine With Mounting and Equipment PDFPorfidi FerrariNo ratings yet

- Cooling System Loader 988GDocument4 pagesCooling System Loader 988Gpurwa cuteNo ratings yet

- 02250209-254 (r01) SullairDocument178 pages02250209-254 (r01) SullairAnonymous ZtXb2RO100% (2)

- Service Bulletin Trucks: Turbocharger Air Intake Pipe ReplacementDocument3 pagesService Bulletin Trucks: Turbocharger Air Intake Pipe ReplacementCristhian Samuel Yacila OrdinolaNo ratings yet

- SM Volvo Ew180c Wheeled ExcavatorDocument22 pagesSM Volvo Ew180c Wheeled ExcavatorAl AminNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- English - No CorretteDocument9 pagesEnglish - No CorretteJohn Earl TejamoNo ratings yet

- Consulate General of Italy in London: PhotoDocument2 pagesConsulate General of Italy in London: PhotoJohn Earl TejamoNo ratings yet

- 04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01Document14 pages04 COOLING WATER SYSTEM W3204L00BTM15A Rev 01John Earl TejamoNo ratings yet

- EMD00100EN 0702 Aut FilterDocument24 pagesEMD00100EN 0702 Aut FilterJohn Earl TejamoNo ratings yet

- Emergency Stop: Component DescriptionDocument10 pagesEmergency Stop: Component DescriptionJohn Earl TejamoNo ratings yet

- Solenoid Valve Block, Water: Component DescriptionDocument16 pagesSolenoid Valve Block, Water: Component DescriptionJohn Earl TejamoNo ratings yet

- MAINTENANCE SCHEDULE W32A4L00BTM01A Rev 01Document2 pagesMAINTENANCE SCHEDULE W32A4L00BTM01A Rev 01John Earl TejamoNo ratings yet

- 08 AUTOMATION SYSTEM W3208L00BTM10A Rev 01Document42 pages08 AUTOMATION SYSTEM W3208L00BTM10A Rev 01John Earl TejamoNo ratings yet

- Control and Istrumentazion System W3207L00BTM02C Rev 01Document45 pagesControl and Istrumentazion System W3207L00BTM02C Rev 01John Earl TejamoNo ratings yet

- Safety: Separation SystemDocument12 pagesSafety: Separation SystemJohn Earl TejamoNo ratings yet

- 02 FUEL SYSTEM W3202L00BTM04A Rev 01Document64 pages02 FUEL SYSTEM W3202L00BTM04A Rev 01John Earl TejamoNo ratings yet

- 03 LUBRICANT OIL SYSTEM W3203L00BTM08B Rev 01Document41 pages03 LUBRICANT OIL SYSTEM W3203L00BTM08B Rev 01John Earl TejamoNo ratings yet

- 21 - Starting Air SystemDocument11 pages21 - Starting Air SystemJohn Earl TejamoNo ratings yet

- 12 - Cylinder Head With ValvesDocument21 pages12 - Cylinder Head With ValvesJohn Earl TejamoNo ratings yet

- Engine Instruction ManualDocument3 pagesEngine Instruction ManualJohn Earl TejamoNo ratings yet

- Workshop Manual: Technical DataDocument36 pagesWorkshop Manual: Technical DataNaing Min HtunNo ratings yet

- Cat - G 3616Document6 pagesCat - G 3616aghakhanyNo ratings yet

- Turbo ChargerDocument23 pagesTurbo Chargerselvaraj9223100% (1)

- Cummins DGFA Data Sheet PDFDocument4 pagesCummins DGFA Data Sheet PDFSaqib iqbalNo ratings yet

- Plant Air BrochureDocument20 pagesPlant Air Brochure陳0鴻No ratings yet

- 3512 Engine OverhaulDocument7 pages3512 Engine OverhaulDarkman P and B75% (4)

- Optimization Problems Paper FinalDocument14 pagesOptimization Problems Paper FinalEnrique GalindoNo ratings yet

- ME22 ETH - GBDocument189 pagesME22 ETH - GBMUSTAFA0% (1)

- LS-16 Sullair ManualDocument112 pagesLS-16 Sullair Manualbinhleduc36100% (2)

- Operating Instructions: Diesel Engine 12 V 4000 M93 X 16 V 4000 M93 XDocument223 pagesOperating Instructions: Diesel Engine 12 V 4000 M93 X 16 V 4000 M93 XNaftal MassingueNo ratings yet

- Volkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolDocument128 pagesVolkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolAndres Jauregui Garcia100% (3)

- Sullair LS120Document172 pagesSullair LS120martin_jaitman100% (1)

- Assignment 1Document6 pagesAssignment 1kaushalshah28598No ratings yet

- Sperre Air Compressor HV2-200Document30 pagesSperre Air Compressor HV2-200Tomislav Korencic75% (4)

- MS150048 04e 20V4000M93Document200 pagesMS150048 04e 20V4000M93Giang DoNo ratings yet

- ZR - ZT 110-900 BrochureDocument24 pagesZR - ZT 110-900 BrochureSreenivasNo ratings yet

- System Practices For Ammonia and Carbon Dioxide RefrigerantsDocument27 pagesSystem Practices For Ammonia and Carbon Dioxide Refrigerants1940LaSalleNo ratings yet

- D-Line: Operation ManualDocument134 pagesD-Line: Operation Manualabduallah muhammadNo ratings yet

- Cat 3612leDocument4 pagesCat 3612letomjones77100% (1)

- Two Stage Air CompressorDocument7 pagesTwo Stage Air CompressormohammedNo ratings yet

- UntitledDocument1 pageUntitledJehana NaolNo ratings yet

- Moisture Separators enDocument4 pagesMoisture Separators enLa Ode AdhanNo ratings yet

- Operacion MotorDocument67 pagesOperacion Motorvictor100% (1)

- TE-I Lesson PlanDocument6 pagesTE-I Lesson PlanArunkumar MunimathanNo ratings yet