Professional Documents

Culture Documents

HTM 02-01 50Hz (PureMed) Medical Air Plant TDS

HTM 02-01 50Hz (PureMed) Medical Air Plant TDS

Uploaded by

Chou AllenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HTM 02-01 50Hz (PureMed) Medical Air Plant TDS

HTM 02-01 50Hz (PureMed) Medical Air Plant TDS

Uploaded by

Chou AllenCopyright:

Available Formats

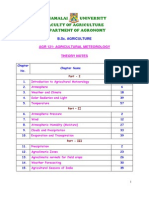

Technical Datasheet

Medical Air Plant

HTM 02-01 • 50 Hz

Description

Medical Air Plants are intended to provide a continuous

supply of medical quality air conforming to the European

Pharmacopoeia medicinal air monograph (ref. 1238), for

respiratory use in healthcare facilities. The system shall

be duplex such that the supply is maintained in single

fault condition. Standby compressors shall be provided

such that the specified volumetric flow is achieved with

either one reserve compressor on standby where an

automatic backup manifold of sufficient capacity is

provided, or two compressors not running if the backup

manifold is unable to deliver the medical air system

design flow. Medical Air Plants shall be supplied fully

tested and comply with the United Kingdom Department

of Health (DoH) publication HTM 02-01, NHS Model

Engineering Specification C11 and ISO 7396-1.

Pneumatech Medical Gas Solutions Medical Air Plants

are CE marked to the Medical Device Directive • Activated carbon filter: max remaining total oil

93/42/EEC under the auspices of notified body no. 0088 content of 0,003 mg/m³, tested according to ISO

(Lloyd’s). Under this directive, Medical Air Plants are 8573-5 & ISO12500-2;

classified as Class IIb Medical Devices. • Bacterial filter: particle count efficiency of

99,98% at MPPS=0.06µm, tested according to

Compressors ISO 12500-3.

Compressors shall be Atlas Copco GA MED or GA VSD+ Contaminants in the delivered air downstream of the

MED oil injected rotary screw compressors suitable for bacteria filters shall be maintained at levels below those

both continuous and frequent start/stop operation at a shown in the table below:

nominal outlet pressure of 750kPa (7.5bar), 1000 kPa (10

bar) or 1300 kPa (13 bar) gauge. Compressors shall be

supplied with a block and fin style after cooler with a Contaminant Threshold

dedicated quiet running fan to maximise cooling and

efficiency. A multistage oil separator capable of achieving 67ppm v/v (-46°C atm.

H2O

2ppm oil carry over shall be fitted to minimise dp)

contamination and maintenance. Minimum IE3 (IEC CO 5 ppm v/v

60034) rated, IP55 class F electric motors shall be used CO2 500 ppm v/v

and incorporate maintenance-free bearings. Motors with

lower efficiency ratings are not acceptable. SO2 1 ppm v/v

NO 2 ppm v/v

If not variable speed, than compressor shall be provided NO2 2 ppm v/v

with Star-Delta (Wye-Delta) motor starters and each

motor shall be protected by a thermal overload relay. The Dry particulates ISO 8573-1 particle purity

incoming supply shall terminate at a door interlock Class 2

isolator. An ammeter shall be fitted to each starter panel Oil (droplet or mist) 0.1 mg/m³

indicating the current drawn by the motor. Tested under factory and site reference conditions.

Purification Module The purification module shall have the water

The duplexed filter and dryer module shall incorporate concentration in the delivered air continuously monitored

high efficiency oil coalescing filters, heatless by a dedicated sensor providing an alarm indication for

regenerative desiccant dryers, impregnated activated high dew point on the respective dryer.

carbon filters and bacterial filters. The performance of the

filters shall be according to below specifications: The outlet air pressure shall be regulated through a

duplex arrangement of non-relieving pressure regulators

• Oil coalescing high efficiency filter: mass and protected from over-pressure by duplex pressure

efficiency of 99,92%, tested according to ISO safety valves.

8573-2 & ISO 12500-1;

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Dryer Purge Control Each air receiver shall be fitted with an electrically

The dryer control system shall incorporate a Purge Saver actuated drain valve with integral solid-state timer

Energy Management system that freezes the providing user adjustable opening time and actuation

regeneration of the desiccant once adequate dew point frequency. The valve shall be fitted with a manual test

is reached in the inactive tower. Only when the dewpoint button and LED indication lights to show operating status.

level in the active tower deteriorates to an unacceptable The drain shall be protected from blockage by debris with

level will the intelligent controller switch towers. This shall a strainer. Float type mechanically actuated drain valves

be achieved by including an additional dew point sensor are not acceptable. Drain valves to be connected locally

and associated software in the dryer controller to to a single phase supply.

effectively manage the system as well as providing on

screen measurements of purge savings. Optional Items

There shall be the followings options available for

Plant Control Unit enhanced operation of the air plant system:

The central control system shall provide an intelligent

human machine interface incorporating on board flash • Phase sequence relays that prevent

memory and real-time clock for recording operational unintentional reverse operation of the

parameters in the in-built event log. The central control compressors (standard for GA15-26 MED &

system shall operate at low voltage and include BMS GA7-37 VSD+ MED compressors);

connection for plant fault, plant emergency, reserve fault • OCS water/oil separator for the air plant system;

and pressure fault. Visualisation of plant inputs, outputs • Synthetic oil for increased compressor life;

and status through a web browser, using a simple • Tropical thermostatic sensors for countries with

Ethernet connection shall be available. The central high humidity;

control unit shall incorporate a user friendly 3.5” high- • Heavy duty inlet filters for compressors installed

definition colour display with clear pictograms and LED in areas of highly concentrated dust levels;

indicators, providing easy access to system operational • 380V 60Hz versions are available on

information. The software shall be developed according request.

to EN 62304. A mechanical back-up facility shall ensure

continued operation in the event of a control system Note: Interconnecting pipework between

malfunction. The control system shall normally employ components to be made on site and provided by the

automatic rotation of the lead compressor to maximise installer. Controller CAN cables are provided as a

life and ensure even wear. 10m assembly with each compressor which can be

Digital Dew Point Display shortened on site if required.

The purification module shall incorporate a dew point

Combined Air Plant Sizing Guide

hygrometer with an accuracy of ±3°C in the range +20 to

In HTM02-01, the relative size of receiver capacity and

-60°C atmospheric dew point and 4-20 mA analogue

compressor capacity on surgical air or combined

output. Aluminium oxide or palladium wire sensors are

medical/surgical air systems changes according to the

not acceptable. An alarm condition shall trigger on the

design flow rate. In order to correctly calculate the

dryer control panel if the dew point exceeds a -46°C receiver capacity and compressor capacity, both the

atmospheric (67 ppm v/v) set point. Voltage-free contacts medical and surgical design flow-rates (DF’s) are

shall be included to enable the dew point alarm signal required. It should be noted that for all combined air

(Plant Emergency) to be connected to a central medical systems, an additional duplex regulating station (ordered

gas alarm system and/or building management system separately) is needed to supply the medical air pipeline.

(BMS).

Design Flow Value ‘A’

Air Receiver(s) (l/min) FAD (l)

Surgical Air

Air receivers shall comply with BS EN 286-1;+A2 2005 <500 0.33 x DF

Compressors

and be manufactured from heavy gauge fusion welded 500 - 3500 0.66 x DF

steel with a minimum wall thickness of 5 mm and dished >3500 0.5 x DF

ends with a minimum wall thickness of 6 mm. Total air Table 1: Surgical Air Flow Rate Multiplier Value ‘A’

receiver volume shall be at least 50% of the plant

capacity in 1 minute in terms of free air delivered at Design Flow Value ‘B’

normal working pressure. Air receiver shall be connected (l/min) FAD (l)

to the dryer in parallel such that operation of the system Surgical Air <500 1 x 200% x DF

Receivers 500 - 2000 2 x 66.6% x DF

can continue during receiver isolation for periodic internal

2001 - 3500 2 x 50% x DF

inspection. The receiver assembly shall be fitted with a

>3500 3 x 33.3% x DF

pressure safety valve set at 11 or 14bar. The receiver

Table 2: Surgical Air Receiver Multiplier Value ‘B’

shall be further protected by a fusible plug and include a

100 mm nominal diameter pressure gauge complete with

isolating valve.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Example

Receiver Sizing

Flow Rate and Dryer Sizing From Table 2 surgical air DF is between 500-2000 l/min,

so the multiplying factor ‘B’ = 2 x 2/3

Medical Air DF = 1550 l/min (FAD) (4 Bar)

Capacity = (Med. DF x 0.5) + (Surg. DF x B)

Surgical Air DF = 1550 l/min (FAD) (7 Bar)

= (1638 x 0.5) + (1638 x 2 x 2/3)

Combined/total DF = 3100 l/min (FAD) (11 Bar high

pressure system) = 819 + 2162

A dryer greater than 3100 l/min outlet flow should be = 2981 litres

selected

A combination of receivers with a minimum number of 2

(Outlet flow is the inlet flow minus purge losses) should be selected

= PureMed45 inlet flow 3645 l/min, outlet flow 3142 Selected receiver capacity = 3000 litres (2 x 1500 litre)

l/min

Plant System Selection

Flow Rate and Compressor Sizing Selected plant part number = MEDAIR-3225-10GTV

From Table 1 surgical air DF is between 500-3500 l/min,

so the multiplying factor ‘A’ = 0.66

If no standard model is available for selection from the

Compressor flow rate = Med. DF + (Surg. DF x A) standard range a bespoke configuration of dryer,

compressors and receivers are available and can be

= 1550 + (1550 x 0.66) quoted by our sales and sales support teams

= 1550 + 1023

= 2573 l/min

We also need to add the purge losses to the

compressor output. For additional purge consumption

use:-

Inlet - outlet = purge losses l/min

= 3645 - 3142 = 503 l/min

Compressors should be selected with a flow rate

greater than

2573 l/min + 503 l/min = 3076 l/min

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Receiver Selection Table

Receiver Capacity (litres) 250 500 1000 1500 2000 3000

Maximum working pressure (bar) 11 11 11 11 11 11

Receiver Dimensions

457/2020 610/2105 762/2630 900/2670 1067/2775 1220/3050

(diameter, height) mm

Receiver Weight (kg) 155 195 380 520 800 1000

Receiver Inlet/Outlet (mm) 28 28 42 42 42 42

Receiver Part Number 8102340570 8102340574 8102340576 8102340578 8102340580 8102340582

Receiver Kit * 8102340590 8102340594 8102340596 8102340598 8102340600 8102340602

Receiver Capacity (litres) 250 500 1000 1500 2000 3000

Maximum working pressure (bar) 14 14 14 14 14 14

Receiver Dimensions

457/2050 610/2105 762/2650 915/2650 1067/2725 1220/3200

(diameter, height) mm

Receiver Weight (kg) 160 200 500 575 950 1400

Receiver Inlet/Outlet (mm) 28 28 42 42 42 42

Receiver Part Number 8102340571 8102340575 8102340577 8102340579 8102340581 8102340583

Receiver Kit * 8102340591 8102340595 8102340597 8102340599 8102340601 8102340603

* Receiver kit complete with pressure safety valve, zero loss electronic drain valve (with isolation and bypass valve), pressure gauge (with isolation valve), pressure relief valve, fusible

plug, copper inlet/outlet connection pipes (each with isolation valve).

For single vessel applications, lockable bypass line valves are available.

28mm lockable line valve - 6000723

42mm lockable line valve - 6000725

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Dryer Selection Table

Model Name PureMED25 PureMED35 PureMED45 PureMED100 PureMED145

Inlet flow (l/min) at 7.5 bar 1500 2100 2700 6000 8700

Outlet flow (l/min) at 4 bar line pressure * 1222 1711 2200 4890 7090

Inlet flow (l/min) at 10 bar 1800 2520 3240 7200 10440

Outlet flow (l/min) at 7 bar line pressure * 1523 2132 2741 6091 8832

Inlet flow (l/min) at 13 bar 2025 2835 3645 8100 11745

Outlet flow (l/min) at 10 bar line pressure * 1746 2444 3142 6982 10124

Footprint L x W x H (mm) 1720 x 1130 x 1590 1720 x 1130 x 1590 1720 x 1130 x 1590 1720 x 1470 x 1610 1720 x 1470 x 2060

Dryer weight (kg) 400 407 434 689 845

Inlet/outlet connection (mm) 15 15 28 28 28

Supply voltage (v) 230 230 230 230 230

Supply frequency (Hz) 50 50 50 50 50

Central control supply – single phase

1.5 (2) 1.5 (2) 1.5 (2) 1.5 (2) 1.5 (2)

(mm2/Amps)

Part number – Dryer @ 4 bar outlet 8102370190 8102370193 8102370196 8102370199 8102370202

Part number – Dryer @ 7 bar outlet 8102370191 8102370194 8102370197 8102370200 8102370203

Part number – Dryer @ 10 bar outlet 8102370192 8102370195 8102370198 8102370201 8102370204

*Output flow rate includes calculated purge lost during the regeneration process.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Compressor Selection Table – Fixed Speed – GA MED

Model Name GA5 MED GA7 MED GA11 MED GA15 MED GA18 MED GA22 MED GA26 MED

Output flow (l/min) 7.5 bar variant * 900 1308 1842 2736 3384 3870 4362

Outlet flow (l/min) 10 bar variant * 702 1032 1560 2268 2814 3246 3960

Output flow (l/min) 13 bar variant * 504 852 1320 1938 2364 2850 3360

1140 x 700 x 1140 x 700 x 1140 x 700 x 1280 x 780 x 1280 x 780 x 1280 x 780 x 1280 x 780 x

Footprint L x W x H (mm)

1240 1240 1240 1220 1220 1220 1220

Compressor weight (kg) 270 284 310 455 464 480 490

Service connection (mm) 22 22 22 22 22 22 22

Noise level (dB[A]) 60 61 62 65 67 68 69

Maximum ambient temperature (°C) 46 46 46 46 46 46 46

Supply voltage (v) 400 400 400 400 400 400 400

Supply frequency (Hz) 50 50 50 50 50 50 50

Nominal motor rating (kW) 5 7 11 15 18 22 26

Full load current per compressor (A) 17 22 32 33.3 40.7 47.4 57

Starting current (A) 98.6 131 188 109.89 138.38 180.12 210.9

Cooling air flow per Compressor

0.8 0.8 1 0.5 0.7 1.1 1.1

(m³/s)

Part number – 7.5 bar 8153 0344 86 8153 0344 94 8153 0345 02 8153 6162 82 8153 6163 16 8153 6163 40 8153 6163 73

Part number - 10 bar 8152 0341 89 8153 0342 05 8153 0342 21 8153 6162 90 8153 6163 24 8153 6163 57 8153 6163 81

Part number – 13 bar 8153 0341 97 8153 0342 13 8153 0342 39 8153 6163 08 8153 6163 32 8153 6163 65 8153 6163 99

Drawing number 9828 4969 26 9828 4969 26 9828 4969 26 9828083180 9828083180 9828083180 9828083180

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Compressor Selection Table – Variable Speed – GA VSD+ MED

Model Name GA7 VSD+ GA11 VSD+ GA15 VSD+ GA18 VSD+ GA22 VSD+ GA26 VSD+ GA30 VSD+ GA37 VSD+

MED MED MED MED MED MED MED MED

Output flow (l/min) 7 bar variant * 1302 1950 2508 3750 4506 5148 5844 6900

Outlet flow (l/min) 10 bar variant * 1080 1632 2130 3216 3912 4704 5136 6138

Output flow (l/min) 13 bar variant * 852 1410 1674 2610 3246 3870 4320 5202

Footprint L x W x H (mm) 720 x 630 x 720 x 630 x 720 x 630 x 990 x 790 x 990 x 790 x 990 x 790 x 990 x 790 x 990 x 790 x

1420 1420 1420 1590 1590 1590 1590 1590

Compressor weight (kg) 208 211 214 387 387 393 396 396

Service connection (mm) 22 22 22 22 22 22 22 22

Noise level (dB[A]) 62 63 64 67 67 67 67 67

Maximum ambient temperature (°C) 46 46 46 46 46 46 46 46

Supply voltage (v) 380-460 380-460 380-460 380-460 380-460 380-460 380-460 380-460

Supply frequency (Hz) 50 50 50 50 50 50 50 50

Nominal motor rating (kW)

2.9 – 7.9 2.9 – 12.1 3 – 17.1 5 – 20.1 5.1 - 24 5. - 29 5. – 34.3 5.4 - 41.2

(1900 rpm – 5250 rpm full load)

Full load current per compressor (A) tbc tbc tbc tbc tbc tbc tbc tbc

Cooling air flow per Compressor

0.8 0.8 0.8 1.3 1.3 1.6 1.6 1.6

(m³/s)

Part number 8102 3414 20 8102 3414 23 8102 3414 26 8102 3414 29 8102 3414 32 8102 3414 35 8102 3414 38 8102 3414 41

*Variable speed drive compressors operate from 4-13 bar – start current not applicable for VSD

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Compressor Selection Table – Fixed Speed – LE MED

Model Name LE5 MED LE7 MED LE10 MED LE15 MED LE20 MED

Outlet flow (l/min) 10 bar * 540 816 1008 1734 2004

Footprint L x W x H (mm) 600 x 1000 x 600 x 1000 x 600 x 1000 x 600 x 1000 x 600 x 1000 x

756 836 836 928 928

Compressor weight (kg) 90 110 120 200 220

Service connection (mm) 22 22 22 22 22

Noise level (dB[A]) 79 80 81 89 87.5

Maximum ambient temperature (°C) 40 40 40 40 40

Supply voltage (v) 400 400 400 400 400

Supply frequency (Hz) 50 50 50 50 50

Nominal motor rating (kW) 4 5.5 7.5 11 15

Full load current per compressor (A) 9.5 13.3 19 28.5 38

Cooling air flow per Compressor

0.16 0.5 0.5 0.75 0.75

(m³/s)

Part number - 10 bar 8102 3399 25 8102 3399 29 8102 3399 14 8102 3399 17 8102 3399 21

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

Standard Plant Range

HTM 02-01 4 Bar 50Hz Medical Air Plant Specifications – GA MED

Sound Pressure Level/

Standby Compressors

per compressor (m3/s)

Nominal Motor Power

per Compressor (A)(2)

per Compressor (kW)

Compressor dB(A)(4)

Motor Rated Supply

per Compressor (A)

Compressor Model

Duty Compressors

Free Air Delivered

Air Receiver Total

Air Receiver(s) to

Full Load Current

Receiver Volume

Electrical Supply

Approx. Starting

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Cooling air flow

BS 5169:1992

Configuration

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

(420kPa)

(7.5 Bar)

(l/min)(1)

(litres)

8102340620 MEDAIR-500-4GT 500 5 GA5 MED 400 V 3~ 50 Hz SD 17 98.6 32 Triplex 1 2 60 0.8 3.6 1 250 250 PureMED25

8102340621 MEDAIR-630-4GT 630 5 GA5 MED 400 V 3~ 50 Hz SD 17 98.6 32 Triplex 1 2 60 0.8 3.6 2 250 500 PureMED25

8102340622 MEDAIR-1000-4GT 1000 7 GA7 MED 400 V 3~ 50 Hz SD 22 131 32 Triplex 1 2 61 0.8 3.7 2 250 500 PureMED25

8102340624 MEDAIR-1230-4GT 1230 11 GA11 MED 400 V 3~ 50 Hz SD 32 188 40 Triplex 1 2 62 1 5.1 2 500 1000 PureMED25

8102340625 MEDAIR-1465-4GT 1464 11 GA11 MED 400 V 3~ 50 Hz SD 32 188 40 Triplex 1 2 62 1 5.1 2 500 1000 PureMED35

8102340626 MEDAIR-1720-4GT 1722 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 110 50 Triplex 1 2 65 0.5 12.2 2 500 1000 PureMED35

8102340627 MEDAIR-2000-4GT 2000 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 110 50 Triplex 1 2 65 0.5 12.2 2 500 1000 PureMED45

8102340629 MEDAIR-2730-4GT 2730 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Triplex 1 2 68 1.1 12.2 2 1000 2000 PureMED100

8102340630 MEDAIR-3220-4GT 3222 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Triplex 1 2 69 1.1 12.2 2 1000 2000 PureMED100

8102340631 MEDAIR-4000-4GQ 4000 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 252 50 Quadruplex 2 2 65 0.5 12.2 2 1000 2000 PureMED100

8102340632 MEDAIR-4860-4GQ 4860 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 302 63 Quadruplex 2 2 67 0.7 12.2 2 1500 3000 PureMED100

8102340633 MEDAIR-5115-4GQ 5795 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 302 63 Quadruplex 2 2 67 0.7 12.2 2 1500 3000 PureMED145

8102340634 MEDAIR-6000-4GQ 6000 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 383 80 Quadruplex 2 2 68 1.1 12.2 2 1500 3000 PureMED145

8102340635 MEDAIR-6085-4GQ 6087 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Quadruplex 2 2 68 1.1 12.2 2 2000 4000 PureMED145

8102340636 MEDAIR-7045-4GQ 7047 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Quadruplex 2 2 69 1.1 12.2 2 2000 4000 PureMED145

1. Data measured and stated in accordance with ISO1217 Ed.4, Annex C & Annex E and Pneurop/Cagi PN2CPTC2 with one compressor on standby and with an air intake at 1013 mbar, 20°C and 0% RH. Tropical thermostats

may reduce the free air delivery marginally.

2. These are typical figures and may vary with the specific motor used. Consult the motor nameplate for exact figures.

3. Two standby compressors should be provided unless the automatic backup manifold is of sufficient capacity to deliver the system design flow.

4. Measured in free field conditions in accordance with the Pneurop/Cagi PN8TNC2.2 test code. Subject to a tolerance of +/- 3 dB

5. Other models and layouts are available to suit particular site requirements. Contact your local representative for support.

6. Design flow in terms of free air delivered after losses at working pressure with reserve compressor(s) on standby. Tolerance ±5%.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 7 Bar 50Hz Combined Medical and Surgical Air Plant Specifications – GA MED

Sound Pressure Level/

Standby Compressors

Nominal Motor Power

per Compressor (kW)

Full Load Current per

Air Receiver(s) to BS

Compressor dB(A)(4)

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Receiver Volume

Electrical Supply

Approx. Starting

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

5169:1992

(800kPa)

(10 Bar)

(l/min)(1)

(litres)

8102340640 MEDAIR-650-7GT 432 5 GA5 MED 400 V 3~ 50 Hz SD 17 98.6 32 Triplex 1 2 60 0.8 3.6 2 500 1000 PureMED25

8102340641 MEDAIR-800-7GT 762 7 GA7 MED 400 V 3~ 50 Hz SD 22 131 32 Triplex 1 2 61 0.8 3.7 2 500 1000 PureMED25

8102340642 MEDAIR-1145-7GT 762 7 GA7 MED 400 V 3~ 50 Hz SD 22 131 32 Triplex 1 2 61 0.8 3.7 2 1000 2000 PureMED25

8102340643 MEDAIR-1530-7GT 1290 11 GA11 MED 400 V 3~ 50 Hz SD 32 188 40 Triplex 1 2 62 1 5.1 2 1000 2000 PureMED25

8102340644 MEDAIR-2140-7GT 1890 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 110 50 Triplex 1 2 65 0.5 12.2 2 1000 2000 PureMED35

8102340645 MEDAIR-2705-7GT 2244 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Triplex 1 2 67 0.7 12.2 2 1500 3000 PureMED45

8102340647 MEDAIR-3275-7GT 2820 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Triplex 1 2 69 1.1 12.2 2 1500 3000 PureMED100

8102340648 MEDAIR-3400-7GT 2820 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Triplex 1 2 69 1.1 12.2 2 2000 4000 PureMED100

8102340649 MEDAIR-4090-7GQ 3396 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 110 50 Quadruplex 2 2 65 0.5 12.2 2 2000 4000 PureMED100

8102340650 MEDAIR-5335-7GQ 4488 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Quadruplex 2 2 67 0.7 12.2 2 2000 4000 PureMED100

8102340651 MEDAIR-5405-7GQ 4488 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Quadruplex 2 2 67 0.7 12.2 2 3000 6000 PureMED100

8102340652 MEDAIR-6000-7GQ 5352 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Quadruplex 2 2 68 1.1 12.2 3 1500 4500 PureMED100

8102340653 MEDAIR-6060-7GQ 5352 22 GA22 MED 400 V 5~ 50 Hz SD 47.4 180 80 Quadruplex 2 2 68 1.1 12.2 3 2000 6000 PureMED100

8102340654 MEDAIR-6450-7GQ 4839 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Quadruplex 2 2 68 1.1 12.2 3 2000 6000 PureMED145

8102340655 MEDAIR-6870-7GP 5151 15 GA15MED 400 V 3~ 50 Hz SD 33.3 110 50 Pentaplex 3 2 65 0.5 12.2 3 2000 6000 PureMED145

8102340656 MEDAIR-8000-7GQ 6267 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Quadruplex 2 2 69 1.1 12.2 3 2000 6000 PureMED145

8102369718 MEDAIR08355-7GQ 6267 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Quadruplex 2 2 69 1.1 12.2 3 3000 9000 PureMED145

8102340657 MEDAIR-8355-7GQ 6267 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Quadruplex 2 2 69 1.1 12.2 4 2000 8000 PureMED145

8102369719 MEDAIR-8785-7GP 6789 18 GA18 MED 400 V 3~ 50 Hz SD 43 302 63 Pentaplex 3 2 67 0.7 12.2 3 3000 9000 PureMED145

8102340658 MEDAIR-8785-7GP 6789 18 GA18 MED 400 V 3~ 50 Hz SD 43 302 63 Pentaplex 3 2 67 0.7 12.2 4 2000 8000 PureMED145

1. Data measured and stated in accordance with ISO1217 Ed.4, Annex C & Annex E and Pneurop/Cagi PN2CPTC2 with one compressor on standby and with an air intake at 1013 mbar, 20°C and 0% RH. Tropical thermostats

may reduce the free air delivery marginally.

For 700kPa and 1000kPa, combined air plant capacity is rated with a 50/50 split of surgical and medical air (within the design parameters stated in HTM 02-01).

2. These are typical figures and may vary with the specific motor used. Consult the motor nameplate for exact figures.

3. Two standby compressors should be provided unless the automatic backup manifold is of sufficient capacity to deliver the system design flow.

4. Measured in free field conditions in accordance with the Pneurop/Cagi PN8TNC2.2 test code. Subject to a tolerance of +/- 3 dB

5. Other models and layouts are available to suit particular site requirements. Contact your local representative for support.

6. Design flow in terms of free air delivered after losses at working pressure with reserve compressor(s) on standby. Tolerance ±5%.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 10 Bar 50Hz Combined Medical and Surgical Air Plant Specifications – GA MED

Standby Compressors

Nominal Motor Power

Full Load Current per

per Compressor (kW)

per Compressor (A)

Motor Rated Supply

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Level/Compressor

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Air Receiver(s) to

Electrical Supply

Receiver Volume

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

BS 5169:1992

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

(1100kPa)

(l/min)(1)

(13 Bar)

dB(A)(4)

(litres)

8102340660 MEDAIR-800-10GT 582 7 GA7 MED 400 V 3~ 50 Hz SD 22 131 32 Triplex 1 2 61 0.8 3.7 2 500 1000 PureMED25

8102340661 MEDAIR-875-10GT 582 7 GA7 MED 400 V 3~ 50 Hz SD 22 131 32 Triplex 1 2 61 0.8 3.7 2 1000 2000 PureMED25

8102340662 MEDAIR-1580-10GT 1050 11 GA11 MED 400 V 3~ 50 Hz SD 32 188 40 Triplex 1 2 62 1 5.1 2 1000 2000 PureMED25

8102340663 MEDAIR-1755-10GT 1668 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 110 50 Triplex 1 2 65 0.5 12.2 2 1000 2000 PureMED25

8102340665 MEDAIR-2180-10GT 1986 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Triplex 1 2 67 0.7 12.2 2 1000 2000 PureMED35

8102340666 MEDAIR-2395-10GT 1986 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Triplex 1 2 67 0.7 12.2 2 1500 3000 PureMED35

8102340667 MEDAIR-2455-10GT 2457 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Triplex 1 2 68 1.1 12.2 2 1500 3000 PureMED35

8102340668 MEDAIR-2745-10GT 2280 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Triplex 1 2 68 1.1 12.2 2 1500 3000 PureMED45

8102340672 MEDAIR-4325-10GQ 3588 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Quadruplex 2 2 67 0.7 12.2 2 2000 4000 PureMED100

8102369720 MEDAIR-5330-10GQ 5330 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Quadruplex 2 2 68 1.1 12.2 2 2000 4000 PureMED100

8102340673 MEDAIR-5495-10GQ 4560 22 GA22MED 400 V 3~ 50 Hz SD 47.4 180 80 Quadruplex 2 2 68 1.1 12.2 3 1500 4500 PureMED100

8102340674 MEDAIR-6000-10GP 5439 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Pentaplex 3 2 67 0.7 12.2 3 1500 4500 PureMED100

8102340675 MEDAIR-6550-10GP 5439 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Pentaplex 3 2 67 0.7 12.2 3 2000 6000 PureMED145

8102340676 MEDAIR-6960-10GP 5580 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Pentaplex 3 2 67 0.7 12.2 3 2000 6000 PureMED100

8102340677 MEDAIR-6960-10GQ 5580 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Quadruplex 2 2 69 1.1 12.2 3 2000 6000 PureMED100

8102340678 MEDAIR-7250-10GP 5439 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Pentaplex 3 2 67 0.7 12.2 3 2000 6000 PureMED145

8102340679 MEDAIR-8000-10GP 6897 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Pentaplex 3 2 68 1.1 12.2 3 2000 6000 PureMED145

8102340680 MEDAIR-9195-10GP 6897 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Pentaplex 3 2 68 1.1 12.2 4 2000 8000 PureMED145

8102340681 MEDAIR-10090-10GP 8427 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Pentaplex 3 2 69 1.1 12.2 4 2000 8000 PureMED145

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 10 Bar 50Hz Surgical Air Plant Specifications – GA MED

Free Air Delivered (l/min)(1)

Level/Compressor dB(A)(4)

Compressor Configuration

Nominal Motor Power per

Standby Compressors

per Compressor (A)(2)

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Air Receiver Total

Compressor (kW)

Air Receiver(s) to

Full Load Current

Receiver Volume

Electrical Supply

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

BS 5169:1992

Part Number

Dryer Model

Current (A)

Model Ref.

(1100kPa)

(13 Bar)

(litres)

8102340685 MEDAIR-1000-10GS 1050 11 GA11 MED 400 V 3~ 50 Hz SD 32 188 40 Simplex 1 - 62 1 5.1 2 500 1000 PureMED25

8102340686 MEDAIR-1590-10GS 1050 11 GA11 MED 400 V 3~ 50 Hz SD 32 188 40 Simplex 1 - 62 1 5.1 2 1000 2000 PureMED25

8102340687 MEDAIR-2000-10GS 1560 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 110 50 Simplex 1 - 65 0.5 12.2 2 1000 2000 PureMED35

8102340688 MEDAIR-2365-10GS 1560 15 GA15 MED 400 V 3~ 50 Hz SD 33.3 110 50 Simplex 1 - 65 0.5 12.2 2 1500 3000 PureMED35

8102340689 MEDAIR-2720-10GS 1794 18 GA18 MED 400 V 3~ 50 Hz SD 40.7 138 63 Simplex 1 - 67 0.7 12.2 2 1500 3000 PureMED45

8102340690 MEDAIR-3455-10GS 2280 22 GA22 MED 400 V 3~ 50 Hz SD 47.4 180 80 Simplex 1 - 68 1.1 12.2 2 2000 4000 PureMED45

8102340692 MEDAIR-4000-10GS 2220 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Simplex 1 - 69 1.1 12.2 2 2000 4000 PureMED100

8102340693 MEDAIR-4440-10GS 2220 26 GA26 MED 400 V 3~ 50 Hz SD 57 211 80 Simplex 1 - 69 1.1 12.2 3 1500 4500 PureMED100

1. Data measured and stated in accordance with ISO1217 Ed.4, Annex C & Annex E and Pneurop/Cagi PN2CPTC2 with one compressor on standby and with an air intake at 1013 mbar, 20°C and 0% RH. Tropical thermostats

may reduce the free air delivery marginally.

2. These are typical figures and may vary with the specific motor used. Consult the motor nameplate for exact figures.

3. Two standby compressors should be provided unless the automatic backup manifold is of sufficient capacity to deliver the system design flow.

4. Measured in free field conditions in accordance with the Pneurop/Cagi PN8TNC2.2 test code. Subject to a tolerance of +/- 3 dB

5. Other models and layouts are available to suit particular site requirements. Contact your local representative for support.

6. Design flow in terms of free air delivered after losses at working pressure with reserve compressor(s) on standby. Tolerance ±5%.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 4 Bar 50Hz Medical Air Plant Specifications – GA VSD+ MED

Nominal Motor Power

Full Load Current per

per Compressor (kW)

Air Receiver(s) to BS

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Level/Compressor

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Electrical Supply

Receiver Volume

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

Compressors

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

5169:1992

(420kPa)

(7.5 Bar)

Standby

(l/min)(1)

dB(A)(4)

(litres)

8102342220 MEDAIR-500-4GTV 500 2.9 - 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 62 0.8 TBC 1 250 250 PureMED25

8102342221 MEDAIR-1000-4GTV 1000 2.9 – 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 62 0.8 TBC 2 250 500 PureMED25

8102342222 MEDAIR-1030-4GTV 1032 2.9 – 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 62 0.8 TBC 2 500 1000 PureMED25

8102342223 MEDAIR-1230-4GTV 1230 2.9 – 12.1 GA11 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 63 0.8 TBC 2 500 1000 PureMED25

8102342224 MEDAIR-1230-4GQV 1230 2.9 – 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 62 0.8 TBC 2 500 1000 PureMED25

8102342225 MEDAIR-1570-4GTV 1572 2.9 – 12.1 GA11 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 63 0.8 TBC 2 500 1000 PureMED35

8102342226 MEDAIR-1720-4GTV 1722 3 – 17.1 GA15 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 64 0.8 TBC 2 500 1000 PureMED35

8102342227 MEDAIR-1720-4GQV 1722 2.9 – 12.1 GA11 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 63 0.8 TBC 2 500 1000 PureMED35

8102342228 MEDAIR-1940-4GTV 1938 3 – 17.1 GA15 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 64 0.8 TBC 2 500 1000 PureMED45

8102342229 MEDAIR-2035-4GQV 2034 2.9 – 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 62 0.8 TBC 2 1000 2000 PureMED45

8102342231 MEDAIR-2610-4GTV 2610 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 67 1.3 TBC 2 1000 2000 PureMED100

8102342232 MEDAIR-2760-4GQV 2760 2.9 – 12.1 GA11 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 63 0.8 TBC 2 1000 2000 PureMED100

8102342233 MEDAIR-3365-4GTV 3366 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 67 1.3 TBC 2 1000 2000 PureMED100

8102342234 MEDAIR-3875-4GQV 3876 3 – 17.1 GA15 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 64 0.8 TBC 2 1000 2000 PureMED100

8102342235 MEDAIR-4000-4GTV 4000 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 67 1.6 TBC 2 1000 2000 PureMED100

8102342236 MEDAIR-4705-4GTV 4704 5 – 34.3 GA30 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 67 1.6 TBC 2 1500 3000 PureMED100

8102342237 MEDAIR-4860-4GTV 4860 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 67 1.6 TBC 2 1500 3000 PureMED100

8102342239 MEDAIR-5245-4GTV 5247 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Triplex 1 2 67 1.6 TBC 2 1500 3000 PureMED145

8102342240 MEDAIR-5845-4GQV 5847 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 67 1.3 TBC 2 1500 3000 PureMED145

8102369714 MEDAIR-6000-4GQV 6000 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 67 1.3 TBC 2 1500 3000 PureMED145

8102369715 MEDAIR-7045-4GQV 7047 5.1 - 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a TBC Quadruplex 2 2 67 1.3 TBC 2 2000 4000 PureMED145

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 7 Bar 50Hz Combined Medical and Surgical Air Plant Specifications – GA VSD+ MED

Nominal Motor Power

Full Load Current per

per Compressor (kW)

Air Receiver(s) to BS

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Level/Compressor

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Electrical Supply

Receiver Volume

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

Compressors

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

5169:1992

(1100kPa)

Standby

(l/min)(1)

(13 Bar)

dB(A)(4)

(litres)

8102369930 MEDAIR-800-7GTV 810 2.9 – 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 62 0.8 tbc 2 500 1000 PureMED25

8102369931 MEDAIR-975-7GTV 810 2.9- 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 62 0.8 tbc 2 1000 2000 PureMED25

8102369932 MEDAIR-1530-7GTV 1362 2.9 – 12.1 GA11 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 63 0.8 tbc 2 1000 2000 PureMED25

8102369933 MEDAIR-2110-7GTV 1752 3 – 17.1 GA15 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 64 0.8 tbc 2 1000 2000 PureMED35

8102369934 MEDAIR-3030-7GTV 2646 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.3 tbc 2 1500 3000 PureMED45

8102369935 MEDAIR-3340-7GTV 2772 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.3 tbc 2 2000 4000 PureMED100

8102369936 MEDAIR-4000-7GTV 3564 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 2 1500 3000 PureMED100

8102369937 MEDAIR-4295-7GTV 3564 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 2 2000 4000 PureMED100

8102369938 MEDAIR-4815-7GTV 3996 5 – 34.3 GA30 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 2 2000 4000 PureMED100

8102369939 MEDAIR-5330-7GTV 4998 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 2 2000 4000 PureMED100

8102369940 MEDAIR-6000-7GTV 4998 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 3 1500 4500 PureMED100

8102369941 MEDAIR-6060-7GQV 5292 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 2 3000 6000 PureMED100

8102369942 MEDAIR-6060-7GQV 5292 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 3 2000 6000 PureMED100

8102369943 MEDAIR-8000-7GQV 6171 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 2 3000 6000 PureMED145

8102369944 MEDAIR-8000-7GQV 6171 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 3 2000 6000 PureMED145

8102369945 MEDAIR-8228-7GQV 6171 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 3 3000 9000 PureMED145

8102369946 MEDAIR-8787-7GQV 7755 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.6 tbc 3 3000 9000 PureMED145

8102369947 MEDAIR-8787-7GPV 7995 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Pentaplex 3 2 67 1.3 tbc 3 3000 9000 PureMED145

1. Data measured and stated in accordance with ISO1217 Ed.4, Annex C & Annex E and Pneurop/Cagi PN2CPTC2 with one compressor on standby and with an air intake at 1013 mbar, 20°C and 0% RH. Tropical thermostats

may reduce the free air delivery marginally.

For 700kPa and 1000kPa, combined air plant capacity is rated with a 50/50 split of surgical and medical air (within the design parameters stated in HTM 02-01).

2. These are typical figures and may vary with the specific motor used. Consult the motor nameplate for exact figures.

3. Two standby compressors should be provided unless the automatic backup manifold is of sufficient capacity to deliver the system design flow.

4. Measured in free field conditions in accordance with the Pneurop/Cagi PN8TNC2.2 test code. Subject to a tolerance of +/- 3 dB

5. Other models and layouts are available to suit particular site requirements. Contact your local representative for support.

6. Design flow in terms of free air delivered after losses at working pressure with reserve compressor(s) on standby. Tolerance ±5%.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 10 Bar 50Hz Combined Medical and Surgical Air Plant Specifications – GA VSD+ MED

Nominal Motor Power

Full Load Current per

per Compressor (kW)

Air Receiver(s) to BS

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Level/Compressor

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Electrical Supply

Receiver Volume

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

Compressors

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

5169:1992

(1100kPa)

Standby

(l/min)(1)

(13 Bar)

dB(A)(4)

(litres)

8102342250 MEDAIR-800-10GTV 582 2.9 – 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 62 0.8 tbc 2 500 1000 PureMED25

8102342251 MEDAIR-874-10GTV 582 2.9- 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 62 0.8 tbc 2 1000 2000 PureMED25

8102342252 MEDAIR-1600-10GTV 1140 2.9 – 12.1 GA11 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 63 0.8 tbc 2 1000 2000 PureMED25

8102342253 MEDAIR-1690-10GTV 1404 3 – 17.1 GA15 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 64 0.8 tbc 2 1000 2000 PureMED25

8102369759 MEDAIR-1755-10GTV 1755 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.3 tbc 2 1000 2000 PureMED25

8102342254 MEDAIR-2180-10GTV 2232 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.3 tbc 2 1000 2000 PureMED35

8102342255 MEDAIR-2455-10GTV 2232 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.3 tbc 2 1500 3000 PureMED35

8102342256 MEDAIR-3225-10GTV 2676 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.3 tbc 2 1500 3000 PureMED45

8102342258 MEDAIR-3830-10GTV 3180 5 – 34.3 GA30 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 2 2000 4000 PureMED100

8102342259 MEDAIR-4365-10GTV 4062 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 2 2000 4000 PureMED100

8102342260 MEDAIR-4895-10GTV 4062 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 2 3000 6000 PureMED100

8102342261 MEDAIR-4895-10GTV 4062 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Triplex 1 2 67 1.6 tbc 3 1500 4500 PureMED100

8102342262 MEDAIR-4915-10GQV 4080 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 2 2000 4000 PureMED100

8102342263 MEDAIR-5335-10GQV 5352 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 2 2000 4000 PureMED100

8102342264 MEDAIR-6000-10GQV 5352 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 3 1500 4500 PureMED100

8102342265 MEDAIR-6450-10GQV 5352 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 2 3000 6000 PureMED100

8102342266 MEDAIR-6450-10GQV 5352 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 3 2000 6000 PureMED100

8102342268 MEDAIR-6960-10GQV 6600 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.6 tbc 2 3000 6000 PureMED100

8102342267 MEDAIR-6960-10GQV 6600 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.6 tbc 3 2000 6000 PureMED100

8102342269 MEDAIR-7335-10GQV 6087 5 – 20 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.6 tbc 3 2000 6000 PureMED145

8102342272 MEDAIR-8000-10GPV 6177 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Pentaplex 3 2 67 1.3 tbc 3 2000 6000 PureMED145

8102342271 MEDAIR-8000-10GQV 6987 5 – 34.3 GA30 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.6 tbc 3 2000 6000 PureMED145

8102342273 MEDAIR-8235-10GPV 6177 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Pentaplex 3 2 67 1.3 tbc 3 3000 9000 PureMED145

8102342274 MEDAIR-8420-10GQV 6987 5 – 34.3 GA30 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.6 tbc 3 3000 9000 PureMED145

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 10 Bar 50Hz Combined Medical and Surgical Air Plant Specifications – GA VSD+ MED – Continued

Nominal Motor Power

Full Load Current per

per Compressor (kW)

Air Receiver(s) to BS

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Level/Compressor

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Part Number2222

Electrical Supply

Receiver Volume

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

Compressors

Compressor

Dryer Model

Current (A)

Model Ref.

5169:1992

(1100kPa)

Standby

(l/min)(1)

(13 Bar)

dB(A)(4)

(litres)

MEDAIR-10090-

8102342275 8751 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Pentaplex 3 2 67 1.3 tbc 3 3000 9000 PureMED145

10GPV

MEDAIR-10090-

8102342276 8085 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Quadruplex 2 2 67 1.3 tbc 3 3000 9000 PureMED145

10GQV

1. Data measured and stated in accordance with ISO1217 Ed.4, Annex C & Annex E and Pneurop/Cagi PN2CPTC2 with one compressor on standby and with an air intake at 1013 mbar, 20°C and 0% RH. Tropical thermostats

may reduce the free air delivery marginally.

For 700kPa and 1000kPa, combined air plant capacity is rated with a 50/50 split of surgical and medical air (within the design parameters stated in HTM 02-01).

2. These are typical figures and may vary with the specific motor used. Consult the motor nameplate for exact figures.

3. Two standby compressors should be provided unless the automatic backup manifold is of sufficient capacity to deliver the system design flow.

4. Measured in free field conditions in accordance with the Pneurop/Cagi PN8TNC2.2 test code. Subject to a tolerance of +/- 3 dB

5. Other models and layouts are available to suit particular site requirements. Contact your local representative for support.

6. Design flow in terms of free air delivered after losses at working pressure with reserve compressor(s) on standby. Tolerance ±5%.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 10 Bar 50Hz Surgical Air Plant Specifications – GA VSD+ MED

Nominal Motor Power

Full Load Current per

per Compressor (kW)

Air Receiver(s) to BS

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Level/Compressor

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Electrical Supply

Receiver Volume

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

Compressors

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

5169:1992

(1100kPa)

Standby

(l/min)(1)

(13 Bar)

dB(A)(4)

(litres)

8102342500 MEDAIR-880-10GSV 582 2.9 – 7.9 GA7 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 62 0.8 tbc 2 500 1000 PureMED25

8102342501 MEDAIR-1725-10GSV 1140 2.9 – 12.1 GA11 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 63 0.8 tbc 2 1000 2000 PureMED25

8102342502 MEDAIR-1965-10GSV 1296 3 – 17.1 GA15 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 64 0.8 tbc 2 1000 2000 PureMED35

8102342503 MEDAIR-2455-10GSV 2232 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.3 tbc 2 1500 3000 PureMED35

8102342504 MEDAIR-3090-10GSV 2040 5 – 20.1 GA18 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.3 tbc 2 2000 4000 PureMED45

8102342505 MEDAIR-3480-10GSV 2676 5.1 – 24 GA22 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.3 tbc 2 2000 4000 PureMED45

8102342506 MEDAIR-4135-10GSV 2730 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.6 tbc 3 1500 4500 PureMED100

8102342507 MEDAIR-4135-10GSV 2730 5 – 29 GA26 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.6 tbc 2 3000 6000 PureMED100

8102342508 MEDAIR-4500-10GSV 3180 5 – 34.3 GA30 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.6 tbc 3 1500 4500 PureMED100

8102342509 MEDAIR-4820-10GSV 3180 5 – 34.3 GA30 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.6 tbc 3 2000 6000 PureMED100

8102342510 MEDAIR-6000-10GSV 4062 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.6 tbc 3 2000 6000 PureMED100

8102342511 MEDAIR-6960-10GSV 4062 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.6 tbc 3 3000 9000 PureMED100

8102342512 MEDAIR-6960-10GSV 4062 5.4 – 41.2 GA37 VSD+ 400 V 3~ 50Hz DOL tbc n/a tbc Simplex 1 - 67 1.6 tbc 4 2000 8000 PureMED100

1. Data measured and stated in accordance with ISO1217 Ed.4, Annex C & Annex E and Pneurop/Cagi PN2CPTC2 with one compressor on standby and with an air intake at 1013 mbar, 20°C and 0% RH. Tropical thermostats

may reduce the free air delivery marginally.

2. These are typical figures and may vary with the specific motor used. Consult the motor nameplate for exact figures.

3. Two standby compressors should be provided unless the automatic backup manifold is of sufficient capacity to deliver the system design flow.

4. Measured in free field conditions in accordance with the Pneurop/Cagi PN8TNC2.2 test code. Subject to a tolerance of +/- 3 dB

5. Other models and layouts are available to suit particular site requirements. Contact your local representative for support.

6. Design flow in terms of free air delivered after losses at working pressure with reserve compressor(s) on standby. Tolerance ±5%.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

HTM 02-01 7 Bar 50Hz Combined Medical & Surgical Air Plant Specifications – LE MED

Nominal Motor Power

Full Load Current per

per Compressor (kW)

Air Receiver(s) to BS

Motor Rated Supply

per Compressor (A)

Cooling air flow per

Compressor Model

Duty Compressors

compressor (m3/s)

Level/Compressor

Free Air Delivered

Air Receiver Total

Compressor (A)(2)

Electrical Supply

Receiver Volume

Approx. Starting

Sound Pressure

Starting Method

Capacity (litres)

Capacity (litres)

Compressor Oil

Configuration

Compressors

Part Number

Compressor

Dryer Model

Current (A)

Model Ref.

5169:1992

(420kPa)

Standby

(l/min)(1)

(10 Bar)

dB(A)(4)

(litres)

8102342070 MEDAIR-350-7LET 234 4 LE5-10 400 V 3~ 50Hz SD 9.5 tbc tbc Triplex 1 2 79 0.16 0.8 1 500 500 PureMED25

8102342071 MEDAIR-650=7LET 432 5.5 LE7-10 400 V 3~ 50Hz SD 13.3 tbc tbc Triplex 1 2 80 0.5 1.4 2 1000 2000 PureMED25

8102342072 MEDAIR-810-7LET 672 7.5 LE10-10 400 V 3~ 50Hz SD 19 tbc tbc Triplex 1 2 81 0.5 1.4 2 1000 2000 PureMED25

8102342073 MEDAIR-1400-7LET 1164 11 LE15-10 400 V 3~ 50Hz SD 28.5 tbc tbc Triplex 1 2 89 0.75 5.4 2 1000 2000 PureMED25

8102342074 MEDAIR-1530-7LET 1530 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Triplex 1 2 87.5 0.75 5.4 2 1000 2000 PureMED25

8102342076 MEDAIR-1815-7LEQ 1506 7.5 LE10-10 400 V 3~ 50Hz SD 19 tbc tbc Quadruplex 2 2 81 0.5 1.4 2 1000 2000 PureMED35

8102342077 MEDAIR-1835-7LET 1524 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Triplex 1 2 87.5 0.75 5.4 2 1000 2000 PureMED35

8102342078 MEDAIR-2665-7LEP 2256 7.5 LE10-10 400 V 3~ 50Hz SD 19 tbc tbc Pentaplex 3 2 81 0.5 1.4 2 1000 2000 PureMED45

8102342080 MEDAIR-3210-7LEQ 2664 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Quadruplex 2 2 87.5 0.75 5.4 2 1500 3000 PureMED100

8102342081 MEDAIR-3810-7LEP 3162 11 LE15-10 400 V 3~ 50Hz SD 28.5 tbc tbc Pentaplex 3 2 89 0.75 5.4 2 1500 3000 PureMED100

8102342082 MEDAIR-4000-7LEP 4566 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Pentaplex 3 2 87.5 0.75 5.4 2 1500 3000 PureMED100

8102369756 MEDAIR-5335-7LEP 4566 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Pentaplex 3 2 87.5 0.75 5.4 2 2000 4000 PureMED100

8102342083 MEDAIR-5500-7LEP 4566 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Pentaplex 3 2 87.5 0.75 5.4 2 3000 6000 PureMED100

8102369757 MEDAIR-5535-7LEH 4566 11 LE15-10 400 V 3~ 50Hz SD 28.5 tbc tbc Hexaplex 4 2 89 0.75 5.4 2 3000 6000 PureMED100

8102342085 MEDAIR-6060-7LEH 6000 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Hexaplex 4 2 87.5 0.75 5.4 2 3000 6000 PureMED100

8102369758 MEDAIR-7175-7LEH 5955 15 LE20-10 400 V 3~ 50Hz SD 38 tbc tbc Hexaplex 4 2 87.5 0.75 5.4 3 2000 6000 PureMED145

1. Data measured and stated in accordance with ISO1217 Ed.4, Annex C & Annex E and Pneurop/Cagi PN2CPTC2 with one compressor on standby and with an air intake at 1013 mbar, 20°C and 0% RH. Tropical thermostats

may reduce the free air delivery marginally.

For 700kPa and 1000kPa, combined air plant capacity is rated with a 50/50 split of surgical and medical air (within the design parameters stated in HTM 02-01).

2. These are typical figures and may vary with the specific motor used. Consult the motor nameplate for exact figures.

3. Two standby compressors should be provided unless the automatic backup manifold is of sufficient capacity to deliver the system design flow.

4. Measured in free field conditions in accordance with the Pneurop/Cagi PN8TNC2.2 test code. Subject to a tolerance of +/- 3 dB

5. Other models and layouts are available to suit particular site requirements. Contact your local representative for support.

6. Design flow in terms of free air delivered after losses at working pressure with reserve compressor(s) on standby. Tolerance ±5%.

8102341122 Ed4

© Pneumatech Medical Gas Solutions 2017

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

You might also like

- Method Statement For Field Erection Storage TanksDocument29 pagesMethod Statement For Field Erection Storage TanksTee Klong Rung100% (1)

- Nirvana 15-30kW (20-40Hp) TroubleshootingDocument34 pagesNirvana 15-30kW (20-40Hp) Troubleshootinggilang278No ratings yet

- Air 4 Bar PlantDocument7 pagesAir 4 Bar PlantAbu ZakaNo ratings yet

- Domnick Hunter MX 102-110DryerServiceDocument28 pagesDomnick Hunter MX 102-110DryerServiceUntung DarmawanNo ratings yet

- Condensation CalculationDocument40 pagesCondensation Calculationbinhjuki100% (2)

- Active Chilled BeamsDocument36 pagesActive Chilled Beamsrated_eigh100% (1)

- HTM 2022 50Hz (PureMed) Medical Air Plant TDSDocument14 pagesHTM 2022 50Hz (PureMed) Medical Air Plant TDSChou AllenNo ratings yet

- HTM 2022 60Hz (PureMed) Medical Air Plant TDSDocument13 pagesHTM 2022 60Hz (PureMed) Medical Air Plant TDSChou AllenNo ratings yet

- EN Premium RX 540 - OXYGEN GENERATORDocument4 pagesEN Premium RX 540 - OXYGEN GENERATORSean AkirangaNo ratings yet

- 187 - GB - 200809 CL 3... C 9Document8 pages187 - GB - 200809 CL 3... C 9Ghufran KhanNo ratings yet

- Airliquide PDFDocument41 pagesAirliquide PDFTan Hung LuuNo ratings yet

- Instruction Manual: Nitrogen Generator System (HP Included) 2-Column System X-VersionDocument61 pagesInstruction Manual: Nitrogen Generator System (HP Included) 2-Column System X-VersionAldhair Perseo Oliva EscobedoNo ratings yet

- Nitrogen Plant Genertor CDocument8 pagesNitrogen Plant Genertor CDEVAM PATELNo ratings yet

- XAS 146-186pb enDocument6 pagesXAS 146-186pb enSergei KurpishNo ratings yet

- Total Air Solutions CatalogueDocument12 pagesTotal Air Solutions CatalogueShanna CollinsNo ratings yet

- Presentation AC ZR VSD - IPM 2019Document13 pagesPresentation AC ZR VSD - IPM 2019Aldhair Perseo Oliva Escobedo100% (1)

- Filter Solutions English Feb 2019 HR-páginas-1,8-9,25-26Document5 pagesFilter Solutions English Feb 2019 HR-páginas-1,8-9,25-26samuelNo ratings yet

- 2915 8275 00 - Fluids and Lubricants - 2017Document20 pages2915 8275 00 - Fluids and Lubricants - 2017GuptaNo ratings yet

- Roto ZDocument3 pagesRoto Zjayakumar rajanNo ratings yet

- MED12 142plus Medical Air Purifier ISO Sales Leaflet en 2212021829Document8 pagesMED12 142plus Medical Air Purifier ISO Sales Leaflet en 2212021829RUN GONo ratings yet

- Manual Instalação Booster b1 - 4505 - AngDocument28 pagesManual Instalação Booster b1 - 4505 - AngBruno LeãoNo ratings yet

- 2447 - Pneumatech Gas Generator Catalogue - LR PDFDocument24 pages2447 - Pneumatech Gas Generator Catalogue - LR PDFwgonzalesm100% (1)

- Health Technical Memorandum 08-03 - Bed Head UnitDocument58 pagesHealth Technical Memorandum 08-03 - Bed Head UnitRagline SerranoNo ratings yet

- Technical Description Sigma Air Manager: GSM Modem Retrofit KitDocument20 pagesTechnical Description Sigma Air Manager: GSM Modem Retrofit KitEvandro Jva compressoresNo ratings yet

- Atlas Copco GX22Document16 pagesAtlas Copco GX22Elementos IndustrialesNo ratings yet

- Manual Transporte Booster b2 - 4505 - AngDocument14 pagesManual Transporte Booster b2 - 4505 - AngBruno LeãoNo ratings yet

- Line Filter Cartridges Plus - English Print - tcm835-3558191Document4 pagesLine Filter Cartridges Plus - English Print - tcm835-3558191jackyt09No ratings yet

- Atlas Copco LE LF LTBrochureDocument12 pagesAtlas Copco LE LF LTBrochurecaptain GuillemotNo ratings yet

- Maxigas User ManualDocument30 pagesMaxigas User ManualSameer LambayNo ratings yet

- BD 1050 PartesDocument26 pagesBD 1050 PartesFelipe RojasNo ratings yet

- ZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413Document24 pagesZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413karun agrawalNo ratings yet

- Data Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enDocument2 pagesData Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enMohamed Abd-alfattah100% (1)

- Agss Plant IomDocument31 pagesAgss Plant Iomwaleed.murad@gmail.comNo ratings yet

- Company Profile Ias (22-23)Document15 pagesCompany Profile Ias (22-23)Radziel EngineeringNo ratings yet

- Kaeser Screw Compressors ASD, BSD, CSD SeriesDocument12 pagesKaeser Screw Compressors ASD, BSD, CSD SeriesJoseph Geraci0% (1)

- Kaesr Filter CompresorDocument11 pagesKaesr Filter CompresorAgus Waluyo100% (1)

- Activated Carbon Filter For Compressed Air: Atlas CopcoDocument26 pagesActivated Carbon Filter For Compressed Air: Atlas CopcoAtikah BawazierNo ratings yet

- Juhayna ZR200 Motor Repair OfferDocument6 pagesJuhayna ZR200 Motor Repair OfferAmer Samir AttiaNo ratings yet

- HTM02 01 Triplex Vacuum Plant O M Rev 2Document26 pagesHTM02 01 Triplex Vacuum Plant O M Rev 2Wekesa RobinsonNo ratings yet

- Fabrication Bill of MaterialDocument8 pagesFabrication Bill of MaterialHashemAliHashemNo ratings yet

- MSQH-Hospital Accreditation Survey Process Guide, 5th Edition 2017Document62 pagesMSQH-Hospital Accreditation Survey Process Guide, 5th Edition 2017Razali FaisalNo ratings yet

- Assembly and Operating Manual: Retrofit Kit Ethernet/IpDocument28 pagesAssembly and Operating Manual: Retrofit Kit Ethernet/IpJuan Diego Tovar MorenoNo ratings yet

- Aib-Zr-Zt 75-90 VSDDocument142 pagesAib-Zr-Zt 75-90 VSDRoel ZaportizaNo ratings yet

- Kaeser Booster CompressorsDocument8 pagesKaeser Booster CompressorsRafatNo ratings yet

- Roto Z en 2935004221Document2 pagesRoto Z en 2935004221Madjid HernandezNo ratings yet

- Roto Synthetic Fluid ULTRA: High Quality Synthetic Oil For Demanding ApplicationsDocument2 pagesRoto Synthetic Fluid ULTRA: High Quality Synthetic Oil For Demanding ApplicationsJoao BotasNo ratings yet

- GD Katalog Esm 7-22 I Vs 7-22Document12 pagesGD Katalog Esm 7-22 I Vs 7-22San Svake TasteNo ratings yet

- Oil Free. Disrupted: Your Always Better Choice Is HereDocument24 pagesOil Free. Disrupted: Your Always Better Choice Is Herevuongdt1995No ratings yet

- Aib-Fd160 1998-12-01Document16 pagesAib-Fd160 1998-12-01Filipe GuaranyNo ratings yet

- RS Ultra Latest MSDSDocument2 pagesRS Ultra Latest MSDSRamraj EnterprisesNo ratings yet

- Modulation Option On R90-160 Installation InstructionDocument23 pagesModulation Option On R90-160 Installation InstructionLiviu HogeaNo ratings yet

- New Maxigas Service Manual 061006Document36 pagesNew Maxigas Service Manual 061006Service Air-PartNo ratings yet

- Comprssor Kaeser SX 3T PDFDocument9 pagesComprssor Kaeser SX 3T PDFSyaf HudaNo ratings yet

- Kits OSC Atlas Copco PDFDocument2 pagesKits OSC Atlas Copco PDFSebastian CholulaNo ratings yet

- 36930071-2 Rev1 PoplDocument14 pages36930071-2 Rev1 PoplAnish SinghNo ratings yet

- 050 Vacuum Pump SystemsDocument174 pages050 Vacuum Pump SystemsOséias Maciel SilvaNo ratings yet

- Atlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90Document16 pagesAtlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90mahdiNo ratings yet

- 2 DX 2 DN VSD AIB EN Lille 1901077772Document181 pages2 DX 2 DN VSD AIB EN Lille 1901077772Chris Gaveva100% (1)

- Instruction Manual, QGV 2015Document188 pagesInstruction Manual, QGV 2015davidNo ratings yet

- MedicalGasPipelineSystemsPolicy201306 PDFDocument47 pagesMedicalGasPipelineSystemsPolicy201306 PDFVijayakumar MadhaiyanNo ratings yet

- I1 PureGUARD 6 Digital Alarm AIBDocument36 pagesI1 PureGUARD 6 Digital Alarm AIBdan singh choudharyNo ratings yet

- BMed Medical Air Systems Oil-Injected Screw HTM 60Hz Technical Datasheet EN 4233500085.00Document19 pagesBMed Medical Air Systems Oil-Injected Screw HTM 60Hz Technical Datasheet EN 4233500085.00kareemNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- HTM 2022 60Hz (PureMed) Medical Air Plant TDSDocument13 pagesHTM 2022 60Hz (PureMed) Medical Air Plant TDSChou AllenNo ratings yet

- HTM 2022 50Hz (PureMed) Medical Air Plant TDSDocument14 pagesHTM 2022 50Hz (PureMed) Medical Air Plant TDSChou AllenNo ratings yet

- Copper Tubes, Fittings and Valves BrochureDocument4 pagesCopper Tubes, Fittings and Valves BrochureChou AllenNo ratings yet

- Brochure FLUIDYS EN EDocument7 pagesBrochure FLUIDYS EN EChou AllenNo ratings yet

- Solutions Start Here: Respiratory Care & Mobile SolutionsDocument17 pagesSolutions Start Here: Respiratory Care & Mobile SolutionsChou AllenNo ratings yet

- Medical Flowmeter: Solutions Start Here..Document11 pagesMedical Flowmeter: Solutions Start Here..Chou AllenNo ratings yet

- Oxygen Regulator Diaphragm Type2Document1 pageOxygen Regulator Diaphragm Type2Chou AllenNo ratings yet

- SMP Oxygen-Regulator-User-ManualDocument7 pagesSMP Oxygen-Regulator-User-ManualChou AllenNo ratings yet

- TDS - Aqua PU Anti-SkidDocument2 pagesTDS - Aqua PU Anti-SkidHeramb TrifaleyNo ratings yet

- PLP P 5 2003, Molecular Sieve DehydrationDocument73 pagesPLP P 5 2003, Molecular Sieve Dehydrationivanov5559100% (1)

- Water Vapor Pressure FormulationsDocument9 pagesWater Vapor Pressure FormulationsNikunj PipariyaNo ratings yet

- IRM200 Insulation Selection-Cold PDFDocument6 pagesIRM200 Insulation Selection-Cold PDFmika cabelloNo ratings yet

- Semco Enthalpy Wheel Technical ManualDocument37 pagesSemco Enthalpy Wheel Technical ManualjvalkenburgNo ratings yet

- Refrigeration and Air-ConditioningDocument24 pagesRefrigeration and Air-ConditioningKumar SahebNo ratings yet

- Agricultural Meteorology - Part - IIDocument44 pagesAgricultural Meteorology - Part - IIMaruthavanan Ganapathy100% (13)

- 11.6202 MUS - KS07 - Active - Carbon - Filter - Dryer - 2009Document40 pages11.6202 MUS - KS07 - Active - Carbon - Filter - Dryer - 2009Jessica ThomasNo ratings yet

- Painting Procedure (Repainting Flow Indicator)Document6 pagesPainting Procedure (Repainting Flow Indicator)nds setyawanNo ratings yet

- Rac 4,5Document22 pagesRac 4,5vipsdgr8No ratings yet

- Chapter13 PDFDocument21 pagesChapter13 PDFGiyantoNo ratings yet

- Air CondDocument34 pagesAir CondAnonymous k90SvONo ratings yet

- Ingersoll Rand D5IM User ManualDocument20 pagesIngersoll Rand D5IM User ManualEthanNo ratings yet

- Catalogo PDFDocument372 pagesCatalogo PDFWilber Fernando Nina ChambillaNo ratings yet

- Sikalastic®-632: Product Data SheetDocument5 pagesSikalastic®-632: Product Data SheetShanaei MiskinNo ratings yet

- Moisture MeasurementDocument8 pagesMoisture MeasurementnimasinaNo ratings yet

- ThermalPhysics 5Document16 pagesThermalPhysics 5abrahamchavezNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- Terra Universal, Inc.: Catalog 105 Sections Available ForDocument19 pagesTerra Universal, Inc.: Catalog 105 Sections Available Forchteo1976No ratings yet

- Tdp-201 Psychrometrics Level 1 FundamentalsDocument71 pagesTdp-201 Psychrometrics Level 1 FundamentalsSNMNo ratings yet

- Models Ta410, TA430 AND TA440: AnemometersDocument2 pagesModels Ta410, TA430 AND TA440: AnemometersakaretlerNo ratings yet

- The Psychrometric Chart and Air Conditioning SystemsDocument2 pagesThe Psychrometric Chart and Air Conditioning SystemsSaif MohammadNo ratings yet

- PDS HEMPELS PHENOLIC EPOXY 163US en-USDocument2 pagesPDS HEMPELS PHENOLIC EPOXY 163US en-USRyan DuhonNo ratings yet

- Topics-III RefhvacDocument21 pagesTopics-III Refhvacwarren carozcaNo ratings yet

- Dehydration of Natural GasDocument22 pagesDehydration of Natural GasCyrus iraniNo ratings yet

- Water ActivityDocument5 pagesWater ActivityJALAJ'S WORLDNo ratings yet

- C5a14a87 Fundamentals of Physical Geography Ncert Class 11 PDF Notes by Ookul Sample PDFDocument15 pagesC5a14a87 Fundamentals of Physical Geography Ncert Class 11 PDF Notes by Ookul Sample PDFmotu179No ratings yet