Professional Documents

Culture Documents

Textile Syllabus

Textile Syllabus

Uploaded by

Jagdish RudaniCopyright:

Available Formats

You might also like

- Kate Fletcher, Lynda Grose, Paul Hawken-Fashion & Sustainability - Design For Change-Laurence King Publishing (2012)Document193 pagesKate Fletcher, Lynda Grose, Paul Hawken-Fashion & Sustainability - Design For Change-Laurence King Publishing (2012)Clara Trindade50% (2)

- Soil FertilityDocument244 pagesSoil FertilityTäð Œvê MîðNo ratings yet

- BS Databook2002Document93 pagesBS Databook2002Dani WijayaNo ratings yet

- Handloom MarkDocument10 pagesHandloom MarkrskshankarNo ratings yet

- c364 Series Pri Dlbt1320426en 0Document9 pagesc364 Series Pri Dlbt1320426en 0Андрей КрупкинNo ratings yet

- EBD 89 Application FormDocument29 pagesEBD 89 Application Formsushil aroraNo ratings yet

- Avantel LimitedDocument17 pagesAvantel LimitedContra Value BetsNo ratings yet

- PROTOCOLSDocument3 pagesPROTOCOLSJeiseane EspirituNo ratings yet

- Receipt #312761199: Total Contribution 1000.00Document1 pageReceipt #312761199: Total Contribution 1000.00ReyanshNo ratings yet

- VardhmanDocument37 pagesVardhmancool20071No ratings yet

- Machinery 40 - 14Document6 pagesMachinery 40 - 14Mohamed NaeimNo ratings yet

- Sourcing and Costing of A GarmentDocument21 pagesSourcing and Costing of A Garmentishita khannaNo ratings yet

- Internship Doc Raymond'sDocument229 pagesInternship Doc Raymond'srahul rajNo ratings yet

- Birla-Century Parichay InductionDocument53 pagesBirla-Century Parichay InductionMahesh KumarNo ratings yet

- ITMSS Vol37 2014Document69 pagesITMSS Vol37 2014Juan Francisco Rubio JovelNo ratings yet

- Daily Statement of FRM & ChemicalsDocument43 pagesDaily Statement of FRM & Chemicalssukallan dharNo ratings yet

- Englishprojecttt 150230Document17 pagesEnglishprojecttt 150230Heemanth ReddyNo ratings yet

- Transformation ProcessDocument1 pageTransformation ProcessBalte, Richard F.No ratings yet

- Regional Timing WindowsDocument3 pagesRegional Timing WindowsnNo ratings yet

- AmbikaCottonMills PDFDocument11 pagesAmbikaCottonMills PDFaradhana avinashNo ratings yet

- 1 s2.0 S0959652608002916 MainDocument7 pages1 s2.0 S0959652608002916 MainMeenakshi SamiduraiNo ratings yet

- The Italian Textile IndustryDocument7 pagesThe Italian Textile IndustryDirk100% (1)

- Framework For CRMDocument18 pagesFramework For CRMmusafirNo ratings yet

- It's Telephone Ringing Everywhere in India - The TribuneDocument19 pagesIt's Telephone Ringing Everywhere in India - The TribuneGurpreet SinghNo ratings yet

- IX Class Computer Science AbbreviationsDocument7 pagesIX Class Computer Science AbbreviationsAmna FaisalNo ratings yet

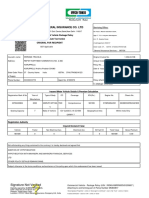

- Iffco - Tokio General Insurance Co. LTDDocument2 pagesIffco - Tokio General Insurance Co. LTDkRiZ kRiShNaNo ratings yet

- NYUSIM-based Millimeter Wave Propagation Channel Model in 5GDocument6 pagesNYUSIM-based Millimeter Wave Propagation Channel Model in 5GInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- UnionDocument16 pagesUnionRazu Alam100% (1)

- 06.10.2020 Atmanirbhar Bharat Relief For Contractor-Developers of Road Sector-RegDocument2 pages06.10.2020 Atmanirbhar Bharat Relief For Contractor-Developers of Road Sector-RegSIPL DARA QSNo ratings yet

- IPru Transportation and Logistics Fund PPT For NFODocument39 pagesIPru Transportation and Logistics Fund PPT For NFODeepak GoyalNo ratings yet

- Production Order in SAP CO01 MD16 CO02 CO15Document13 pagesProduction Order in SAP CO01 MD16 CO02 CO15Muhammad GamalNo ratings yet

- 5.2.1 List of Placed Students VESIT NAAC TPCDocument154 pages5.2.1 List of Placed Students VESIT NAAC TPCRashmi RanjanNo ratings yet

- Software Upgrade Procedure Smartpack2 Controller Udoc 370036.063!1!2 1Document44 pagesSoftware Upgrade Procedure Smartpack2 Controller Udoc 370036.063!1!2 1pap_ingosNo ratings yet

- Despiece GT250Document74 pagesDespiece GT250javierNo ratings yet

- 1 s2.0 S0959652613002850 MainDocument9 pages1 s2.0 S0959652613002850 MainLakshay sharmaNo ratings yet

- Aalberts 2020Document128 pagesAalberts 2020gaja babaNo ratings yet

- Network SecurityDocument14 pagesNetwork SecurityHina AkramNo ratings yet

- ANPR CAMERA MANUAL (Network Traffic Camera)Document79 pagesANPR CAMERA MANUAL (Network Traffic Camera)Vivek PalNo ratings yet

- Design and Development of Hank Dyeing Machine and In-House Field Trials For Khadi ClusterDocument11 pagesDesign and Development of Hank Dyeing Machine and In-House Field Trials For Khadi ClusterIJRASETPublicationsNo ratings yet

- Presto Price List For Mto May 2022Document61 pagesPresto Price List For Mto May 2022Sandy ka FundaaNo ratings yet

- b247fdc5 6694 45b6 8bf7 2b1f5502ffb8Document8 pagesb247fdc5 6694 45b6 8bf7 2b1f5502ffb8SaurabhNo ratings yet

- VoThiThao AutomationTesting FinalDocument20 pagesVoThiThao AutomationTesting FinalNguyễn LộcNo ratings yet

- What Drives Smartphone Purchase Intention Perspective From Technology, Price, and E-Wom As MediatorsDocument7 pagesWhat Drives Smartphone Purchase Intention Perspective From Technology, Price, and E-Wom As MediatorsInternational Journal of Innovative Science and Research Technology100% (1)

- Ministry of Commerce Internship ReportDocument30 pagesMinistry of Commerce Internship ReportGhulam RahimNo ratings yet

- Harga Clutch Plate KeretaDocument1 pageHarga Clutch Plate KeretaFazhaNo ratings yet

- 1000kgh Laundry Soap Finish Line-20180131 - 2Document14 pages1000kgh Laundry Soap Finish Line-20180131 - 2yeneneh14No ratings yet

- EarningUpdatesPresentation BBL 30092021 PDFDocument29 pagesEarningUpdatesPresentation BBL 30092021 PDFsuman sheikhNo ratings yet

- Jutti Keyword KeywordeverywhereDocument15 pagesJutti Keyword KeywordeverywhereRiya GupteNo ratings yet

- IFFCO at A Glance 2012-13Document148 pagesIFFCO at A Glance 2012-13Sangram PandaNo ratings yet

- Honour Crimes IranDocument5 pagesHonour Crimes Iranivu charlesNo ratings yet

- Traditional Hand Loom TextilesDocument24 pagesTraditional Hand Loom Textilesshubha mahajanNo ratings yet

- How Robotic Process Automation Is Transforming Accounting and AuditingDocument6 pagesHow Robotic Process Automation Is Transforming Accounting and AuditingWening RestiyaniNo ratings yet

- Roberto Moreno - Final Research ProposalDocument9 pagesRoberto Moreno - Final Research Proposalapi-643290237No ratings yet

- Tesda Op Co 03 F04 Dow NC Ii NewDocument16 pagesTesda Op Co 03 F04 Dow NC Ii NewHoney Belarmino GonzaloNo ratings yet

- Weaving ReportDocument68 pagesWeaving ReportSagar ShriNo ratings yet

- 53-Article Text-353-1-10-20210820Document10 pages53-Article Text-353-1-10-20210820Resandi MuhamadNo ratings yet

- Steelez 'We Make It Easy' FARA.Document21 pagesSteelez 'We Make It Easy' FARA.Ashish MishraNo ratings yet

- Copia de Reporte - Vencimiento2022 - Prop (1) ATICODocument49 pagesCopia de Reporte - Vencimiento2022 - Prop (1) ATICOjesus angel quispe agramonteNo ratings yet

- DOCBusiness Plan - DANIEL NANGUMA2022 JULY.Document47 pagesDOCBusiness Plan - DANIEL NANGUMA2022 JULY.Kevinwalker 254100% (1)

- KPSC Sa-P 2019Document12 pagesKPSC Sa-P 2019M UllerNo ratings yet

- Computer SyllabusDocument226 pagesComputer Syllabus2132 CO Rohit TandelNo ratings yet

- Publication-List-21 7 2022 PDFDocument10 pagesPublication-List-21 7 2022 PDFJagdish RudaniNo ratings yet

- Sitra'S Services For Weaving MillsDocument2 pagesSitra'S Services For Weaving MillsJagdish RudaniNo ratings yet

- Analysis of Number of Yarn Breaks During Warping Process: Kushal N. Vashi, Mox C. Patel, Mayur C. PatelDocument8 pagesAnalysis of Number of Yarn Breaks During Warping Process: Kushal N. Vashi, Mox C. Patel, Mayur C. PatelJagdish RudaniNo ratings yet

- Booking Details: What Documents I Need To Board My Bus?Document2 pagesBooking Details: What Documents I Need To Board My Bus?Jagdish RudaniNo ratings yet

- Trends On The Cellulose-Based Textiles Raw Materials and TechnologiesDocument20 pagesTrends On The Cellulose-Based Textiles Raw Materials and TechnologiesLANo ratings yet

- Kape 203Document54 pagesKape 203Muhammad Shahzad50% (2)

- IKEA Catalogue 2011Document189 pagesIKEA Catalogue 2011Shantanu SharmaNo ratings yet

- The Environmental Aspects of SolventDocument5 pagesThe Environmental Aspects of SolventAditya ShrivastavaNo ratings yet

- Grasin Industry LTDDocument30 pagesGrasin Industry LTDAbhishek RaoNo ratings yet

- Men S Textiles Forecast A W 25 26 Re Generations enDocument19 pagesMen S Textiles Forecast A W 25 26 Re Generations enYashvi MishraNo ratings yet

- 1.textile As A Wonder For NotesDocument201 pages1.textile As A Wonder For NotesAmarjeet KumarNo ratings yet

- About The Dyes: Dyes For Cellulose FibersDocument4 pagesAbout The Dyes: Dyes For Cellulose FibersmanqabatNo ratings yet

- Textile 1Document118 pagesTextile 1Alina EneNo ratings yet

- Developments in The Processing of Lyocel PDFDocument20 pagesDevelopments in The Processing of Lyocel PDFAliMuhammadNo ratings yet

- Viscose RayonDocument12 pagesViscose RayonnatarajantexNo ratings yet

- Weaving DetailsDocument134 pagesWeaving DetailsSALIMNo ratings yet

- Reflectance FT-IR Spectroscopy As A Viable OptionDocument11 pagesReflectance FT-IR Spectroscopy As A Viable OptionRoanne ArceoNo ratings yet

- WIW JFH Catalogue June'21Document84 pagesWIW JFH Catalogue June'21eshasayajiNo ratings yet

- Semi SyntheticDocument8 pagesSemi SyntheticArresh NadeanNo ratings yet

- Types of FabricsDocument19 pagesTypes of FabricsKapil Saini75% (4)

- Natural and Sustainable Raw Materials For Sanitary Napkin 2165 8064 1000308Document3 pagesNatural and Sustainable Raw Materials For Sanitary Napkin 2165 8064 1000308Aqib MohammedNo ratings yet

- Chronicle April07Document26 pagesChronicle April07Moni Sanker100% (1)

- Post-Coronavirus - Defensive TextilesDocument19 pagesPost-Coronavirus - Defensive TextilesNataliaMaceiraNo ratings yet

- Chemical EngineeringDocument3 pagesChemical EngineeringLUcii OstoRgaNo ratings yet

- Textile-Enhancers - PDF MomentiveDocument17 pagesTextile-Enhancers - PDF MomentiveGokhan RamiNo ratings yet

- Design To Reduce Chemical Impacts PDFDocument29 pagesDesign To Reduce Chemical Impacts PDFRayeddNo ratings yet

- Fabric Physical Properties and Clothing ComfortDocument7 pagesFabric Physical Properties and Clothing Comfortdr beshoy awadNo ratings yet

- Kohinoor Mill ProjectDocument8 pagesKohinoor Mill ProjectJack DenielNo ratings yet

- Chapter 1:-Sportswear: IntroductionDocument6 pagesChapter 1:-Sportswear: IntroductionTejaswini SinghNo ratings yet

- The Rieter Manual of Spinning Vol. 7 2451-V1 en Original 68509Document78 pagesThe Rieter Manual of Spinning Vol. 7 2451-V1 en Original 68509Prasad Potdar50% (2)

- Bamboo Fabric Products and UsesDocument7 pagesBamboo Fabric Products and UsesDorin VladNo ratings yet

- Modal FabricDocument30 pagesModal FabricGillian Faye LechocoNo ratings yet

- trm-2 AssignmentDocument9 pagestrm-2 AssignmentBoier Sesh PataNo ratings yet

Textile Syllabus

Textile Syllabus

Uploaded by

Jagdish RudaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Textile Syllabus

Textile Syllabus

Uploaded by

Jagdish RudaniCopyright:

Available Formats

DIPLOMA IN TEXTILE TECHNOLOGY

COURSES OFFERED

Course Code

Courses Credits Year / Semester

(15O)

A. Foundation Technology Courses - 49 Credits (Common to all Programmes)

0101 Communicative English – I 5 I / ODD

0102 Engineering Mathematics – I 8 I / ODD

0103 Engineering Physics – I 5 I / ODD

0104 Engineering Chemistry – I 5 I / ODD

0105 Engineering Physics – I Practical 1 I / ODD

0106 Engineering Chemistry – I Practical 1 I / ODD

0107 Communicative English – II 4 I / EVEN

0108 Engineering Mathematics – II 5 I / EVEN

0109 Applied Mathematics 5 I / EVEN

0110 Engineering Physics – II 4 I / EVEN

0111 Engineering Chemistry – II 4 I / EVEN

0112 Engineering Physics – II Practical 1 I / EVEN

0113 Engineering Chemistry – II Practical 1 I / EVEN

B. Core Technology Courses - 45 Credits

0201 Workshop Practical 1 I / ODD

0202 Engineering Graphics – I 3 I / ODD

0203 Engineering Graphics– II 3 I / EVEN

0204 Computer Applications Practical – I 1 I / ODD

0205 Computer Applications Practical – II 1 I / EVEN

Diploma in Textile Technology Page 1

Course Code

Courses Credits Year / Semester

(15O)

5201 Fibre Science and Technology 5 II / ODD

5202 Yarn Manufacture – I 5 II / ODD

5203 Fabric Manufacture– I 6 II / ODD

5204 Textile Wet Processing – I 5 II / EVEN

5205 Basic Engineering 5 II / EVEN

5206 Fibre Identification Practical 2 II / ODD

5207 Yarn Manufacture –I Practical 3 II / ODD

5208 Fabric Manufacture – I Practical 3 II / ODD

5209 Life and Employability Skills Practical 2 II / ODD

C. Applied Technology Courses – 57 Credits

5301 Yarn Manufacture – II 6 II / EVEN

5302 Textile Design 4 II / EVEN

5303 Fabric Manufacture – II 5 III / ODD

5304 Textile Wet Processing – II 4 III / ODD

5305 Garment Manufacture 4 III / ODD

5306 Textile Testing 5 III / ODD

5307 Textile Management 5 III / EVEN

5308 Yarn Manufacture –II Practical 3 II / EVEN

5309 Textile Design Practical 2 II /EVEN

5310 Textile Wet Processing Practical 3 II / EVEN

5311 Fabric Manufacture – II Practical 2 III / ODD

5312 Garment Pattern Making Practical 2 III / ODD

5313 Garment Manufacture Practical 3 III / EVEN

5314 Textile Testing Practical 3 III / ODD

5315 Textile and Garment CAD Practical 2 III / EVEN

5316 Professional Practice & Mini project 2 III / ODD

5317 Project Work 2 III / EVEN

Diploma in Textile Technology Page 2

Course Code

Courses Credits Year / Semester

(15O)

D. Diversified Technology Courses – 14 Credits (Any one Group)

Group A

5401A Advanced Textile Manufacture 6 III / EVEN

5402A Garment Quality Control and Merchandising 5 III / EVEN

5403A Advanced Textile Manufacture Practical 3 III / EVEN

Group B

5401B Fashion Designing 6 III / EVEN

5402B Quality Assurance in Textile Processing 5 III / EVEN

5403B Fashion Designing Practical 3 III / EVEN

Diploma in Textile Technology Page 3

CURRICULUM OUTLINE

(Aided and SS Programmes)

SEMESTER I [ODD (I)]

Practical/

Code Theory Tutorial Total

Course Drawing Credits

(15O)

Periods / Week

0101 Communicative English – I 5 - - 5 5

0102 Engineering Mathematics – I 8 - - 8 8

0103 Engineering Physics – I 5 - - 5 5

0104 Engineering Chemistry – I 5 - - 5 5

0105 Engineering Physics – I Practical - 2 - 2 1

0106 Engineering Chemistry – I Practical - 2 - 2 1

0201B Basic Design Practical - I - 3 - 3 1

0202 Engineering Graphics – I - 6 - 6 3

0204 Computer Applications Practical –I - 2 - 2 1

Test - - 2 2 -

TOTAL 23 15 2 40 30

SEMESTER II [EVEN (I)]

Practical/

Code Theory Tutorial Total

Course Drawing Credits

(15O)

Periods / Week

0107 Communicative English – II 4 - 1 5 4

0108 Engineering Mathematics – II 5 - - 5 5

0109 Applied Mathematics 5 - 1 6 5

0110 Engineering Physics – II 4 - 1 5 4

0111 Engineering Chemistry – II 4 - 1 5 4

0112 Engineering Physics – II Practical - 2 - 2 1

0113 Engineering Chemistry – II - 2 - 2 1

Practical

0203 Engineering Graphics – II - 6 - 6 3

0205 Computer Applications Practical– II - 2 - 2 1

Test - - 2 2 -

TOTAL 22 12 6 40 28

Diploma in Textile Technology Page 4

DIPLOMA IN TEXTILE TECHNOLOGY

CURRICULUM FOR 15O SCHEME

(Effect from June 2016)

SEMESTER III [ODD (II)]

Drawing / Tutorial/

Code Theory Total

Course Practical Test Credits

(15O)

Periods / Week

5201 Fibre Science and Technology 5 - - 5 5

5202 Yarn Manufacture – I 5 - - 5 5

5203 Fabric Manufacture – I 6 - - 6 6

5206 Fibre Identification Practical - 4 - 4 2

5207 Yarn Manufacture – I Practical - 6 - 6 3

Fabric Manufacture – I

5208 - 6 - 6 3

Practical

Life and Employability Skills

5209 - 4 - 4 2

Practical

Library 1 1 -

Seminar 1 1 -

Test - - 2 2 -

Total 16 20 4 40 26

SEMESTER IV [EVEN (II)]

Drawing / Tutorial/

Theory Total

Code Practical Test

Course Credits

(15O)

Periods / Week

5204 Textile Wet Processing – I 5 - - 5 5

5205 Basic Engineering 5 - - 5 5

5301 Yarn Manufacture – II 6 - - 6 6

5302 Textile Design 4 - - 4 4

Yarn Manufacture – II

5308 - 6 - 6 3

Practical

5309 Textile Design Practical - 4 - 4 2

Textile Wet Processing

5310 - 6 - 6 3

Practical

Library 1 1 -

Seminar 1 1 -

Test - - 2 2 -

Total 20 16 4 40 28

Diploma in Textile Technology Page 5

SEMESTER V [ODD (III)]

Drawing / Tutorial/

Code Theory Total

Course Practical Test Credits

(15O)

Periods / Week

5303 Fabric Manufacture – II 5 - - 5 5

5304 Textile Wet Processing– II 4 - - 4 4

5305 Garment Manufacture 4 - - 4 4

5306 Textile Testing 5 - - 5 5

5311 Fabric Manufacture-II Practical - 4 - 4 2

Garment Pattern Making

5312 - 4 - 4 2

Practical

5314 Textile Testing Practical - 6 - 6 3

Professional Practice and

5316 - 4 - 4 2

Mini Project

Library 1 1

Seminar 1 1

Test 2 2 -

Total 18 18 4 40 27

SEMESTER VI [EVEN (III)]

Drawing / Tutorial/

Code Theory Total

Course Practical Test Credits

(15O)

Periods / Week

5307 Textile Management 5 - - 5 5

5401 Diversified Course – I Theory * 6 - - 6 6

5402 Diversified Course – II Theory * 5 - - 5 5

5403 Diversified Course Practical * - 6 - 6 3

5313 Garment Manufacture Practical - 6 - 6 3

Textile and Garment CAD

5315 - 4 - 4 2

Practical

5317 Project work - 4 - 4 2

Library 1 1

Seminar 1 1

Test 2 2 -

Total 16 20 4 40 26

Note:

* Students can opt Diversified Courses from either Group – A or Group – B in Semester VI

Library and Seminar Periods are allotted in all the semesters. The students must present a

power point presentation in each course which will be facilitated by the respective faculty.

The hardcopy of the presentation must be collected by the respective faculty for records.

Diploma in Textile Technology Page 6

SCHEME OF EXAMINATION

For all Theory Courses

Duration of Examination 3 Hours

Continuous Assessment marks 25

Semester End Examination marks 75

Total marks 100

Minimum marks for a pass in a course is 40

(Out of which a minimum of 30 marks is to be scored in the semester-end examination)

For all Practical Courses

Duration of Examination 3 Hours

Continuous Assessment marks 25

Semester End Examination marks 75

Total marks 100

Minimum marks for a pass in a course is 50

(Out of which a minimum of 35 marks is to be scored in the semester-end examination)

PATTERN OF QUESTION PAPERS IN AUTONOMOUS EXAMINATIONS

Time: 3Hrs. Max.Marks:75

PART A (1 to 8)

5 Questions are to be answered out of 8. Answering of 8th

question is compulsory. Minimum one question and 5 x 2 Marks 10 Marks

maximum of two questions from each unit.

(Questions on Definition, Statement, Formula, Statement

of Theorem etc.)

PART B (9 to 16)

5 Questions are to be answered out of 8.Answering of 16th

question is compulsory. Minimum one question and 5 x 3 Marks 15 Marks

maximum of two questions from each unit.

(Short answer type questions.)

PART C (17 to 21)

All the 5 questions are to be answered. Each question will

be either orpattern. This question may have sub-divisions 5 x 10 Marks 50 Marks

also. One question from each unit

(Descriptive type questions.)

Total 75 Marks

Diploma in Textile Technology Page 7

Alternative Courses for Second & Third Year under 11O-Scheme to 15O-Scheme

Sem Course 11O-Scheme Courses Sem Course 15O-Scheme Courses

Code (Old Scheme) Code (Revised Scheme)

(with effect from October/November 2016 Examinations)

5201 Fibre Science and Technology 5201 Fibre Science and Technology

5301 Yarn Manufacture - I 5202 Yarn Manufacture - I

5304 Fabric Manufacture - I 5203 Fabric Manufacture - I

III 5205 Fibre Identification Practical III 5206 Fibre Identification Practical

5309 Yarn Manufacture – I Practical 5207 Yarn Manufacture – I Practical

5312 Fabric Manufacture – I Practical 5208 Fabric Manufacture – I Practical

5208 Communication and Life Skills Practical 5209 Life and Employability Skills Practical

(with effect from April 2017 Examinations)

5307 Basic Engineering 5205 Basic Engineering

5202 Chemical Processing -I 5204 Textile Wet Processing -I

5302 Yarn Manufacture – II 5301 Yarn Manufacture – II

IV 5306 Textile Design IV 5302 Textile Design

5206 Chemical Processing Practical 5310 Textile Wet Processing Practical

5310 Yarn Manufacture – II Practical 5308 Yarn Manufacture - II Practical

5209 Computer Applications Practical - No Alternative Course

(with effect from October/November 2017 Examinations)

5204 Textile Testing 5306 Textile Testing

5303 Yarn Manufacture - III - No Alternative Course

5203 Chemical Processing -II 5304 Textile Wet Processing -II

5305 Fabric Manufacture - II 5303 Fabric Manufacture - II

V 5207 Textile Testing Practical V 5314 Textile Testing Practical

5311 Yarn Manufacture – III Practical -- No Alternative Course

5313 Fabric Manufacture – II Practical 5311 Fabric Manufacture – II Practical

Professional Practice and Professional Practice and

5315 5316

Mini Project Mini Project

(with effect from April 2018 Examinations)

5308 Textile Management 5307 Textile Management

5401A Garment Manufacture -- No Alternative Course

5402A Advanced Textile Manufacture 5401A Advanced Textile Manufacture

5403A Garment Manufacture Practical 5313 Garment Manufacture Practical

Advanced Textile Manufacture

5404A Advanced Textile Manufacture Practical 5403A

Practical

5401B Fashion Designing 5401B Fashion Designing

VI 5402B Quality Assurance in Textile Processing VI 5402B Quality Assurance in Textile Processing

5403B Fashion Designing Practical 5403B Fashion Designing Practical

Quality Assurance in Textile Processing

5404B -- No Alternative Course

Practical

5314 Textile & Garment CAD Practical 5315 Textile & Garment CAD Practical

Project Work, In plant Training,

5316 Entrepreneurship, Environment and 5317 Project work

Disaster Management

Diploma in Textile Technology Page 8

SEMESTER - III

Diploma in Textile Technology Page 9

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM

Programme : TEXTILE TECHNOLOGY

Semester : III

Course Code : 15O - 5201

Course Name : FIBRE SCIENCE AND TECHNOLOGY

TEACHING AND SCHEME OF EXAMINATION

No. of weeks per Semester: 15 weeks

Examinations

Instructions

Max.Marks

Course

Semester - Duration

Periods / Periods / Continuous

End Total

Week Semester Assessment

Examination

Fibre science and

5 75 25 75 100 3 Hours

Technology

TOPICS AND ALLOCATION OF PERIODS

No. of

Unit No. Topic

Periods

I FIBRE CLASSIFICATION &FUNDAMENTAL CONCEPTS 12

II NATURAL CELLULOSE FIBRES 12

III NATURAL PROTEIN FIBRES 12

IV NATURAL POLYMER FIBRES 13

V SYNTHETIC POLYMER FIBRES 13

INDUSTRIAL VISITS 04

CONTINUOUS ASSESSMENT TEST AND MODEL EXAMS 09

TOTAL 75

RATIONALE

Fibres are the basic raw materials for the manufacture of yarns and fabrics. The ultimate property of

a yarn or fabric depends on the property of the fibre in it. Therefore, it is important to study the

fibre properties. Different fibres exhibit different physical and chemical properties. This is due to a

number of factors like the material of the fibre, its molecular structure and length and the amount of

draft applied to it during its spinning.

Fabrics made from different fibres and their blends are put to specific uses such as summer wear,

winter wear, industrial wear etc., depending on their particular properties.

Therefore it is very important for a textile student to study the science of fibres and the technology

of extraction of natural fibres and the manufacture of man made fibres.

Diploma in Textile Technology Page 10

OBJECTIVES

At the end of the Course, the students will be able to

Learn the terms related to fibres, yarn, fabrics and fibre forming polymers.

Understand the basic concepts and different types of natural fibres used.

Know the terms and definitions related to fibre forming polymers

Understand the important fibre properties and uses of natural and synthetic fibres.

Know the major fibre producing countries and synthetic fibre manufacturers

Gain knowledge on different types of rayons including high tenacity and eco-friendly rayon

Understand the sequence of manufacture of nylon ,polyester and acrylic fibres

Gain knowledge on the properties and end uses of spandex, glass, asbestos carbon and

metal fibres widely used

Know the different techniques of spinning manmade fibres by melt, dry and wet spinning

methods.

DETAILED SYLLABUS

UNIT – I FIBRE CLASSIFICATION &FUNDAMENTAL CONCEPTS .....12 PERIODS

1.1 Classification of fibres:Definition of textile fibre; classification of textile fibres with

regard to origin and chemical nature – Natural, natural polymer and synthetic fibres 3 Per

with examples. Properties required for an ideal textile fibre.

1.2 Terminology related to Fibres:Introduction to common forms of textile fibres; staple

fibre, filament tow UDY, POY and FOY; Dope dyed and delisted fibres.

Types of yarn – spun, continuous filament, mono filament, multi filament, flat and

textured yarn – single, ply and cabled yarns; 6 Per

Definition of terminology related to polymers; monomer, polymer, photopolymer,

copolymer, main monomer, monomer, oligomer, repeat unit, me weight,

polymerisation, degree of polymerisation, polymer molecular weight.

(Refer Web Link : https://www.youtube.com/watch?v=kaoq8Mc4xxw for polymerisation process)

1.3 Fibre structure: Orientation and crystallinity; Crystalline and amorphous content of

common natural and man made fibres. End uses of textile fibres. 3 Per

UNIT – II NATURAL CELLULOSE FIBRES .....12 PERIODS

2.1 Cotton:Stages in the growth and development of the cotton fibre. Cotton maturity –

matured, half mature, and dead fibres. Effect of immaturity in spinning and further 3 Per

processes– Cotton producing countries and states in India.

(Refer Web Link : https://www.youtube.com/watch?v=Vfds4KyaJjI for cotton cultivation)

2.2 Cotton Structure and Properties:Physical structure of cotton; chemical composition of

raw cotton. Commercial classification of world cottons with brief details of their

length, fineness, colour and spinnability. Important cotton varieties grown in India and 4 Per

their characteristics; Physical and chemical properties of cotton. Uses of cotton. Brief

study of Organic cotton &Hybrid Cotton.

2.3 Jute :Cultivation and harvesting of jute; Steps in the extraction of the fibre from plant.

Physical and chemical properties of jute. Uses of jute – Major jute producing countries 5 Per

and states in India.

Diploma in Textile Technology Page 11

Flax : Cultivation and harvesting of flax; Steps in the extraction of fibre from the plant.

Physical and chemical properties of flax – Uses of flax. Uses of kapok, ramie, hemp,

soya, banana, sisal ,pine apple and bamboo fibres – Major flax producing countries.

(Refer Web Link : https://www.youtube.com/watch?v=07mMlazrXYE for harvesting jute)

UNIT –III NATURAL PROTEIN FIBRES - SILK &WOOL .....12 PERIODS

3.1 Silk: Names of major silk producing countries. Different types of silk– wild and

cultivated silk. Sericulture and life cycle of silk worm. Silk reeling, throwing and

doubling ;Types of silk yarn commonly produced Degumming of silk and weighting of

6 Per

silk – Differences between raw and degummed silk .Waste silk – noils, dupion silk;

Chemical composition of silk. Physical and chemical properties of silk. Uses of silk.

Outline of process for the manufacture of spun silk.

(Refer Web Link : https://www.youtube.com/watch?v=wOEJ_78L29c for silk reeling)

3.2 Wool:Names of major wool producing countries. Classification of wool with respect to

sheep and by fleece. Grading of wool – American system and the British systems.

Physical and chemical structure of wool. Chemical composition of raw wool.

6 Per

differences in characteristics of woolen and worsted yarn and fabric. Brief study on

Virgin wool and remanufactured wool. Importance of wool marks. Physical and

chemical properties of wool. Uses of wool.

(Refer Web Link : https://www.youtube.com/watch?v=3DvddZZW1HA for shearing of wool)

UNIT – IV NATURAL POLYMER FIBRES ..... 13 PERIODS

4.1 Viscose Rayon: Introduction to rayon– Names of manufacturers of rayon’s; Chemical

reactions in viscose rayon manufacture; Process flow and sequences in the 3 Per

manufacture of viscose solution from its raw materials

(Refer Web Link : https://www.youtube.com/watch?v=9-Arybl6evcfor woodpulp production )

4.2 Process and Properties of Viscose:Outline the process sequence in the production of

viscose staple fibre. Physical and chemical properties of viscose rayon fibre. Uses of 3 Per

viscose rayon fibre.

(Refer Web Link : https://www.youtube.com/watch?v=5QFOnZ3TLHQ for viscose rayon manufacturing)

4.3 Spinning of Polynosic: Wet spinning of polynosic fibre. Physical and chemical

3 Per

properties of polynosic rayon fibre. Uses of polynosic rayon fibre.

4.4 Modification of Viscose rayon:Modifications in the regular viscose process for the

production of high tenacity viscose rayon; Properties and uses of HT rayon; Outline of

4 Per

Lyocell production; Properties of Lyocell (in comparison with regular / HT viscose and

other rayon).Uses of Lyocell.

UNIT –V SYNTHETIC POLYMER FIBRES ..... 13 PERIODS

5.1 Nylon 6:Manufacture processes of the Nylon 6 filament. Physical and chemical

properties of Nylon – 6 fibre. Uses of the fibre. Properties and uses of high tenacity 3 Per

nylon– 6 yarn– Names of manufacturers of Nylon – 6 fibres in India.

(Refer Web Link : https://www.youtube.com/watch?v=4GxeSO7DyaE for manufacturing of nylon filament)

5.2 Nylon 66: Manufacture processes of the Nylon 66 filament. Physical and chemical

properties of Nylon – 66 fibre. Uses of the fibre. Uses of Nomex and Kevlar fibres –

3 Per

Names of manufacturers of Nylon – 66 fibres in India

Diploma in Textile Technology Page 12

5.3 Polyester :Manufacture processes of the polyester continuous filament yarn and

staple fibre form.Physical and chemical properties of PET fibre– Uses of PET fibre –

3 Per

Names of manufacturers of Polyester fibre (PET) in India.Brief study of principles of

Draw and Air – jet Texturising

(Refer Web link: https://www.youtube.com/watch?v=VJGbg6zIugsfor manufacturing of polyester filament)

5.4 Acrylic and Special Fibres:Sequence of processes in the manufacture of acrylic staple

fibre. Physical and chemical properties of acrylic fibre. Uses of acrylic fibre. Uses of

4 Per

polyethylene, LDPE,HDPE, Polypropylene, spandex, modacrylic, hi– bulk acrylic,glass ,

asbestos ,carbon and metal fibres – Name of manufacturers of acrylic fibres in India

LIST OF PROPOSED STUDENT ACTIVITIES:

I. INDUSTRIAL VISITS

Imparting industrial visits to any one of the following industries to understand real time

applications :

1. M/s.District Sericulture Complex, Salem

2. M/s. The Salem Polypacks Ltd., Rasipuram

3. M/s. Avinaash Silk , Salem

Industrial visit report has to be submitted by the students as assignment through Black board and

as hard copy to the faculty concerned.

II. SEMINARS

Seminars to be organized on any one of the following topics in association with the IE(I)/ISTE and

the Students’ Technical Association of Textile Technology Programme.

1. Innovation of New Fibres

2. Applications of High Performance fibres

III. OPEN SOURCE SOFTWARE/LEARNING WEBSITES:

1. http..//www.textile manufacture process.com

2. http..//www.textilecoolsocial.net

3. http..//www.nptelonlinecourses.com

TEXT BOOKS

Year of

S.No Title Author Publisher

Publishing

Woodhead Publishing

1. Textile Fibres J.Gorden Cook Ltd., Cambridge, 2001

England

2. Man Made Fibres R.W.Moncrieff Mc Graw Hill, 1975

Textile fibres 2nd Revised Sevak Publications,

3. Prof V.A.Shenai 2000

Edition Vol .I Mumbai.

Diploma in Textile Technology Page 13

Prof. Bernard

4. Textiles;Fibres to Fabric Mc Graw hill, 1993

Corbman

5. Textile fibres Prof. V.K.Kothari IAFL publications, 2000

6. Fibre science and Technology Premamoy Ghosh Tata Mc Graw Hill, 2004

REFERENCE BOOKS

Year of

S.No Title Author Publisher

Publishing

Abishek publications, 2002

1. Elements of fibre science Williams S. Murphy

Chennai.

Oxford &IBH publishing

2. Fibre science and Technology Akira Namamura 2000

co, Chennai.

Abishek publications,

3. Waste silk spinning Hollins Rayner 1998

Chennai.

Abishek publications,

4. Woollen spinning Vickerman 1998

Chennai

Diploma in Textile Technology Page 14

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM – 636 005

(Autonomous Institution)

DIPLOMA IN TEXTILE TECHNOLOGY

Fibre Science and Technology

Model Question Paper– I

Year / Sem : II / III Max. Marks : 75

Code: 15O-5201 Time : 3 hr.

PART-A (5 x 2 = 10)

Note: (i) Answer any FIVE questions out of which question No. 8 is compulsory.

(ii) All questions carry equal marks.

1. What is a textile fibre?

2. Mention the crystalline, Amorphous content for any two fibres.

3. Mention any four cotton producing countries.

4. Mention the sequence of processes in flax fibre extraction.

5. What is virgin wool?

6. Mention the various types of rayon’s available.

7. Mention the uses of acrylic fibre.

8. Mention the reason for addition of Tio2 in synthetic yarn manufacture.

PART-B (5 x 3 = 15)

Note: (i) Answer any FIVE questions out of which question No. 16 is compulsory.

(ii) All questions carry equal marks.

9. What is dope dyed yarn and Delustered yarn?

10. How can cotton fibre be identified?

11. What do you understand by Cotton maturity?

12. Explain the different types of silk.

13. Mention any three differences in characteristics of woollen and worsted yarn.

14. List the uses of Lyocell.

15. State any three physical and chemical properties of polyethylene.

16. Explain the principle of air-jet texturising.

Diploma in Textile Technology Page 15

PART-C (5 x 10 = 50)

Note: (i) Answer all the questions choosing either sub-division (A) or sub-division (B) of each question.

(ii) All questions carry equal marks.

17. A. How are textile fibres classified? Give examples for each of them. 10

(OR)

B. Explain the Properties required for an ideal textile fibre. 10

18. A. With a line sketch, explain the physical structure of a cotton fibre andwrite the 10

chemical composition of cotton.

(OR)

B. How is jute fibre extracted from its stalk after harvest? Explain. 10

19. A. Explain the production of reeled silk from cocoons. Draw suitable line sketches. 10

(OR)

B. Describe the physical and chemical properties of wool. 10

20. A. Explain the process sequence in the manufacture of viscose rayon, with suitable 10

Block diagrams.

(OR)

B. Describe the physical and chemical properties of polynosic rayon. 10

21. A. Explain in brief the production of nylon6 filament yarn from its raw material. 10

(OR)

B. Explain the manufacture of acrylic filament yarn by any one spinning method. 10

Diploma in Textile Technology Page 16

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM – 636 005

(Autonomous Institution)

DIPLOMA IN TEXTILE TECHNOLOGY

Fibre Science and Technology

Model Question Paper – II

Year / Sem : II / III Max. Marks : 75

Code: 15O-5201 Time : 3 hr.

PART-A (5 x 2 = 10)

Note: (i) Answer any FIVE questions out of which question No. 8 is compulsory.

(ii) All questions carry equal marks.

1. What is a natural fibre?

2. Mention the major jute producing countries.

3. What are convolutions in cotton?

4. What is meant by silk cocoon?

5. What is recycled wool?

6. What is the use of Topham box in rayon manufacture?

7. What are the raw materials required for manufacturing nylon 66 fibres?

8. Mention the spinning method used for acrylic fibre manufacture and state its reasons.

PART-B (5 x 3 = 15)

Note: (i) Answer any FIVE questions out of which question No. 16 is compulsory.

(ii) All questions carry equal marks.

9. What is regenerated yarn?

10. What is dry spinning?

11. State the uses of flax.

12. Draw the longitudinal, cross sectional view of jute fibre.

13. Mention the process sequence in viscose rayon manufacture.

14. Explain the principle of Draw texturising.

15. State any three physical and chemical properties of Nylon 6.

16. What is Tachikawa process in polynosic rayon manufacture?

Diploma in Textile Technology Page 17

PART-C (5 x 10 = 50)

Note: (i) Answer all the questions choosing either sub-division (A) or sub-division (B) of each question.

(ii)All questions carry equal marks.

17. A. Describe the important characteristics of a textile fibre. 10

(OR)

B. Explain a) orientation and crystallinity b) End uses of textile fibres 10

18. A. State the important physical and chemical properties of cotton fibre. 10

(OR)

B. Explain the sequence of processes in the extraction of flax fibre from the plant 10

source.

19. A. Explain the life cycle of silk worm with necessary sketches. 10

(OR)

B. How is wool classified by sheep and by fleece? Explain. 10

20. A. With a line sketch, explain in detail the wet spinning and post spinning of viscose 10

rayon.

(OR)

B. What are the modifications In the regular viscose process for the production of HT 10

rayon and also Write its properties and uses.

21. A. Explain the steps in the manufacture of Nylon66 filament yarn from its raw 10

materials.

(OR)

B. State the physical and chemical properties of polyester and mention their uses. 10

Diploma in Textile Technology Page 18

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM

Programme : TEXTILE TECHNOLOGY

Semester : III

Course Code : 15O – 5202

Course Name : YARN MANUFACTURE – I

TEACHING AND SCHEME OF EXAMINATION

No. of weeks per Semester: 15 weeks

Examinations

Instructions

Max.Marks

Course

Semester– Duration

Periods / Periods / Continuous

End Total

Week Semester Assessment

Examination

Yarn

5 75 25 75 100 3 Hours

Manufacture – I

TOPICS AND ALLOCATION OF PERIODS

Unit No. Topic No. of

Periods

I GINNING,MIXING AND OPENING MACHINES 12

II CLEANING MACHINES,SCUTCHER AND LAP FORMING 12

III CARDING 12

IV MODERN DEVELOPMENTS IN CARDING 13

V DRAWFRAME 13

INDUSTRIAL VISITS 04

CONTINUOUS ASSESSMENT TEST AND MODEL EXAMS 09

TOTAL 75

RATIONALE

The basic idea about Ginning, blending, mixing, blow room machineries and the working of the

various components of the blow room are essential for the understanding of the preparation to

spinning process. The students will be able to understand the objects, principles and Modern

developments in blow room, carding and drawing, principles of doubling and drafting in draw frame

and other functional components. This will enable the students to perform the necessary setting

changes required for processing different counts and do calculations related with the production

and efficiency of the machines, draft applied etc.

Diploma in Textile Technology Page 19

OBJECTIVES

At the end of the course, the students will be able to

Acquire knowledge on various blow room machinery.

Understand the working of various opening and cleaning machinery.

Understand the working of scutcher unit.

Calculate the speed, production and efficiency of blow room machinery.

Acquire knowledge on working of high production carding machine.

Learn the various settings in a high production card.

Gain knowledge on modern developments in a card.

Calculate the speed, draft, production and efficiency in card.

Acquire knowledge on the maintenance of blow room and carding machine.

Gain knowledge on the importance of Draw frame.

Learn the working of different drafting systems in draw frame.

Acquire knowledge on the settings of drafting rollers to process short, medium

and long staple cottons.

Calculate the speed, draft, production and efficiency in draw frame.

DETAILED SYLLABUS

UNIT– I GINNING, MIXING AND OPENING MACHINES .....12 PERIODS

1.1 Ginning :Objects – types of Ginning– working of knife roller gin– defects in ginning–

2 Per

causes and remedies

(Refer Web Link : https://www.youtube.com/watch?v=3prPlanYtW0 for working of Ginning machine)

1.2 Bale Opening Machines :Objects of Blow room–principles of opening and cleaning

– construction and working of automatic bale opening machine – BLENDOMAT 3 Per

Machine –construction and working of mixing bale opener

(Refer Web Link : https://www.youtube.com/watch?v=q2cTU7l0teY for working of BLENDOMAT )

1.3 Mixing:Objects – methods of mixing– fibre properties to be considered for mixing

Objects of blending – comparison between mixing and blending – antistatic agents 4 Per

used in mixing – construction and working of Multimixer and Unimix.

(Refer Web Link :https://www.youtube.com/watch?v=hxK008cHtWM for working of Unimix)

1.4 Contamination Remover :Construction and working of hopper feeder –

Contamination– definition – Effect of contamination–construction and working of 3 Per

contamination remover– Vision shield.

UNIT–II CLEANING MACHINES, SCUTCHER AND LAP FORMING .....12 PERIODS

2.1 Opening & Cleaning Machines :Construction and working of Step cleaner, Mono

cylinder cleaner, ERM cleaner,Pre– Cleaner CL – P and CLEANOMAT CL– C1 and 2 Per

Kirschner beater.

2.2 Scutcher :Objects– passage of material through single process scutcher – brief study

2 Per

of lap length measuring motion and automatic lap doffing.

Diploma in Textile Technology Page 20

2.3 Ancillary Equipments :Objects of condenser, two way distributor , Bye pass

arrangement and safety devices–metal extractors –brief study of electronic metal 2 Per

extractors –fire eliminators

2.4 Dust extraction in blow room : Brief study of automatic waste evacuation system

(AWES) and automatic waste baling system – construction and working of 1 Per

Dedusting machine

2.5 Quality norms for Blow room lap :Defects in blow room – causes and remedies–

modern features of blow room – trash % in lap, cleaning efficiency ,lap C.V % – 2 Per

Maintenance schedule of Blow room – RH% in Blow room

2.6 Blow room sequence : Blow room sequence employed for fine, medium and coarse

1 Per

cotton (latest openers and beaters ) –flow chart only

2.7 Blow room calculations:Calculations pertaining to speed, hank of lap, production

2 Per

and efficiency of scutcher

(Refer Web Link :http://textalks.com/rieter-rsb-d40-an-introductional-animation/ and

https://www.youtube.com/watch?v=f19bY-esqKs for working of Blowroom line machines)

UNIT–III CARDING ....12 PERIODS

3.1 Carding :Objects–carding and stripping actions – passage of material through High

4 Per

Production card –study of different parts of a carding machine and their functions

3.2 Card Settings :Different setting points in carding machine–frequency of setting–

gauges used–Card settings recommended for different grades of cotton and 3 Per

manmade fibres– types of waste collected from carding machine

3.3 Card clothing : Types of card clothing –brief study of metallic wire specifications of

licker – in , cylinder ,doffer and flats (PPSI, Angle of wire points, Height and width ) 3 Per

for cotton processing

3.4 Card wires Grinding:Objects – types of grinding – grinding schedule–Study of fibre

2 Per

arrangements in card sliver.

(Refer Web Link : https://www.youtube.com/watch?v=pYruLp-X2Jw for working of a Card)

UNIT –IV MODERN DEVELOPMENTS IN CARDING .....13 PERIODS

4.1 Modern Developments in Carding: Licker-in – Flats–Cylinder region.

Brief study on Integrated grinding system [IGS], automatic waste evacuation and 4 Per

automatic baling. Salient features of modern carding machine

4.2 Chute feed system : Construction and working of flock feeder – merits and

2 Per

demerits of chute feed system

4.3 Autoleveller:Objects –open loop and closed loop systems–brief study of working of

2 Per

autoleveller in modern cards.

Diploma in Textile Technology Page 21

4.4 Quality norms for Carding Sliver :Defects in card sliver – causes and remedies –

trash % in sliver – card waste % – neps – U% in card sliver –Maintenance 2 Per

schedule of carding machine – RH% in carding department

4.5 Carding calculations: Calculations pertaining to Mechanical draft, Actual draft,

3 Per

speed, Production, hank and efficiency.

(Refer Web Link : https://www.youtube.com/watch?v=xcJQWiynD-4 for working of a Modern Card)

UNIT–V DRAW FRAME ..... 13 PERIODS

5.1 Drawing : Objects – principles of doubling and drafting – passage of material

2 Per

through L.R. draw frame – functions of different parts of Draw frame.

5.2 Drafting arrangement:Bottom and top rollers – types of top roller weighting

systems – Study of Spring loading of top rollers –Top roller shore hardness.

3 Per

Construction and working of 3/3 Pressure bar drafting system – Study of fibre

arrangements in draw frame sliver.

5.3 Roller setting and Draft :Bottom roller settings and its importance –brief note on

2 Per

drafting waves–roller slip –roller eccentricity –draft and its distribution.

5.4 Auto leveller and Draw frame sliver Defects : Brief study of working of Autoleveller

in modern draw frame– sliver quality monitoring device– stop motions – salient

4 Per

features of modern draw frames – Defects in draw frame sliver – causes and

remedies –Maintenance schedule of draw frame–RH% in draw frame department.

5.5 Draw frame Calculations: Calculations pertaining to speed, draft, production and

2 Per

efficiency.

(Refer Web Link :https://www.youtube.com/watch?v=CMEUG7QKHLM for of Draw frame)

LIST OF PROPOSED STUDENT ACTIVITIES

I.INDUSTRIAL VISITS

Imparting industrial visits to any one of the following industries to understand

real time applications :

1. M/s.Sambandam Spinning Mills Unit-I, Salem

2. M/s. Kandagiri Spinning Mills Ltd., Unit-I, Salem

3. M/s. Dharanidhara Spinning Mills Ltd., Salem

Industrial visit report has to be submitted by the students as assignment through Black board and as

hard copy to the faculty concerned.

II.SEMINARS

Seminars to be organized on any one of the following topics in association with the IE(I)/ISTE and

the Students’ Technical Association of Textile Technology Programme.

1. Latest developments in Licker-in, cylinder, doffer and flat wires.

2. Rieter RSB Draw frame – Drafting system – Autoleveller – Salient features

Diploma in Textile Technology Page 22

III.OPEN SOURCE SOFTWARE/ LEARNING WEBSITES:

1. http..//www.textile manufacture process spinning

2. http..//www.rieter.com

3. http..//www.truetzschler.com

4. http..//www.lakshmimach.com

5. http..//geron.card.com

STANDARDS / NORMS / CODES

1. SITRA , BTRA, ATIRA and NITRA Norms

TEXT BOOKS

S.No Title Author Publisher Year of Publishing

The Textile Institute

1. Opening and cleaning W.A.Hunter 1992

Manchester, U.K.

A practical guide to The Textile Institute

2. W. Klein 1987

opening and carding Manchester, U.K.

A practical guide to The Textile Institute

3. W. Klein 1987

Combing and drawing Manchester, U.K.

REFERENCE BOOKS

S.No Title Author Publisher Year of Publishing

Universal Book

Cotton

1. William Scott Taggart Corporation, 1996

spinning – Vol 1

Bombay

Cotton opening and

2. G. R Merrill Gilbert R-Merrill 1996

picking

3. Cotton carding G. R Merrill 1996

Saravana

Spun yarn technology Venkatasubramani

4. publications, 1998

Volume I, II , III

Madurai

Diploma in Textile Technology Page 23

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM – 636 005

(Autonomous Institution)

DIPLOMA IN TEXTILE TECHNOLOGY

Yarn Manufacture – I

Model Question Paper – I

Year / Sem : II / III Max. Marks : 75

Code: 15O-5202 Time : 3 hr.

PART-A (5 x 2 = 10)

Note: (i) Answer any FIVE questions out of which question No. 8 is compulsory.

(ii) All questions carry equal marks.

1. State the objects of Ginning. Mention the names of ginning machines and their suitability.

2. Mention any two modern mixing machines.

3. What do you understand by AWES in Blow room?

4. Mention any two lap defects in Blow room.

5. State the objects of carding machine.

6. State the object of grinding in a carding machine. Also mention the frequency of grinding in a

carding machine.

7. Mention the objects of Draw frame.

8. If the weight per metre of lap is 400grams, find the hank of lap.

PART-B (5 x 3 = 15)

Note: (i) Answer any FIVE questions out of which question No. 16 is compulsory.

(ii) All questions carry equal marks.

9. State the principles of opening and cleaning in blow room machinery.

10. Mention the purpose of two way distributor in blow room.

11. Draw a simple sketch of Blow room machinery sequence employed for processing fine variety of

cotton.

12. Mention briefly about carding and stripping actions.

13. Mention briefly about chute feed system.

14. State the formula for hank of sliver, mechanical draft and actual draft in a carding machine.

15. Mention briefly about drafting waves in draw frame sliver.

16. State the importance of roller setting in a draw frame.

Diploma in Textile Technology Page 24

PART-C (5 x 10 = 50)

Note: (i) Answer all the questions choosing either sub-division (A) or sub-division (B) of each question.

(ii) All questions carry equal marks.

17. A. With a neat sketch explain the working of BLENDOMAT automatic bale opening 10

machine.

(OR)

B. With a neat sketch explain the working of Unimix. 10

18. A. With a neat sketch explain the passage of material through single process scutcher. 10

(OR)

B. Calculate the production of the scutcher in kg for a shift of 8 Periods from the 10

following data:

Calendar roller dia. - 7 inches

Calendar roller speed - 11rpm

Efficiency - 88%

Wt./metre of lap - 400 grams

19. A. With a neat line diagram explain the passage of material through high production 10

card.

(OR)

B. With a neat sketch write the important setting points in a high production carding 10

machine for processing medium variety of cotton.

20. A. With neat sketches briefly explain the developments in the Licker-in, flats and 10

cylinder regions in Latest Generation carding machines.

(OR)

B. Describe the working of autoleveller in modern card with a neat sketch. 10

21. A. Trace the passage of material through L.R. draw frame and explain its working. 10

(OR)

B. State any ten important salient features of modern draw frame. 10

Diploma in Textile Technology Page 25

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM – 636 005

(Autonomous Institution)

DIPLOMA IN TEXTILE TECHNOLOGY

Yarn Manufacture – I

Model Question Paper – II

Year / Sem : II / III Max. Marks : 75

Code: 15O-5202 Time : 3 hr.

PART-A (5 x 2 = 10)

Note: (i) Answer any FIVE questions out of which question No. 8 is compulsory.

(ii) All questions carry equal marks.

1. State the objects of Mixing.

2. Mention the purpose of vision shield.

3. What is the purpose of lap length measuring motion?

4. Calculate the hank of lap if wt./metre of lap is 425 grams.

5. State the speed of licker-in and cylinder in rpm.

6. What is the function of flats?

7. State any two defects in card sliver.

8. If hank of card sliver is 0.16Ne, hank of draw frame sliver is 0.165 Ne., No. of doublings is 8, find

the draft in draw frame.

PART-B (5 x 3 = 15)

Note: (i) Answer any FIVE questions out of which question No. 16 is compulsory.

(ii) All questions carry equal marks.

9. State the advantages of BLENDOMAT automatic bale opening machine.

10. What is the purpose of electronic metal extractor?

11. What are the functions of bye pass arrangement?

12. Mention the metallic wire specifications for cylinder, doffer, Licker-in for processing cotton.

13. Mention the setting between:-

(i)cylinder to flats (ii)cylinder to doffer (iii) cylinder to Licker-in

14. List the advantages and disadvantages of chute feed system.

15. What do you understand by open loop and closed loop Autoleveller?

16. What is roller eccentricity? Explain its effect on draw frame sliver quality.

Diploma in Textile Technology Page 26

PART-C (5 x 10 = 50)

Note: (i) Answer all the questions choosing either sub-division (A) or sub-division (B) of each question.

(ii) All questions carry equal marks.

17. A. With a neat sketch explain the working of Multi mixer. 10

(OR)

B. With a neat sketch explain the working of Hopper feeder. 10

18. A. With a neat sketch explain the working of ERM cleaner. 10

(OR)

B. Describe the working of single process scutcher with a neat sketch. 10

19. A. Draw the passage of material through High production card and explain. 10

(OR)

B. Mention the speeds and settings in a carding machine for 40s mix with a neat 10

sketch.

20. A. With a neat sketch explain the working of chute feed system. 10

(OR)

B. Calculate the production in kg of a card room per shift of 8 Periods. 10

Hank of lap fed - 0.0012 Ne

Mechanical draft - 98

Doffer speed - 32 rpm

Total waste extracted - 4.8%

No. of cards in the card room - 20

Card room efficiency - 84%

Doffer diameter - 27 inches

21. A. Trace the passage of material through Draw frame and explain. 10

(OR)

B. State and explain at least 5 defects, their causes and remedies in draw frame sliver. 10

Diploma in Textile Technology Page 27

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM

Programme : TEXTILE TECHNOLOGY

Semester : III

Course Code : 15O – 5203

Course Name : FABRIC MANUFACTURE–I

TEACHING AND SCHEME OF EXAMINATION

No. of weeks per Semester: 15 weeks

Examinations

Instructions

Max.Marks

Course

Semester– Duration

Periods / Periods / Continuous

End Total

Week Semester Assessment

Examination

Fabric

6 90 25 75 100 3 Hours

Manufacture – I

TOPICS AND ALLOCATION OF PERIODS

Unit No. Topic No. of

Periods

I WINDING 15

II WARPING 14

III SIZING 14

IV LOOM MECHANISM – PRIMARY MOTION 17

V SECONDARY AND AUXILARY MOTION 17

INDUSTRIAL VISITS 04

CONTINUOUS ASSESSMENT TEST AND MODEL EXAMS 09

TOTAL 90

RATIONALE

A basic knowledge about the different processes like cone winding, pirn winding, warping, sectional

warping, sizing, drawing-in and denting are essential for the students to understand the sequence of

operations in the weaving preparatory process. Hence they must be taught to the students to

enhance their knowledge and skill in the setting and operation of the preparatory machines and also

to perform necessary weaving preparatory calculations.

OBJECTIVES

At the end of the course, the students will be able to

Understand the terms related to winding, Principles of winding

Acquire knowledge on Yarn Clearers

Diploma in Textile Technology Page 28

Know about Autoconer Cone winding machine and Features.

Gain knowledge on Schweiter pirn winding machine and controls of weft winding.

Learn about warping machine and special feature of computerized sectional warping

machine.

Acquire knowledge on theobjects of sizing, types and function of sizing ingredients.

Understand the Passage of Multi cylinder sizing machine.

Acquire knowledge on Loom Mechanisms – Plain Power loom.

Learn about the object of Shedding, Picking and Beat-up Motion.

Understand the construction and working of shedding, picking and beat-up Motion.

Gain knowledge on the objects of Take-up, Let-off, weft stop motion, warp protector motion

and temples.

Learn about the Construction and working of Take-up, Let-off, weft stop motion, warp

protector motion and temples.

DETAILED SYLLABUS

UNIT – I WINDING .....15 PERIODS

1.1 Cone Winding: Brief study of Sequence of Process in weaving Preparatory –

Object of winding – terminology related to winding; angle of cone, angle of wind,

traverse, double traverse, number of winds and wind ratio – Passage of Drum 4 Per

winding machine – brief Introduction to Precision winding machine; passage of

yarn in Precision winding machine.

1.2 Auxiliary device: Object of Tensioner – Types of Tensioner ,Merits and Demerits

– Object of Slub Catchers or Yarn Clearers – Study of Electronic Yarn Clearer; 3 Per

Principles of Photo cell and Capacitance type; Merits and Demerits

1.3 Clearers: Definitions for Clearing efficiency and knot factor – Principles of ribbon

formation; Study of Autoconer; Special feature of Schlafhorst Autoconer –

4 Per

Object of Air and Wet Splicing – Advantages of Splicing – Defects in Cones;

Causes and Remedies

(Refer Web Link : https://www.youtube.com/watch?v=UlPckcu9R4E for working of High speed cone

winding machine)

1.4 Weft Winding : Object of Weft Winding and rewinding of Weft Yarn – Study of

Schweiter – Passage of Yarn and features – Study of Controls in Weft Winding;

4 Per

Pirn diameter, bunch, chase length, traverse – Defects in pirns; Causes and

Remedies

UNIT – II WARPING .....14 PERIODS

2.1 Warping: Objects – Study of high Speed of Warping machine; Passage of yarn;

Features – Study on the types of creels; ’V’creel, Rectangular creel, Magazine

4 Per

creel and ‘V’ type moveable creel –Brief study of Electrical warp stop motion,

Expanding comb.

(Refer Web Link : https://www.youtube.com/watch?v=98q09czOeQ8 for working of warping machine)

Diploma in Textile Technology Page 29

2.2 Sectional Warping: Study of Sectional Warping Machine, Passage of yarn – Brief

Study of salient feature of Computerized Sectional Warping Machine – Breaking

4 Per

norms for broken warping yarn.

(Refer Web Link : https://www.youtube.com/watch?v=7zf8XNYjV-w for working of sectional warping

machine)

2.3 Calculation: Calculations on Yarn Numbering –Ne,Tex &Denier

Calculations pertaining to Production of Cone Winding, Pirn Winding, Warping, 6 Per

Sizing and Plain Power loom

UNIT – III SIZING .....14 PERIODS

3.1 Sizing: Object of Sizing – terminology related to Sizing; Warp beam, Sized beam,

3 Per

Set, Size Pick Up, tape Length and cut length

3.2 Sizing Ingredients: Study of Size Ingredients, Type and Functions; Study of Size

4 Per

Mixing and cooking beck– Precautions to be taken during mixing and cooking

3.3 Sizing Machine:– Study of Multi Cylinder Sizing Machine: Passage of warp –

factors affecting size pick – up–object of Cut Marking motion – Measuring 4 Per

motion

3.4 Sizing machine Controls:Objects of Controls in Sizing machine –Brief study of

3Per

single end sizing; Advantages of single end sizing.

(Refer Web Link : https://www.youtube.com/watch?v=P-h94uAEy20 for working of multi cylinder sizing

machine)

UNIT – IV LOOM MECHANISMS – PRIMARY MOTION .....17 PERIODS

4.1 Introduction to Weaving: Passage of Warp through a Plain Power Loom – Right

2 Per

hand and Left hand Looms and Shuttles

4.2 Shedding: Object of Shedding – Types of sheds – Working of Negative tappet

shedding motion – advantages and disadvantages of Negative Shedding Motion –

Brief study of Positive tappet shedding – Object, Construction and working of 5 Per

Counter shaft arrangement

(Refer Web Link :https://www.youtube.com/watch?v=W5BRDDhR0dI for working of Negative tappet

shedding )

4.3 Picking: Object and types of Picking – Construction and Working of Cone over

pick and Side lever Under pick Motions– Methods of altering the picking force– 5 Per

Objective of Stearn’s parallel picking motion – Shuttle Checking devices

4.4 Beat Up: Object and construction and working of crank beat up motion – object

of reed – Eccentricity of Sley and its effect on various sizes of looms – Timing 5 Per

circle of Primary motions of a tappet Loom

(Refer Web Link : https://www.youtube.com/watch?v=g5_wRrBaGGY for working of Beat-up motion)

Diploma in Textile Technology Page 30

UNIT –V SECONDARY AND AUXILIARY MOTIONS .....17 PERIODS

5.1 Take –up Motion: Object and types of take- up motion – Construction and working

of 7 wheel take up motion – cloth wind up systems –Definition of Dividend 3 Per

(Refer Web Link : https://www.youtube.com/watch?v=9N17f4yxlSU for working of Take-up motion)

5.2 Let –off Motion: Object and types of let-off motion – Construction and working of

negative let-off motion – Study of Oscillating back rest 3 Per

(Refer Web Link : https://www.youtube.com/watch?v=kXZE8B-IiVc for working of let-off motion)

5.3 Weft Stop Motion: Object and types of weft fork motion – Construction and

Working of side weft fork and centre weft fork motions – Comparison between 3 Per

side and centre weft fork motions

(Refer Web Link : https://www.youtube.com/watch?v=cTnYIPwK7uo for working of warp stop motion)

5.4 Warp Protector Motion: Object and types of warp protector motion –

Construction and Working of Loose reed and fast reed motions – Comparison 6 Per

between Loose reed and fast reed motion

5.5 Temples: Object and types and construction of temples and their uses 2 Per

LIST OF PROPOSED STUDENT ACTIVITIES

I.INDUSTRIAL VISITS

Imparting industrial visit to any one of the following industries to understand real time

applications :

1. M/s. Anandhalakshmi Sizing Mills, Tiruchengode

2. M/s. The Lakshmi Mills Ltd., Palladam

3. M/s. Arthanari Loom Centre, Salem.

Industrial visit report has to be submitted by the students as assignment through Black board and

as hard copy to the faculty concerned.

II.SEMINARS

Seminars to be organized on any one of the following topics in association with the IE(I)/ISTE and

the Students’ Technical Association of Textile Technology Programme.

1. Latest developments in winding

2. Modern developments in Sizing

III.OPEN SOURCE SOFTWARE/ LEARNING WEBSITES:

1. http..//www.textilelearners.blog.spot.com

2. http..//www.textile manufacture process weaving

3. http..//www.textileslideshare.net

STANDARDS / NORMS / CODES

1. SITRA , BTRA, ATIRA and NITRA Norms

Diploma in Textile Technology Page 31

TEXT BOOKS

S.No Title Author Publisher Year of Publishing

1. Principles of weaving Marks &Robinson The Textile 1976

Institute,

Manchester

2. Woven Fabric NCUTE NCUTE, 2002

Production– I New Delhi

REFERENCE BOOKS

S.No Title Author Publisher Year of Publishing

1. Hand book of weaving Dr.Sabit Adhenur Technomic 2001

Publishing

Company Inc.

Lancester, Basel,UK

2. Sizing materials, Bhuvanesh C.Goswami Marshel Dekker 2004

Methods &Machines &Rajesh D Anand Inc., New York

Jiwala

3. Modern Preparation A.Ormerod Butterworths, 1983

and Weaving London

Machinery

4. Weaving Calculations R.Sengupta D.B.Taraporevala 1996

sons &co

Ltd.,Mumbai

5. The Mechanism of Talukdar, Sriramulu, Mahajan publishers 1988

Weaving Ajonkar (P) Ltd., Mumbai

Diploma in Textile Technology Page 32

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM – 636 005

(Autonomous Institution)

DIPLOMA IN TEXTILE TECHNOLOGY

Fabric Manufacture – I

Model Question Paper – I

Year / Sem : II / III Max. Marks : 75

Code: 15O-5203 Time : 3 hr.

PART-A (5 x 2 = 10)

Note: (i) Answer any FIVE questions out of which question No. 8 is compulsory.

(ii) All questions carry equal marks.

1. What are the advantages of rewinding?

2. State any two features of high speed warping machine.

3. List out any four size ingredients used in size mixing.

4. Define English count.

5. What are the functions of shuttle checking devices?

6 State the functions of Oscillating backrest.

7. What are the types of warp protecting mechanisms?

8. State the importance of temples used in plain power loom.

PART-B (5 x 3 = 15)

Note: (i) Answer any FIVE questions out of which question No. 16 is compulsory.

(ii) All questions carry equal marks.

9. What are the objects of tensioner?

10. What are the types of splicing?

11. Mention the types of creels used in warping machine.

12. What are the factors affect the size pick up?

13. What are the controls available in a sizing machine?

14. What are Shuttle checking devices? Explain.

15. What are the differences between loose reed and fast reed motions?

16. What is the necessity and object of auxiliary motions in a plain power loom?

Diploma in Textile Technology Page 33

PART-C (5 x 10 = 50)

Note: (i) Answer all the questions choosing either sub-division (A) or sub-division (B) of each question.

(ii) All questions carry equal marks.

17. A. Explain the different types of Tensioning devices and yarn clearers used in Cone 10

winding machine.

(OR)

B. Describe the salient features of Schlafhorst Autoconer. 10

18. A. Trace the passage of material through sectional warping machine and explain. 10

(OR)

B. Calculate the production in kg. of pirn winding machine with the following 10

particulars.

Speed of the pirn - 10000 rpm Time - 8 Per

Pirn diameter - 26mm Efficiency - 80 %

Count - 40s

No.of pirn winding units /machine - 60

19. A. What are the functions of size ingredients in size mixing? 10

(OR)

B. Explain the details of size mixing and cooking 10

20. A. With a neat sketch explain the passage of through a plain power loom. 10

(OR)

B. Explain the working of side lever under picking mechanism with a neat line 10

diagram.

21. A. What is the object of let-off? With a neat sketch explain the working of negative 10

let-off motion.

(OR)

B. With a neat sketch explain the working of side weft fork motion. 10

Diploma in Textile Technology Page 34

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM – 636 005

(Autonomous Institution)

DIPLOMA IN TEXTILE TECHNOLOGY

Fabric Manufacture – I

Model Question Paper – II

Year / Sem : II / III Max. Marks : 75

Code: 15O-5203 Time : 3 hr.

Note: (i) Answer any FIVE questions out of which question No. 8 is compulsory.

(ii) All questions carry equal marks.

1. What are the objects of cone winding ?

2. What is the object of tensioner and slub catcher?

3. State any two uses of computerized sectional warping machine.

4. What are the objects of sizing process?

5. Mention the primary motions in plain power loom.

6. What are the types of sheds?

7. What are the objects of reed ?

8. Why is centre weft fork mechanism recommended for weaving fine and delicate fabrics?

PART-B (5 x 3 = 15)

Note: (i) Answer any FIVE questions out of which question No. 16 is compulsory.

(ii) All questions carry equal marks.

9. Define angle of cone, angle of wind and traverse.

10. Mention any two defects in pirns and write their causes and remedies.

11. What are the types of warping machines?

12. Mention any three precautions taken during size mixing and cooking.

13. What are the objects of primary motions in plain power loom?

14. What are the defects found in negative let-off motion?

15. What are the uses of temples?

16. How can the picking force be altered in over pick looms?

Diploma in Textile Technology Page 35

PART-C (5 x 10 = 50)

Note: (i) Answer all the questions choosing either sub-division (A) or sub-division (B) of each

question.

(ii) All questions carry equal marks.

17. A. Draw the passage of material through Autoconer cone winding machine and 10

explain its working.

(OR)

B. Explain the working of Schweiter automatic pirn winding machine with a neat 10

line diagram.

18. A. Describe the passage of material through high speed beam warping machine 10

with a neat diagram.

(OR)

B. Calculate the production in kgs of cone winding department with the following 10

particulars.

No. of machine - 10 Time - 8 Per

No. of drums/Machine - 120 Efficiency - 85%

Drum speed - 1600rpm Count - 20s

Drum dia - 3 1/8 inch

19. A. Explain with a neat sketch, the passage of material through the multi cylinder 10

sizing machine.

(OR)

B. Explain in details various factors affecting the size pickup percentage 10

20. A. Explain in detail, the working of a negative tappet shedding mechanism with a 10

neat sketch.

(OR)

B. What is over pick? Describe the working of a cone over pick mechanism with a 10

neat sketch.

21. A. Explain the working of seven wheel take-up mechanism with neat sketch. 10

(OR)

B. What are warp protector mechanisms? Explain the working of fast reed 10

mechanism with a neat sketch.

Diploma in Textile Technology Page 36

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM

Programme : TEXTILE TECHNOLOGY

Semester : III

Course Code :15O-5206

Course Name : FIBRE IDENTIFICATION PRACTICAL

TEACHING AND SCHEME OF EXAMINATION

No. of weeks per Semester: 15 weeks

Examinations

Instructions

Max.Marks

Course

Semester– Duration

Periods / Periods / Continuous

End Total

Week Semester Assessment

Examination

Fibre Identification

4 60 25 75 100 3 Hours

Practical

RATIONALE

To enhance the practical knowledge of students and to make them capable of identifying the natural

and man made fibres by microscopic appearance, solubility and burning tests. Also to acquire

practical skill to identify the blend proportion of different fibres in the yarn and fabric.

OBJECTIVES

At the end of the Course, the students will be able to

Identify the natural and man made fibres by microscopic appearance.

Classify the natural and man made fibres by burning tests.

Identify the natural and man made fibres by solubility tests.

Analyse the blend proportions in Polyester viscose blended yarn and fabrics.

Learn the blend proportions in polyester cotton blended yarn and fabrics.

Acquire knowledge on linear density of monofilament, multifilament and textured yarns.

Diploma in Textile Technology Page 37

DETAILED SYLLABUS

LIST OF EXPERIMENTS

1. Identification of the natural fibres with their Microscopical views for cotton, Jute, silk, and

wool.

2. Identification of the Man made fibres by examining the Microscopical views for Viscose

rayon, Polyester, nylon and acrylic fibres.

3. Identification of the natural fibres by burning test

4. Identification of the man made fibres by burning test.

5. Identification of the natural fibres using solvent for cotton, jute. Silk and wool

6. Identification of the man made fibres using solvents for viscose rayon and polyester.

7. Identification of the man made fibres using solvents for nylon and acrylic.

8. Determination of the blend proportions in a polyester /viscose spun yarns using solvents.

9. Determination of the blend proportions in a polyester/ cotton spun yarns using solvents.

10. Determination of the blend proportions of the given polyester/ viscose fabric.

11. Determination of the blend proportions of the given polyester/ cotton fabric.

12. Determination of the mean linear density of monofilament yarns.

13. Determination of the mean linear density of multifilament yarns.

14. Determination of the mean linear density of texturised yarns.

15. Determination of the mean twist of continuous multifilament yarn.

LIST OF EQUIPMENT REQUIRED

Sl.No. Name of the Equipment Quantity

1. Dye bath 2 Nos.

2. Glass plate 4 Nos.

3. Microscope 1 No.

4. Single yarn twist tester 1 No.

5. Bunsen burner 2 Nos.

6. Wrap reel 1 No.

7. Single Yarn tensile strength tester 1 No.

8. Conical flask 10 Nos.

9. Test tube 10 Nos.

10. Different types of fibres and blended fabrics. 10 Nos.

Diploma in Textile Technology Page 38

THIAGARAJAR POLYTECHNIC COLLEGE, SALEM

15O – SCHEME

Programme : TEXTILE TECHNOLOGY

Semester : III

Course Code : 15O – 5207

Course Name : YARN MANUFACTURE – I PRACTICAL

TEACHING AND SCHEME OF EXAMINATION

No. of weeks per Semester: 15 weeks

Examinations

Instructions

Max. Marks

Course

Semester– Duration

Periods / Periods / Continuous

End Total

Week Semester Assessment

Examination

Yarn Manufacture – I

6 90 25 75 100 3 Hours

Practical

RATIONALE

In Diploma level engineering education, skill development plays a vital role. The skill development

can be achieved by hands on experience in various instruments, apparatus and equipment. This is

accomplished by doing engineering related experiments in practical classes in various laboratories.

OBJECTIVES

At the end of the course, the students will be able to

Acquire knowledge on the gearing diagram and calculate the speeds of various parts of the

blow room machinery such as Hopper bale breaker, Step cleaner, Condenser, Hopper

feeder, Kirschner Beater and Scutcher.

Gain knowledge on the settings of the blow room machinery such as, Hopper bale breaker,

Step cleaner, Hopper feeder, Kirschner Beater and Scutcher.

Calculate the production and efficiency of the blow room line.

Acquire knowledge on the gearing diagram and calculate the speeds of various parts of the

carding machine.

Calculate the drafts between the various carding elements of the carding machine and to

calculate the draft constant of the carding machine.

Understand the settings of carding machine for processing and short, medium and long

staple cottons.

Calculate the production and efficiency of the carding machine.

Gain knowledge on the gearing diagram and calculate the speeds of various parts of the

Draw frame.

Calculate the drafts between the various drafting rollers of the Draw frame and to calculate

the draft constant of the Draw frame.