Professional Documents

Culture Documents

ICS SMNCI RA 004 Cable Tray Installation

ICS SMNCI RA 004 Cable Tray Installation

Uploaded by

Jayson EscamillanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICS SMNCI RA 004 Cable Tray Installation

ICS SMNCI RA 004 Cable Tray Installation

Uploaded by

Jayson EscamillanCopyright:

Available Formats

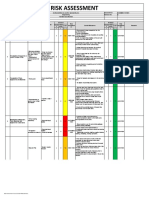

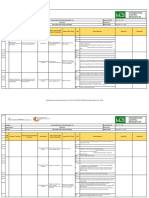

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• All personnel to have completed the site

specific induction.

• Precise coordination.

Site Survey of area for the • Ensure that workers are educating on spotting

• Site Hazards and • Bodily Injury,

1 Cable Tray installation 4 3 12 HIGH RISK potential hazards. 2 1 2 LOW RISK

Lay out Fracture

• Refer to engineering drawing or the as- built

documents of the work area.

• Coordinate the activity to the Project End-user

and Project Owner before commencing.

• Follow Schedule and arrange the required

document to avoid any cause of delay.

• Miscommunication

• Delay to schedule

with the Project End- • Refer to gant chart as the reference for

and work activity.

user and Project preparing PTW.

• May result in

Preparation of documents or Owner MEDIUM

2 exposing workers and 3 2 6 • Supervisor and Safety Officer shall ensure 2 1 2 LOW RISK

Permit To Work (PTW) • Unauthorized RISK obtaining and maintaining valid work permit and

or potential to harm

commencement of

and danger. all mandatory associated permits.

works

• Inform all workers regarding permit condition

before work starts.

• Supervisor shall conduct toolbox talks about

nature of works

• Provide and associated

an awareness training potential

regarding line of

hazards

fire and their

and hand essential

finger safety. precautionary

measure.

Preparation of Tools, • Cuts, wound/hand • Know the hazards and dangers in the job to be

3 • Pinch point 4 3 12 HIGH RISK 2 2 4 LOW RISK

Equipments and Materials injury done.

• Be aware of potential pinch points

• Check

Remove andany

inspect

itemsthethattools

maythat they are

obstruct the in

work

good condition

activity. Keep theand safe toarea,

working use. platform clear of

• Wearor

debris safety

liquidgloves

spills.

• Cordon the area and keep sign to warn others

of the potential hazard.

• Ensure close monitoring and supervision.

• Materials to be stored in a safe and secure

manner.

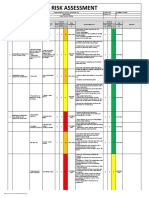

• Sprain / strain /

• Physical injury to • Wear suitable Safety Shoes.

fracture MEDIUM

workers due to Slip / 3 2 6 • (Practice Good Housekeeping) Remove 3 1 3 LOW RISK

RISK

trip hazard unnecessary materials that may cause trip, slip.

• Make sure the work area is left clean and tidy.

• Check all the potential cause of trip and slip

and remove it in the work area.

• Provision of Safe pedestrian access.

• Ensure all workers abide to the traffic rules

• Hit by moving and regulations in the plant.

Mobilization of Manpower,

machinery • Physical injury/ EXTREME

4 Tools, Materials and 5 3 15 2 2 4 LOW RISK

fatality RISK

Equipments to work area

• Ensure workers use the pedestrian walkway

provided during travelling.

• Check Vehicle of its road worthiness.

• Physical injury/ • Comply with plant road speed limits and driving

• Be extra careful when crossing the road

• Hit against Fatality EXTREME regulations.

5 3 15 • Banksman or spotter shall be provided during 2 2 4 LOW RISK

personnel or property • Property damage RISK

loading, unloading, moving operation.

• Keep access and egress routes clear and

segregate the work area from others and

vehicles in access areas.

• Remove any items that may obstruct the work

activity; and

• Check for any items that may cause slips, trips

• Sprain / strain /

• Slip and Trip 4 3 12 HIGH RISK and falls and remove or secure them as 2 1 2 LOW RISK

Fracture required.

• Review prospective route of access prior to

carrying materials to work area with

consideration given to any obstacles / trip or slip

hazards

• Prior to the commencing of activities all

personnel

• Involved has attended the safety induction re

covid-19.

• Compliance to 100% PPE. Including face mask

and hand gloves medical and cotton.

• Social distancing of 1 meter is mandatory

instructed.

• Proper hygiene by means of washing the hand

by soap and alcohol.

• Continue monitoring of Body temperature will

• Transmission of EXTREME be conducted by our First Aider using therma MEDIUM

• Spreading of virus 5 3 15 gun scanner. 3 2 6

Covid-19 disease RISK RISK

• In case if there will be a suspected infected

worker he will be removed from the site and

proper medical administration will apply.

• A quarantine area will be provided to the

affected Worker

• Proper tracing will be conducted by our

management

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

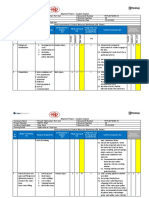

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Assess lift, lift within capabilities, use correct

lifting procedure,

• Ensure correct manual handling techniques,

warm up & stretch to avoid strains / sprains.

• Do not carry long or awkward materials on your

own.

• Designing and organizing tasks to avoid

manual handling completely or at least restrict it.

• Neck and Back • Organizing manual/lifting task in a safe way,

injuries with loads split into smaller ones, and proper

• Strains and Sprains rest period provided.

• Slip and fall crush • Providing information and training to workers

incidents on tasks, and the use of equipment and correct

• Crush, bruises and handling/lifting technique.

Loading and unloading of • Manual Lifting / broken bones • Using automation and lifting equipment.

5 4 3 12 HIGH RISK • Move your feet rather than twist your back. 4 1 4 LOW RISK

materials to work area manual handling • Hand and foot

injuries • Keep the load in front and close to your body

• Hernias and straighten your legs to lift.

• Occupational • Never lift a heavy object above shoulder level.

Overuse Syndrome • During long shifts, change tasks around to give

(OOS) muscle a break.

• Wear appropriate PPE’s for the tasks

• Never walk away from a machine that is turn

on or coasting.

• Discuss and point out pinch point hazards as

part of your risk assessment and toolbox

meeting.

• Pay attention to where your hands are around

any moving parts that have the potential to

move.

• Bruising • Do not place your hands where you cannot see

• Cuts and Laceration them.

• Pinch point (Hand • Sprains

4 3 12 HIGH RISK • Wear the proper gloves and PPE for the jobs 4 1 4 LOW RISK

hazards) • Fractures where you can get injured.

• Crushing • Communicate with your co-workers when

• Punctures working with materials that could cause a

hazard.

• Provide an awareness training regarding line of

fire and hand finger safety.

• Ensure workers use all necessary PPE.

• Strive to maintain a safe distance outside of

the swing radius of lifting materials.

• Proper communication and coordination before

lifting tubular and long objects.

• Struck by/against • Workers should always wear proper PPE such

• Physical injury 4 3 12 HIGH RISK as hard hats, safety glasses, goggles and safety 4 1 4 LOW RISK

lifting materials

shoes to help protect workers from flying, falling,

hitting, swinging, and rolling objects.

• Ensure equipment is placed firmly on floorings,

and load is evenly distributed.

• Loads projecting beyond vehicle must be

flagged

• Damage / injury due • Park vehicle in a stable position, in gear with

• Serious injury

to crane or boom

• Property damage EXTREME handbrake on MEDIUM

truck / forklift failure 5 3 15 • Operators / helpers must be competent and 3 2 6

• Fatality RISK RISK

or incompetent qualified.

operator • Plant and lifting equipment must be in

serviceable condition and have documented

maintenance records

• Access/egress points are checked regularly

including condition of tiles, steps, handrails,

doors and handles.

• Actions are in place to deal with hazardous

weather conditions which could affect

access/egress.

• Adequate lighting at entrance /exit (inside and

outside).

• Fire exit are clearly marked.

• Door regularly checked and kept clear from

• Poor access and obstruction.

egress (Poor lighting, • No trip hazards on entrance/exit routes and

obstructed door) • Delayed escape in walkways.

• Slip, trip and fall the event of fire or • Stair and steps identified and particular

hazards including other emergency precautions in place to prevent slips, trips and

6 Preparation of work area mats, broken tiles, • Sprain / strain / 4 3 12 HIGH RISK falls including operational controls, 4 1 4 LOW RISK

holes in floor, trailing Fracture environmental controls, hazardous steps and

cables • Physical injury handrails.

• Poor or bad weather • Make sure all access and egress, access

condition ladders, steps and ramps are safe and secure.

• Immediately cease work in hazardous weather

condition such as:

Strong winds that may cause loss of balance.

Rain is causing a slippery work surface.

Thunder storm and lightning.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

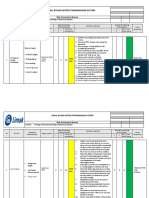

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• The maximum open circuit voltage for welder is

80 volts.

• Wear dry gloves in good condition for welding.

• Do not touch the electrode or metal parts with

skin or wet clothing while the machine is turn on.

• Keep dry insulation between the body and any

grounded metal.

• Do not stand in water while welding.

• Do not place liquids on or above

welders/electrical equipment.

• Keep welding cables and electrode holders in

good condition.

• Earthing installation on welding equipment

should always be checked.

• Be sure the welder is properly installed and

Fabricate cable tray support • Serious Injuries

EXTREME grounded. MEDIUM

7 and bracket(welding, cutting, • Electrical shock • Fatalities 5 3 15 • Welding equipment and grounding circuits are 3 2 6

RISK RISK

grinding and drilling works) checked and tested regularly.

• Welding operators also should inspect the

electrode holder for damage before beginning to

weld and keep the welding cable and electrode

holder insulation in good condition.

• All electrical cord shall be inspected and in

good working condition prior to use.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• All combustible materials should be removed or

adequately protected or covering with fire

resistant materials. (Good housekeeping in the

workplace is very important in preventing fire).

• Provide suitable fire extinguisher and fire

blanket.

• Provide appropriate ventilation.

• Property damage • Assign competent fire watcher.

• Serious injury EXTREME • Only competent personnel with NCII certified MEDIUM

• Fire hazard 5 3 15 can perform the welding works. 3 2 6

• Fatality RISK RISK

• A responsible person should keep the welding

site under observation for at least an hour after

the completion of work.

• Continues gas monitoring at work area.

• Fabricate cable tray support at workshop to

prevent and eliminate fire hazard in the work

area.

• Take proper precautions to prevent fire

• Always wear suitable PPE's for welding works

(Welding mask (hardhat mounted), welding

gloves, respiratory protection, ear plug, welding

• Contact with hot

• Skin burn 4 3 12 HIGH RISK apron). 2 2 4 LOW RISK

surface • Treat all material to be welded as potentially

hot.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Wear a suitable mask (minimum P2 grade

mask) when welding galvanized steel to avoid

• Pneumonia inhaling fumes.

• Occupational • Only competent personnel with NCII certified

Asthma can perform the welding works.

• Health hazard due • Ensure workplace is well ventilated.

• Cancer

to welding fumes 4 3 12 HIGH RISK • Always wear suitable PPE's for welding works 2 2 4 LOW RISK

• Metal fume fever

inhalation (Welding mask (hardhat mounted), welding

• Throat and lung

irritation gloves, respiratory protection, ear plug, welding

apron).

• Wear eye protection at all times.

• Welding helmet with side shield.

• Allocate eye wash station near the work area.

• Foreign bodies • Always wear suitable PPE's for welding works

• Particulate fumes

• Eye injury 4 3 12 HIGH RISK (Welding mask (hardhat mounted), welding 2 2 4 LOW RISK

and gases gloves, respiratory protection, ear plug, welding

apron).

• Wear hearing protection at all times when you

are in or nearby fabrication area.

MEDIUM • Work rotation to minimize noise exposure.

• Noise hazard • Hearing impairment 3 3 9 • Limiting access by keeping people out of noisy 2 1 2 LOW RISK

RISK

areas (85db high).

• All power tools are to have a current test tag

attached.

• Ensure pre checks are carried out on all

equipment prior to use.

• Only use equipment with guards and auxiliary

handles in place.

• Ensure that when changing drill bits, grinding /

cutting discs or adjusting the grinder guard that

the power is disconnected (i.e. plug is

disconnected from the power source). If a

portable grinder is being used engage the

‘switch lock’.

• When carrying the portable grinder engage the

‘switch lock’ to prevent the unit from being

accidentally switched on.

• Prior to grinding or drilling work ensure that

the piece to be worked is secured and the off-cut

• Injury due to unsafe • Hand injury supported using clamps or having another

or incorrectly used • Disability 4 3 12 HIGH RISK person assist by holding the piece being worked 2 2 4 LOW RISK

hand/power tools so that the grinder drill can be operated using

both hands.

• Do not use damaged or defective equipment.

• Place an Out of Service Tag on any damaged

or defective equipment and advise your

supervisor.

• All extension leads are to be raised at least 2

meters off the ground by insulated hooks.

• Check that power tools are dry and safe to use

after wet weather.

• Use Ground fault circuit interrupter (GFCI)

extension.

• Always use the right tools for the job.

• Prevent unintentional starting of drill

• Keep hands away from drill spinning chuck

• Hands or cloth when turning on the drill.

getting caught on • Hand injury 4 3 12 HIGH RISK • Don’t wear loose clothing 2 2 4 LOW RISK

spinning drill chuck • Wearing of gloves

• Inspect tools/extension cords prior to use.

• Use only double- insulated or 3-wire grounded

power tools.

• Utilize extension cords that are double-

insulated and rated for the work environment.

• Extension cords shall not be located in

standing water, placed so that they create a trip

hazard, ran over by vehicles or equipment, or

otherwise damage.

• GFCI protection is mandatory for construction

and outdoor areas.

• GFCIs shall be tested daily before use.

• Unplug power tools before servicing.

• Electrical repairs shall be made only by

qualified personnel.

• Removed any damaged cords or defective

Cut cable trays to fit using • Electrical shock tools from service and tag them “Out of Service”.

• Hand/Power tool

8 hack saw, drop saw or angle /Electrocution 4 3 12 HIGH RISK • Always followed the equipment manufacturing 2 2 4 LOW RISK

use operational safety procedure.

grinder

• Keep tools and equipment in good condition.

• Inspect tools/ equipment for assessment

before use and report defects immediately to the

site engineer/supervisor.

• Prepare the GFCI and test before using it to

the power tool.

• Right tools for the right job.

• Wear suitable PPE at all times.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Wear gloves during all manual handling tasks.

• Only competent personnel to perform the

tasks.

• Only competent personnel to use grinders and

drop saws.

• Ensure that when changing grinding / cutting

discs or adjusting the grinder guard that the

power is disconnected (i.e. plug is disconnected

from the power source). If a portable grinder is

being used engage the ‘switch lock’.

• When carrying the portable grinder engage the

‘switch lock’ to prevent the unit from being

accidentally switched on.

MEDIUM • Prior to grinding work ensure that the piece to

• Cuts and abrasions • Hand injury 3 3 9 be worked is secured and the off-cut supported 2 1 2 LOW RISK

RISK

using clamps or having another person assist by

holding the piece being worked so that the

grinder can be operated using both hands.

• Never remove the burs from cut metal on the

side of a drop saw or cutting disc. Only use a

grinding disc or a hand file.

• Use tools/equipment for their intended purpose

only.

• Observe suitable awareness.

• Wear suitable safety gloves.

MEDIUM

• Sharp blade/Edge • Cuts and laceration 3 3 9 • Only competent personnel to perform the 2 1 2 LOW RISK

RISK

tasks.

• Avoid using dull blade.

• Proposed wall / floor / ceiling to be penetrated,

may need to be scanned or available drawings

reviewed to identify any potential concealed

services

• When drilling in slabs a depth gauge of no

more than 50mm must be used to limit the

penetration depth. If it is likely that a concealed

service may be affected by the desired

penetration the relevant circuits must be

isolated.

• Employees must confirm relevant area isolation

procedure with their supervisor before

• Property damage

Floor and wall penetration • Striking buried commencing work task.

9 • Serious injury 4 3 12 HIGH RISK 2 2 4 LOW RISK

(Drilling, Chipping and Coring) electrical circuits • Prior to grinding or drilling work ensure that the

piece to be worked is secured and the off-cut

supported using clamps or having another

person assist by holding the piece being worked

so that the grinder drill can be operated using

both hands

• Only competent personnel to perform the

tasks.

• Ensure close supervision.

• Wear safety glass/goggles or face shield while

• Foreign objects drilling and coring.

• Excessive noise • Eye injury • Wear hearing protection such as earmuff or ear

from drilling, coring • Hearing impairment 4 3 12 HIGH RISK plug. 4 1 4 LOW RISK

and chipping works • Work rotation of personnel to minimize noise

exposure.

• Complete edge protection to working flat form

• Safe access and egress from the scaffold must

be provided.

• Install independent lifeline

• Ensure close supervision

• Ensure 100% tie-off of full body harness

• Serious injury lanyard

Installation of Cable Tray EXTREME MEDIUM

10 • Fall from heights • Fatality 5 3 15 3 2 6

supports and hanger RISK RISK

• Ensure 3 point of contact while descending and

ascending on scaffold ladder and working flat

form.

• Make sure all workers stay fully within the

scaffold at all times.

• Personnel to wear suitable full body harness

with double lanyards and shock absorber.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Install Safety Nets to prevent materials from

falling directly on the ground. (if necessary)

• Provide tool holster for workers working at

height.

• Provision of Toe boards

• Attach small rope to the tools to prevent it from

falling

• Bring only what you need and don’t bring

unnecessary tools.

• Use suitable PPE: Hard Hat, Safety Glass,

Gloves, Safety Shoes

• Barricade or cordon the area to prevent an

entry of unauthorized personnel.

• Provide signage’s to warn other “Working @

Height” and “Falling Debris”

• All raising and lowering of materials to be

carried out in controlled manner (i.e. hand to

• Serious injury

• Falling of tools and EXTREME hand, by light-line, nylon rope and fitting bags.) MEDIUM

• Property damage 5 3 15 • Workers at height shall ensure tools and 3 2 6

materials RISK RISK

materials are secured from falling.

• Only the materials being used to be out on the

scaffold until boarded areas are erected to store.

• Materials to be stored in a safe and secure

manner, to prevent them accidentally falling or

being knocked off the working platform when at

height.

• 2 persons used to pass materials to higher lifts.

• Provide and install fall arrester.

• Provide independent lifeline.

• Provide training/orientation on working at

heights and ladder safety.

• Conduct and discuss Method Statement & Risk

Assessment to all working personnel.

• Practice 100% tied-off

• Provide adequate railings to prevent personnel

from falling.

• Falling of Personnel • Serious injury • Railings shall be free from defects.

EXTREME MEDIUM

due to unsuitable • Fatality 5 3 15 • Provide suitable access and egress complete 3 2 6

RISK RISK

access and egress. with railings

• Provision of suitable signage’s to remind

workers in the hazards of falling.

• Adequate Information & Instruction to all

working personnel

• Ensure scaffolding are in good condition with

“GREEN TAG” prior to use

• All combustible materials should be removed or

adequately protected or covering with fire

resistant materials. (Good housekeeping in the

workplace is very important in preventing fire).

• Provide suitable fire extinguisher and fire

blanket.

• Provide appropriate ventilation.

• Property damage • Assign competent fire watcher.

• Serious injury EXTREME • Only competent personnel with NCII certified MEDIUM

• Fire hazard 5 3 15 can perform the welding works. 3 2 6

• Fatality RISK RISK

• A responsible person should keep the welding

site under observation for at least an hour after

the completion of work.

• Continues gas monitoring at work area.

• Fabricate cable tray support at workshop to

prevent and eliminate fire hazard in the work

area.

• Take proper precautions to prevent fire.

• Complete edge protection to working flat form

• Safe access and egress from the scaffold must

be provided.

• Install independent lifeline

• Ensure close supervision

• Ensure 100% tie-off of full body harness

• Serious injury

Secure and Install Cable trays EXTREME lanyard MEDIUM

11 • Fall from heights • Fatality 5 3 15 3 2 6

to support RISK RISK

• Ensure 3 point of contact while descending and

ascending on scaffold ladder and working flat

form.

• Make sure all workers stay fully within the

scaffold at all times.

• Personnel to wear suitable full body harness

with double lanyards and shock absorber.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-004

Department/s Engineering Revision No 0

Job Description Cable Tray Installation

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Install Safety Nets to prevent materials from

falling directly on the ground. (if necessary)

• Provide tool holster for workers working at

height.

• Provision of Toe boards

• Attach small rope to the tools to prevent it from

falling

• Bring only what you need and don’t bring

unnecessary tools.

• Use suitable PPE: Hard Hat, Safety Glass,

Gloves, Safety Shoes

• Barricade or cordon the area to prevent an

entry of unauthorized personnel.

• Provide signage’s to warn other “Working @

Height” and “Falling Debris”

• All raising and lowering of materials to be

carried out in controlled manner (i.e. hand to

• Serious injury

• Falling of tools and EXTREME hand, by light-line, nylon rope and fitting bags.) MEDIUM

• Property damage 5 3 15 • Workers at height shall ensure tools and 3 2 6

materials RISK RISK

materials are secured from falling.

• Only the materials being used to be out on the

scaffold until boarded areas are erected to store.

• Materials to be stored in a safe and secure

manner, to prevent them accidentally falling or

being knocked off the working platform when at

height.

• 2 persons used to pass materials to higher lifts.

• Provide and install fall arrester.

• Provide independent lifeline.

• Provide training/orientation on working at

heights and ladder safety.

• Conduct and discuss Method Statement & Risk

Assessment to all working personnel.

• Practice 100% tied-off

• Provide adequate railings to prevent personnel

from falling.

• Falling of Personnel • Serious injury • Railings shall be free from defects.

EXTREME MEDIUM

due to unsuitable • Fatality 5 3 15 • Provide suitable access and egress complete 3 2 6

RISK RISK

access and egress with railings

• Provision of suitable signage’s to remind

workers in the hazards of falling.

• Adequate Information & Instruction to all

working personnel

• Ensure scaffolding are in good condition with

“GREEN TAG” prior to use

• Conduct regular exercise and stretching before

the activity.

• Maintain neutral posture whenever possible.

• Ergonomics

hazards: repeated MEDIUM • Change positions often, take stretch breaks.

• Body pain 3 3 9 2 1 2 LOW RISK

motions in awkward RISK

position

• Workers should be trained on proper work

technique.

• Avoid awkward position to prevent body

pain/back pain.

• Working area should be clear of unnecessary

material and waste

• Walkway should be maintained without tripping

caused material

• When work finishes, housekeeping shall be

implemented

• Supervisors need to inspect the area before

dismissal of work

• Isolate or remove all tripping hazards in the

workplace and passage area.

• Remove any items that may obstruct the work

activity; and

material • Check for any items that may cause slip, trip

• Slip and trip • Physical Injury and falls and remove or secured them as

MEDIUM

12 House keeping • Obstruction to other • Fracture 3 3 9 required. 2 1 2 LOW RISK

RISK

trade contractor • Ensure all material off cuts and rubbish are

removed as they are generated and disposed of

in appropriate receptacles.

• Ensure all materials/tools and equipment is

removed from the work area when departing.

• Cleanup work area and dispose of all rubbish

in bins.

• Maintain good housekeeping practices before,

during and after the activity.

Prepared by / Date: Checked by / Date: Approved by / Date:

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

You might also like

- Roadmap B2+ SB - AnswersDocument56 pagesRoadmap B2+ SB - AnswersshadowM84% (32)

- Risk Assessment For Concrete Coring, Chipping and DrillingDocument17 pagesRisk Assessment For Concrete Coring, Chipping and DrillingJayson Escamillan80% (5)

- JOB HAZARD ANALYSIS - Cable PullingDocument7 pagesJOB HAZARD ANALYSIS - Cable PullingJayson Escamillan100% (2)

- SNB QuestionsDocument53 pagesSNB QuestionsMaribel Pagsinuhin100% (4)

- Risk Assessment For BorescopeDocument14 pagesRisk Assessment For BorescopeJayson Escamillan100% (1)

- Omni Aviation SMS Emergency Response PlanDocument70 pagesOmni Aviation SMS Emergency Response PlanAvtech100% (1)

- GMB Flexibility Resource Guide PDFDocument41 pagesGMB Flexibility Resource Guide PDFdundovicdavor9No ratings yet

- ICS SMNCI RA 001 Temfacil ConstructionDocument7 pagesICS SMNCI RA 001 Temfacil ConstructionJayson Escamillan100% (1)

- ICS SMNCI RA 001 Temfacil ConstructionDocument7 pagesICS SMNCI RA 001 Temfacil ConstructionJayson Escamillan100% (1)

- Risk Assessment of Scaffolding Works - Rev. 1Document20 pagesRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (2)

- JSEA-ICS-004 Cable Laying and PullingDocument16 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- ICS SMNCI RA 007 Cable Wire TerminationDocument7 pagesICS SMNCI RA 007 Cable Wire TerminationJayson EscamillanNo ratings yet

- ICS SMNCI RA 006 Cable Laying PullingDocument6 pagesICS SMNCI RA 006 Cable Laying PullingJayson EscamillanNo ratings yet

- ICS SMNCI RA 005 Electrical Conduit InstallationDocument8 pagesICS SMNCI RA 005 Electrical Conduit InstallationJayson EscamillanNo ratings yet

- Risk Assessment For FlushingDocument9 pagesRisk Assessment For FlushingABDUL BASITHNo ratings yet

- Risk AssessmentDocument20 pagesRisk AssessmentAbuAbdullaMohsenNo ratings yet

- TRA 003-010 (1) - RemovedDocument7 pagesTRA 003-010 (1) - RemovedrashidNo ratings yet

- E&i JsaDocument7 pagesE&i JsaMohammad Irfan Kiki IsmailNo ratings yet

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- Electrical, Rev 01Document235 pagesElectrical, Rev 01Samy KsNo ratings yet

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDocument16 pagesRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanNo ratings yet

- 0000000working in Live AreasDocument1 page0000000working in Live Areasgueettaf faresNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- Date Jsa Team (Name List) Name Position & SignatureDocument8 pagesDate Jsa Team (Name List) Name Position & SignatureMuralimohan PandianNo ratings yet

- Iaslc Ms 004 Tower Crane ErectionDocument12 pagesIaslc Ms 004 Tower Crane ErectionJoe PsNo ratings yet

- HIRA Temporary Electrical SuppliesDocument3 pagesHIRA Temporary Electrical SuppliesChandresh SinghNo ratings yet

- #Hiradec - DeaeratorDocument6 pages#Hiradec - DeaeratorPankaj PandeyNo ratings yet

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- Prequalification Checklist - (Coastline Geophysical Saudi Arabia) 2nd ReviewDocument9 pagesPrequalification Checklist - (Coastline Geophysical Saudi Arabia) 2nd ReviewShafie ZubierNo ratings yet

- Safety Alert: Amine Leakage CaseDocument2 pagesSafety Alert: Amine Leakage CaseAadil HaroonNo ratings yet

- Job Safety Analysis Sheet: Manual ExcavationDocument1 pageJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalNo ratings yet

- HIPhazard Id PlanDocument27 pagesHIPhazard Id PlanAhmed Raza KhanNo ratings yet

- Form Pengeluaran Apd (Ppe Issued Form) : Pt. Hana Nuansa PratamaDocument1 pageForm Pengeluaran Apd (Ppe Issued Form) : Pt. Hana Nuansa PratamaAndi Rogers Sitepu100% (1)

- Hazard Identification, Risk Assessment and Risk Control (Hirarc)Document2 pagesHazard Identification, Risk Assessment and Risk Control (Hirarc)Khaty JahNo ratings yet

- VSAP Safety Induction Audit ChecklistDocument110 pagesVSAP Safety Induction Audit ChecklistNabi AkramNo ratings yet

- Vacuum Truck Plant Pre-Acceptance ChecklistDocument3 pagesVacuum Truck Plant Pre-Acceptance Checklistحماية منتجNo ratings yet

- JSA E&I 3..electrical Equipment Installation (Lighting)Document6 pagesJSA E&I 3..electrical Equipment Installation (Lighting)AmyNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- Plant Safety Instructions PDFDocument16 pagesPlant Safety Instructions PDFapsNo ratings yet

- HSE Inspection Report 148 AttendDocument11 pagesHSE Inspection Report 148 Attendtuan mai vanNo ratings yet

- Core Cutting JHA For Cooling Tower.Document11 pagesCore Cutting JHA For Cooling Tower.Omkar Mishra100% (1)

- HEMP/JHA/RA/HITRA - Pneumatic TestingDocument7 pagesHEMP/JHA/RA/HITRA - Pneumatic TestingSidhanath SinghNo ratings yet

- Safety Program Audit 1684314377Document24 pagesSafety Program Audit 1684314377Annisa AgustinaNo ratings yet

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- JSA Excavation For Lighting Pole FoundationDocument18 pagesJSA Excavation For Lighting Pole FoundationMohammad Al Masa'deh100% (1)

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Static Spark From Explosive Vapours Ignites Road Tanker: Case StudyDocument7 pagesStatic Spark From Explosive Vapours Ignites Road Tanker: Case Studyعمر هشام100% (1)

- Installation Testing Commisiioning of LPG SYSTEMDocument12 pagesInstallation Testing Commisiioning of LPG SYSTEMYounis KhanNo ratings yet

- DAIS I1912 HSE CRA AIPL 08 (Installation of Pelmet)Document2 pagesDAIS I1912 HSE CRA AIPL 08 (Installation of Pelmet)Aiplshubh ChavanNo ratings yet

- J S A Extract Fan InstallationDocument3 pagesJ S A Extract Fan InstallationASLAM MULANINo ratings yet

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 pagesPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanNo ratings yet

- Risk Assesment LT & EI JobsDocument2 pagesRisk Assesment LT & EI JobsMudassar MustafaNo ratings yet

- Safety Campaign-Energy Isolation-April 2022Document7 pagesSafety Campaign-Energy Isolation-April 2022HSE99 BHDCNo ratings yet

- 022 - Bored Cast in Place Concrete Piles - Night WorksDocument15 pages022 - Bored Cast in Place Concrete Piles - Night WorksMohammed Adnan100% (1)

- Risk Assessment - Working in or Near WaterDocument5 pagesRisk Assessment - Working in or Near WaterabogadieNo ratings yet

- Incident Report, Underground PipeDocument1 pageIncident Report, Underground PipeSalim MuftahNo ratings yet

- AE-SWM - 12B-LG-Marine-Rev-02Document61 pagesAE-SWM - 12B-LG-Marine-Rev-02Planning C7100% (1)

- TRA Cable Laying & Allied WorkDocument3 pagesTRA Cable Laying & Allied WorkswathishNo ratings yet

- 07-0.042023. Planning Cycle 2023-Machining Div-Rev5Document2 pages07-0.042023. Planning Cycle 2023-Machining Div-Rev5Cemuk MuawanahNo ratings yet

- Capa Register: Doc No: D0022401-V-CE-00-000-HS-FOR-038Document5 pagesCapa Register: Doc No: D0022401-V-CE-00-000-HS-FOR-038hsesterling ikeaNo ratings yet

- Testing Comissioning of Electrical SystemDocument8 pagesTesting Comissioning of Electrical Systemmo7d aliNo ratings yet

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- JHA-scaffolding & Hot Work For TrizacDocument12 pagesJHA-scaffolding & Hot Work For Trizacsaud salemNo ratings yet

- 47 Cable Glanding and TerminationDocument3 pages47 Cable Glanding and TerminationvasudevanmNo ratings yet

- CRA All PDFDocument42 pagesCRA All PDFRohan PanditNo ratings yet

- Risk Assessment - ExcavationDocument6 pagesRisk Assessment - Excavationganesh gbNo ratings yet

- 1 - Emergency Respond ProcedureDocument18 pages1 - Emergency Respond ProcedureNur NurNo ratings yet

- Audit ReportDocument6 pagesAudit ReportkumarNo ratings yet

- Assess The Initial RiskDocument12 pagesAssess The Initial RiskZubair KhanNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- JOB HAZARD ANALYSIS - Cable TrayDocument10 pagesJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- ICS SMNCI RA 007 Cable Wire TerminationDocument7 pagesICS SMNCI RA 007 Cable Wire TerminationJayson EscamillanNo ratings yet

- ICS SMNCI RA 006 Cable Laying PullingDocument6 pagesICS SMNCI RA 006 Cable Laying PullingJayson EscamillanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- ICS SMNCI RA 005 Electrical Conduit InstallationDocument8 pagesICS SMNCI RA 005 Electrical Conduit InstallationJayson EscamillanNo ratings yet

- JOB HAZARD ANALYSIS - Electrical WorksDocument9 pagesJOB HAZARD ANALYSIS - Electrical WorksJayson Escamillan100% (1)

- JOB HAZARD ANALYSIS - ConduitDocument9 pagesJOB HAZARD ANALYSIS - ConduitJayson Escamillan100% (2)

- Job Hazard Analysis - TubingsDocument9 pagesJob Hazard Analysis - TubingsJayson Escamillan100% (1)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document3 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document8 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Risk Assessment of Conduit Pipe InstallationDocument17 pagesRisk Assessment of Conduit Pipe InstallationJayson Escamillan75% (4)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document4 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- EL S EC: Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Document8 pagesEL S EC: Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Jayson EscamillanNo ratings yet

- Risk Assessment of Manual Excavation and TrenchingDocument14 pagesRisk Assessment of Manual Excavation and TrenchingJayson Escamillan100% (1)

- Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Document7 pagesJob Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Jayson EscamillanNo ratings yet

- Company Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateDocument11 pagesCompany Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateJayson EscamillanNo ratings yet

- JSEA-ICS-005-Erection Modification and Dismantling of ScaffoldingDocument17 pagesJSEA-ICS-005-Erection Modification and Dismantling of ScaffoldingJayson EscamillanNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument13 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- Jsea - Ics - 008: Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Document14 pagesJsea - Ics - 008: Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Jayson EscamillanNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument17 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- Old Cables, Conduits and Cable Trays Dismantling - JSEA FormDocument40 pagesOld Cables, Conduits and Cable Trays Dismantling - JSEA FormJayson Escamillan100% (2)

- Syllabus - 300620200523101219 (3) - 221109 - 215139Document62 pagesSyllabus - 300620200523101219 (3) - 221109 - 215139Anurag DixitNo ratings yet

- J Forsciint 2018 05 043Document37 pagesJ Forsciint 2018 05 043oxa aqilla putriNo ratings yet

- BandagingDocument94 pagesBandagingDexter LicongNo ratings yet

- Spectra and Spectra II Series™ Plug-In and Feeder Busway: Installation and Maintenance InstructionsDocument34 pagesSpectra and Spectra II Series™ Plug-In and Feeder Busway: Installation and Maintenance InstructionsmahmoudNo ratings yet

- Injured Jasprit Bumrah in Doubt For The T20 World CupDocument2 pagesInjured Jasprit Bumrah in Doubt For The T20 World CupRashid anwerNo ratings yet

- Waiver of LiabilityDocument1 pageWaiver of Liabilitybusn201No ratings yet

- American Surgeon Future Healers ManuscriptDocument9 pagesAmerican Surgeon Future Healers ManuscriptJulia HuffmanNo ratings yet

- Vocal Cord ParalysisDocument26 pagesVocal Cord ParalysisELIA RICHARDNo ratings yet

- LAW OF TORTS - Module 2Document63 pagesLAW OF TORTS - Module 2chanakya8999No ratings yet

- Pit-Os National High School Semi-Final Test in Mapeh: GRADE-9 S. Y. 2019-2020Document3 pagesPit-Os National High School Semi-Final Test in Mapeh: GRADE-9 S. Y. 2019-2020Rommel P. MesiasNo ratings yet

- Swms NPG Rev2 Smeg WarehouseDocument9 pagesSwms NPG Rev2 Smeg WarehousemhwjgcnsnzNo ratings yet

- Instruments and EquipmentDocument1 pageInstruments and EquipmentSandra GarciaNo ratings yet

- 판독 양식 (사랑 병원에서 쓰던거)Document24 pages판독 양식 (사랑 병원에서 쓰던거)eosfieldNo ratings yet

- Anterior Triangle of Neck Practice QuizDocument6 pagesAnterior Triangle of Neck Practice QuizMr .Hacker xDNo ratings yet

- Alistair IEB (2021) - A Comparison of Fibula Pro-Tibia Fixation VersusDocument10 pagesAlistair IEB (2021) - A Comparison of Fibula Pro-Tibia Fixation VersusHariom ShuklaNo ratings yet

- Materi Pembelajaran Praktikum Online Myologi SuperiorDocument65 pagesMateri Pembelajaran Praktikum Online Myologi Superiorerikson leeNo ratings yet

- Mechanisms of Penetrating Trauma To The Neck: Ranjan Gupta, MD, Sushruta Nagarkatti, MDDocument8 pagesMechanisms of Penetrating Trauma To The Neck: Ranjan Gupta, MD, Sushruta Nagarkatti, MDRanjan GuptaNo ratings yet

- NCM 104 Rle 3f PGDocument7 pagesNCM 104 Rle 3f PGKianna Eunice CasioNo ratings yet

- اسئله جراحه مدققهDocument59 pagesاسئله جراحه مدققهNour AhmededNo ratings yet

- Accidents RiddorDocument8 pagesAccidents RiddorSafrina RamadhaniNo ratings yet

- Wound Healing: Biology Presentation by AbbyDocument8 pagesWound Healing: Biology Presentation by AbbyRaymundus Deaven GoanaNo ratings yet

- Use This Thermometer and Take His Fever/heat/temperatureDocument6 pagesUse This Thermometer and Take His Fever/heat/temperatureRobbyAlivianNo ratings yet

- Ergonomics and Facilities Planning For The Hospitality Industry Prelims HandoutDocument24 pagesErgonomics and Facilities Planning For The Hospitality Industry Prelims Handoutmarygracebarobaro04No ratings yet

- Introduction and Organization of Nervous System: Presented by Dr. Amen FatimaDocument37 pagesIntroduction and Organization of Nervous System: Presented by Dr. Amen FatimaShanailNo ratings yet

- MCQS Snell Anatomy 9th EditionDocument65 pagesMCQS Snell Anatomy 9th EditionUsama198750% (2)

- Risk Assessment - Site Establishment - 2021Document6 pagesRisk Assessment - Site Establishment - 2021Asakundwi Mukhwa100% (3)