Professional Documents

Culture Documents

SOP FOR Drainer Inspection

SOP FOR Drainer Inspection

Uploaded by

uvsubhadraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP FOR Drainer Inspection

SOP FOR Drainer Inspection

Uploaded by

uvsubhadraCopyright:

Available Formats

SOP FOR inspection of drainer

1. Layout sketch of the gas pipeline where drainer inspection has to be done should be

available.

2. The drainer of gas pipeline to be inspected should be first thoroughly visual inspected for

any leakage point or locations at which temporary epoxy repair has been carried out.

Such points may have gas leakage during inspection.

3. It should be clear what type of drainer is being inspected. Whether it is CO, BF,LD or from

Mixed gas high pressure, low pressure.

4. During inspection of the drainer before opening the inspection nipple, ensure your

position is opposite the wind direction and your co gas monitor is calibrated and on.

5. If there is no gas coming from the inspection nipple than use a welding rod to poke

inside.

6. If still no gas than it is confirmed that there is choking on upper valve or cone. It should

informed to shift in charge and mention in log book.

7. Approach to the all valves like Upper valve, lower valve, inspection nipple are clear.

8. Approach to the drainer is should be clear. If there are any obstruction it should be

removed or informed to shift in charge.

9. Strength of platform and ladder should be checked before using it.

10. Simply operate the lower valve and upper valve to check its working, it should not be

fully tight with spanner to avoid the falling stuck-up of the gate of valve.

11. Syphon of the drainer should be check properly. If there is any choking use light

hammering to clear it . Should not be over hammer.

12. Thoroughly check the condensate pipe of the drainer for any leakage or rusting. If there

is any leakage it should informed to shift in charge and mention in log book.

13. Drainer pot is also checked thoroughly for any leaking of water. If there is any leakage

then lower valve should be closed and informed to shift in charge and gas safety.

14. Thoroughly checked the condensate water are dripping through the syphon. If not then

checked for water inside the drain pot. If there is sufficient water inside the drain pot it

may be choking in syphon. It should be clear by above said method and report the shift in

charge.

15. Drainer bleeder should be checked properly for rusting.

16. Oiling of all valves is to be done in every inspection .

17. After every inspection all observation should be logged in drainer register properly and if

there is any problem it should be informed to shift in charge or related agency.

18. After proper inspection before leaving the place, check the area by co gas monitor.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Ez32 CardDocument10 pagesEz32 Carduvsubhadra0% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Oracle Siebel Application TestingDocument27 pagesOracle Siebel Application TestingaustinfruNo ratings yet

- Drainer Insp ScheduleDocument2 pagesDrainer Insp ScheduleuvsubhadraNo ratings yet

- Alcatel Omnipcx Enterprise: 1 The Communication ArchitectureDocument6 pagesAlcatel Omnipcx Enterprise: 1 The Communication ArchitectureuvsubhadraNo ratings yet

- Alcatel Omni PCXDocument143 pagesAlcatel Omni PCXuvsubhadra100% (1)

- Steel Plant Communication EquipmentDocument5 pagesSteel Plant Communication EquipmentuvsubhadraNo ratings yet

- Alcatel Comm ServerDocument14 pagesAlcatel Comm ServeruvsubhadraNo ratings yet

- Handbook On VHF Set 25 WDocument24 pagesHandbook On VHF Set 25 WuvsubhadraNo ratings yet

- Wire Tracer Amprobe T2005Document24 pagesWire Tracer Amprobe T2005uvsubhadraNo ratings yet

- 990dsl Manu Copper Loop TesterDocument218 pages990dsl Manu Copper Loop TesteruvsubhadraNo ratings yet

- Alcatel Comm ServerDocument14 pagesAlcatel Comm ServeruvsubhadraNo ratings yet

- Basic NetworkingDocument3 pagesBasic NetworkinguvsubhadraNo ratings yet

- Aes Test TRB Chapter 4Document135 pagesAes Test TRB Chapter 4bsunanda01No ratings yet

- MC3372Document19 pagesMC3372zef1No ratings yet

- Rack World Product CatalogueDocument84 pagesRack World Product CatalogueErich KnoopNo ratings yet

- Default Rules OMDocument6 pagesDefault Rules OMSravaniMeessaragandaM0% (1)

- Header Data: SymptomDocument2 pagesHeader Data: SymptomMoeed Ahmed BaigNo ratings yet

- ArditHoda ECVDocument3 pagesArditHoda ECVArdit HodaNo ratings yet

- FAG VibracijeDocument44 pagesFAG VibracijeTalicni TomNo ratings yet

- Engine Oil Chart2Document1 pageEngine Oil Chart2djdeeabloNo ratings yet

- 3296 Trimmer PotensiometerDocument2 pages3296 Trimmer PotensiometerNgurah SatriawanNo ratings yet

- ResumeDocument2 pagesResumespandanaNo ratings yet

- Daily Revenue Report DT Business Bay: 02 March 2021Document1 pageDaily Revenue Report DT Business Bay: 02 March 2021Jeric VendiolaNo ratings yet

- ITIL Service Operation in PolicyDocument7 pagesITIL Service Operation in PolicyilayavplNo ratings yet

- Marsman vs. PgiDocument2 pagesMarsman vs. PgiMarianne AndresNo ratings yet

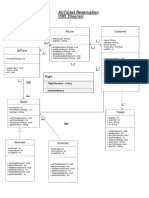

- Airticket Reservation Uml Diagram: FlightDocument1 pageAirticket Reservation Uml Diagram: Flightsalman mughalNo ratings yet

- QF-002-PUR Requisition Form Rev 00Document2 pagesQF-002-PUR Requisition Form Rev 00Putera AuroraNo ratings yet

- Catalog Metering TransformersDocument48 pagesCatalog Metering Transformersddsf2012No ratings yet

- Solid Waste ManagementDocument4 pagesSolid Waste ManagementTrishia Arielle HernandezNo ratings yet

- KTR-Katalog en PDFDocument302 pagesKTR-Katalog en PDFveljegNo ratings yet

- Grove b4 b5 b7 Ball Valve Brochure PDFDocument32 pagesGrove b4 b5 b7 Ball Valve Brochure PDFIrfan FahmiNo ratings yet

- The Vienna Donau City TowerDocument9 pagesThe Vienna Donau City TowerSakisNo ratings yet

- Alabama DOT Roadway Plans Preparation ManualDocument52 pagesAlabama DOT Roadway Plans Preparation ManualDen OghangsombanNo ratings yet

- Precast Concrete Panel Systems For Full-Depth Pavement Repairs - Field TrialsDocument84 pagesPrecast Concrete Panel Systems For Full-Depth Pavement Repairs - Field TrialsTim LinNo ratings yet

- Atlassian Harvard Business Review Agile ReportDocument16 pagesAtlassian Harvard Business Review Agile ReportKemala Andriani100% (1)

- Chapter 8: Facility and Work DesignDocument11 pagesChapter 8: Facility and Work DesignPaulo BernasNo ratings yet

- Feedmill of The FutureDocument14 pagesFeedmill of The FutureMilling and Grain magazineNo ratings yet

- SMR As of Nov. 23, 2022Document35 pagesSMR As of Nov. 23, 2022Francis DedumoNo ratings yet

- Aspire Technology - Radio Planning and Optimiation Engineer Autumn 2014Document2 pagesAspire Technology - Radio Planning and Optimiation Engineer Autumn 2014Tanzyy.2018No ratings yet

- JHMCS-D 2002Document83 pagesJHMCS-D 2002MeNo ratings yet

- Rocket Engine HistoryDocument160 pagesRocket Engine HistoryAviation/Space History Library100% (2)