Professional Documents

Culture Documents

3.1.2.2 Equipment Examble: Ideal Planning / Dimensioning

3.1.2.2 Equipment Examble: Ideal Planning / Dimensioning

Uploaded by

rahul4u180 ratings0% found this document useful (0 votes)

29 views3 pages1. Production and set-up costs were calculated for a worm gear housing and housing cover being produced at 95,000 units per year. The worm gear housing had production costs of €27.41/unit and set-up costs of €35.41/lot. The housing cover had production costs of €2.87/unit and set-up costs of €34.41/lot.

2. Manufacturing costs were €38.36/unit for the worm gear housing and €6.38/unit for the housing cover.

3. Optimal lot sizes were calculated to be 1480 units/lot for the worm gear housing and 3584 units/lot for the housing cover based on

Original Description:

Original Title

2022_FactoryPlanning_Mueller_E1_Results

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Production and set-up costs were calculated for a worm gear housing and housing cover being produced at 95,000 units per year. The worm gear housing had production costs of €27.41/unit and set-up costs of €35.41/lot. The housing cover had production costs of €2.87/unit and set-up costs of €34.41/lot.

2. Manufacturing costs were €38.36/unit for the worm gear housing and €6.38/unit for the housing cover.

3. Optimal lot sizes were calculated to be 1480 units/lot for the worm gear housing and 3584 units/lot for the housing cover based on

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

29 views3 pages3.1.2.2 Equipment Examble: Ideal Planning / Dimensioning

3.1.2.2 Equipment Examble: Ideal Planning / Dimensioning

Uploaded by

rahul4u181. Production and set-up costs were calculated for a worm gear housing and housing cover being produced at 95,000 units per year. The worm gear housing had production costs of €27.41/unit and set-up costs of €35.41/lot. The housing cover had production costs of €2.87/unit and set-up costs of €34.41/lot.

2. Manufacturing costs were €38.36/unit for the worm gear housing and €6.38/unit for the housing cover.

3. Optimal lot sizes were calculated to be 1480 units/lot for the worm gear housing and 3584 units/lot for the housing cover based on

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

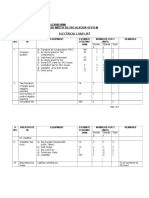

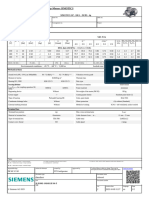

Equipment

Ideal planning / Dimensioning

3.1.2.2 Equipment examble

kg/unit €/kg

Part 1 - Worm gear housing M 001 7,5 1,4600

Part 2 - Housing cover M 002 1,8 1,9500

Part 1 - Worm gear housing M 001

Name of operating procedure

Equipment Set-up time ts [min/lot] Production time per unit tu [min/ unit]

1-10 auto. abrasive blasting inside & out 1225 external - -

1-20 temp. corrosion protection 1225 external - - external - -

1-30 milling of reference areas in jig (3 side processing), SPC DMU 35 16 6

1-40 finish milling (5 side processing) CWK 500 28 32

1-50 deburring Deburring area 8 2

1-60 testing acc. to testing schedule - - -

Part 2 - Housing cover M 002

Name of operating procedure

Equipment Set-up time ts [min/lot] Production time per unit tu [min/ unit]

2-10 auto. abrasive blasting external - -

2-20 temp. corrosion protection external - -

2-30 face milling of face being built up to final machining allowance DMU 35 12 2

2-40 drilling, facing and tapping of all drill holes, complete CWK 500 30 2

2-50 deburring Deburring area 8 1

2-60 testing acc. to testing schedule - - -

Equipment fCS-Set-up [€/h] fCm-production [€/h]

ABS 265 18,9 15,9 You want to produce 95.000 units of each part per year.

RAYO 54,2 50 1. Please calculate production costs and set-up costs

H 100 29,7 26,6

for worm gear housing and housing cover!

PE 150 C 57,3 52,1

DMU 35 38,3 34,3 2. Please calculate manufacturing costs for worm gear

CWK 500 48,6 44 housing and housing cover!

Deburring area 18,4 15,3

Quelle: Grundig

ZX 1 35,3 31,2 3. Please calculate lotsize Xopt for worm gear housing

PF 150 78,2 70,6 and housing cover (Interest rate

Multiple for storage

Machine OperationIs=8% )

Slide 0

Dipl.-Ing. Robert Müller // Factory planning and engineering // Email: robert.mueller2@hof-university.de

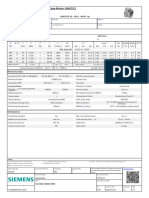

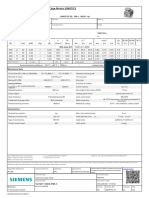

Equipment

Ideal planning / Dimensioning

3.1.2.2 Equipment examble II

Part 1 - Worm gear housing M 001

Name of operating procedure Lot size

Equipment Set-up time ts [min/lot] Production time per unit tu [min/ unit] Part 1 450

1-10 auto. abrasive blasting inside & out 1225 external - - Part 2 1200

1-20 temp. corrosion protection 1225 external - - external - - Part 3 750

1-30 milling of reference areas in jig (3 side processing), SPC DMU 35 16 6

1-40 finish milling (5 side processing) CWK 500 28 32

1-50 deburring Deburring area 8 2

1-60 testing acc. to testing schedule - - -

Part 2 - Housing cover M 002

Name of operating procedure

Equipment Set-up time ts [min/lot] Production time per unit tu [min/ unit]

2-10 auto. abrasive blasting external - -

2-20 temp. corrosion protection external - -

2-30 face milling of face being built up to final machining allowance DMU 35 12 2

2-40 drilling, facing and tapping of all drill holes, complete CWK 500 30 2

2-50 deburring Deburring area 8 1

2-60 testing acc. to testing schedule - - -

Part 3 – Transmission housing M 011

Name of operating procedure

Equipment Set-up time ts [min/lot] Production time per unit tu [min/ unit]

3-10 auto. abrasive blasting external - -

2-20 temp. corrosion protection external - -

3-30 turning complete Rayo 165 22 10

3-40 drilling, facing and tapping of all drill holes, complete DMU 35 20 4

3-50 testing acc. to testing schedule - - -

Quelle: Grundig Dw [d/a] Tev [min/S] n max

4. Please calculate number of DMU 35 needed for 1 and 2 shifts! 248 480 0.9

Multiple Machine Operation

Slide 1

Dipl.-Ing. Robert Müller // Factory planning and engineering Dw

// [d/a] Tev [min/S] n max

Email: robert.mueller2@hof-university.de

5. Please calculate number of CWK 500 needed for 1 and 2 shifts! 248 480 0.75

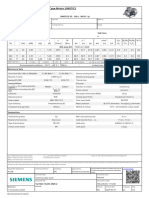

Equipment

Ideal planning / Dimensioning

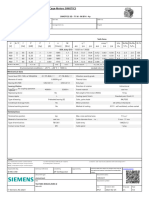

3.1.2.2 Equipment examble - results

You want to produce 95.000 units of each part per year.

1. Please calculate production costs and set-up costs for worm gear housing and housing cover!

worm gear housing: production costs = 27.41 €/unit and set-up costs = 35.41 €/lot

housing cover: production costs = 2.87 €/unit and set-up costs = 34.41 €/lot

2. Please calculate manufacturing costs for worm gear housing and housing cover!

worm gear housing: manufacturing costs = 38.36 €/unit

housing cover: manufacturing costs = 6.38 €/unit

3. Please calculate lotsize Xopt for worm gear housing and housing cover (Interest rate for storage Is=8%)

worm gear housing: lotsize = 1479.2 units/lot → 1480 units/lot

housing cover: lotsize = 3583.41 units/lot → 3584 units/lot

4. Please calculate number of DMU 35 needed for 1 and 2 shifts!

1 shift: 10.7 DMU → 10 DMU

2 shifts: 5.35 DMU → 5 DMU

5. Please calculate number of CWK 500 needed for 1 and 2 shifts!

1 shift: 36.27 CWK → 36 CWK (or 33 CWK)

2 shifts:

Quelle: Grundig 18.14 CWK → 18 CWK (or 17 CWK)

Multiple Machine Operation

Slide 2

Dipl.-Ing. Robert Müller // Factory planning and engineering // Email: robert.mueller2@hof-university.de

You might also like

- Installation Instruction V8 and V12 PDFDocument228 pagesInstallation Instruction V8 and V12 PDFBayanaka Tehnik75% (4)

- Bearing Capacity Excel SheetDocument2 pagesBearing Capacity Excel SheetHanafiahHamzahNo ratings yet

- JUPITER2200-01 1233-SA EngDocument189 pagesJUPITER2200-01 1233-SA EngZdenko Nagy100% (2)

- PRP A-01 PDFDocument47 pagesPRP A-01 PDFPablo di Pasquo100% (1)

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Vibration Analysis Handbook - James TaylorDocument345 pagesVibration Analysis Handbook - James Taylormmbataineh91% (33)

- 3 Cylinders Engines For Skoda Cars (Engine Code AWY & AZQ)Document26 pages3 Cylinders Engines For Skoda Cars (Engine Code AWY & AZQ)kikouchaa100% (7)

- BOP Test Procedure - Drilling - Mud Docs & JobsDocument7 pagesBOP Test Procedure - Drilling - Mud Docs & Jobskrishnsgk100% (2)

- Scuderia Topolino - Technical AdviceDocument130 pagesScuderia Topolino - Technical AdviceNikNo ratings yet

- Siemens MotorDocument1 pageSiemens MotorFarshad MahmoudiNo ratings yet

- Anonymous@2024 05 30 12 34 43 - Ml-C-550-Anonymous@2024 05 30 12 34 43-20240530143346293Document5 pagesAnonymous@2024 05 30 12 34 43 - Ml-C-550-Anonymous@2024 05 30 12 34 43-20240530143346293jesus francoNo ratings yet

- Epc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListDocument2 pagesEpc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListvenkateshbitraNo ratings yet

- Annex 6Document2 pagesAnnex 6venkateshbitraNo ratings yet

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNo ratings yet

- 1LE1503-2AA43-4AA4 Datasheet enDocument1 page1LE1503-2AA43-4AA4 Datasheet enAndrei LupuNo ratings yet

- LPT Shaft InspectionDocument6 pagesLPT Shaft InspectionSonny RaymundoNo ratings yet

- Oil FilterDocument4 pagesOil FilterRameswar PradhanNo ratings yet

- Specific Requirements & Scope of Work For RCC PilingDocument38 pagesSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadNo ratings yet

- Working GeometryDocument1 pageWorking Geometrydidi setiawanNo ratings yet

- Cleaning of Contact Points and Wiring HarnessesDocument3 pagesCleaning of Contact Points and Wiring HarnessesRafa Montes MOralesNo ratings yet

- 1LE1503-1DB43-4FK4 Datasheet enDocument1 page1LE1503-1DB43-4FK4 Datasheet enNicolas RossettoNo ratings yet

- SP350VS非液压软管总成扣压机 sp350Document14 pagesSP350VS非液压软管总成扣压机 sp350walk666No ratings yet

- Bhel Haridwar Training Report 800-MW Bar CIM-block-4 EEEDocument26 pagesBhel Haridwar Training Report 800-MW Bar CIM-block-4 EEEShubham GoelNo ratings yet

- Annex 1 CCM ProcessDocument16 pagesAnnex 1 CCM ProcessehsanNo ratings yet

- AMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitDocument10 pagesAMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitIrfan05100% (1)

- Silnik - Karta Katalogowa 1LE1002 0EB02 2JA4Document2 pagesSilnik - Karta Katalogowa 1LE1002 0EB02 2JA4artur.sowaNo ratings yet

- TAP - A330 Removal of The Exhaust Nozzle AssemblyDocument7 pagesTAP - A330 Removal of The Exhaust Nozzle AssemblyEdson CarvalhoNo ratings yet

- MPT - GR 11Document4 pagesMPT - GR 11Prathiksha TNo ratings yet

- Am528jxvafh2aa Submittal 230V+HP 03122019Document3 pagesAm528jxvafh2aa Submittal 230V+HP 03122019Luis PaizNo ratings yet

- G43 UfDocument44 pagesG43 UfdwilhNo ratings yet

- TR deDocument9 pagesTR deRameswar PradhanNo ratings yet

- 1le1503 0CB22 2ka4 Z - H22+L25Document3 pages1le1503 0CB22 2ka4 Z - H22+L2501666754614No ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- WMS-002 Pile Driving by Pile-Driving Barge REV.ADocument136 pagesWMS-002 Pile Driving by Pile-Driving Barge REV.AVan Cuong PhamNo ratings yet

- PTJ - Lasagne - Structural Steel Installation - Impact Claim Rev1Document4 pagesPTJ - Lasagne - Structural Steel Installation - Impact Claim Rev1Ahmed al-sheaikhNo ratings yet

- Machining Costs in Grinding: 11 International Scientific Conference On Production Engineering - Cim2007Document5 pagesMachining Costs in Grinding: 11 International Scientific Conference On Production Engineering - Cim2007vaibhavgitevaibhav_9No ratings yet

- Silnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99Document2 pagesSilnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99artur.sowaNo ratings yet

- Ot2168-110-Me-Lt-0001 - D - Mechanical Equip Load ListDocument2 pagesOt2168-110-Me-Lt-0001 - D - Mechanical Equip Load ListGaurav WaliaNo ratings yet

- TAP - A330 Removal of The Forward (FWD) Plug AssemblyDocument5 pagesTAP - A330 Removal of The Forward (FWD) Plug AssemblyEdson CarvalhoNo ratings yet

- Etp Ticknical Data ReportDocument18 pagesEtp Ticknical Data Reportshaik abidNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document4 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102victorNo ratings yet

- 24-21-00-210-811-A - Check Torque of IDG Quick-Attach-Detach Tension BoltDocument7 pages24-21-00-210-811-A - Check Torque of IDG Quick-Attach-Detach Tension BoltHarold Boya AncichoNo ratings yet

- QCG Pe 2020-02Document13 pagesQCG Pe 2020-02Roosevelt A. SantosNo ratings yet

- Bhel Haridwar Training Report 800 MW Bar CIM Block 4 EEEDocument27 pagesBhel Haridwar Training Report 800 MW Bar CIM Block 4 EEEAkshay TyagiNo ratings yet

- Airframe-Mounted Oil-Tank Drain Valve - Removal/InstallationDocument6 pagesAirframe-Mounted Oil-Tank Drain Valve - Removal/InstallationAdrian LauNo ratings yet

- Fmu A330Document16 pagesFmu A330Ivan KryskoNo ratings yet

- Baws001 Ex GBR 2Document21 pagesBaws001 Ex GBR 2liyuping200809No ratings yet

- Fatigue Analysis SeminarDocument42 pagesFatigue Analysis SeminarDavid JeongNo ratings yet

- System Specifications: CompatibilityDocument3 pagesSystem Specifications: Compatibilityjosel506No ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- 1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enDocument2 pages1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enTien NguyenNo ratings yet

- Manual de Armado HD785-7 - Compressed (1) - Compressed-201-216Document16 pagesManual de Armado HD785-7 - Compressed (1) - Compressed-201-216Gustavo RolongNo ratings yet

- Assemblies: Numbering and Identification For Turbocompressors and Turbines 800 450 98Document7 pagesAssemblies: Numbering and Identification For Turbocompressors and Turbines 800 450 98SreekanthMylavarapuNo ratings yet

- Airframe-Mounted Oil-Tank Probe - Removal/InstallationDocument8 pagesAirframe-Mounted Oil-Tank Probe - Removal/InstallationAdrian LauNo ratings yet

- 1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enDocument2 pages1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enTien NguyenNo ratings yet

- AMM Deactivation of The Thrust Reverser SystemDocument11 pagesAMM Deactivation of The Thrust Reverser Systemmantenimientotalmaoma032No ratings yet

- TASK-G73-22-10-810-824-G00, Airplane TAT and Engine T12 Disagree Fault - Fault IsolationDocument3 pagesTASK-G73-22-10-810-824-G00, Airplane TAT and Engine T12 Disagree Fault - Fault Isolationimran.ahmad.khiNo ratings yet

- TS For Pipe-Duct DismantlingDocument10 pagesTS For Pipe-Duct DismantlingAmitava SilNo ratings yet

- Medición en La ArmaduraDocument5 pagesMedición en La ArmaduraAlvaro arceNo ratings yet

- Bhel Report Block 4Document25 pagesBhel Report Block 4PRASHANT SRIVASTAVNo ratings yet

- 72-41-00-290-802-A - Borescope Inspection of Combustion Chamber and HPT Nozzle Guide VanesDocument95 pages72-41-00-290-802-A - Borescope Inspection of Combustion Chamber and HPT Nozzle Guide VanesAndre SanarNo ratings yet

- Genuine Answers For Land & Environment OptimizationDocument31 pagesGenuine Answers For Land & Environment OptimizationChakroune100% (2)

- Technial Specification - Transformer and Reactor Part 4Document10 pagesTechnial Specification - Transformer and Reactor Part 4amulya00428No ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Group-3 Beer & Grill Party - Sprint 2Document5 pagesGroup-3 Beer & Grill Party - Sprint 2rahul4u18No ratings yet

- Seminar Work Topic:: Identification of WST and SCM, LEAN Principles in Supply Chain of AmazonDocument20 pagesSeminar Work Topic:: Identification of WST and SCM, LEAN Principles in Supply Chain of Amazonrahul4u18No ratings yet

- Unstoppable SCM Team4Document26 pagesUnstoppable SCM Team4rahul4u18No ratings yet

- Supply Chain Management: Team MembersDocument26 pagesSupply Chain Management: Team Membersrahul4u18No ratings yet

- HB 250 A DatasheetDocument2 pagesHB 250 A Datasheetmr banano tvNo ratings yet

- Knife Gate Valves PDFDocument2 pagesKnife Gate Valves PDFashish_pradhan75No ratings yet

- Expansion Joint Fitting InstructionsDocument9 pagesExpansion Joint Fitting Instructionsxyztaa100% (1)

- SolidWorks Motion AnalysisDocument37 pagesSolidWorks Motion Analysiswidi_115No ratings yet

- Brake Pedal Lower Links Stress Analysis ReportDocument26 pagesBrake Pedal Lower Links Stress Analysis Reportquoteszone100% (1)

- Falcon User's Manual: Mortch International LTDDocument22 pagesFalcon User's Manual: Mortch International LTDstalky36No ratings yet

- C-Mueller - Indd 1 9/5/06 10:48:30 AM 9/5/06 10:48:30 AMDocument32 pagesC-Mueller - Indd 1 9/5/06 10:48:30 AM 9/5/06 10:48:30 AMأحمد محمد قدريNo ratings yet

- Wrought Iron: Prepared & Submitted byDocument14 pagesWrought Iron: Prepared & Submitted bysujan shresthaNo ratings yet

- Technical Specifications Tecumseh Compressor 3hp R22 MHBP TFH5540E TUBEDocument2 pagesTechnical Specifications Tecumseh Compressor 3hp R22 MHBP TFH5540E TUBEVictor Hugo Oropeza MonjeNo ratings yet

- PCM Rod Stretch Calculation Chart - B - Oct2020Document1 pagePCM Rod Stretch Calculation Chart - B - Oct2020Harry HudiniNo ratings yet

- TR2343 - Preservation Requirements For Supplier PackagesDocument10 pagesTR2343 - Preservation Requirements For Supplier Packagesmaximusala83No ratings yet

- TugasDocument18 pagesTugasWicaksana try YudhantoNo ratings yet

- HAZOP Study Checklist (26092011) - 3Document1 pageHAZOP Study Checklist (26092011) - 3Hina ImranNo ratings yet

- Research For ME ShopDocument37 pagesResearch For ME ShopGrace LuceroNo ratings yet

- Prasath K: Career ObjectivesDocument4 pagesPrasath K: Career ObjectivesPrasathNo ratings yet

- Information Letter 412-04-53: A Subsidiary of Textron, IncDocument2 pagesInformation Letter 412-04-53: A Subsidiary of Textron, IncAli SyahbanaNo ratings yet

- BT 2004 Basic Civil Engineering and Engineering Mechanics Cbgs Dec 2017Document2 pagesBT 2004 Basic Civil Engineering and Engineering Mechanics Cbgs Dec 201713DEEPENDRANo ratings yet

- Kolmeks Pump Catalogue Low PDFDocument260 pagesKolmeks Pump Catalogue Low PDFsriguruprasathsNo ratings yet

- EXERCISE 11.1: (Answer Key With Explanation)Document24 pagesEXERCISE 11.1: (Answer Key With Explanation)John MarksNo ratings yet

- AIR RESEARCH 2410 CAT C9 STD Base - 110825 - 1 PDFDocument30 pagesAIR RESEARCH 2410 CAT C9 STD Base - 110825 - 1 PDFHussain ShahNo ratings yet

- 1NZ-FE Engine Control System PDFDocument12 pages1NZ-FE Engine Control System PDFjuan50% (2)

- Notes For Students of Process DiagramsDocument38 pagesNotes For Students of Process DiagramsRida akhtarNo ratings yet

- Icse X Calorimetry Question BankDocument9 pagesIcse X Calorimetry Question BankanimeshtechnosNo ratings yet

- Code-Check of Anchors (AISC) - IDEA StatiCaDocument7 pagesCode-Check of Anchors (AISC) - IDEA StatiCamehmetmehmetmehmet111111No ratings yet