Professional Documents

Culture Documents

Thru Flush Specifications

Thru Flush Specifications

Uploaded by

Riego Fertirrigacion Riego SustentableCopyright:

Available Formats

You might also like

- o & M Instruction Manual (Rapid Gravity Filter)Document68 pageso & M Instruction Manual (Rapid Gravity Filter)ahmed salam100% (1)

- Manual of Abacre Points of Sale, POSDocument26 pagesManual of Abacre Points of Sale, POSdarwinism100% (1)

- Mini-Media - Irrigation Sand Media: Product SpecificationsDocument1 pageMini-Media - Irrigation Sand Media: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Flush - Screen Filters: Product SpecificationsDocument1 pageMaxi-Flush - Screen Filters: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Clean SpecificationsDocument1 pageMaxi-Clean SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Sand Media Stainless Steel SpecificationsDocument1 pageSand Media Stainless Steel SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Filtration SystemDocument11 pagesFiltration Systemwaleed.murad@gmail.comNo ratings yet

- Tender Specifications-Exhaust SystemDocument6 pagesTender Specifications-Exhaust Systemgullipalli srinivasa raoNo ratings yet

- Dual Media Filters - O&M - ManualDocument17 pagesDual Media Filters - O&M - Manualmasoodism100% (1)

- Cartridge Filter Application NotesDocument5 pagesCartridge Filter Application NotesSamik MukherjeeNo ratings yet

- MAK_MITA_Cloth-Filtration-Brochure-ENGDocument8 pagesMAK_MITA_Cloth-Filtration-Brochure-ENG2014200481No ratings yet

- LS 023 PWC Sample SpecsDocument2 pagesLS 023 PWC Sample SpecsRaja TouseefNo ratings yet

- Filtration Systems With Pile Cloth Filter MediaDocument8 pagesFiltration Systems With Pile Cloth Filter MediaSagnik DasNo ratings yet

- MRO 4-V Specifications (6-176)Document5 pagesMRO 4-V Specifications (6-176)jmharrison3196No ratings yet

- 30-36 Filter ManualDocument10 pages30-36 Filter ManualDavid RodriguezNo ratings yet

- Micron S602 ECODocument4 pagesMicron S602 ECOTan Kang YaoNo ratings yet

- Premium Multi-Stage Whole House Filter System W/ 0.5 Micron Carbon BlockDocument5 pagesPremium Multi-Stage Whole House Filter System W/ 0.5 Micron Carbon BlockzacxblueNo ratings yet

- UHP Spec Essentials Rev2 PDFDocument17 pagesUHP Spec Essentials Rev2 PDFfaisal abbasNo ratings yet

- 21 20Document1 page21 20Renata ReljacNo ratings yet

- Water Production and TreatmentDocument8 pagesWater Production and TreatmentSolMonteroNo ratings yet

- SEC 15490 Swimming PoolsDocument8 pagesSEC 15490 Swimming Poolsjaianit89No ratings yet

- LS 035 JPX Spec SheetDocument6 pagesLS 035 JPX Spec SheetRaja TouseefNo ratings yet

- Cartridge FiltersDocument7 pagesCartridge FiltersMohamed TallyNo ratings yet

- Rev0617Document7 pagesRev0617eduardo corsNo ratings yet

- Reskem ResinmediatrapsDocument2 pagesReskem ResinmediatrapsdeyprasenNo ratings yet

- Outer Scraper Self-Cleaning Filter CatalogueDocument1 pageOuter Scraper Self-Cleaning Filter CatalogueCarlos BarriosNo ratings yet

- 01 Filtrazione-EN SPDocument40 pages01 Filtrazione-EN SPNermeen ElmelegaeNo ratings yet

- Installation and Service Guide: Please Read This Manual Carefully Before Attempting InstallationDocument9 pagesInstallation and Service Guide: Please Read This Manual Carefully Before Attempting InstallationNazım TolaNo ratings yet

- 259-Swimming Pool Quote-40 Feet X 12feet-1Document3 pages259-Swimming Pool Quote-40 Feet X 12feet-1Mohit SharmaNo ratings yet

- Precoate Filtration EquipmentDocument8 pagesPrecoate Filtration Equipmenthansenmike698105No ratings yet

- PR BW600Document8 pagesPR BW600tata_77No ratings yet

- Split FlowDocument8 pagesSplit Flowrimi7alNo ratings yet

- LS 036 JPL Spec SheetDocument4 pagesLS 036 JPL Spec SheetRaja TouseefNo ratings yet

- US600A B ManualDocument8 pagesUS600A B ManualebevmNo ratings yet

- Sanicom & Sanitop Installation GuideDocument9 pagesSanicom & Sanitop Installation GuideSimona Maria PruteanuNo ratings yet

- De Pura DoraDocument53 pagesDe Pura DoraKenneth BlackNo ratings yet

- Coarse Sand Media:: Volume 2-Employer's Requirements Sewage Treatment Plant at KaggadasapuraDocument5 pagesCoarse Sand Media:: Volume 2-Employer's Requirements Sewage Treatment Plant at Kaggadasapurasharan kommiNo ratings yet

- Austin Catalogue - Small 2Document148 pagesAustin Catalogue - Small 2alexesc100% (1)

- Filtomat M100-6800 - GRPDocument17 pagesFiltomat M100-6800 - GRPJose Angel Malpica PNo ratings yet

- Commercial Offer About The PET Washing Line, Capacity 1000 KG/HDocument13 pagesCommercial Offer About The PET Washing Line, Capacity 1000 KG/HAnkitNo ratings yet

- Standard Specification: 2.10.3 Pressure FiltersDocument8 pagesStandard Specification: 2.10.3 Pressure FiltersmakcodetechNo ratings yet

- SeriesDocument4 pagesSeriesteguheafNo ratings yet

- Facts at Your Fingertips-201008-Heat Transfer Fluids System FiltrationDocument1 pageFacts at Your Fingertips-201008-Heat Transfer Fluids System Filtrationonizuka-t2263No ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p13-16Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p13-16SonNguyenNo ratings yet

- ElectroFin Coil Cleaning RecommendationsDocument3 pagesElectroFin Coil Cleaning RecommendationsHarry A HartmanNo ratings yet

- Installation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsDocument6 pagesInstallation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsSunil TiwariNo ratings yet

- Safespill Floor HF - Product DescriptionDocument2 pagesSafespill Floor HF - Product DescriptionskgefrcNo ratings yet

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- Reverse Osmosis System Quotation For RO System 20m /H Recovery Rate 73%Document6 pagesReverse Osmosis System Quotation For RO System 20m /H Recovery Rate 73%tata_77No ratings yet

- Filters For Compressed Air: Product InformationDocument16 pagesFilters For Compressed Air: Product InformationAnthony JamesNo ratings yet

- Engineering Town (Noor Qadir)Document5 pagesEngineering Town (Noor Qadir)Shahid MughalNo ratings yet

- Eaton Tubular Backwashing AFC AFR & F-Series FiltersDocument14 pagesEaton Tubular Backwashing AFC AFR & F-Series FiltersJuan CarvajalNo ratings yet

- Therminol Bulletin 3 - FiltrationDocument4 pagesTherminol Bulletin 3 - FiltrationAnonymous 20VAruNo ratings yet

- MRO 4-LP RO Specifications (6-183)Document5 pagesMRO 4-LP RO Specifications (6-183)sanusiibrahimNo ratings yet

- Size Drawing Number Name Date CTC PF Name Date 5/27/2009 RevDocument3 pagesSize Drawing Number Name Date CTC PF Name Date 5/27/2009 RevJelena Kalc100% (1)

- Skid Pack: Monoblock-FilterDocument55 pagesSkid Pack: Monoblock-FilterAsuncion Gomez-Cambronero LoroNo ratings yet

- Jabsco Deluxe Toilets Eng PDFDocument9 pagesJabsco Deluxe Toilets Eng PDFurania22000No ratings yet

- Service FiltrosDocument43 pagesService FiltrosVpemuNo ratings yet

- E7709 3 06 12 - RF3 - WebDocument8 pagesE7709 3 06 12 - RF3 - WebNicolas Alvarez GomezNo ratings yet

- Installation GuideDocument7 pagesInstallation GuideJake SmithNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Separators Specifications IrrigationDocument1 pageSeparators Specifications IrrigationRiego Fertirrigacion Riego SustentableNo ratings yet

- Sand Media Stainless Steel SpecificationsDocument1 pageSand Media Stainless Steel SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Mini-Media - Irrigation Sand Media: Product SpecificationsDocument1 pageMini-Media - Irrigation Sand Media: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Clean SpecificationsDocument1 pageMaxi-Clean SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Flush - Screen Filters: Product SpecificationsDocument1 pageMaxi-Flush - Screen Filters: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- IRRBIN111 WarrantyDocument2 pagesIRRBIN111 WarrantyRiego Fertirrigacion Riego SustentableNo ratings yet

- An Introduction To Closed Loop MarketingDocument40 pagesAn Introduction To Closed Loop MarketingGeorgiana VasilescuNo ratings yet

- Manual Ex Rated DBDocument37 pagesManual Ex Rated DBAFSALNo ratings yet

- Endpd PDFDocument29 pagesEndpd PDFNaveen AgrawalNo ratings yet

- Syllabus MAN 5322 Technology & Operations Management (Core Courses)Document7 pagesSyllabus MAN 5322 Technology & Operations Management (Core Courses)Ardian SyahNo ratings yet

- Milwaukee Sales FlyerDocument11 pagesMilwaukee Sales FlyerJason GodwinNo ratings yet

- ETS100 Parameters Sheet ResetDocument2 pagesETS100 Parameters Sheet Resetbelarofonte88No ratings yet

- Relays and SwitchesDocument5 pagesRelays and SwitchesBattinapati ShivaNo ratings yet

- USP797GCDocument25 pagesUSP797GCTuan NguyenNo ratings yet

- Vctds 02324 Figure 4020a enDocument5 pagesVctds 02324 Figure 4020a enFreddy Gómez GuillénNo ratings yet

- 1.EBS1 EPFA76 EBPI SPPA 1001 D01 External Cathodic Protection SpecificationDocument27 pages1.EBS1 EPFA76 EBPI SPPA 1001 D01 External Cathodic Protection SpecificationRedhaa .kNo ratings yet

- ATV600 Getting Started en EAV63253 03Document4 pagesATV600 Getting Started en EAV63253 03Pustinjak SaharicNo ratings yet

- Gasliftequipments PDFDocument51 pagesGasliftequipments PDFSufian R EllabbadNo ratings yet

- Physics Formula Sheet PDFDocument4 pagesPhysics Formula Sheet PDFSuneel KumarsinghNo ratings yet

- Fix 3Document12 pagesFix 3Eng TrNo ratings yet

- References STP Aviation EnglishDocument9 pagesReferences STP Aviation Englishexemplo55509No ratings yet

- Ef-10 Duty: Laboratory Building Hvac Airflow and Control DiagramDocument1 pageEf-10 Duty: Laboratory Building Hvac Airflow and Control DiagrampNo ratings yet

- Spin Coat Organic CompoundsDocument6 pagesSpin Coat Organic CompoundsMatthew WrightNo ratings yet

- Safety Policy Statement For EmployeesDocument139 pagesSafety Policy Statement For Employeesapi-268196629100% (1)

- Series Solutions Airy's EquationDocument5 pagesSeries Solutions Airy's Equationtarun gehlotNo ratings yet

- 1974 Ski DooDocument292 pages1974 Ski DooVincent RoyNo ratings yet

- Submersible Pump Research PaperDocument8 pagesSubmersible Pump Research Paperjcrfwerif100% (1)

- Spez KR CYBERTECH Nano en PDFDocument161 pagesSpez KR CYBERTECH Nano en PDFRahulRChpoudhariNo ratings yet

- What'S New in Websphere Message Broker: Jonathan WoodfordDocument26 pagesWhat'S New in Websphere Message Broker: Jonathan WoodfordRajsekhar PillatuNo ratings yet

- NewFunctions enDocument3 pagesNewFunctions enGeo PuiuNo ratings yet

- QuantelRio Release Notes V4.4.1Document17 pagesQuantelRio Release Notes V4.4.1Darius WhiteNo ratings yet

- Chilled Water1Document2 pagesChilled Water1lhhjklll0% (1)

- Remote Sensing PresentationDocument18 pagesRemote Sensing PresentationShoaibNo ratings yet

- Datasheet 40 PDFDocument1 pageDatasheet 40 PDFRezaadityamuhaNo ratings yet

- Git Hub PDF Cheat SheetDocument2 pagesGit Hub PDF Cheat SheetasdkuvheriugbzjNo ratings yet

Thru Flush Specifications

Thru Flush Specifications

Uploaded by

Riego Fertirrigacion Riego SustentableOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thru Flush Specifications

Thru Flush Specifications

Uploaded by

Riego Fertirrigacion Riego SustentableCopyright:

Available Formats

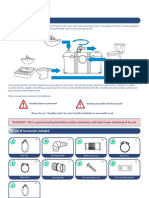

THRU-FLUSH | SS SERIES STAINLESS STEEL SCREEN FILTERS

PRODUCT SPECIFICATIONS

General: The filtration system shall remove suspended solids down to 75 microns (depending on

screen mesh selection) from the water source. The filter system is shipped unassembled

and shall include filters, interconnecting piping, valves, gauges, fittings and optional automatic

controls. Screen sizes available in 40, 80,100,150, and 200 mesh. Pressure drop through the

filter at maximum rated flow shall not exceed 3 PSI.

Filter Tanks: Filter tanks shall be fabricated of Type 304 stainless steel and shall feature a safety lock lid

closure assembly. After fabrication the filter housing shall be passivated for enhanced

corrosion protection.

Piping: The filter system shall be provided with carbon steel inlet and outlet piping. Piping shall be

connected with grooved type couplings. The filter system piping shall be sandblasted and

fusion epoxy lined standard. "Wet applied" epoxy coating systems shall not be used as an

environmental coating.

Valving: Automatic or manual "Thru-Flush" valves are provided for filter flushing. Valves shall be

assembled using grooved type couplings.

Screen Filter The filter cartridge shall be constructed of noncorrosive polymeric materials and stainless

Cartridge: steel. The cartridge shall feature a pre-filter chamber (for removal of coarse materials) and a

fine mesh filtration chamber. These portions of the cartridge shall be "O" ring sealed between

the dirty water and clean water areas. Fine filtration mesh shall be polymeric material. All

screen mesh shall be replaceable through manual disassembly of the cartridge (no tools

required). The fine mesh screen shall be supported in the cartridge by use of a polyethylene

intermediate weave for optimum screen mesh utilization. Through the use of the intermediate

weave 100% of the screen surface shall be utilized. Where coarse filtration objectives are

established fine mesh filtration may be substituted with 1/16" or 1/32" perforated stainless

steel cartridge construction.

Automatic The filter system will include a solid state automatic controller. This controller will provide

Controls: labor saving, unattended automatic backflush on a time selected interval. In addition, there

(Optional) will be included an automatic pressure differential override safety circuit. The filters are

assured of being cleaned on a time scheduled basis, however, should the source water

quality vary and pressure differential develop to a preset limit prior to the backwash time, the

P.D. circuit will activate a backwash cycle. Controller shall be 110 VAC or 12 VDC powered.

Filter Flushing: The filter shall feature a flushing capability for removal of suspended solids. The filter shall

utilize the "Thru-Flush" action of the filter for dirt removal without the use of moving parts.

Flush duration shall be 30 seconds or less.

Fusion Bonded The filter piping shall be lined with Yardney Type 134 fusion bonded epoxy. All metal

Epoxy Lining: surfaces shall be sandblasted to a white metal condition prior to epoxy application. Metal

surfaces shall be preheated to 450°F prior to electrostatic application of the powder coating.

After coating, application parts shall be cured at 400°F for a minimum of 20 minutes.

Application shall provide an even holiday free lining of the thermoset epoxy powder coating 8-

10 mils. thick. The coating material is nontoxic and is approved for potable water application.

YLT502-05-2015

6666 Box Springs Blvd. | Riverside, CA 92507 | T 951.656.6716 | F 951.656.3867 | yardneyfilters.com

You might also like

- o & M Instruction Manual (Rapid Gravity Filter)Document68 pageso & M Instruction Manual (Rapid Gravity Filter)ahmed salam100% (1)

- Manual of Abacre Points of Sale, POSDocument26 pagesManual of Abacre Points of Sale, POSdarwinism100% (1)

- Mini-Media - Irrigation Sand Media: Product SpecificationsDocument1 pageMini-Media - Irrigation Sand Media: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Flush - Screen Filters: Product SpecificationsDocument1 pageMaxi-Flush - Screen Filters: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Clean SpecificationsDocument1 pageMaxi-Clean SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Sand Media Stainless Steel SpecificationsDocument1 pageSand Media Stainless Steel SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Filtration SystemDocument11 pagesFiltration Systemwaleed.murad@gmail.comNo ratings yet

- Tender Specifications-Exhaust SystemDocument6 pagesTender Specifications-Exhaust Systemgullipalli srinivasa raoNo ratings yet

- Dual Media Filters - O&M - ManualDocument17 pagesDual Media Filters - O&M - Manualmasoodism100% (1)

- Cartridge Filter Application NotesDocument5 pagesCartridge Filter Application NotesSamik MukherjeeNo ratings yet

- MAK_MITA_Cloth-Filtration-Brochure-ENGDocument8 pagesMAK_MITA_Cloth-Filtration-Brochure-ENG2014200481No ratings yet

- LS 023 PWC Sample SpecsDocument2 pagesLS 023 PWC Sample SpecsRaja TouseefNo ratings yet

- Filtration Systems With Pile Cloth Filter MediaDocument8 pagesFiltration Systems With Pile Cloth Filter MediaSagnik DasNo ratings yet

- MRO 4-V Specifications (6-176)Document5 pagesMRO 4-V Specifications (6-176)jmharrison3196No ratings yet

- 30-36 Filter ManualDocument10 pages30-36 Filter ManualDavid RodriguezNo ratings yet

- Micron S602 ECODocument4 pagesMicron S602 ECOTan Kang YaoNo ratings yet

- Premium Multi-Stage Whole House Filter System W/ 0.5 Micron Carbon BlockDocument5 pagesPremium Multi-Stage Whole House Filter System W/ 0.5 Micron Carbon BlockzacxblueNo ratings yet

- UHP Spec Essentials Rev2 PDFDocument17 pagesUHP Spec Essentials Rev2 PDFfaisal abbasNo ratings yet

- 21 20Document1 page21 20Renata ReljacNo ratings yet

- Water Production and TreatmentDocument8 pagesWater Production and TreatmentSolMonteroNo ratings yet

- SEC 15490 Swimming PoolsDocument8 pagesSEC 15490 Swimming Poolsjaianit89No ratings yet

- LS 035 JPX Spec SheetDocument6 pagesLS 035 JPX Spec SheetRaja TouseefNo ratings yet

- Cartridge FiltersDocument7 pagesCartridge FiltersMohamed TallyNo ratings yet

- Rev0617Document7 pagesRev0617eduardo corsNo ratings yet

- Reskem ResinmediatrapsDocument2 pagesReskem ResinmediatrapsdeyprasenNo ratings yet

- Outer Scraper Self-Cleaning Filter CatalogueDocument1 pageOuter Scraper Self-Cleaning Filter CatalogueCarlos BarriosNo ratings yet

- 01 Filtrazione-EN SPDocument40 pages01 Filtrazione-EN SPNermeen ElmelegaeNo ratings yet

- Installation and Service Guide: Please Read This Manual Carefully Before Attempting InstallationDocument9 pagesInstallation and Service Guide: Please Read This Manual Carefully Before Attempting InstallationNazım TolaNo ratings yet

- 259-Swimming Pool Quote-40 Feet X 12feet-1Document3 pages259-Swimming Pool Quote-40 Feet X 12feet-1Mohit SharmaNo ratings yet

- Precoate Filtration EquipmentDocument8 pagesPrecoate Filtration Equipmenthansenmike698105No ratings yet

- PR BW600Document8 pagesPR BW600tata_77No ratings yet

- Split FlowDocument8 pagesSplit Flowrimi7alNo ratings yet

- LS 036 JPL Spec SheetDocument4 pagesLS 036 JPL Spec SheetRaja TouseefNo ratings yet

- US600A B ManualDocument8 pagesUS600A B ManualebevmNo ratings yet

- Sanicom & Sanitop Installation GuideDocument9 pagesSanicom & Sanitop Installation GuideSimona Maria PruteanuNo ratings yet

- De Pura DoraDocument53 pagesDe Pura DoraKenneth BlackNo ratings yet

- Coarse Sand Media:: Volume 2-Employer's Requirements Sewage Treatment Plant at KaggadasapuraDocument5 pagesCoarse Sand Media:: Volume 2-Employer's Requirements Sewage Treatment Plant at Kaggadasapurasharan kommiNo ratings yet

- Austin Catalogue - Small 2Document148 pagesAustin Catalogue - Small 2alexesc100% (1)

- Filtomat M100-6800 - GRPDocument17 pagesFiltomat M100-6800 - GRPJose Angel Malpica PNo ratings yet

- Commercial Offer About The PET Washing Line, Capacity 1000 KG/HDocument13 pagesCommercial Offer About The PET Washing Line, Capacity 1000 KG/HAnkitNo ratings yet

- Standard Specification: 2.10.3 Pressure FiltersDocument8 pagesStandard Specification: 2.10.3 Pressure FiltersmakcodetechNo ratings yet

- SeriesDocument4 pagesSeriesteguheafNo ratings yet

- Facts at Your Fingertips-201008-Heat Transfer Fluids System FiltrationDocument1 pageFacts at Your Fingertips-201008-Heat Transfer Fluids System Filtrationonizuka-t2263No ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p13-16Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p13-16SonNguyenNo ratings yet

- ElectroFin Coil Cleaning RecommendationsDocument3 pagesElectroFin Coil Cleaning RecommendationsHarry A HartmanNo ratings yet

- Installation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsDocument6 pagesInstallation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsSunil TiwariNo ratings yet

- Safespill Floor HF - Product DescriptionDocument2 pagesSafespill Floor HF - Product DescriptionskgefrcNo ratings yet

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- Reverse Osmosis System Quotation For RO System 20m /H Recovery Rate 73%Document6 pagesReverse Osmosis System Quotation For RO System 20m /H Recovery Rate 73%tata_77No ratings yet

- Filters For Compressed Air: Product InformationDocument16 pagesFilters For Compressed Air: Product InformationAnthony JamesNo ratings yet

- Engineering Town (Noor Qadir)Document5 pagesEngineering Town (Noor Qadir)Shahid MughalNo ratings yet

- Eaton Tubular Backwashing AFC AFR & F-Series FiltersDocument14 pagesEaton Tubular Backwashing AFC AFR & F-Series FiltersJuan CarvajalNo ratings yet

- Therminol Bulletin 3 - FiltrationDocument4 pagesTherminol Bulletin 3 - FiltrationAnonymous 20VAruNo ratings yet

- MRO 4-LP RO Specifications (6-183)Document5 pagesMRO 4-LP RO Specifications (6-183)sanusiibrahimNo ratings yet

- Size Drawing Number Name Date CTC PF Name Date 5/27/2009 RevDocument3 pagesSize Drawing Number Name Date CTC PF Name Date 5/27/2009 RevJelena Kalc100% (1)

- Skid Pack: Monoblock-FilterDocument55 pagesSkid Pack: Monoblock-FilterAsuncion Gomez-Cambronero LoroNo ratings yet

- Jabsco Deluxe Toilets Eng PDFDocument9 pagesJabsco Deluxe Toilets Eng PDFurania22000No ratings yet

- Service FiltrosDocument43 pagesService FiltrosVpemuNo ratings yet

- E7709 3 06 12 - RF3 - WebDocument8 pagesE7709 3 06 12 - RF3 - WebNicolas Alvarez GomezNo ratings yet

- Installation GuideDocument7 pagesInstallation GuideJake SmithNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Separators Specifications IrrigationDocument1 pageSeparators Specifications IrrigationRiego Fertirrigacion Riego SustentableNo ratings yet

- Sand Media Stainless Steel SpecificationsDocument1 pageSand Media Stainless Steel SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Mini-Media - Irrigation Sand Media: Product SpecificationsDocument1 pageMini-Media - Irrigation Sand Media: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Clean SpecificationsDocument1 pageMaxi-Clean SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- Maxi-Flush - Screen Filters: Product SpecificationsDocument1 pageMaxi-Flush - Screen Filters: Product SpecificationsRiego Fertirrigacion Riego SustentableNo ratings yet

- IRRBIN111 WarrantyDocument2 pagesIRRBIN111 WarrantyRiego Fertirrigacion Riego SustentableNo ratings yet

- An Introduction To Closed Loop MarketingDocument40 pagesAn Introduction To Closed Loop MarketingGeorgiana VasilescuNo ratings yet

- Manual Ex Rated DBDocument37 pagesManual Ex Rated DBAFSALNo ratings yet

- Endpd PDFDocument29 pagesEndpd PDFNaveen AgrawalNo ratings yet

- Syllabus MAN 5322 Technology & Operations Management (Core Courses)Document7 pagesSyllabus MAN 5322 Technology & Operations Management (Core Courses)Ardian SyahNo ratings yet

- Milwaukee Sales FlyerDocument11 pagesMilwaukee Sales FlyerJason GodwinNo ratings yet

- ETS100 Parameters Sheet ResetDocument2 pagesETS100 Parameters Sheet Resetbelarofonte88No ratings yet

- Relays and SwitchesDocument5 pagesRelays and SwitchesBattinapati ShivaNo ratings yet

- USP797GCDocument25 pagesUSP797GCTuan NguyenNo ratings yet

- Vctds 02324 Figure 4020a enDocument5 pagesVctds 02324 Figure 4020a enFreddy Gómez GuillénNo ratings yet

- 1.EBS1 EPFA76 EBPI SPPA 1001 D01 External Cathodic Protection SpecificationDocument27 pages1.EBS1 EPFA76 EBPI SPPA 1001 D01 External Cathodic Protection SpecificationRedhaa .kNo ratings yet

- ATV600 Getting Started en EAV63253 03Document4 pagesATV600 Getting Started en EAV63253 03Pustinjak SaharicNo ratings yet

- Gasliftequipments PDFDocument51 pagesGasliftequipments PDFSufian R EllabbadNo ratings yet

- Physics Formula Sheet PDFDocument4 pagesPhysics Formula Sheet PDFSuneel KumarsinghNo ratings yet

- Fix 3Document12 pagesFix 3Eng TrNo ratings yet

- References STP Aviation EnglishDocument9 pagesReferences STP Aviation Englishexemplo55509No ratings yet

- Ef-10 Duty: Laboratory Building Hvac Airflow and Control DiagramDocument1 pageEf-10 Duty: Laboratory Building Hvac Airflow and Control DiagrampNo ratings yet

- Spin Coat Organic CompoundsDocument6 pagesSpin Coat Organic CompoundsMatthew WrightNo ratings yet

- Safety Policy Statement For EmployeesDocument139 pagesSafety Policy Statement For Employeesapi-268196629100% (1)

- Series Solutions Airy's EquationDocument5 pagesSeries Solutions Airy's Equationtarun gehlotNo ratings yet

- 1974 Ski DooDocument292 pages1974 Ski DooVincent RoyNo ratings yet

- Submersible Pump Research PaperDocument8 pagesSubmersible Pump Research Paperjcrfwerif100% (1)

- Spez KR CYBERTECH Nano en PDFDocument161 pagesSpez KR CYBERTECH Nano en PDFRahulRChpoudhariNo ratings yet

- What'S New in Websphere Message Broker: Jonathan WoodfordDocument26 pagesWhat'S New in Websphere Message Broker: Jonathan WoodfordRajsekhar PillatuNo ratings yet

- NewFunctions enDocument3 pagesNewFunctions enGeo PuiuNo ratings yet

- QuantelRio Release Notes V4.4.1Document17 pagesQuantelRio Release Notes V4.4.1Darius WhiteNo ratings yet

- Chilled Water1Document2 pagesChilled Water1lhhjklll0% (1)

- Remote Sensing PresentationDocument18 pagesRemote Sensing PresentationShoaibNo ratings yet

- Datasheet 40 PDFDocument1 pageDatasheet 40 PDFRezaadityamuhaNo ratings yet

- Git Hub PDF Cheat SheetDocument2 pagesGit Hub PDF Cheat SheetasdkuvheriugbzjNo ratings yet