Professional Documents

Culture Documents

PZLN56DG01-10000 - Boiler Ga

PZLN56DG01-10000 - Boiler Ga

Uploaded by

V U P RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PZLN56DG01-10000 - Boiler Ga

PZLN56DG01-10000 - Boiler Ga

Uploaded by

V U P RaoCopyright:

Available Formats

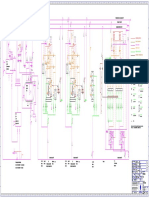

12 11 10 9 8 7 6 5 4 3 2 1

NOZZLE SCHEDULE

NOZZLE SIZE FL RATING DESCRIPTION

N1 40 NB DIN PN 25 FEED WATER INLET PUMP

N2 80 NB ANSI CL.300 STEAM OUTLET

H N3 80 NB ANSI CL.150 SAFETY VALVE OUTLET H

N4 25 NB ANSI CL.300 AIR VENT O

N5 40 NB ANSI CL.300 SHELL BLOWDOWN

N6 1/2" - LEVEL TRANSMITTER DRAIN CONN.

N7 50 NB DIN PN 16 INLET - NATURAL GAS

N9,N10 1/2" GAUGE GLASS DRAIN CONN. FLUE GAS OUTLET FLANGE DETAIL

-

N11 15 NB EXPANSION VESSAL DRAIN CONN.

N12 25 NB ANSI CL.300 SPILL BACK CONN.

N14 3/4'' EXPANSION TANK SAFTY VALVE EXAUST

N15 R1" - OIL INLET ( BURNER )

N16 R1/2" OIL OUTLET ( BURNER )

G G

N19 50 NB IBR TABLE `H' CONTINUOUS BLOWDOWN CONN.

F1 - SEE DETAIL FLUE GAS OUTLET

SMOKE

CHAMBER

CIRCULATION

PIPING

F F

BURNER

FEED

PIPE

ACCESS

VIEW B DOOR

E E

PLAN VIEW.

EXPANSION VESSAL

D D

HRU

LADDER & CATWALK

C C

B A

REVERSAL

CHAMBER

REVERSAL

CHAMBER

BURNER

BURNER

FEED SMOKE

WATER PUMP CHAMBER

B B

CONTROL

PANEL

ELEVATION

VIEW A

LH SIDE VIEW.

FOR ALTERATION DETAILS, REFER FIRST SHEET OF THE DRAWING PRODUCT Wt.IN kg.= -

SAFETY VALVE ESCAPE PIPEWORK :- BOILER SPECIFICATIONS :- SM GLOBAL 50 E/17.5 /HSD/NG/OILON

NOTES ALT. ALTERATION MADE CHKD (APPROX)

OUT OUR WRITTEN CONSENT THEY SHOULD

THE RECIPIENT PERSONALLY REMAINS THE

IVERED OR MADE KNOWN TO THIRD PARTY.

EXCLUSIVE PROPERTY OF THE FIRM. WITH-

1) BOILER EVAPORATION CAPACITY ..........5000 kg/hr.

NOT BE COPIED OR REPRODUCED OR DEL-

No. BY BY

AND OF ALL ENCLOSURES ENTRUSTED TO

1) THE DISCHARGE PIPE WORK MUST NOT BE SMALLER IN DIAMETER THAN THE VALVE OUTLET.

* FOR MACHINING MARKS, GENERAL TOL-

ERANCES, WELDING DETAILS & SURFACE

* THE COPYRIGHT OF THESE DRAWINGS

A 1) ALL DIMENSION ARE IN MM. TITLE SCALE DESIGNED SWP 20.01.22

TREATMENT REFER DRG. WS-03-40016

2) DISCHARGE PIPE SHOULD BE EQUAL OR LARGER IN DIAMETER TO KEEP THE BACK PRESSURE LESS THAN 10% OF 2) WORKING PRESSURE............................... 17.5 kgf/sq.cm.g

2) SUFFICINENT OPERATING SPACE SHOULD BE PROVIDED AROUND THE BOILER.

THE SET PRESSURE 3)HYDRAULIC TEST PRESSURE............................... 26.2 kgf/sq.cm.g.

GENERAL ARRANGEMENT DRAWN YTS 20.01.22

3) ALL FLANGE HOLES ARE OFF CENTRED.

AND TERMINAL POINTS 1:25 CHECKED AKJ 20.01.22

* IF IN DOUBT PLEASE ASK.

3) INSTALLATION & MAINTENANCE INSTRUCTIONS SHOULD BE CONSULTED PRIOR TO INSTALLATION .

4) REMOVE ALL BURS AND SHARP EDGES. APPROVED PMS 20.01.22

4) IF A RISE IN DISCHARGE PIPEWORK CANNOT BE AVOIED THEN A SMALL BORE DRAIN SHOULD BE PROVIDED AT THE

5) LAGGING TO BE DONE AFTER HYDROSTATIC TESTING & INSPECTION

POINT WHERE WATER COULD COLLECT.

THERMAX LIMITED DRG. No. ALT. No.

CHINCHWAD PUNE 411019

COMPUTER FILE NAME:- PZLN56DG01-10000 PLOTTING SCALE:- 1:25 DRG.FILE LOCATION:-

(C & H HEATING-ENGINEERING) PZ LN56 DG01 - 1 0

THERMAX

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Open Well StaircaseDocument3 pagesOpen Well Staircaseबिजेन्द्र प्रधान100% (2)

- TS Curve RPHDocument2 pagesTS Curve RPHV U P RaoNo ratings yet

- Screenshot 2023-10-08 at 9.41.21 AMDocument8 pagesScreenshot 2023-10-08 at 9.41.21 AMV U P RaoNo ratings yet

- QUOTESDocument11 pagesQUOTESV U P RaoNo ratings yet

- Draft Award Letter - GlobalDocument2 pagesDraft Award Letter - GlobalV U P RaoNo ratings yet

- Steam Scheme 851140169-0-00Document1 pageSteam Scheme 851140169-0-00V U P RaoNo ratings yet

- Scaph SpecnDocument3 pagesScaph SpecnV U P RaoNo ratings yet

- Data Sheet For L.P Dosing SystemDocument2 pagesData Sheet For L.P Dosing SystemV U P RaoNo ratings yet

- 13.specification Steam and Condensate SystemDocument2 pages13.specification Steam and Condensate SystemV U P RaoNo ratings yet

- Pzi148df01-30000 - Foundation Load DataDocument1 pagePzi148df01-30000 - Foundation Load DataV U P RaoNo ratings yet

- Steam Consumption: Example For A Single-Corrugator Work Width 2200mmDocument2 pagesSteam Consumption: Example For A Single-Corrugator Work Width 2200mmV U P RaoNo ratings yet

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocument1 pageMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNo ratings yet

- Project: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedDocument2 pagesProject: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedV U P RaoNo ratings yet

- Stuffing Box: SR No DescriptionDocument2 pagesStuffing Box: SR No DescriptionV U P RaoNo ratings yet

- Safety Data Sheet TGX-2209: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument16 pagesSafety Data Sheet TGX-2209: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingV U P RaoNo ratings yet

- TG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationDocument1 pageTG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationV U P RaoNo ratings yet

- Power Plant and Calculations - Safety Valves and Its Basic ConceptsDocument4 pagesPower Plant and Calculations - Safety Valves and Its Basic ConceptsV U P RaoNo ratings yet

- BHG Actvie CahtDocument6 pagesBHG Actvie CahtV U P RaoNo ratings yet

- Diagrid - The Language of Modern Day BuilderDocument16 pagesDiagrid - The Language of Modern Day BuildervijeshrajNo ratings yet

- APT10 and APT14: For Effective Condensate Drainage and RemovalDocument12 pagesAPT10 and APT14: For Effective Condensate Drainage and RemovalwimpievdsNo ratings yet

- Pump E Series Manual - v2Document36 pagesPump E Series Manual - v2Morteza ShakerienNo ratings yet

- ADM APN050 en - 0314Document8 pagesADM APN050 en - 0314Aadarsh SubramaniamNo ratings yet

- Tech CR Next Gen Novolac Epoxy VEDocument8 pagesTech CR Next Gen Novolac Epoxy VEanggiNo ratings yet

- Catalogue-KCC Epoxy PDFDocument49 pagesCatalogue-KCC Epoxy PDFTàiChínhDoanhNghiệpNo ratings yet

- Design of Pressure VesselDocument19 pagesDesign of Pressure VesselSazzad hussain ProttoyNo ratings yet

- CIMA TechnicalBulletin01Document4 pagesCIMA TechnicalBulletin01Ammar AzharNo ratings yet

- Full Description of Civil Engineering BranchesDocument7 pagesFull Description of Civil Engineering BranchesAmeer HamzaNo ratings yet

- Genesis Vertical Lift Planning GuideDocument36 pagesGenesis Vertical Lift Planning Guideivanpabon217No ratings yet

- B31.3 Process Piping Course - 13 Inspection, Examination and TestingDocument19 pagesB31.3 Process Piping Course - 13 Inspection, Examination and TestingferooxidanNo ratings yet

- VOLVO EW160B-6 SteeringDocument21 pagesVOLVO EW160B-6 SteeringPIKO MOBNo ratings yet

- About Rotational MoldingDocument7 pagesAbout Rotational MoldingPatel DarshanNo ratings yet

- Blanco Silgranit Puradur Ii: The Precious Stone in The KitchenDocument20 pagesBlanco Silgranit Puradur Ii: The Precious Stone in The KitchenvjvarNo ratings yet

- Construction and Building Materials: Tianyu Xie, M.S. Mohamad Ali, Mohamed Elchalakani, Phillip VisintinDocument15 pagesConstruction and Building Materials: Tianyu Xie, M.S. Mohamad Ali, Mohamed Elchalakani, Phillip VisintinFernando TomeoNo ratings yet

- POM Delrin 100Document5 pagesPOM Delrin 100countzeroaslNo ratings yet

- Exercise 5Document10 pagesExercise 5DivyeshNo ratings yet

- What Is Column End Conditions What Are Effective Lengths of Columns EquivalenDocument15 pagesWhat Is Column End Conditions What Are Effective Lengths of Columns EquivalenMd. Mizanur RahamanNo ratings yet

- A301 Section Aa and BBDocument1 pageA301 Section Aa and BBDavidson DavidNo ratings yet

- Catalogue Uk PDFDocument2 pagesCatalogue Uk PDFramjee prasad jaiswalNo ratings yet

- HAZOPDocument18 pagesHAZOPMark GuevarraNo ratings yet

- Driil StringDocument38 pagesDriil Stringsuresh_501No ratings yet

- Nec B310-5Document5 pagesNec B310-5Yudy StNo ratings yet

- Department of Civil Engineering: Permanent Way of RailwayDocument40 pagesDepartment of Civil Engineering: Permanent Way of RailwayFarooq AhmedNo ratings yet

- Iwp Hydrotesting Checklist: Appendix - 14Document4 pagesIwp Hydrotesting Checklist: Appendix - 14Soumitra GuptaNo ratings yet

- At Product Sheet MK 90dDocument2 pagesAt Product Sheet MK 90dmetalurg87No ratings yet

- Case Study Arch BridgeDocument4 pagesCase Study Arch Bridgekunal humaneNo ratings yet

- ME351 BucklingDocument14 pagesME351 BucklingRyan ArcherNo ratings yet

- Is - 14687-1999 Falsework For Concrete StructuresDocument27 pagesIs - 14687-1999 Falsework For Concrete StructuresJarrod HarrellNo ratings yet