Professional Documents

Culture Documents

How To Use This Competency-Based Learning Material: Task Sheets and Job Sheets Are Activity Sheets That Will Help You

How To Use This Competency-Based Learning Material: Task Sheets and Job Sheets Are Activity Sheets That Will Help You

Uploaded by

Evander Renz Adolfo AngCopyright:

Available Formats

You might also like

- Understanding The Borderline Mother Helping Her CHDocument4 pagesUnderstanding The Borderline Mother Helping Her CHemanuelabiancaNo ratings yet

- PawnshopsDocument41 pagesPawnshopsrishipath100% (1)

- Republic of The Philippines Central Mindanao University College of Nursing Course OutlineDocument3 pagesRepublic of The Philippines Central Mindanao University College of Nursing Course OutlineEmvie Loyd Pagunsan-ItableNo ratings yet

- 6c Managing Service Demand & Capacity-1Document81 pages6c Managing Service Demand & Capacity-1Divya VartakNo ratings yet

- CBLM PackageDocument32 pagesCBLM PackageRalph Castillo100% (6)

- ENT MnemonicsDocument5 pagesENT MnemonicsCharm Meel100% (1)

- Training Session Evaluation Form Instructions:: Gaton RanciaDocument5 pagesTraining Session Evaluation Form Instructions:: Gaton RanciaEvander Renz Adolfo AngNo ratings yet

- 04trainee's Record BookDocument2 pages04trainee's Record BookEvander Renz Adolfo AngNo ratings yet

- On-the-Job TRAINING PLAN: Qualification Title: Slaughtering Operations (Large Animals) NCIIDocument2 pagesOn-the-Job TRAINING PLAN: Qualification Title: Slaughtering Operations (Large Animals) NCIIEvander Renz Adolfo AngNo ratings yet

- Session Plan: Learning OutcomesDocument5 pagesSession Plan: Learning OutcomesEvander Renz Adolfo AngNo ratings yet

- Lesson Exemplar Science8 WEEK 6Document118 pagesLesson Exemplar Science8 WEEK 6Richard F. TalameraNo ratings yet

- Dian B. Villavicencio (Final Copy of Thesis Maed 3a)Document112 pagesDian B. Villavicencio (Final Copy of Thesis Maed 3a)Dian VillavicencioNo ratings yet

- Entrepreneursh IP: Teacher: Mrs. Cartney M. KalaquianDocument19 pagesEntrepreneursh IP: Teacher: Mrs. Cartney M. KalaquianJulie Ann ParajasNo ratings yet

- Business TaxDocument8 pagesBusiness TaxClarish S. TanNo ratings yet

- Bustax Quiz 1 ReviewerDocument10 pagesBustax Quiz 1 ReviewerEleina Bea BernardoNo ratings yet

- Criminal Law Reviewer (Elements) PDFDocument84 pagesCriminal Law Reviewer (Elements) PDFVal Gem Pulmones GatuslaoNo ratings yet

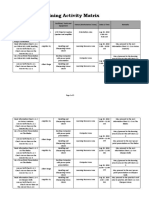

- 02training Activity Matrix FinalDocument3 pages02training Activity Matrix FinalEvander Renz Adolfo AngNo ratings yet

- Theories and PrinciplesDocument19 pagesTheories and PrinciplesRaven Micah Ella P. QuizanaNo ratings yet

- BW-LECT 7business Communication and TechnologyDocument59 pagesBW-LECT 7business Communication and TechnologyErickNo ratings yet

- Week 2-The Origin and The Structure of The EarthDocument36 pagesWeek 2-The Origin and The Structure of The EarthB07 Lorenzo Martin PerezNo ratings yet

- The Advantages and Disadvantages of Self Learning Especially in Senior High School StudentsDocument19 pagesThe Advantages and Disadvantages of Self Learning Especially in Senior High School Studentsnovajoesge guillermoNo ratings yet

- Material SelfDocument19 pagesMaterial SelfKeizer SilangNo ratings yet

- Functions of Mass MediaDocument5 pagesFunctions of Mass MediaNitesh KotianNo ratings yet

- Wilson v. GirardDocument1 pageWilson v. GirardFatima Blanca SolisNo ratings yet

- Chapter 7 Developing Good Work EthicsDocument23 pagesChapter 7 Developing Good Work Ethicscj.terragoNo ratings yet

- 04institutional Assessment ToolsDocument12 pages04institutional Assessment ToolsEvander Renz Adolfo Ang100% (1)

- Chapter 3 - Good Governance and Code of EthicsDocument31 pagesChapter 3 - Good Governance and Code of Ethicscj.terragoNo ratings yet

- SESSION PLAN CORE - Plan Training SessionDocument8 pagesSESSION PLAN CORE - Plan Training SessionRomz ATNo ratings yet

- 03 Communication Tools in The Hospitality IndustryDocument5 pages03 Communication Tools in The Hospitality IndustryReynavecNo ratings yet

- Bible CharadesDocument20 pagesBible CharadesCaroline EmadNo ratings yet

- TOS 1stPeriodicalExam in Bio1Document1 pageTOS 1stPeriodicalExam in Bio1Pantz Revibes PastorNo ratings yet

- Series and Parallel ConnectionDocument3 pagesSeries and Parallel ConnectionBia Aranilla MijaresNo ratings yet

- English 3 Map DirectionsDocument4 pagesEnglish 3 Map Directionsanaliza balagosaNo ratings yet

- Final Concept PaperDocument16 pagesFinal Concept PaperCrystian Trias CocjinNo ratings yet

- Corporation CodeDocument55 pagesCorporation CodemarizenocNo ratings yet

- Lesson 2 Select and Use ICT Tools For Teaching and LearningDocument16 pagesLesson 2 Select and Use ICT Tools For Teaching and LearningKelly Danielle QuitonNo ratings yet

- 5 Impacts of E-BusinessDocument18 pages5 Impacts of E-BusinessJohn Edwinson JaraNo ratings yet

- Slaughtering CBLMDocument81 pagesSlaughtering CBLMydbkakovvtwtpkhuthNo ratings yet

- DLP Grade10Document9 pagesDLP Grade10shen llamasNo ratings yet

- Atoms and Atomic Structure - Word Search PuzzleDocument2 pagesAtoms and Atomic Structure - Word Search PuzzleLama DebanyNo ratings yet

- Math 6 - Weeks 1 3Document25 pagesMath 6 - Weeks 1 3Ann PamaNo ratings yet

- NCP Gestational HypertensionDocument3 pagesNCP Gestational HypertensionCameron De GuzmanNo ratings yet

- Information Age PresentationDocument44 pagesInformation Age PresentationVillamor PicsiwenNo ratings yet

- Movie AssignmentDocument2 pagesMovie AssignmentAlishba KhanNo ratings yet

- DLP MitosisDocument4 pagesDLP MitosisArlene c.buisanNo ratings yet

- School of Health & Natural Sciences: Saint Mary's University Bayombong, Nueva VizcayaDocument5 pagesSchool of Health & Natural Sciences: Saint Mary's University Bayombong, Nueva VizcayaSarah Agudo FernandezNo ratings yet

- Climate ChangeDocument26 pagesClimate Changeagnes gwen cabelloNo ratings yet

- Problem ListDocument2 pagesProblem List22 - Fernandez, Lyza Mae D.No ratings yet

- BES 124 Sections of Research PaperDocument9 pagesBES 124 Sections of Research PaperSeira MolinaNo ratings yet

- #50 Agyao vs. CSC - TingDocument2 pages#50 Agyao vs. CSC - TingJrPelayoNo ratings yet

- Chapter 4Document10 pagesChapter 4Jayzle MortelNo ratings yet

- Solid Waste PollutionDocument20 pagesSolid Waste Pollutionanon-82902088% (8)

- Basic Concepts On EstimationDocument15 pagesBasic Concepts On EstimationMiteigiNo ratings yet

- 14 - Cambodia V ThailandDocument5 pages14 - Cambodia V ThailandGuian LimNo ratings yet

- Effects of Political Campaigning To The Voting Preferences of Residents in Barangay BacaganDocument9 pagesEffects of Political Campaigning To The Voting Preferences of Residents in Barangay BacaganSañata GonzalesNo ratings yet

- Effectiveness of Metacognition-Based Reading Enrichment ProgramDocument10 pagesEffectiveness of Metacognition-Based Reading Enrichment ProgramLeo Vigil Molina BatuctocNo ratings yet

- Lesson Plan in Health For Grade 4 Ma. Elaine E. BalbedinaDocument6 pagesLesson Plan in Health For Grade 4 Ma. Elaine E. Balbedinaapi-310858766No ratings yet

- Perform Pre-Lay and Lay-ActivtiesDocument38 pagesPerform Pre-Lay and Lay-Activtiesmichelle.tagalaNo ratings yet

- CBLM - MPDCI (Perform Pre-Lay and Lay Activities)Document33 pagesCBLM - MPDCI (Perform Pre-Lay and Lay Activities)robelyn verano100% (4)

- W CBLM-new Care and Maintain CropsDocument106 pagesW CBLM-new Care and Maintain Cropsanna luna llubitNo ratings yet

- CBLM 4 OhsDocument106 pagesCBLM 4 OhsOrlando Najera100% (1)

- CBLM FinalDocument9 pagesCBLM FinalChriz Codamon100% (1)

- On-the-Job TRAINING PLAN: Qualification Title: Slaughtering Operations (Large Animals) NCIIDocument2 pagesOn-the-Job TRAINING PLAN: Qualification Title: Slaughtering Operations (Large Animals) NCIIEvander Renz Adolfo AngNo ratings yet

- 04trainee's Record BookDocument2 pages04trainee's Record BookEvander Renz Adolfo AngNo ratings yet

- 01memorandum of AgreementDocument3 pages01memorandum of AgreementEvander Renz Adolfo AngNo ratings yet

- 02training Activity Matrix FinalDocument3 pages02training Activity Matrix FinalEvander Renz Adolfo AngNo ratings yet

- Supervised Industry Training or On The Job Training Evaluation FormDocument2 pagesSupervised Industry Training or On The Job Training Evaluation FormEvander Renz Adolfo AngNo ratings yet

- Training Session Evaluation Form Instructions:: Gaton RanciaDocument5 pagesTraining Session Evaluation Form Instructions:: Gaton RanciaEvander Renz Adolfo AngNo ratings yet

- Session Plan: Learning OutcomesDocument5 pagesSession Plan: Learning OutcomesEvander Renz Adolfo AngNo ratings yet

- 04institutional Assessment ToolsDocument12 pages04institutional Assessment ToolsEvander Renz Adolfo Ang100% (1)

- Parental Expectations and Its Relation To Academic Stress Among School StudentsDocument4 pagesParental Expectations and Its Relation To Academic Stress Among School StudentsAndrei BantilingNo ratings yet

- Parales, Alberto Custodio 2081007534Document7 pagesParales, Alberto Custodio 2081007534brip selNo ratings yet

- ITMProposers Day2022020v6Document32 pagesITMProposers Day2022020v6熊俊捷No ratings yet

- 3) +jurkes,+heni+wulandari-3Document8 pages3) +jurkes,+heni+wulandari-3punctumlacrimaleNo ratings yet

- IELTS 12 T5 Listening AnswerDocument1 pageIELTS 12 T5 Listening Answerphuonganhphmvu05No ratings yet

- Mohit Gupta: Writer Business Services Pvt. LTDDocument5 pagesMohit Gupta: Writer Business Services Pvt. LTDMohit GuptaNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingDocument7 pagesSafety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingabonatuconnex8926No ratings yet

- Subconscious WhispersDocument54 pagesSubconscious Whispersmanish GuptaNo ratings yet

- Organization and Functions of Nursing Services and Education at NationalDocument27 pagesOrganization and Functions of Nursing Services and Education at NationalDelphy Varghese80% (5)

- Week 2Document5 pagesWeek 2stray kids zoneNo ratings yet

- Đề Thi HSG Số 1Document5 pagesĐề Thi HSG Số 1Trang NguyễnNo ratings yet

- JCMR - Serial T1 Mapping of Right Ventricle in Pulmonary HypertensionDocument9 pagesJCMR - Serial T1 Mapping of Right Ventricle in Pulmonary HypertensionShyama SharmaNo ratings yet

- OET Speaking Guide Part 2 Clinical CommunicationDocument46 pagesOET Speaking Guide Part 2 Clinical CommunicationAhmed GülNo ratings yet

- Citric Acid MonohydrateDocument6 pagesCitric Acid MonohydrateOussama SissaouiNo ratings yet

- China Guideline - Food - Additives - enDocument9 pagesChina Guideline - Food - Additives - enNisrina RofifahNo ratings yet

- Syunik-Development Ngo: Special Issue 2020Document13 pagesSyunik-Development Ngo: Special Issue 2020Syunik NGONo ratings yet

- Article Careers360 20240223115102Document17 pagesArticle Careers360 20240223115102r786khan668No ratings yet

- Ethical Challenges in The Pharmaceutical Industry: Pharmaceuticals Policy and Law April 2012Document7 pagesEthical Challenges in The Pharmaceutical Industry: Pharmaceuticals Policy and Law April 2012RizwanNo ratings yet

- Group 1 Noun and PronounDocument2 pagesGroup 1 Noun and PronounMaya JenitaNo ratings yet

- Luna National High SchoolDocument52 pagesLuna National High SchoolZach MallavoNo ratings yet

- Test-Taking Skills Booster: Summit Can Be Found in The Summit ActiveteachDocument10 pagesTest-Taking Skills Booster: Summit Can Be Found in The Summit ActiveteachBernoliNo ratings yet

- TF-CBT and Complex TraumaDocument14 pagesTF-CBT and Complex TraumaDaniel Hidalgo LimaNo ratings yet

- FINAL COOKERY9 Q1 W3 Clean and Maintain Kitchen Tools Equipment and PremisesDocument4 pagesFINAL COOKERY9 Q1 W3 Clean and Maintain Kitchen Tools Equipment and PremisesDyəm MęępoNo ratings yet

- Thales G1. Chapter 1Document5 pagesThales G1. Chapter 1Jenalyn Miranda Cayanan - MarayagNo ratings yet

- BSM - SOUTH - AFRICA - Brochure - 22Document26 pagesBSM - SOUTH - AFRICA - Brochure - 22Delta PayNo ratings yet

- Nursing Care in The HomeDocument4 pagesNursing Care in The HomeAnna NanaNo ratings yet

- Women's Health UK 09.2022Document124 pagesWomen's Health UK 09.2022ΑΡΙΣΤΟΤΕΛΗΣ ΓΕΩΡΓΟΠΟΥΛΟΣNo ratings yet

- Chromotherapy EssayDocument12 pagesChromotherapy EssayCarlos CherrezNo ratings yet

How To Use This Competency-Based Learning Material: Task Sheets and Job Sheets Are Activity Sheets That Will Help You

How To Use This Competency-Based Learning Material: Task Sheets and Job Sheets Are Activity Sheets That Will Help You

Uploaded by

Evander Renz Adolfo AngOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Use This Competency-Based Learning Material: Task Sheets and Job Sheets Are Activity Sheets That Will Help You

How To Use This Competency-Based Learning Material: Task Sheets and Job Sheets Are Activity Sheets That Will Help You

Uploaded by

Evander Renz Adolfo AngCopyright:

Available Formats

HOW TO USE THIS COMPETENCY-BASED LEARNING

MATERIAL

Welcome to the module in Handle and Sharpen Knives. This module

contains training materials and activities for you to complete.

The unit of competency, “Handle and Sharpen Knives” contains

knowledge, skills and attitudes required for Slaughtering Operation (Large

Animals) NCII.

This module, Handling and Sharpening Knives, covers the skills

and knowledge required to maintain knives for safe and effective use in

slaughtering and meat establishments.

You are required to go through a series of learning activities in order

to complete each learning outcome of the module. Information Sheets has a

learning contents that you need to learn. Each Information Sheet has

learning objective that you need to attain while reading the information

sheets. After each information sheet is a self-check that will help you test

yourself if you have attained the learning objectives.

Task Sheets and Job Sheets are activity sheets that will help you

practice the skills previously discussed in the Information Sheet or

demonstrated by your trainer. A performance Criteria Checklist is provided

with the task sheets and job sheets which will allow for self-evaluation or

evaluate your performance. Follow these activities on your own. If you have

questions, don’t hesitate to ask your trainer for assistance.

Remember to:

Work through all the information and complete the activities in each

section.

Read information sheets and complete the self-check. Suggested

references are included to supplement the materials provided in this

module.

Perform the task sheets and job sheets until you are confident that

your outputs conform to the performance criteria checklist that

follows the sheets.

Submit outputs of the task sheet and job sheets to your facilitator for

evaluation and recording in the Progress Chart. Outputs shall serv as

your portfolio during the institutional competency evaluation. When

you feel confident that you have had sufficient practice, ask your

trainer to evaluate you. The results of your assessment will be

recorded in your progress chart.

You must pass the institutional competency evaluation for this

competency before moving to another competency. A certificate of

achievement will be awarded to you after passing the evaluation.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 1 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

SLAUGHTERING OPERATION (LARGE ANIMALS) NCII

Competency-Based Learning Materials

List of Competencies

No. Unit of Competency Module Title Code

1 Handle and sharpen Handling and sharpening PFB751335

knives knives

2 Perform initial preparation Performing initial PFB751336

procedures preparation procedures

3 Prepare carcass Preparing carcass PFB751337

4 Perform final procedures Performing final procedures PFB751338

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 2 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

MODULE CONTENT

Qualification Title : Slaughtering Operation (Large Animals) NCII

Unit of Competency : Handle and sharpen knives

Module Title : Handling and sharpening knives

Introduction

This unit covers the skills and knowledge required to maintain knives for

safe and effective use in slaughtering and meat establishments.

Learning Outcomes:

Upon completion of this module, you must be able to:

LO1 - Sharpen knives

LO2 - Work safely with knives

LO3 - Maintain knives and associated equipment

Assessment Criteria:

1. Knives are sharpened according to workplace requirements

2. Knives are sharpened to maintain a bevel edge

3. Steel is used correctly to maintain a bevel edge and to meet

Occupational Safety and Health Standards (OSHS)

4. Personal Protective Equipment(PPE) are used according to OSHS

5. Knives are used in ways which minimize the risk of injury

6. Knives are used safely at all times in accordance to regulatory

requirements

7. Knives are maintained in accordance to hygiene and sanitation and

workplace requirements

8. Knife sharpening equipment is maintained, cleaned and stored to

hygiene and sanitation and workplace requirements

9.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 3 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

LEARNING OUTCOME #1 SHARPEN KNIVES

CONTENTS:

1. Critical risk: Knife handling

2. Knives Anatomy

3. The Blades

4. Sharpen knife

ASSESSMENT CRITERIA:

1. Knives are sharpened according to workplace requirements

2. Knives are sharpened to maintain a bevel edge

3. Steel is used correctly to maintain a bevel edge and to meet

Occupational Safety and Health Standards (OSHS)

4. Personal Protective Equipment(PPE) are used according to OSHS

CONDITION:

Students/Trainees must be provided with the following:

1. Workplace location

2. Tools and equipment/utensils appropriate to knife

sharpening

3. Materials relevant to the proposed activity and tasks

ASSESSMENT METHOD:

Trainees will measure the underpinning knowledge and skill and

attitude in Handling and sharpening knives through the following

assessment method:

1. Written Exam

2. Demonstration with Oral Questioning

3. Interview/Oral Questioning

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 4 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

LEARNING EXPERIENCE

LEARNING OUTCOME 1

SHARPEN KNIVES

Learning Activities Special Instructions

Read Information Sheet 1.1-1 on Read and understand the

Critical risk: Knife handling information sheet and check

yourself by answering the self-

Answer Self-Check 1.1-1 check. You must answer all the

questions correctly before

Check Answer base on the Answer Key

proceedings to the next activity

1.1-1

Read Information Sheet 1.1-2 on Refer to Task sheets, it will help

Knives Anatomy you practice your skills.

Answer Self-Check 1.1-2

The performance criteria

Check Answer base on the Answer Key checklist will guide and help you

1.1-2 evaluate your work as you are

Read Information Sheet 1.1-3 on The practicing your skills.

Blades

Evaluate your own performance

Answer Self-Check 1.1-3 using the performance criteria

checklist. When you are ready,

Check Answer base on the Answer Key present your work to your trainer

1.1-3 for final evaluation and

Read Information Sheet 1.1-4 on recording.

Sharpen knife

If you have questions and

Answer Self-Check 1.1-4 clarification fell free to ask your

trainer.

Check Answer base on the Answer Key

1.1-4 After doing all the activities for

Refer to Job Sheet 1.1-4 on Sharpen this LO – Sharpen Knives you are

Knives ready to proceed to the next LO -

Work safely with knives.

Perform Job Sheets 1.1-4

Evaluates own performance using the

performance criteria checklist 1.1-4

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 5 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Information Sheet 1.1-1

Critical risk: Knife handling

Learning Objectives:

After reading this Information Sheet you should be able to:

1. Identify and understand the critical risk in handling knifes

Identifying the risk:

Knives are important tools in

the meat industry. However,

they are also one of the most

dangerous utensils if they are

not handled and used correctly

and safely.

The most important thing to

remember is that a sharp knife

is a safe knife. Blunt knives require more grip and more force to do the job

and therefore can result in serious strains and sprains to workers and can

cause lasting injuries. Workers with sharp knives do not have to push the

knife and therefore get less tired and sore over the course of the day.

Likewise, an operator using a blunt knife that needs to be forced through

the meat is more likely to accidently stab themselves or those working

around them.

Potential impact of the risk:

The number of injuries involving knives is a major concern in the meat

processing industry. The most common type of injuries are lacerations.

These often require medical attention and may need suturing or skin

grafting. Injuries include:

cuts to the non-knife hand or arm (most common)

cuts to the hand holding the knife which occur when the hand slips

off the handle

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 6 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

cuts which occur with a reverse grip and pulling back towards the

body

cuts to another person, inadvertently, where people are too close

together when

working

sprains or strains (e.g. from the extra effort required to use knives

that are not enough sharp).

Supervisor Responsibilities:

Supervisors have responsibilities in implementing and monitoring all

procedures that apply to the work performed by the employees in their area.

This includes:

instructing workers in safe and healthy work practices

providing information on particular hazards in work tasks

monitoring staff in how they apply safe work practices

participating in changes to procedures where there are problems

ensuring appropriate PPE is used and maintained correctly

ensuring appropriate hazard information signs and other OH&S

information is displayed

ensuring any staff who receives a knife injury receives first aid

treatment reporting the incident to the correct authority.

In summary, supervisors should provide relevant and practical information,

training and supervision to all employees in their area.

Preventing the risk:

Avoid injuring yourself with a knife. Commonsense and concentration will

help avoid knife accidents. Knife accidents are most likely to occur when

workers are tired and not concentrating on the job they are doing. It is very

easy to cut yourself when you become distracted from your job or careless in

your approach to work.

Complacency is a common cause of knife accidents. Workers become so

accustomed to handling knives they quickly forget how dangerous they are.

Make sure your staff receive adequate knife safety training. Always put

knives in their pouch when not in use. Don’t talk with a knife in your hand

especially if you ‘talk with your hands’.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 7 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Don’t use a knife to move pieces of meat, especially to someone else e.g. a

slicer to a packer. One slip and you’ve stabbed someone. Don’t use a knife

as a scraper.

Apply the following rules to avoid injury.

When using a sharpening stone, make sure the stone is on a slip-

proof, flat surface.

Make sure your steel has a safety guard between the handle and the

body of the steel.

When using a grindstone, make sure the rotation of the stone and the

cutting edge of the blade are away from your body.

If you drop your knife let it fall, don’t try to catch it.

Always place your knife in the scabbard or pouch when not in use.

Don’t use a blunt knife as you will need to use more force which gives

you less control.

Never take your eyes off the cutting path of the knife, if you must look

away, stop cutting.

Never cut towards yourself or towards another individual.

Always be aware of the movement of people around you.

Never fool around with a knife in your hand or fool around with others

who may have a knife in their hand.

Keep the handle of the knife clean and free of fat and grease at all

times.

Personal protective equipment is a vital part of knife safety and workers

should always use PPE when working with a knife. The range of PPE

equipment used can include:

o mesh gloves

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 8 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

mesh aprons

cut resistant gloves

arm guards

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 9 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Hierarchy of control measures

Effectiveness Types of Examples

control

Most effective Elimination Redesign the workplace to remove the

need for inappropriate work practices

e.g., using a knife to transfer meat by

piercing and levering.

Substitution Replace old, blunt knives with well-

designed and sharpened knives.

Isolation Redesign the workplace to minimize

distractions from the task, reduce

additional stressors and minimise

fatigue e.g., reduce noise, provide

comfortable working temperatures and

reduce uncomfortable working postures.

Engineering Provide sufficient work space for each

Controls worker to reduce the risk of one worker

stabbing or cutting another.

Administrative Train staff in knife safety and

controls sharpening knives. Provide training to

allow safe and effective rotation, where

appropriate, to minimise risk of

occupational overuse injuries. Discuss

SOPs and work instructions for knife

safety during induction.

Least Effective Personal Wear cut-resistant gloves on the knife

Protective hand and a mesh gauntlet (or a

Equipment combination of a mesh glove and arm

guard) on the non-knife hand. Wear

mesh aprons.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 10 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Self-Check 1.1-1 (True or False)

Instruction: Write TRUE if the statement is correct and FALSE if it is

incorrect. Write your answer on a separate sheet of paper

1. When using a sharpening stone, make sure the stone is on a slippery

so that it is easy to sharpen knifes, flat surface.

2. Make sure your steel has a safety guard between the handle and the

body of the steel.

3. When using a grindstone, make sure the rotation of the stone and the

cutting edge of the blade are away from your body.

4. If you drop your knife catch it using the mesh gloves.

5. Always place your knife in the scabbard or pouch when not in use.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 11 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Answer Key 1.1-1

1. FALSE

2. TRUE

3. TRUE

4. FALSE

5. TRUE

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 12 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Information Sheet 1.1-2

Knives Anatomy

Learning Objectives:

After reading this Information Sheet you should be able to:

2. Examine and learn the knifes anatomy

Part of a Knife DescribedKnives are a

commonly used tool that we often take

for granted. We expect them to perform

and cut with ease, but we rarely pay any

more attention to our knives than that.

To understand your knife, it is important

to learn about its construction and be

able to identify the various knife parts.

First, it is easy to divide the knife into

two main parts, the handle and the

blade. But each of those two parts can

also be subdivided into its own parts.

With the help of the photo at right and

the descriptions below, you will better

understand what components make up

your knife.

Point – The point is the part of the knife

where the edge and spine come together.

The point is often used for piercing.

Tip – The tip is the forward part of the

knife and includes the knife point. The

tip is used detailed or delicate cutting.

Edge – The edge is the cutting part of the

blade. It extends from the point to the

heel of the knife.

Heel - The heel is the rear part of the edge, opposite the point.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 13 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Spine - The spine is the top of the knife blade, opposite the knife edge.

Bolster - The bolster is the band that joins the blade of the knife to its

handle. The bolster provides balance for the knife and also helps to protect

the hand from getting in the way of the knife edge.

Tang - The tang is the part of the blade that extends into the handle of the

knife. It is the surface to which the handle attaches to the blade.

Scales – The scales are the part of the knife that creates the handle. Scales

are often made of synthetic material or wood. Two scales are typically

attached to the tang with rivets.

Rivets – The rivets are metal pins used to join the scales to the tang to form

the handle.

Butt – The butt is the end of the handle of the knife.

Different Knives Anatomy

A simple knife seems easy to describe. A blade and handle are the

obvious terms that generalize the knife as a hand knife. A hand knife is one

that is meant to be in the hand. You might be surprised how many knives

are in the world; there are knives to plane wood, knives to shear steel,

knives to separate particles in industrial process applications. In my

upcoming book, I'll go into the bewildering classification of knives and

blades, and our government's idea that they can classify, track, and identify

them all!

The following dozen illustrations point out and describe various hand

knife components and areas. It's easy enough to identify specific

components and their location (like the point of the blade), other knife parts

are more generalized to an area (like the grind). Items that accompany, are

part of, or are attached to the knife blade (like the bolsters) can have widely

varying shapes, arrangements, and purposes.

Knife Anatomy 1

This picture starts what seems to be

obvious. The knife has a handle and a

blade. The blade has a point (or tip) and the

point often determines the use, style, and

connotation describing the knife blade

shape. More on that later.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 14 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

The spine (also sometimes called the back) is the thickest, heaviest length of

the blade and supports the entire blade. The wider and thicker the spine,

the stronger the blade along its length.

You might read elsewhere on the internet that it is debatable whether the

full tang or the hidden tang is stronger. This is not even a close argument.

The full tang has full thickness across the width of the blade at the most

critical area, in front of and behind the front bolster location. On a hidden

tang, this is where the blade is ground down and reduced in size and

thickness to a shoulder (below). The hidden tang also only has a small width

of tang running through the handle to the threaded portion where the

pommel is screwed on. So there simply is no way that the hidden tang is

even comparable in blade-to-handle strength to the full tang. The hidden

tang simply has less metal in the entire handle. Detailed description and

illustration of the hidden tang knife handle below.

The handle of this full tang knife is framed in by the front and rear bolster.

The bolsters do exactly that, they bolster the blade's strength in the critical

areas: the handle to blade junction, and the rear or butt of the knife where

heavy blows or impact require reinforcement. The bolsters also help to

protect and mechanically secure the handle.

Knife Anatomy 2

A few more details here. The thickest

part of the knife blade: the spine, is also

the blade flat, the part of the blade that

is flat ground and both sides are typically

parallel. It extends up to the thumb rise

on this example, where the thumb rests

in a traditional grip style, and down to

the ricasso, the heavy thick shank of the

blade between the grind and the front bolster. It extends (in this illustration)

toward the point. The grind or hollow grind in this case is the part of the

knife where the blade is thinned along its length to yield a uniform, thin

cutting edge. The grind is a very distinctive part of the knife, and fine

workmanship is usually noticed here by how deep, matched, regular, and

well-finished the grind is. Some older texts and beginners in knife chat sites

and forums call the grind a bevel but this is technically incorrect, since

there may be many actual geometric bevels on a knife, and a bevel is a slope

or slant of a line, and therefore straight. On a flat ground knife, one might

call it a bevel, but knives are ground in many ways: hollow, convex, tapered,

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 15 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

flat, and even a combination of grind geometries. Since modern knives are

nearly all abrasively ground, the area is called a grind.

The front quillon stops the hand from sliding forward on the blade, and in

this knife pattern, the hand is locked between the front and rear quillons.

The rear quillon also aids in removing the knife from the sheath. The handle

belly makes many knives more comfortable to hold. The handle scales rest

between the bolsters and should be pinned, riveted, screwed, or mounted

with mechanical as well as adhesive means.

Knife Anatomy 3

A spear point designation used to refer to a

double edge, but nowadays it can refer to the

almost uniform geometry of the point. If you

were to bisect the profile of the point, you

would see a nearly symmetrical profile on

both sides of the center line, like a spear of

old. In this drawing, you'll notice grind

terminology. The grind termination is at the ricasso, plunges into the meaty

part of the blade, has a radius that delineates the transition between the

grind termination and and the grind line, and leads off the blade at the

spine near the point. The grind termination radius is determined by the

wheel size if hollow ground and other factors.

The choil is considered the start of the cutting edge. In days of old, the choil

was perpendicular to the edge, and is often still described as the lower part

of the ricasso, the part that is unsharpened and at the full thickness of the

blade. In the modern knife, it can be carved, fluted, fileworked, and a

separate feature of a fine knife. It's purpose is to have a definite location to

start the sharpened edge of the knife.

It's interesting to note that for nearly all United States locations, laws state

that blade length is not the length of the cutting edge, but the length of the

blade from the tip to the front bolster face.

In this drawing you can see why this rear quillon is often called a hawk's

bill.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 16 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Self-Check 1.1-2 (Multiple Choice)

Instruction: In a separate sheet of paper write the letter of the correct

answer.

1. Is the part of the knife where the edge and spine come together.

a. Point

b. Tip

c. Edge

d. Heel

2. Is the forward part of the knife and includes the knife point

a. Point

b. Edge

c. Heel

d. Tip

3. Is the top of the knife blade, opposite the knife edge

a. Bolster

b. Spine

c. Tang

d. Scales

4. Is the band that joins the blade of the knife to its handle. It provides

balance for the knife and also helps to protect the hand from getting

in the way of the knife edge

a. Bolster

b. Spine

c. Tang

d. Scales

5. Are metal pins used to join the scales to the tang to form the handle.

a. Tang

b. Scales

c. Rivets

d. Butt

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 17 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Answer Key 1.1-2

1. A-Point

2. D-Tip

3. B-Spine

4. A-Bolster

5. C-Rivets

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 18 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Information Sheet 1.1-3

The Blades

Learning Objectives:

After reading this Information Sheet you should be able to:

1. Examine and learn the knife blade and its parts

Here on the Lansky Sharpeners Blog we’ve been providing some serious

education on all the different types of blades and grinds. When you first

start learning about knife sharpening and knives, it can be like trying to sip

from a fire hydrant on full blast; there’s a lot of information and it comes at

you fast. For such a seemingly simple concept, knives and knife sharpening

can get very complicated, very fast. So, what makes it seem so complicated?

First off, the sea of terminology used to describe different parts of knives can

be daunting. Many of the terms used to describe the different parts of a

knife stem from other languages and historical terms not in use today.

Second, knives have gone through (and still do) so many modifications and

changes over the years and more and more terms are added to the

vocabulary.

Combine these two factors and it could lead a grown man to hide in a

corner weeping over the good old days when a knife had three parts; a blade,

guard and handle. So wash your hands, slip on your lab coat and put that

silly paper mask on. It’s time to learn anatomy; Fixed Blade Knife Anatomy.

Let’s start with the basics; the visible characteristics on a

basic fixed blade knife going from the tip of the blade to

ricasso. As I mentioned in my last post Knife Blade

Profiles and Uses knife blade come in many shapes and

types. Though knife blades may have different

characteristics and design, their anatomy (the different

sections and pieces that form a serviceable knife) can generally be broken

down with just a few variances.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 19 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

FIXED BLADE ANATOMY

The Blade

The Tip or Point of a blade is simple; it’s the pointy end of the blade.

You should know that by now, but I won’t blame you. Tip and point

can be used interchangeably but may be used separately to describe

two different aspects of the anatomy. The “point” being literally the

point where the spine and edge meet and the “tip” referring to a small

section at the front of the blade that leads up to the point.

The Cheek or Face of a blade refers to each side of the blade, often

used to refer to the section separate from the grind but can be used to

refer to each side of the blade, including the grind.

The Spine of a blade refers to the dull, unsharpened back of a blade,

the opposite side of the edge. Double edged blades (daggers) do not

have a spine but most knives found in the home or for outdoor use

will have a spine.

The Grind or Bevel of the blade is explained thoroughly in my

post Knife Edge Grinds and Usesand refers to the cross section of the

blade, or the section ground down to form the Edge. For more

information about different grinds and their significance, follow my

link above.

The Edge is the cutting surface of a blade that extends from point to

heel. It’s the sharp part! And also, the reason I have gainful

employment.

The Belly of the blade refers to the curved section of the edge leading

up to the tip. The belly on a blade increases the surface area of the

edge and aids in making cuts or slices. Blades with large curved edges

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 20 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

like fillet knives and scimitar style daggers have large bellies intended

for strong slicing cuts.

The Heel of the blade refers the section of the blade next to the guard

or handle. The heel encompasses a small section of the grind,

the Plunge Line and the Ricasso.

The Plunge Line is where the grind stops and meets the edge, often at

a right angle to the grind.

The Ricasso is the unsharpened section of a blade, closest to the

guard/handle.

Some blades may have a Choil. A choil is an unsharpened indent on a

blade where it meets the handle or at the plunge line. The size of a

choil dictates its purpose, if it’s large then it can be used as a forward

finger grip. If it’s small then the choil may be there to creat a stopping

point when sharpening, to protect the handle.

A Fuller or Blood Groove (not shown) is a decorative feature that

runs the length or a partial length of the blade. A fuller may be used

to reduce the weight of the blade but often is used purely for

decoration.

Jibbing (not shown) refers to a pattern of gouges or notches made on

the spine of a blade close to the handle. Jibbing is used to aid in grip

when doing fine work and as a decorative feature.

The Guard, Handle and Tang

Alright knife fans, now that you've committed the anatomy of the knife blade

to your memory, let’s move on to the rest of the knife. I know I've said it

before and I’ll say it again; the blade’s edge is the true technology that we

are concerned with. That’s not to say the other parts of the knife aren't as

important, but I like to look at the rest of a knife as a way to compliment the

edge I am using. Apart from just the aesthetic design of a knife; the guard,

handle and how all the pieces are attached is an important factor when

deciding what knife is the best for your purposes. So let’s take the plunge

one more time with fixed blade anatomy focusing on the guard, handle,

tang(s and beyond!

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 21 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

FIXED BLADE ANATOMY

The Guard on a knife is located between the handle and the blade,

sandwiched between the ricasso and the handle. The guard’s purpose is to

literally guard your hand from slipping up the handle and onto the blade.

Just like anything else knife related, guards come in different shapes and

styles. Some are purely decorative, they line up perfectly with the handle

and offering no protection and some guards are meant purely for balance.

Guards that are intended to protect your hand will often have Quillions; a

section of the guard that extends past the handle to protect the knife users

hand from slipping onto the blade. Commonly, quillions found on outdoor

style knives will extend out to the front of the knife but quillions found on

more aggressive fighting or multipurpose blade will extend out from both the

front and back of the blade.

If a knife lacks a guard it may have a Bolster (not shown); a bolster is

usually found between the blade and the handle (although bolsters can be

found on different sections of the handle) and is often sandwiching the

blade’s tang. The Bolster can provide balance to a blade and is more

commonly found on full tang knives. Bolsters can also be used to “bolster”

or strengthen the weak points on a knife, such as where the blade ends and

the tang and handle begins. Bolster may also be shaped like a guard (with

quillions) to offer protection.

Next, we have the Handle. The handle of a knife is the portion you grip.

Handles come in all shapes and sizes and can be made from countless

materials and combinations. Handles are a very important aspect of a blade,

I’ve heard it said “The blade is what makes a knife; the handle is what sells

it”. How the handle is attached to a blade plays a large role in the actual

strength and durability of a knife.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 22 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

The Handle of a knife can be attached in several ways. This is done through

the Tang of a knife blade. The Tang is the stock material portion of the

blade steel that extends from the blade for the purpose of attaching the

handle and hardware. Tangs are an important factor when constructing a

blade; they will help determine overall weight, balance and usage of the

knife. There are several types of knife tangs, but they can be broken down

simply into two categories Full Tang and Partial Tang.

Full Tang (displayed above) - refers to a knife tang that extends the full

length and width of the handle and is often visible. Full tang constructed

knives generally form the handle by the use of Scale material. Scales refer

to two pieces of handle material that sandwich the tang between them and

are attached to the tang by adhesive and/or rivets /pins. Full Tang knife

construction is generally considered the most durable and solid knife

construction available and is intended for hard working knives that can take

a solid beating.

Skeletonized Tang

A tang that has portions of material removed

from the tang stock. Often found on knives with

full tang construction but without handle

material. Skeletonized tang construction is

popular on bare bones survival blades and neck knives. May feature a cord

wrapped handle.

Partial Tang refers to a knife tang that doesn’t fully extend and/or match

the width of the blade and handle material. Generally considered weaker

than Full Tangs, Partial Tangs have their place in the knife world and

generally produce much lighter knives. Partial Tangs can be broken down

further in sub categories.

Push Tang

A shortened tang that tapers after the

blade portion of a knife. Partial Tangs don’t

generally run the full length of the handle

and are pushed or forced into the handle material and secured with

adhesive.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 23 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Hidden Tang

Very similar to a Push Tang, the

Hidden Tang tapers after the blade

portion and is attached to the handle

with adhesive and generally has no

outside evidence of its attachment. Hidden Tangs can also run longer than

the full length of the handle and can be secured by a pommel/butcap

through threading and screwing like a nut and bolt or by peening the end.

Rat Tail and Stick Tangs

Also known as a “false tang” is the

weakest of knife tangs. Rat tail tangs are

generally reserved for cheap or display

knives. Either a piece of steel welded to

the blade or a significant and abrupt

taper from the blade, rat tail tangs are to be avoided.

The final piece of anatomy for a fixed blade knife is the Pommel (or Butt

Cap) (not shown). Not every knife features a pommel, they are most often

found on hidden tang knives. A Pommel can serve multiple purposes aside

from a method to attach and secure a handle and guard, a pommel can be

used to add balance to a knife or it can even be used a striking surface.

The edge or grind on a knife is the true “technology” that allows us to use a

knife properly but in many cases the shape or profile of a knife blade can be

equally important. Much like the grind of knife the profile of a knife implies

a lot about the blades use and can also say a lot about culture, utility and

history of the knife you carry.

**”tip” and “point” are used interchangeably

The Simple/Normal Blade

A simple blade has a straight spine with a curving

edge that meets to form the tip of the knife, which is

on the same plane and parallel to the spine of the knife. The straight spine

of this knife allows the blade to be used with both hands for safely adding

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 24 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

pressure. This also allows the user to concentrate the force of their cut to a

smaller area, which increases the cutting edge’s effectiveness. The simple

blade is a very strong blade type, these knife profiles are ideal for heavier

work such as batoning wood and cutting heavy rope or roots. The simple

blade is a must have knife for people trying to improve their sharpening

skills and knowledge.

Trailing Point Blade

A trailing point blade has a large curved edge and

the spine curves upward to meet the edge forming

the tip of the blade. The tip is generally found higher

than the handle in profile and gave rise to the name “trailing point”. The

curve of this blade allows for greater surface area of the edge (called a ‘belly’)

which aids in slicing, slashing and making long, even cuts. This type of

knife profile is most commonly used for fillet knives, but also seen in

slashing weapons. The large surface area of the edge combined with the

thin tip make it ideal for processing fish and other small wild life.

Clip Point Blade

A clip point blade is similar to the simple/normal

blade where it has a (mostly) straight spine. What

makes it different is that near the tip of the blade

the rest of the spine is “clipped” (has a section of the blade that is seemingly

removed) and forms the tip of the blade. The “clipped” section of the blade

can be either concave or straight and may even posses a false edge on the

spine which can be sharpened. This type of blade profile forms a much

finer, or needle like tip to the blade which makes it ideal for piercing or

cutting/slicing in tight spots. The tip of the blade is often either parallel to

the center of the blade or parallel to the spine of the blade. A clip point

blade with a tip that is parallel to the center of the blade has the advantage

of more control and force when piercing. Clip point blades are very popular

and can be found on a range of blades from pocket folders to large fix blade

hunting and fighting knives. The iconic American Bowie is a classic

example of a clip point blade.

Drop Point Blades

A drop point blade has a convex curve to the spine

as it approaches the tip of the blade. Or simply put,

the spine of the blade starts to “drop” towards the

tip of the blade where it meets the curve of the belly (edge) of the blade to

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 25 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

form the tip. The drop point blade profile creates a blade with a strong,

robust tip that is easy to direct when cutting or piercing. Ideal for everyday

carry and simple chores, the drop point profile is very popular and used on

a variety of pocket knives and fixed blade knives. The popular Swiss Army

Knife and many chefs’ knives feature a classic drop point profile.

Spear Point Blade

A spear point blade is a symmetrically

pointed blade with a tip that is in line with the

center line of the blade's axis. Generally formed

with double edges, a spear point blade is primarily used for piercing and is

considered a thrusting weapon known as a dagger (although dagger is a

broad term used for many types of blades across many cultures). Many

modifications throughout the years have produced a variety of single and

double edge spear point blades on fix blades and folders but the design is

generally not practical for everyday carry and is primarily used on tactical or

fighting knives.

Needle Point Blade

A needle point blade can be considered a variation

of the spear point blade but the symmetrical blade

tapers significantly to form the needle like tip.

Examples of needle point blades include stilettos and the Arkansas

Toothpick.

Spey Point Blade

A spey point blade is a straight edge blade that has

a sudden, defined curve near the tip of the blade.

The spine of the knife is also mostly straight, but

near the tip of the blade the spine angles downward quickly to meet the

curving edge and forms the tip of the blade. This allows the tip of the blade

to be slightly obtuse and unlikely to pierce accidentally when doing fine

work. This blade type was originally used for speying animals but has

become popular in trapper style knives for skinning and dressing animals

due to the muted tip on the blade.

Tanto Blade

A tanto style blade, sometimes referred to as a chisel

point blade, follows the tradition of Japanese swords

and daggers. This single edge blade has a straight

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 26 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

spine and a primarily straight edge until it approaches the tip of the blade.

Close to the tip of the blade, the edge angles upward to meet the spine at a

straight or slightly convex angle. This produces a very strong and durable

tip to the blade due to the blade thickness present at the tip, but also

slightly decreases its effectiveness for piercing. Tanto style blades have

become very popular for everyday carry folders and tactical fixed/folder

knifes. These blades can be difficult to sharpen due to the angle presented

at the tip of the blade but have found a home in modern knife culture as a

very popular blade type.

Sheepsfoot Blade

Sheepsfoot blades have a completely straight edge

with a spine that convexes down to meet the edge at

the “tip” of the blade. This design produces a very

safe knife with no actual “tip” to pierce with. Originally used to trim the

hooves on sheep, the sheepsfoot blade is popular for fine work such as

woodcarving or even electrical work. Sheepsfoot blades also have a long

history of being used on ships to cut rope because when a ship rocks

suddenly you are unlikely to stab yourself with the blade. Sheepsfoot

blades are great blades that don’t get enough use, the perfect blade type for

teaching wood carving, knife sharpening and knife skills for

newbies/children.

Hawkbill Blade

A hawkbill style blade is simply a blade that has a

concave cutting edge and a claw like shape.

Hawkbill blades don’t have much of a tip for piercing

but are ideal for cutting and carving, especially long

cuts like when installing carpet or linoleum. The shape of the blade and

cutting edge allows the hawkbill to grab material easily and reduces the risk

of accidently stabbing yourself if you slip up. Hawkbill blades also have a

long history of being used as a slashing weapon in eastern cultures. The

Hawkbill has also found resurgence as a defensive tool today with modern

tactical/fighting blades.

Although there are many, many variations of blades out there today, these

nine blade types cover the most common blade profile types you’ll find

today. These classic profiles are utilized worldwide and their uses honestly

depend on whose hand the knife is in. I personally really enjoy

simple/normal profile and drop point profile blades for my everyday carry

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 27 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

and outdoors knives, but I also use a variety of blades for woodworking and

utility, including sheepsfoot blades as well as hawkbill blades. I suggest

finding what knife feels the most comfortable for you and works for your

purposes. Make sure to take other peoples advice with a grain of salt. The

knife you carry is a personal affair and only you can determine what blade

type you prefer. Make sure to bookmark this blog, email it to a friend or add

our RSS feed. Stay tuned as we explore the anatomy of knives in my next

post. Stay an Edge above the Rest!

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 28 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Self-Check 1.1-3 (Multiple Choice)

INSTRUCTION: Write the letter of the correct answer in a separate sheet of

paper.

1. A blade refers to each side of the blade, often used to refer to the

section separate from the grind but can be used to refer to each side

of the blade, including the grind.

a. Tip or Point

b. Cheek or Face

c. Spine

d. Grind or Bevel

2. Is the cutting surface of a blade that extends from point to heel. It’s

the sharp part! And also, the reason I have gainful employment.

a. Spine

b. Grind

c. Edge

d. Belly

3. A blade refers to the curved section of the edge leading up to the tip.

a. Belly

b. Heel

c. Plunge

d. Ricasso

4. Is the unsharpened section of a blade, closest to the guard/handle.

a. Belly

b. Heel

c. Plunge

d. Ricasso

5. Refers to a knife tang that doesn’t fully extend and/or match the

width of the blade and handle material.

a. Partial Tang

b. Push Tang

c. Hidden Tang

d. Rat Tail and Stick Tangs

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 29 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Answer Key 1.1-3

1. B – Cheek or Face

2. C – Edge

3. A – belly

4. D – Ricasso

5. A – Partial Tang

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 30 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Information Sheet 1.1-4

Sharpen knife

Learning Objectives:

After reading this Information Sheet you should be able to:

1. Learn the different method in sharpening knife

2. The steps in sharpening knife in any method

Knife sharpening is the process of making a knife or similar

tool sharp by grinding against a hard, rough surface, typically a stone, or a

soft surface with hard particles, such as sandpaper. Additionally, a

leather razor strop, or strop, is often used to straighten and polish an edge.

Overview

The smaller the angle between the blade and stone, the sharper the knife

will be, but the less side force is needed to bend the edge over or chip it off.

The angle between the blade and the stone is the edge angle – the angle

from the vertical to one of the knife edges, and equals the angle at which the

blade is held. The total angle from one side to the other is called

the included angle – on a symmetric double-ground edge (a wedge shape),

the angle from one edge to the other is thus twice the edge angle. Typical

edge angles are about 20° (making the included angle 40° on a double-

ground edge).[1] The edge angle for very sharp knives can be as little as 10

degrees (for a 20° included angle). Knives that require a tough edge (such as

those that chop) may sharpen at 25° or more.

Different knives are sharpened differently according to grind (edge geometry)

and application. For example, surgical scalpels are extremely sharp but

fragile, and are generally disposed of, rather than sharpened, after

use. Straight razors used for shaving must cut with minimal pressure, and

thus must be very sharp with a small angle and often a hollow grind.

Typically these are stropped daily or more often. Kitchen knives are less

sharp, and generally cut by slicing rather than just pressing, and

are steeled daily. At the other extreme, an axe for chopping wood will be less

sharp still, and is primarily used to split wood by chopping, not by slicing,

and may be reground but will not be sharpened daily. In general, but not

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 31 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

always, the harder the material to be cut, the higher (duller) the angle of the

edge.

The composition of the stone affects the sharpness of the blade (a finer

grain, usually, though not always, produces sharper blades), as does the

composition of the blade (some metals take and keep an edge better than

others). For example, Western kitchen knives are usually made of softer

steel and take an edge angle of 20–22°, while East Asian kitchen knives are

traditionally of harder steel and take an edge angle of 15–18°. The Western-

style kitchen knives are generally in the range of 52–58 on the Rockwell

scale, which denotes the relative hardness of a material.

Method

Knife sharpening proceeds in several stages, in order from coarsest (most

destructive) to finest (most delicate). These may be referred to either by

the effect or by the tool. Naming by effect, the stages are:

1. sharpening: removing metal to form a new edge

1. rough sharpening (using either water stones, oil stones, or

medium grits of sandpaper in the scary sharp method of

sharpening)

2. fine sharpening (using the same tools as above, but in finer

grits)

2. straightening: straightening the existing metal on the blade, but not

removing significant quantities of metal

3. polishing (also called stropping): giving a mirror finish, but not

significantly altering the edge.

polishing may also be achieved by buffing a blade: instead of

moving the knife against a flat leather strop loaded with fine

abrasive, the knife is held still and a powered circular cloth wheel

is moved against the knife.

Named by tools, the same three stages are:

1. grinding (on a grinding wheel) or whetting (on a whetstone)

2. steeling, using a honing steel

3. stropping, on a razor strop or buffing on a wheel

The word "honing" is ambiguous, and may refer to either fine sharpening

(step 1.2) or straightening (step 2).

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 32 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

The finest level of sharpening is done most frequently, while the coarser

levels are done progressively more rarely, and sharpening methods differ

between blades and applications.

For example, a straight razor used for shaving is stropped before each use,

and may be stropped part-way through use, while it will be fine sharpened

on a stone a few times per year, and re-ground on a rough stone after

several years.

By contrast, a kitchen knife is steeled before or after each use (and may be

steeled during heavy use, as by butchers), and sharpened on a stone a few

times per year.

Blade damage

Blades are damaged primarily by buckling – compressive force, from being

pressed into a hard object, such as bone, ice, or a hard cutting board – and

by bending, from sideways pressure. Both of these tend to roll the edge of a

blade, due to metal's ductile nature.

Blades may also be damaged by being corroded by acid (as when cutting

lemons or tomatoes) or by high temperatures and corrosive chemicals in a

dishwasher.

If a knife is used as a scraper, a pry-bar, or encounters hard particles in

softer materials, there may be a sideways load at the tip, causing bending

damage.[2]

Blade damage is avoided by:

using an appropriate blade for the task – a thinner blade for more

delicate work, and a thicker blade whenever a thinner blade is not

required (e.g. a thinner blade might be used to cut fillets, butterfly steak

or roast for stuffing, or perform Mukimono, while a thicker one might be

used to slice or chop repeatedly, separate primal cuts of poultry or small

game, or scrape and trim fat from meat or hide, as these actions would

be more likely to cause unnecessary wear on a thinner blade.)

using a soft cutting surface,

straight cutting, with no side-to-side movement,

immediate cleaning.

oiling (with food grade oil if appropriate)

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 33 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Sharpen a Knife

Cutting with a dull knife can be dangerous. Having to work harder to slice

through whatever you’re cutting means you’re more likely to cut yourself.

Fortunately, it’s easy to sharpen a knife yourself with a whetstone, a honing

rod, or even a coffee mug.

If you want to sharpen a knife with a whetstone, hold the knife against the

rough side of the stone at an angle of about 17°-20°, or use an angle guide

to help hold the knife at a consistent angle. Grind the knife slowly

downwards against the stone continuously until you have ground about

halfway through the sharp end of the blade. Then, flip the knife over and

sharpen the other side. Finish by smoothing both sides of the blade on the

finer side of the whetstone. Keep reading to learn how to sharpen a knife

using a coffee mug!

Using a Whetstone or a Diamond Stone

Pick an angle to sharpen your knife. If

you already know what angle your knife

is sharpened at, you'll probably wish to

sharpen it at this angle again.

Sharpening at a different angle will take

significantly more time and may take a

few goes before any rough angles are

smoothed out.

If you don't know the current angle, ask the manufacturer of your

knife or inquire at a knowledgeable knife shop to determine what

angle is appropriate for your knife.

If you have to make a gut decision, choose an angle of 10° - 30° per

side. Shallower angles make a sharper edge that doesn't last as

long; steeper angles are more durable, so 17° - 20° is a good

compromise between the two.

Lubricate your whetstone or diamond

stone with a small amount of mineral oil.

Look for honing oil, a light kind of mineral

oil. Honing oil will both lubricate the

whetstone, making it easier for the blade of

the knife to pass over the stone, as well as

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 34 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

keep the steel shavings (the by-product of sharpening) from clogging the

stone's pores.

Check with the manufacturer's guidelines for your stone regarding

lubrication. The most common sharpening stones are carborundum

stones, and are designed to be used wet or dry, but are destroyed

when oiled. However, there are some stones that are specifically

designed for oil, and will generally be labeled as "oil stones".

Use an angle guide to control your edge's

angle, if available. A sharpening guide is a

small tool that's placed underneath the

knife in order to maintain a constant angle

when scraping the knife across the surface

of the stone.[2] Otherwise, you will have to

control the angle by hand, which is hard

and requires a well-formed perception of

angles.

One of the most difficult aspects of sharpening a knife is getting the

angle right. To make this process a bit easier, try painting the very tip

of both sides of your blade with a sharpie pen. Then, throughout the

sharpening, inspect whether the marker is being removed during the

process.[3]

Start off on the rough grit side of the stone. Check the grit on your stone,

or the packaging that came with the stone, to identify which is which. In

general, whetstones and diamond stones each have different grits on either

side. The rough grit side is used to grind the steel down, while the fine grit

side is used to sharpen or hone the knife. The grinding process comes first,

so you start on the rough grit side.

For a symmetrical edge, sharpen the knife by dragging it across the

stone in the opposite direction you would move it to slice a thin layer

off the stone. This allows a burr to form and prolongs the stone's life.

Continue grinding at this angle until your grind goes roughly halfway

through the steel. This doesn't need to be precise, just well-estimated. For

a one-sided edge ("scandi grind", "chisel grind", etc.), do not flip the knife

when instructed to do so by this article.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 35 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Flip the knife over and sharpen the other side of the blade until you

create a new edge. The easiest way to determine that you have removed

enough metal is to sharpen until you have raised a burr, a feature that steel

will naturally form when one bevel is ground until it meets another.

Burrs will generally be too small to see, but you can feel it

scraping/catching on your thumb if you stroke away (dull side of the

knife to the sharp) from the edge. Finer stones produce smaller

burrs, but they are still there.

Flip the stone over and begin sharpening one side the blade, this time

using the finer grit. Your goal here is to smooth over and eliminate the

burrs created by sharpening the knife over the coarser grit. This transforms

the blade edge from a ground edge into a finer, honed edge.

Flip the knife and begin sharpening the one side of the knife on the

fine grit side of the stone. Again, make sure you hit both sides of the knife

with the fine grit.

Begin alternating swipes on the fine grit. Sharpen one side of the knife

with a single stroke, then immediately flip the knife and sharpen the other

side. Do this several times for the best result.

If you wish, further polish or even strop the edge to the desired

sharpness. This makes the edge better suited for "push cutting" (cutting

directly into materials, pushing straight down without sliding the blade

across the object) but generally impairs slicing ability: without the

"microscopic serrations" left by grinding with a stone, the blade tends to not

bite into things like tomato skins.

Using a Honing Rod (Sharpening Steel)

Use a honing rod in between sharpenings

to keep your blade from degrading. The

honing rod, or simply "steel" as they're often

called, aren't normally used to resuscitate a

dull blade from the proverbial graveyard.

Instead, they're often used to keep knives

sharp in between use.

Date Developed: Document No. PFB751335

Housekeeping NCII August 2018 Issued by:

Page 36 of 43

QA System CBLMs on Handling and Developed by:

Sharpening Knives Agaton B. Francia

Revision # 01

Using a honing rod regularly delays the need to use a whetstone or

a diamond. This is a good thing: Using whetstones and diamonds

shave metal from the edge of your blade, reducing the knife's

lifespan. The less you use your whetstone, the longer your knives

will thrive.

o What does a honing rod do? A honing rod realigns the

metal in a blade, massaging small nicks, indentations,

and flat spots away. Compared to a whetstone, it does not

remove any significant amount of metal from the blade of

the knife.

Hold the honing rod in your non-dominant hand. The rod should be held

at a comfortable angle facing away from your body. The rod tip should be

elevated above the rod handle.

Hold the knife firmly in your dominant hand. Your four fingers should be

holding onto the handle, while your thumb can be placed on the spine of the

knife, far away from the blade edge.

Hold your knife at approximately 20° in relation to the honing

rod. Your angle doesn't need to be exact, just approximate. Whatever angle

you decide to choose, or unwittingly end up choosing, make sure to

maintain the same angle throughout the honing process. Changing the