Professional Documents

Culture Documents

Procedure Homemade Soap

Procedure Homemade Soap

Uploaded by

Ni Putu Sumaryati 2113081027Copyright:

Available Formats

You might also like

- Aoac MethodDocument4 pagesAoac MethodRam Kumar100% (3)

- Kinetic Versus Thermodynamic Control in Chemical ReactionsDocument8 pagesKinetic Versus Thermodynamic Control in Chemical Reactionsmontanab0093No ratings yet

- Analytical Methods: Determination of Moisture Content (AOAC, 2000)Document4 pagesAnalytical Methods: Determination of Moisture Content (AOAC, 2000)Tamiko Medalith Mitzuma Ulloa100% (3)

- Okuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFDocument588 pagesOkuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFAntonioCanestriJúnior100% (3)

- Oil Tech Final PDFDocument22 pagesOil Tech Final PDFRB CreationNo ratings yet

- Lab Report 5Document10 pagesLab Report 5Ahmad ZakwanNo ratings yet

- Determination of Moisture Content (AOAC, 1999)Document0 pagesDetermination of Moisture Content (AOAC, 1999)Hamid MojiryNo ratings yet

- Biodiesel From Waste Veg. OilDocument4 pagesBiodiesel From Waste Veg. OilupenderdhullNo ratings yet

- Roteiro de SinteseDocument3 pagesRoteiro de SinteseGuilherme FreitasNo ratings yet

- Salicylic AcidDocument4 pagesSalicylic AcidWwJd HeavenNo ratings yet

- Banana OilDocument2 pagesBanana Oilpuskesmas mranggenNo ratings yet

- Total Solid in MilkDocument3 pagesTotal Solid in Milkediasianagri100% (1)

- Cho 393 Sem ReadyDocument11 pagesCho 393 Sem Readypapey42271No ratings yet

- 2nd Experiment - Aldol CondensationDocument2 pages2nd Experiment - Aldol Condensationiluvm92No ratings yet

- CHM557 Experiment 5 - The Robinson Annulation ReactionDocument9 pagesCHM557 Experiment 5 - The Robinson Annulation ReactionMamamia0% (1)

- AOAC 2020.08 Lactose Concentration in Milk, Milk Products and Dairy Ingredients by Megazyme Test KitDocument7 pagesAOAC 2020.08 Lactose Concentration in Milk, Milk Products and Dairy Ingredients by Megazyme Test KitdcardonasterNo ratings yet

- Robinson Annulation Reaction of 3-Nitrochalcone With Ethyl AcetoacetateDocument9 pagesRobinson Annulation Reaction of 3-Nitrochalcone With Ethyl AcetoacetateAmirul Azhar100% (5)

- Hydrometer Method With PhotosDocument10 pagesHydrometer Method With Photosvennila-puviNo ratings yet

- Experiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationDocument3 pagesExperiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationLindelwa MthembuNo ratings yet

- Re Xtal F07Document5 pagesRe Xtal F07prakush_prakushNo ratings yet

- Chemistry Content Based ExpirimentsDocument22 pagesChemistry Content Based ExpirimentsHari VaarthanNo ratings yet

- 7 - Synthesis of Soap PDFDocument4 pages7 - Synthesis of Soap PDFSipahutar Bangkit Kali Syahputra0% (1)

- Acid Hydrolysis of Organic Materials: Sessions Biogeochemistry Lab July, 2009Document2 pagesAcid Hydrolysis of Organic Materials: Sessions Biogeochemistry Lab July, 2009Kris Dela CruzNo ratings yet

- Saponification of Methyl Salicylate 1Document2 pagesSaponification of Methyl Salicylate 1goyal8974No ratings yet

- CHM 556 Experiment 5Document12 pagesCHM 556 Experiment 5Amar Safwan100% (1)

- K-Bglu 1107 DataDocument16 pagesK-Bglu 1107 Datapi_yoanaNo ratings yet

- The Gravimetric Determination of NickelDocument7 pagesThe Gravimetric Determination of Nickelswathi_ravi_5No ratings yet

- Biodiesel Lab: Matt Babb Tommy Haase Andrew Hayduk Mackenzie Bolton Siggy ArndtDocument2 pagesBiodiesel Lab: Matt Babb Tommy Haase Andrew Hayduk Mackenzie Bolton Siggy Arndtapi-279478260No ratings yet

- Exp7 PDFDocument4 pagesExp7 PDFAshkan AbbasiNo ratings yet

- Nickel Gravimetric F08Document4 pagesNickel Gravimetric F08Charles David CabigonNo ratings yet

- BenzoinDocument4 pagesBenzoinNurudeen IbrahimNo ratings yet

- Experiment 24: Methods of Pollution Control and Waste ManagementDocument5 pagesExperiment 24: Methods of Pollution Control and Waste Managementفؤاد مهندسNo ratings yet

- Experiment-Fat EstimationDocument3 pagesExperiment-Fat EstimationRyanNo ratings yet

- Hec Test ProcedureDocument3 pagesHec Test ProcedureAmbrish KumarNo ratings yet

- Experimental Procedures OrganicDocument7 pagesExperimental Procedures OrganicAishahNo ratings yet

- Synthesis of Lidocaine: Chemistry 212 LaboratoryDocument4 pagesSynthesis of Lidocaine: Chemistry 212 LaboratoryNuteLLa Gaming (EFL)No ratings yet

- Soap Is Produced by The Saponification (Hydrolysis) of A Triglyceride (Fat or Oil) - (See Figure 1.)Document5 pagesSoap Is Produced by The Saponification (Hydrolysis) of A Triglyceride (Fat or Oil) - (See Figure 1.)Vignesh SivakumarNo ratings yet

- Tdf100a Tdfc10 en Fibra DieteticaDocument4 pagesTdf100a Tdfc10 en Fibra DieteticaRosa Karen Suarez GuzmanNo ratings yet

- Re CrystallizationDocument7 pagesRe CrystallizationAli NasrallahNo ratings yet

- Recrystallization of AcetanilideDocument6 pagesRecrystallization of AcetanilideButterlesstoastNo ratings yet

- Robinson Annulation Reaction of NItrochalconeDocument10 pagesRobinson Annulation Reaction of NItrochalconeMohd Nakirudin Muhamad NorNo ratings yet

- Exp 3 - F23Document4 pagesExp 3 - F23s127886No ratings yet

- Genomic Dna From InsectsDocument2 pagesGenomic Dna From InsectsErdelyi-Molnár ImolaNo ratings yet

- 24 AspirinDocument4 pages24 AspirinAyoeYoeRamndaniNo ratings yet

- Supersaturated Sodium Acetate: NCSU - Dept. of Chemistry - Lecture DemonstrationsDocument2 pagesSupersaturated Sodium Acetate: NCSU - Dept. of Chemistry - Lecture DemonstrationsansenoraNo ratings yet

- Org Lab 5Document8 pagesOrg Lab 5Bacillus SubtilisNo ratings yet

- Gldchemistry LabDocument4 pagesGldchemistry Labapi-285160591No ratings yet

- K-Sdam DataDocument12 pagesK-Sdam Data2nmzgbvk6cNo ratings yet

- Fooladi Et Al.. 2019. Protocol For Derivatization and Determination of Structural Monosaccharides in Crude Fungal ExopolysaccharideDocument12 pagesFooladi Et Al.. 2019. Protocol For Derivatization and Determination of Structural Monosaccharides in Crude Fungal ExopolysaccharideAzb 711No ratings yet

- Review Ppt.3Document12 pagesReview Ppt.3devikamurugan124206No ratings yet

- Aldol CondensationDocument3 pagesAldol CondensationDaniel McDermottNo ratings yet

- 1 Fischer EsterificationDocument2 pages1 Fischer EsterificationMuhammad Iqbal ChandioNo ratings yet

- 11 Heterocycle - JER 2011 VersionDocument3 pages11 Heterocycle - JER 2011 Versionstudent_4_eva0% (3)

- A 21 A - Whey Protein Nitrogen Index - tcm11-30931Document6 pagesA 21 A - Whey Protein Nitrogen Index - tcm11-30931Sudhanandh VSNo ratings yet

- Fat TotalDocument15 pagesFat TotalFathy MehayaNo ratings yet

- Saponification and The Making of SoapDocument5 pagesSaponification and The Making of SoapMoonlight sweetheartNo ratings yet

- METHODOLOGY For Proxi AnalysisDocument7 pagesMETHODOLOGY For Proxi AnalysisDaw Thant Mon PaingNo ratings yet

- Fat Content DeterminationDocument2 pagesFat Content DeterminationHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Keto Bread: Discover 30 Easy to Follow Ketogenic Cookbook Bread Recipes For Your Low-Carb Diet With Gluten-Free and Wheat to Maximize Your Weight LossFrom EverandKeto Bread: Discover 30 Easy to Follow Ketogenic Cookbook Bread Recipes For Your Low-Carb Diet With Gluten-Free and Wheat to Maximize Your Weight LossRating: 5 out of 5 stars5/5 (2)

- Quick & Easy Delicious Meals on Slow Cooker: 100+ Easy & Quick ways to cook your traditional long forgotten recipes on slow cookerFrom EverandQuick & Easy Delicious Meals on Slow Cooker: 100+ Easy & Quick ways to cook your traditional long forgotten recipes on slow cookerNo ratings yet

- What Is Fsharp Microsoft DocumentDocument582 pagesWhat Is Fsharp Microsoft DocumentMaamar DliouahNo ratings yet

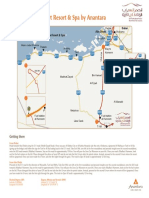

- Qasr Al Sarab Desert Resort Location Map June2012Document1 pageQasr Al Sarab Desert Resort Location Map June2012Anant GârgNo ratings yet

- 4707 Russ Horn Secret MethodDocument2 pages4707 Russ Horn Secret Methodseehari100% (1)

- Máy Ly Tâm Đa Năng Lớn Hơn Hoặc Bằng 4000 V Trên PDocument2 pagesMáy Ly Tâm Đa Năng Lớn Hơn Hoặc Bằng 4000 V Trên PTrần Thanh ViệnNo ratings yet

- FSBB20CH60F 83493Document15 pagesFSBB20CH60F 83493Hla Swe OoNo ratings yet

- Difference Between Evidence and Proof - Definition, Meaning, UsageDocument5 pagesDifference Between Evidence and Proof - Definition, Meaning, UsageAnna VõNo ratings yet

- Introduction To Industrial Automation Topic 1Document13 pagesIntroduction To Industrial Automation Topic 1Vedant .ChavanNo ratings yet

- Determination of Chloride Ions in A Given Water SampleDocument5 pagesDetermination of Chloride Ions in A Given Water SampleMg H100% (2)

- CON4334A2TO130523BL Ch2 Connection Soln PDFDocument8 pagesCON4334A2TO130523BL Ch2 Connection Soln PDFLeung Wai YipNo ratings yet

- Studies On Biosorption of Titan Yellow Dye With Hyptis Suaveolens Powder and Optimization Through Central Composite DesignDocument16 pagesStudies On Biosorption of Titan Yellow Dye With Hyptis Suaveolens Powder and Optimization Through Central Composite DesignInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bahasa Inggris Teknik - Controlling The Plant InstrumentationDocument15 pagesBahasa Inggris Teknik - Controlling The Plant InstrumentationIka Mustika WatiNo ratings yet

- Secant Piled Walls Dsign 160210011455Document54 pagesSecant Piled Walls Dsign 160210011455ariyarathne100% (4)

- Process Hazard Analysis Software GuideDocument6 pagesProcess Hazard Analysis Software GuideAdarsh Sv100% (1)

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- Previous Page: It ThatDocument18 pagesPrevious Page: It ThatKunwar Apoorva SinghNo ratings yet

- Electroceramics Prof. Ashish Garg Department of Materials Science and Engineering Indian Institute of Technology, Kanpur Lecture - 32Document36 pagesElectroceramics Prof. Ashish Garg Department of Materials Science and Engineering Indian Institute of Technology, Kanpur Lecture - 32JATCNo ratings yet

- Pex 03 01Document8 pagesPex 03 01Bianca D. SerlsNo ratings yet

- SECOND PERIODICAL EXAMINATION g-8Document3 pagesSECOND PERIODICAL EXAMINATION g-8Gladys G. Candido100% (4)

- Dbms Imp NotesDocument5 pagesDbms Imp NotesRishi Raj K0% (1)

- Service Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Document100 pagesService Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Wilfredo PérezNo ratings yet

- ESDU BrochureDocument3 pagesESDU BrochureWilhelm ThorleyNo ratings yet

- Questions 1-10: Comprehension Practice Second Term 1Document4 pagesQuestions 1-10: Comprehension Practice Second Term 1leena saNo ratings yet

- 55 60 Manual Tilt SystemDocument38 pages55 60 Manual Tilt SystemRyan ActonNo ratings yet

- Müller & Garcia, 2022b, Oldest Dinosauromorpha South AmericaDocument7 pagesMüller & Garcia, 2022b, Oldest Dinosauromorpha South Americamauricio.garciaNo ratings yet

- Template For Taf, SigmetawlfDocument10 pagesTemplate For Taf, Sigmetawlfchinna rajaNo ratings yet

- Acronis Backup Cloud v.7.7 Troubleshooting enDocument46 pagesAcronis Backup Cloud v.7.7 Troubleshooting enAlexandru PetrașNo ratings yet

- Ritesh Thesis (107ce013)Document43 pagesRitesh Thesis (107ce013)Singh AmitNo ratings yet

- Chapter 5 Stresses in Beams With Solved ProblemsDocument65 pagesChapter 5 Stresses in Beams With Solved ProblemsWnikyla Manggad BalanguiNo ratings yet

- Laboratory Bias Detection Using Single Test Result From Standard MaterialDocument5 pagesLaboratory Bias Detection Using Single Test Result From Standard Materialmohammed karasnehNo ratings yet

Procedure Homemade Soap

Procedure Homemade Soap

Uploaded by

Ni Putu Sumaryati 2113081027Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Homemade Soap

Procedure Homemade Soap

Uploaded by

Ni Putu Sumaryati 2113081027Copyright:

Available Formats

PROCEDURE: A HOMEMADE SOAP

a) Conventional Heating

1. NaOH (1 gram) + Distilled water (2,7 mL)

2. While the NaOH is dissolving, warming the oil (6 gram) in a small beaker on a hot

plate to 115°C. Use a magnetic stir bar to keep the oil moving.

3. Heat the NaOH in erlenmeyer flask use hot plate to 115°C.

4. When the oil and the NaOH solution are both at 115 °C, pour the NaOH solution into

the beaker with the oil, stir the reaction mixture vigorously and maintain a

temperature of 115 °C for 30 minutes.

5. Quickly transfer the contents to a small hexagonal polystyrene weighing boat and the

product must cure for a week’s time in storage.

b) Microwave-Assisted Synthesis

1. NaOH (0,5 gram) + Distilled water (1,5 mL)

2. Place your oil (3 gram) into the chemglass vial and secure the cap tightly.

3. A ramp-to-temperature program is used to heat the oil to 140°C over five minute’s

time.

4. Remove the vial from the carousel and slowly uncap the vial to vent excess pressure.

Quickly add the prepared NaOH solution and a stir bar. Recap the vial and load the

vial into the microwave again.

5. A ramp-to-temperature program will heat the contents to 115°C over three minutes.

This temperature is maintained for an additional 5 minutes.

6. Quickly transfer the product to a hexagonal polystyrene weighing boat.

PROCEDURE: BIODIESEL PRODUCTION

a) Conventional Heating

1. Methanol or ethanol (5 mL) + NaOH (0,1 gram)

2. While the NaOH is dissolving, weigh 10 g of your chosen oil directly into a threaded

round-bottom flask.

3. Assemble a reflux apparatus with a water-jacketed condenser and pre-heat an oil bath

to 50°C on a hot plate.

4. Add NaOH solution to the oil.

5. Attach the flask to the reflux apparatus and begin to heat the solutionuntul 1 hour.

Stir the solution vigorously with a magnetic stir bar to maintain a homogenous

mixture.

6. Upon cooling, two distinct layers should form. Remove the lower layer; this is the

byproduct of the reaction.

7. Qualitatively assess your product. Notice any color changes, changes in viscosity, and

other alterations in appearance. Calculate percent yield, collect an IR spectrum, and

save the product in order to determine the optical rotation.

b) Microwave-Assisted Synthesis

1. Methanol or ethanol or water (2,5 mL) + NaOH (0,05 gram)

2. Add 5 gram of oil to chemglass vial, add the NaOH solution and a stir bar to the

vial and cap the vial tightly.

3. Place the vial in the carousel and transfer it to the CEM MARS microwave unit.

4. A ramp-to-temperature program is used to heat the reaction to 50°C over three

minute’s time and then hold the temperature at 50°C for an additional five

minutes.

5. Remove the lower layer (if applicable); notice any color changes, changes in

viscosity, and other alterations in appearance in the upper layer.

6. Calculate percent yield, collect an IR spectrum, and save the product in order to

determine the optical rotation

You might also like

- Aoac MethodDocument4 pagesAoac MethodRam Kumar100% (3)

- Kinetic Versus Thermodynamic Control in Chemical ReactionsDocument8 pagesKinetic Versus Thermodynamic Control in Chemical Reactionsmontanab0093No ratings yet

- Analytical Methods: Determination of Moisture Content (AOAC, 2000)Document4 pagesAnalytical Methods: Determination of Moisture Content (AOAC, 2000)Tamiko Medalith Mitzuma Ulloa100% (3)

- Okuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFDocument588 pagesOkuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFAntonioCanestriJúnior100% (3)

- Oil Tech Final PDFDocument22 pagesOil Tech Final PDFRB CreationNo ratings yet

- Lab Report 5Document10 pagesLab Report 5Ahmad ZakwanNo ratings yet

- Determination of Moisture Content (AOAC, 1999)Document0 pagesDetermination of Moisture Content (AOAC, 1999)Hamid MojiryNo ratings yet

- Biodiesel From Waste Veg. OilDocument4 pagesBiodiesel From Waste Veg. OilupenderdhullNo ratings yet

- Roteiro de SinteseDocument3 pagesRoteiro de SinteseGuilherme FreitasNo ratings yet

- Salicylic AcidDocument4 pagesSalicylic AcidWwJd HeavenNo ratings yet

- Banana OilDocument2 pagesBanana Oilpuskesmas mranggenNo ratings yet

- Total Solid in MilkDocument3 pagesTotal Solid in Milkediasianagri100% (1)

- Cho 393 Sem ReadyDocument11 pagesCho 393 Sem Readypapey42271No ratings yet

- 2nd Experiment - Aldol CondensationDocument2 pages2nd Experiment - Aldol Condensationiluvm92No ratings yet

- CHM557 Experiment 5 - The Robinson Annulation ReactionDocument9 pagesCHM557 Experiment 5 - The Robinson Annulation ReactionMamamia0% (1)

- AOAC 2020.08 Lactose Concentration in Milk, Milk Products and Dairy Ingredients by Megazyme Test KitDocument7 pagesAOAC 2020.08 Lactose Concentration in Milk, Milk Products and Dairy Ingredients by Megazyme Test KitdcardonasterNo ratings yet

- Robinson Annulation Reaction of 3-Nitrochalcone With Ethyl AcetoacetateDocument9 pagesRobinson Annulation Reaction of 3-Nitrochalcone With Ethyl AcetoacetateAmirul Azhar100% (5)

- Hydrometer Method With PhotosDocument10 pagesHydrometer Method With Photosvennila-puviNo ratings yet

- Experiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationDocument3 pagesExperiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationLindelwa MthembuNo ratings yet

- Re Xtal F07Document5 pagesRe Xtal F07prakush_prakushNo ratings yet

- Chemistry Content Based ExpirimentsDocument22 pagesChemistry Content Based ExpirimentsHari VaarthanNo ratings yet

- 7 - Synthesis of Soap PDFDocument4 pages7 - Synthesis of Soap PDFSipahutar Bangkit Kali Syahputra0% (1)

- Acid Hydrolysis of Organic Materials: Sessions Biogeochemistry Lab July, 2009Document2 pagesAcid Hydrolysis of Organic Materials: Sessions Biogeochemistry Lab July, 2009Kris Dela CruzNo ratings yet

- Saponification of Methyl Salicylate 1Document2 pagesSaponification of Methyl Salicylate 1goyal8974No ratings yet

- CHM 556 Experiment 5Document12 pagesCHM 556 Experiment 5Amar Safwan100% (1)

- K-Bglu 1107 DataDocument16 pagesK-Bglu 1107 Datapi_yoanaNo ratings yet

- The Gravimetric Determination of NickelDocument7 pagesThe Gravimetric Determination of Nickelswathi_ravi_5No ratings yet

- Biodiesel Lab: Matt Babb Tommy Haase Andrew Hayduk Mackenzie Bolton Siggy ArndtDocument2 pagesBiodiesel Lab: Matt Babb Tommy Haase Andrew Hayduk Mackenzie Bolton Siggy Arndtapi-279478260No ratings yet

- Exp7 PDFDocument4 pagesExp7 PDFAshkan AbbasiNo ratings yet

- Nickel Gravimetric F08Document4 pagesNickel Gravimetric F08Charles David CabigonNo ratings yet

- BenzoinDocument4 pagesBenzoinNurudeen IbrahimNo ratings yet

- Experiment 24: Methods of Pollution Control and Waste ManagementDocument5 pagesExperiment 24: Methods of Pollution Control and Waste Managementفؤاد مهندسNo ratings yet

- Experiment-Fat EstimationDocument3 pagesExperiment-Fat EstimationRyanNo ratings yet

- Hec Test ProcedureDocument3 pagesHec Test ProcedureAmbrish KumarNo ratings yet

- Experimental Procedures OrganicDocument7 pagesExperimental Procedures OrganicAishahNo ratings yet

- Synthesis of Lidocaine: Chemistry 212 LaboratoryDocument4 pagesSynthesis of Lidocaine: Chemistry 212 LaboratoryNuteLLa Gaming (EFL)No ratings yet

- Soap Is Produced by The Saponification (Hydrolysis) of A Triglyceride (Fat or Oil) - (See Figure 1.)Document5 pagesSoap Is Produced by The Saponification (Hydrolysis) of A Triglyceride (Fat or Oil) - (See Figure 1.)Vignesh SivakumarNo ratings yet

- Tdf100a Tdfc10 en Fibra DieteticaDocument4 pagesTdf100a Tdfc10 en Fibra DieteticaRosa Karen Suarez GuzmanNo ratings yet

- Re CrystallizationDocument7 pagesRe CrystallizationAli NasrallahNo ratings yet

- Recrystallization of AcetanilideDocument6 pagesRecrystallization of AcetanilideButterlesstoastNo ratings yet

- Robinson Annulation Reaction of NItrochalconeDocument10 pagesRobinson Annulation Reaction of NItrochalconeMohd Nakirudin Muhamad NorNo ratings yet

- Exp 3 - F23Document4 pagesExp 3 - F23s127886No ratings yet

- Genomic Dna From InsectsDocument2 pagesGenomic Dna From InsectsErdelyi-Molnár ImolaNo ratings yet

- 24 AspirinDocument4 pages24 AspirinAyoeYoeRamndaniNo ratings yet

- Supersaturated Sodium Acetate: NCSU - Dept. of Chemistry - Lecture DemonstrationsDocument2 pagesSupersaturated Sodium Acetate: NCSU - Dept. of Chemistry - Lecture DemonstrationsansenoraNo ratings yet

- Org Lab 5Document8 pagesOrg Lab 5Bacillus SubtilisNo ratings yet

- Gldchemistry LabDocument4 pagesGldchemistry Labapi-285160591No ratings yet

- K-Sdam DataDocument12 pagesK-Sdam Data2nmzgbvk6cNo ratings yet

- Fooladi Et Al.. 2019. Protocol For Derivatization and Determination of Structural Monosaccharides in Crude Fungal ExopolysaccharideDocument12 pagesFooladi Et Al.. 2019. Protocol For Derivatization and Determination of Structural Monosaccharides in Crude Fungal ExopolysaccharideAzb 711No ratings yet

- Review Ppt.3Document12 pagesReview Ppt.3devikamurugan124206No ratings yet

- Aldol CondensationDocument3 pagesAldol CondensationDaniel McDermottNo ratings yet

- 1 Fischer EsterificationDocument2 pages1 Fischer EsterificationMuhammad Iqbal ChandioNo ratings yet

- 11 Heterocycle - JER 2011 VersionDocument3 pages11 Heterocycle - JER 2011 Versionstudent_4_eva0% (3)

- A 21 A - Whey Protein Nitrogen Index - tcm11-30931Document6 pagesA 21 A - Whey Protein Nitrogen Index - tcm11-30931Sudhanandh VSNo ratings yet

- Fat TotalDocument15 pagesFat TotalFathy MehayaNo ratings yet

- Saponification and The Making of SoapDocument5 pagesSaponification and The Making of SoapMoonlight sweetheartNo ratings yet

- METHODOLOGY For Proxi AnalysisDocument7 pagesMETHODOLOGY For Proxi AnalysisDaw Thant Mon PaingNo ratings yet

- Fat Content DeterminationDocument2 pagesFat Content DeterminationHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Keto Bread: Discover 30 Easy to Follow Ketogenic Cookbook Bread Recipes For Your Low-Carb Diet With Gluten-Free and Wheat to Maximize Your Weight LossFrom EverandKeto Bread: Discover 30 Easy to Follow Ketogenic Cookbook Bread Recipes For Your Low-Carb Diet With Gluten-Free and Wheat to Maximize Your Weight LossRating: 5 out of 5 stars5/5 (2)

- Quick & Easy Delicious Meals on Slow Cooker: 100+ Easy & Quick ways to cook your traditional long forgotten recipes on slow cookerFrom EverandQuick & Easy Delicious Meals on Slow Cooker: 100+ Easy & Quick ways to cook your traditional long forgotten recipes on slow cookerNo ratings yet

- What Is Fsharp Microsoft DocumentDocument582 pagesWhat Is Fsharp Microsoft DocumentMaamar DliouahNo ratings yet

- Qasr Al Sarab Desert Resort Location Map June2012Document1 pageQasr Al Sarab Desert Resort Location Map June2012Anant GârgNo ratings yet

- 4707 Russ Horn Secret MethodDocument2 pages4707 Russ Horn Secret Methodseehari100% (1)

- Máy Ly Tâm Đa Năng Lớn Hơn Hoặc Bằng 4000 V Trên PDocument2 pagesMáy Ly Tâm Đa Năng Lớn Hơn Hoặc Bằng 4000 V Trên PTrần Thanh ViệnNo ratings yet

- FSBB20CH60F 83493Document15 pagesFSBB20CH60F 83493Hla Swe OoNo ratings yet

- Difference Between Evidence and Proof - Definition, Meaning, UsageDocument5 pagesDifference Between Evidence and Proof - Definition, Meaning, UsageAnna VõNo ratings yet

- Introduction To Industrial Automation Topic 1Document13 pagesIntroduction To Industrial Automation Topic 1Vedant .ChavanNo ratings yet

- Determination of Chloride Ions in A Given Water SampleDocument5 pagesDetermination of Chloride Ions in A Given Water SampleMg H100% (2)

- CON4334A2TO130523BL Ch2 Connection Soln PDFDocument8 pagesCON4334A2TO130523BL Ch2 Connection Soln PDFLeung Wai YipNo ratings yet

- Studies On Biosorption of Titan Yellow Dye With Hyptis Suaveolens Powder and Optimization Through Central Composite DesignDocument16 pagesStudies On Biosorption of Titan Yellow Dye With Hyptis Suaveolens Powder and Optimization Through Central Composite DesignInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bahasa Inggris Teknik - Controlling The Plant InstrumentationDocument15 pagesBahasa Inggris Teknik - Controlling The Plant InstrumentationIka Mustika WatiNo ratings yet

- Secant Piled Walls Dsign 160210011455Document54 pagesSecant Piled Walls Dsign 160210011455ariyarathne100% (4)

- Process Hazard Analysis Software GuideDocument6 pagesProcess Hazard Analysis Software GuideAdarsh Sv100% (1)

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- Previous Page: It ThatDocument18 pagesPrevious Page: It ThatKunwar Apoorva SinghNo ratings yet

- Electroceramics Prof. Ashish Garg Department of Materials Science and Engineering Indian Institute of Technology, Kanpur Lecture - 32Document36 pagesElectroceramics Prof. Ashish Garg Department of Materials Science and Engineering Indian Institute of Technology, Kanpur Lecture - 32JATCNo ratings yet

- Pex 03 01Document8 pagesPex 03 01Bianca D. SerlsNo ratings yet

- SECOND PERIODICAL EXAMINATION g-8Document3 pagesSECOND PERIODICAL EXAMINATION g-8Gladys G. Candido100% (4)

- Dbms Imp NotesDocument5 pagesDbms Imp NotesRishi Raj K0% (1)

- Service Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Document100 pagesService Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Wilfredo PérezNo ratings yet

- ESDU BrochureDocument3 pagesESDU BrochureWilhelm ThorleyNo ratings yet

- Questions 1-10: Comprehension Practice Second Term 1Document4 pagesQuestions 1-10: Comprehension Practice Second Term 1leena saNo ratings yet

- 55 60 Manual Tilt SystemDocument38 pages55 60 Manual Tilt SystemRyan ActonNo ratings yet

- Müller & Garcia, 2022b, Oldest Dinosauromorpha South AmericaDocument7 pagesMüller & Garcia, 2022b, Oldest Dinosauromorpha South Americamauricio.garciaNo ratings yet

- Template For Taf, SigmetawlfDocument10 pagesTemplate For Taf, Sigmetawlfchinna rajaNo ratings yet

- Acronis Backup Cloud v.7.7 Troubleshooting enDocument46 pagesAcronis Backup Cloud v.7.7 Troubleshooting enAlexandru PetrașNo ratings yet

- Ritesh Thesis (107ce013)Document43 pagesRitesh Thesis (107ce013)Singh AmitNo ratings yet

- Chapter 5 Stresses in Beams With Solved ProblemsDocument65 pagesChapter 5 Stresses in Beams With Solved ProblemsWnikyla Manggad BalanguiNo ratings yet

- Laboratory Bias Detection Using Single Test Result From Standard MaterialDocument5 pagesLaboratory Bias Detection Using Single Test Result From Standard Materialmohammed karasnehNo ratings yet