Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

30 viewsTest Report: Shree Siddhivinayak Construction

Test Report: Shree Siddhivinayak Construction

Uploaded by

rahul- The document is a test report from Constrologix Engineering detailing the results of a concrete mix design trial for M20 grade concrete.

- The mix design specifies proportions of cement, fly ash, fine and coarse aggregates, and water to achieve a target 28-day compressive strength of 27.11 N/sq mm.

- Initial slump and 7-day compressive strengths met requirements, indicating the mix design is suitable for the intended pumpable concrete application.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- Mix Design As Per BSDocument10 pagesMix Design As Per BSChetan SohalNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 pagesTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Mercedes Panaromic Roof Lubrication GuideDocument1 pageMercedes Panaromic Roof Lubrication Guidehappy_jonNo ratings yet

- ASHRAE Standards For Cooling TowersDocument51 pagesASHRAE Standards For Cooling TowersAaron M. WardNo ratings yet

- TR24010282 8Document2 pagesTR24010282 8swapnilNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Proposal PT Mutiara Indah ConstructionDocument38 pagesProposal PT Mutiara Indah ConstructionI Wayan PartamaNo ratings yet

- M35 Bhole ConstructionDocument6 pagesM35 Bhole ConstructionBIPL REPORT100% (1)

- M30 Mix Design Concept For RoadDocument5 pagesM30 Mix Design Concept For Roadseemamandal8051No ratings yet

- Mix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTDDocument5 pagesMix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTD123shripadNo ratings yet

- Design Mix M-30 (Result Change)Document6 pagesDesign Mix M-30 (Result Change)sunil prajapatiNo ratings yet

- M-25 Mix DesignDocument2 pagesM-25 Mix DesignSharath RMNo ratings yet

- WMM Mix DesignDocument22 pagesWMM Mix DesignDivyesh AhirNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- DBM Gupta ConstructionDocument24 pagesDBM Gupta Constructionimran khanNo ratings yet

- 3285-SNS M-25 M-30 InterimDocument9 pages3285-SNS M-25 M-30 InterimErHarshGandhiNo ratings yet

- Concrete Mix Design For Grade M - 30Document8 pagesConcrete Mix Design For Grade M - 30AswIni PadhiNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 pagesTest Report: M/S Abhi Engg Corporation PVT LTDimran khanNo ratings yet

- SIR Site Survey Sea Water Pump PKT BontangDocument4 pagesSIR Site Survey Sea Water Pump PKT BontangMuhammad ZakiNo ratings yet

- Mix Design - FlyashDocument1 pageMix Design - FlyashAjay MahaleNo ratings yet

- Concrete Mix DesignDocument58 pagesConcrete Mix Designharikan chaturvediNo ratings yet

- DLC Degin GulbaxaniDocument6 pagesDLC Degin GulbaxaniImran KhanNo ratings yet

- M20 M25 M30 Ultratech PPC Sikaplast 2009 NS 28daysDocument13 pagesM20 M25 M30 Ultratech PPC Sikaplast 2009 NS 28daystalabirachp siteNo ratings yet

- Job Mix For BM 50 MMDocument3 pagesJob Mix For BM 50 MMSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- BHCP1-JEL-RFI-C00-Z0094-Compressive Strength Testing at Koboi Bente & PU Mataram LaboratoryDocument3 pagesBHCP1-JEL-RFI-C00-Z0094-Compressive Strength Testing at Koboi Bente & PU Mataram LaboratoryyohanesfernandoNo ratings yet

- Recommended Sheet: Authorised Signatory Pg. No. 1 of 5Document5 pagesRecommended Sheet: Authorised Signatory Pg. No. 1 of 5KA25 ConsultantNo ratings yet

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- ST2013-120-M15-M25-J K Laxmi-SNDDocument4 pagesST2013-120-M15-M25-J K Laxmi-SNDPrakash MakwanaNo ratings yet

- Balaji Concrete: A. Mix Stipulation 10Document3 pagesBalaji Concrete: A. Mix Stipulation 10Dhananjay PatelNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- Report 3523 M40 08 12 2019Document20 pagesReport 3523 M40 08 12 2019Imran KhanNo ratings yet

- 1 WMM Mix DesignDocument21 pages1 WMM Mix Designvikas kumar100% (1)

- S3 Soil Sample of DudahidaDocument7 pagesS3 Soil Sample of DudahidaSahalii SahaliiNo ratings yet

- S.E.C M35 PIle Birla Gold Cement 1042 UDocument5 pagesS.E.C M35 PIle Birla Gold Cement 1042 UBIPL REPORTNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- M-25 Mix Designs As Per Is-10262-2009Document3 pagesM-25 Mix Designs As Per Is-10262-2009burhan.kanjeta1988No ratings yet

- Nirumand Polymer: Technical Data SheetDocument1 pageNirumand Polymer: Technical Data SheetMahaNo ratings yet

- RDC Concrete (India) Private Limited: Certificate of Concrete Mix DesignDocument1 pageRDC Concrete (India) Private Limited: Certificate of Concrete Mix DesignAkashDashNo ratings yet

- WMM Mix DesignDocument23 pagesWMM Mix DesignjanardangaurNo ratings yet

- Mix Design FormatDocument18 pagesMix Design FormatChandan MondalNo ratings yet

- Bitumin ConcreteDocument10 pagesBitumin ConcreteHariom guptaNo ratings yet

- 21.recycled Coarse AggregatesDocument9 pages21.recycled Coarse AggregatesRupali YadavNo ratings yet

- CLVTDocument2 pagesCLVTOkello StevenNo ratings yet

- M 25 Lakshmi InfraDocument21 pagesM 25 Lakshmi InfraKA25 ConsultantNo ratings yet

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Concrete New Mix DesignsDocument2 pagesConcrete New Mix DesignsPrabhakar Sv100% (1)

- Technical SPECIFICATION FOR PILESDocument13 pagesTechnical SPECIFICATION FOR PILESgopal sudhirNo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- Revised Mix VarrocPolymers 111223Document1 pageRevised Mix VarrocPolymers 111223kkkdjNo ratings yet

- IVS Industries M35 50% Crushed Sand GGBSDocument8 pagesIVS Industries M35 50% Crushed Sand GGBSImran KhanNo ratings yet

- M30Pile Mix Design & Trial SheetDocument3 pagesM30Pile Mix Design & Trial Sheetabir senguptaNo ratings yet

- Nirumand Polymer: Technical Data SheetDocument1 pageNirumand Polymer: Technical Data SheetMahaNo ratings yet

- DM SSSDocument5 pagesDM SSSiitmpdNo ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- M 35 PS Basf UltDocument2 pagesM 35 PS Basf UltSudarsanan KNo ratings yet

- Ijet V4i3p62 PDFDocument7 pagesIjet V4i3p62 PDFInternational Journal of Engineering and TechniquesNo ratings yet

- Ample Nformation Sample No: RL-01: Ement Ests EportDocument3 pagesAmple Nformation Sample No: RL-01: Ement Ests EportweamNo ratings yet

- MSRC Cfa - 20230622 - 0001Document3 pagesMSRC Cfa - 20230622 - 0001Saad MuzaffarNo ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Tds Epocoat MB WhiteDocument3 pagesTds Epocoat MB WhitefcdorupaNo ratings yet

- Annex 1 Essential Safety RequirementDocument12 pagesAnnex 1 Essential Safety Requirementjamil voraNo ratings yet

- Ken Day Method of Mix DesignDocument6 pagesKen Day Method of Mix DesignGaneshNo ratings yet

- What Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialDocument5 pagesWhat Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialjackNo ratings yet

- En 673 LectureDocument12 pagesEn 673 LectureCristian SabauNo ratings yet

- Energy Conscious Architecture - Edge AmsterdamDocument7 pagesEnergy Conscious Architecture - Edge AmsterdamPriyanjita AdhikariNo ratings yet

- Jji Joist Technical Manual Jan 2020Document48 pagesJji Joist Technical Manual Jan 2020Kovacs Zsolt-IstvanNo ratings yet

- Compression TestDocument5 pagesCompression TestSalam AlbaradieNo ratings yet

- Characterisation of AluminiumDocument8 pagesCharacterisation of AluminiumsathishjeyNo ratings yet

- Dipendra GAUTAM: Genesis and Motivation (Or Abstract)Document1 pageDipendra GAUTAM: Genesis and Motivation (Or Abstract)Sbj ThapaNo ratings yet

- Unit - 4 Vapour Power Cycles Session 4 NotesDocument19 pagesUnit - 4 Vapour Power Cycles Session 4 NotesFlamboyantAttittudeNo ratings yet

- CON2910 Project B Basic Wood Joinery NotesDocument8 pagesCON2910 Project B Basic Wood Joinery NotesEd PawliwNo ratings yet

- Durafix Easyweld Flyer EnglishDocument2 pagesDurafix Easyweld Flyer EnglishDavid Assumpção da SilvaNo ratings yet

- 2014 How To Deal With Halen EstateDocument6 pages2014 How To Deal With Halen EstateChiara NaderNo ratings yet

- Tropical DesignDocument30 pagesTropical DesignJohn Lerry Estabillo100% (1)

- Refrigerant Piping Handbook Part I Engineering: Garth DenisonDocument72 pagesRefrigerant Piping Handbook Part I Engineering: Garth Denisonjm sausaNo ratings yet

- Quick Reference Guide: Section VIII, Division I - 2017 EditionDocument1 pageQuick Reference Guide: Section VIII, Division I - 2017 EditionVenicio AchermanNo ratings yet

- Types of Roof Trusses: King Post TrussDocument3 pagesTypes of Roof Trusses: King Post TrussjashndeepNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- Static Recrystalization TextureDocument11 pagesStatic Recrystalization Texture于大放No ratings yet

- Specification For Brick MasonryDocument6 pagesSpecification For Brick Masonrysri10888No ratings yet

- Part B-Arch ExreciseDocument2 pagesPart B-Arch Exrecisestudio surfaceNo ratings yet

- Band Gap Engineering - Lecture 7Document15 pagesBand Gap Engineering - Lecture 7ldaukiyaNo ratings yet

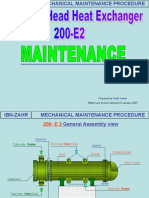

- 200 E 2 Floating Head Heat Exchanger MaintenanceDocument16 pages200 E 2 Floating Head Heat Exchanger Maintenancesubha50% (2)

- Issues To Address... : Chapter 14/15-1Document11 pagesIssues To Address... : Chapter 14/15-1Alex Nico JhoentaxsNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Mohd Said Mohd ZakariaNo ratings yet

- CE 437 - 0014-Compression-Members-2Document6 pagesCE 437 - 0014-Compression-Members-2Md Mufazzel Hossain ChowdhuryNo ratings yet

- Ime Module 4Document32 pagesIme Module 4Prakhyath MNo ratings yet

Test Report: Shree Siddhivinayak Construction

Test Report: Shree Siddhivinayak Construction

Uploaded by

rahul0 ratings0% found this document useful (0 votes)

30 views2 pages- The document is a test report from Constrologix Engineering detailing the results of a concrete mix design trial for M20 grade concrete.

- The mix design specifies proportions of cement, fly ash, fine and coarse aggregates, and water to achieve a target 28-day compressive strength of 27.11 N/sq mm.

- Initial slump and 7-day compressive strengths met requirements, indicating the mix design is suitable for the intended pumpable concrete application.

Original Description:

Original Title

M20

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document- The document is a test report from Constrologix Engineering detailing the results of a concrete mix design trial for M20 grade concrete.

- The mix design specifies proportions of cement, fly ash, fine and coarse aggregates, and water to achieve a target 28-day compressive strength of 27.11 N/sq mm.

- Initial slump and 7-day compressive strengths met requirements, indicating the mix design is suitable for the intended pumpable concrete application.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

30 views2 pagesTest Report: Shree Siddhivinayak Construction

Test Report: Shree Siddhivinayak Construction

Uploaded by

rahul- The document is a test report from Constrologix Engineering detailing the results of a concrete mix design trial for M20 grade concrete.

- The mix design specifies proportions of cement, fly ash, fine and coarse aggregates, and water to achieve a target 28-day compressive strength of 27.11 N/sq mm.

- Initial slump and 7-day compressive strengths met requirements, indicating the mix design is suitable for the intended pumpable concrete application.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

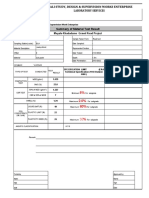

Constrologix Engineering & Research Services Pvt. Ltd.

PLOT.NO.D-III-58/1 BLOCK, MIDC, PIMPRI INDUSTRIAL AREA,

AKURDI, PUNE, Maharashtra, 411019. Corporate Indentity Number:

U73100PN2011PTC138156 GSTIN: 27AAECC2638P1Z9

TEST REPORT

(Concrete mix Design)

Sample No. CPL210119-06-003 Report No: CPL210119-06-003

Customer Name: Shree Siddhivinayak Construction Date Of Reciept: 03 Dec 2021

Customer Address: Gat No. 608 At Post Moi Tal Khed - Pune Maharashtra Date Of Testing: 13 Jan 2022

India

Client Name: Report Date: 14 Jan 2022

Consultant name: Sample Condition: Acceptable

Site/ Name of Work: Gat No. 608 At Post Moi Tal Khed . Pune Maharashtra Witnessed By:

India

Sample Description: CONCRETE MIX DESIGN PUMPABLE

Letter Ref.:

Observation Table & Test Results:

Concrete Mix Design for M20 -

Cement Fly ash Natural Sand Crushed Sand 10 mm Agg. 20 mm Agg Water Admixture

PER CUM IN 280 55 "--" 842 416 745 161 3.18

KG

PER BATCH 50 10 "--" 150.03 74.28 133.03 28.75 0.57

OF 50 KG

W/C RATIO 0.48

Trial Mix Observations

Slump in mm Initial-190,@60min-150, 3 Days compressive strength in N/ "--"

sq mm

@90Min-120

Yield (plastic density) of concrete 2499 7 Days compressive strength in N/ 17.33

in kg/cum sq mm

Accelerated compressive strength "--" 28 Days compressive strength in 27.11

in N/ sq mm N/ sq mm

Properties of Materials used in the proportionong

Type and Brand of Cement Vasavdatta OPC 53 Grade Specific Gravity - 10 mm Agg. 2.87

Specific Gravity of Cement 3.15 Water absorption -10 mm Agg. 1.11

Brand of Fly ash - DLBD- 10 mm Agg. 1.59

Specific Gravity -Fly ash 2.2 Specific Gravity- 20 mm Agg. 2.90

Specific Gravity- Natural Sand "--" Water absorption -20 mm Agg. 0.99

Water absorption- Natural sand "--" DLBD- 20 mm Agg. 1.59

DLBD- Natural Sand "--" Type of Aggregate Crushed Angular agg

Maximum nominal size of Agg.

Specific Gravity- Crushed Sand 2.62 MSA. (mm) 20

Water absorption- Crushed sand 3.61 Chemical Admixture Type -

DLBD-Crushed Sand 1.79 Brand Name of the Admixture BASF 8501(Chloride free)

Zone of fine Agg. I ---- ----

Design Assumptions :

Exposure Condition of concrete Moderate Degree of Supervision Fair

Method of concrete Placing Pumpable

A) Grading of Fine Aggregate

Sr No Natural Sand Crushed Sand Combined blend Percent

Tested By Sachin Chougule Authorized Signatory

Vijay Surve(Manager- Technical)

ULR Number - TC601219000023025N | | Page 1 of 2

Constrologix Engineering & Research Services Pvt. Ltd.

PLOT.NO.D-III-58/1 BLOCK, MIDC, PIMPRI INDUSTRIAL AREA,

AKURDI, PUNE, Maharashtra, 411019.

Corporate Indentity Number: U73100PN2011PTC138156 GSTIN: 27AAECC2638P1Z9

Percent Used 0 100

1 10 mm 0 100.0 100

2 4.75 mm 0 96.47 96.47

3 2.36 mm 0 66.33 66.33

4 1.18 mm 0 44.74 44.74

5 0.600 mm 0 27.51 27.51

6 0.300 mm 0 7.12 7.12

7 0.150 mm 0 4.01 4.01

B) Gradiing of Coarse Aggregate

Combined grading as

Sr No 10 mm Aggregate 20 mm Aggregate Combined grading per IS 383: 1970 RA

2016

Percent Used 40 60

1 40 mm 100.0 100.0 100 100

2 20 mm 100.0 87.48 91 95-100

3 10 mm 85.42 4.69 35 25-55

4 4.75 mm 3.44 0.07 0 0-10

5 2.36 mm 0.0 0.0 0 --

1) Design quantities are based on materials as found in Laboratory and degree of quality control expected to be follow at site as per design

data provided by the client.

2)* Proportions given in this report is based on the Saturated Surface Dry Condition of the aggregate. If otherwise computing the

rfequirement of mixing of water. Allowance should be made for the free moisture contrubited by the fine and coarse aggregate. On yhe other

hand ,if the aggregates are dry, the amount of mixing water should be increased by an amount equal yo the moisture likely to be absorbed by

the aggregates.Necessary adjustments are also required to be made in mass of aggregate. The surface water and percentage water absorption

of aggregates shall be determined according to IS 2386.

3) In case of change in source ,properties /specifications of the ingrediernts and deviation from the design consideration/ the mix should be

redesigned.

4) You are requested to take a site trial give us feedback, which will enable us to give you the correction in mix, before your actual concreting

References:IS 10262 : 2009 Recommanded Guidelines for concrete mix design. IS 9013: 1978 (Reaff. 1999) for determining Comp. strength

of acclerated cured concrete test specimen. IS 456 : 2000 Code of practice for plain & reinforced cement concrete. IS 383 : 1970

Specification for coarse & fine aggregates from natural sources for concrete.

Remark:

*This is an Interim Report

Note: i) The test report and result relate to the particular specimen/ sample (s) of the material as delivered /received and tested in the

laboratory. ii) Any test report shall not be reproduced except in full, without the writen permission from CERSPL.

Tested By Sachin Chougule Authorized Signatory

Vijay Surve(Manager- Technical)

ULR Number - TC601219000023025N | | Page 2 of 2

End of test report

You might also like

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- Mix Design As Per BSDocument10 pagesMix Design As Per BSChetan SohalNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 pagesTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Mercedes Panaromic Roof Lubrication GuideDocument1 pageMercedes Panaromic Roof Lubrication Guidehappy_jonNo ratings yet

- ASHRAE Standards For Cooling TowersDocument51 pagesASHRAE Standards For Cooling TowersAaron M. WardNo ratings yet

- TR24010282 8Document2 pagesTR24010282 8swapnilNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Proposal PT Mutiara Indah ConstructionDocument38 pagesProposal PT Mutiara Indah ConstructionI Wayan PartamaNo ratings yet

- M35 Bhole ConstructionDocument6 pagesM35 Bhole ConstructionBIPL REPORT100% (1)

- M30 Mix Design Concept For RoadDocument5 pagesM30 Mix Design Concept For Roadseemamandal8051No ratings yet

- Mix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTDDocument5 pagesMix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTD123shripadNo ratings yet

- Design Mix M-30 (Result Change)Document6 pagesDesign Mix M-30 (Result Change)sunil prajapatiNo ratings yet

- M-25 Mix DesignDocument2 pagesM-25 Mix DesignSharath RMNo ratings yet

- WMM Mix DesignDocument22 pagesWMM Mix DesignDivyesh AhirNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- DBM Gupta ConstructionDocument24 pagesDBM Gupta Constructionimran khanNo ratings yet

- 3285-SNS M-25 M-30 InterimDocument9 pages3285-SNS M-25 M-30 InterimErHarshGandhiNo ratings yet

- Concrete Mix Design For Grade M - 30Document8 pagesConcrete Mix Design For Grade M - 30AswIni PadhiNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 pagesTest Report: M/S Abhi Engg Corporation PVT LTDimran khanNo ratings yet

- SIR Site Survey Sea Water Pump PKT BontangDocument4 pagesSIR Site Survey Sea Water Pump PKT BontangMuhammad ZakiNo ratings yet

- Mix Design - FlyashDocument1 pageMix Design - FlyashAjay MahaleNo ratings yet

- Concrete Mix DesignDocument58 pagesConcrete Mix Designharikan chaturvediNo ratings yet

- DLC Degin GulbaxaniDocument6 pagesDLC Degin GulbaxaniImran KhanNo ratings yet

- M20 M25 M30 Ultratech PPC Sikaplast 2009 NS 28daysDocument13 pagesM20 M25 M30 Ultratech PPC Sikaplast 2009 NS 28daystalabirachp siteNo ratings yet

- Job Mix For BM 50 MMDocument3 pagesJob Mix For BM 50 MMSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- BHCP1-JEL-RFI-C00-Z0094-Compressive Strength Testing at Koboi Bente & PU Mataram LaboratoryDocument3 pagesBHCP1-JEL-RFI-C00-Z0094-Compressive Strength Testing at Koboi Bente & PU Mataram LaboratoryyohanesfernandoNo ratings yet

- Recommended Sheet: Authorised Signatory Pg. No. 1 of 5Document5 pagesRecommended Sheet: Authorised Signatory Pg. No. 1 of 5KA25 ConsultantNo ratings yet

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- ST2013-120-M15-M25-J K Laxmi-SNDDocument4 pagesST2013-120-M15-M25-J K Laxmi-SNDPrakash MakwanaNo ratings yet

- Balaji Concrete: A. Mix Stipulation 10Document3 pagesBalaji Concrete: A. Mix Stipulation 10Dhananjay PatelNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- Report 3523 M40 08 12 2019Document20 pagesReport 3523 M40 08 12 2019Imran KhanNo ratings yet

- 1 WMM Mix DesignDocument21 pages1 WMM Mix Designvikas kumar100% (1)

- S3 Soil Sample of DudahidaDocument7 pagesS3 Soil Sample of DudahidaSahalii SahaliiNo ratings yet

- S.E.C M35 PIle Birla Gold Cement 1042 UDocument5 pagesS.E.C M35 PIle Birla Gold Cement 1042 UBIPL REPORTNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- M-25 Mix Designs As Per Is-10262-2009Document3 pagesM-25 Mix Designs As Per Is-10262-2009burhan.kanjeta1988No ratings yet

- Nirumand Polymer: Technical Data SheetDocument1 pageNirumand Polymer: Technical Data SheetMahaNo ratings yet

- RDC Concrete (India) Private Limited: Certificate of Concrete Mix DesignDocument1 pageRDC Concrete (India) Private Limited: Certificate of Concrete Mix DesignAkashDashNo ratings yet

- WMM Mix DesignDocument23 pagesWMM Mix DesignjanardangaurNo ratings yet

- Mix Design FormatDocument18 pagesMix Design FormatChandan MondalNo ratings yet

- Bitumin ConcreteDocument10 pagesBitumin ConcreteHariom guptaNo ratings yet

- 21.recycled Coarse AggregatesDocument9 pages21.recycled Coarse AggregatesRupali YadavNo ratings yet

- CLVTDocument2 pagesCLVTOkello StevenNo ratings yet

- M 25 Lakshmi InfraDocument21 pagesM 25 Lakshmi InfraKA25 ConsultantNo ratings yet

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Concrete New Mix DesignsDocument2 pagesConcrete New Mix DesignsPrabhakar Sv100% (1)

- Technical SPECIFICATION FOR PILESDocument13 pagesTechnical SPECIFICATION FOR PILESgopal sudhirNo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- Revised Mix VarrocPolymers 111223Document1 pageRevised Mix VarrocPolymers 111223kkkdjNo ratings yet

- IVS Industries M35 50% Crushed Sand GGBSDocument8 pagesIVS Industries M35 50% Crushed Sand GGBSImran KhanNo ratings yet

- M30Pile Mix Design & Trial SheetDocument3 pagesM30Pile Mix Design & Trial Sheetabir senguptaNo ratings yet

- Nirumand Polymer: Technical Data SheetDocument1 pageNirumand Polymer: Technical Data SheetMahaNo ratings yet

- DM SSSDocument5 pagesDM SSSiitmpdNo ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- M 35 PS Basf UltDocument2 pagesM 35 PS Basf UltSudarsanan KNo ratings yet

- Ijet V4i3p62 PDFDocument7 pagesIjet V4i3p62 PDFInternational Journal of Engineering and TechniquesNo ratings yet

- Ample Nformation Sample No: RL-01: Ement Ests EportDocument3 pagesAmple Nformation Sample No: RL-01: Ement Ests EportweamNo ratings yet

- MSRC Cfa - 20230622 - 0001Document3 pagesMSRC Cfa - 20230622 - 0001Saad MuzaffarNo ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Tds Epocoat MB WhiteDocument3 pagesTds Epocoat MB WhitefcdorupaNo ratings yet

- Annex 1 Essential Safety RequirementDocument12 pagesAnnex 1 Essential Safety Requirementjamil voraNo ratings yet

- Ken Day Method of Mix DesignDocument6 pagesKen Day Method of Mix DesignGaneshNo ratings yet

- What Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialDocument5 pagesWhat Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialjackNo ratings yet

- En 673 LectureDocument12 pagesEn 673 LectureCristian SabauNo ratings yet

- Energy Conscious Architecture - Edge AmsterdamDocument7 pagesEnergy Conscious Architecture - Edge AmsterdamPriyanjita AdhikariNo ratings yet

- Jji Joist Technical Manual Jan 2020Document48 pagesJji Joist Technical Manual Jan 2020Kovacs Zsolt-IstvanNo ratings yet

- Compression TestDocument5 pagesCompression TestSalam AlbaradieNo ratings yet

- Characterisation of AluminiumDocument8 pagesCharacterisation of AluminiumsathishjeyNo ratings yet

- Dipendra GAUTAM: Genesis and Motivation (Or Abstract)Document1 pageDipendra GAUTAM: Genesis and Motivation (Or Abstract)Sbj ThapaNo ratings yet

- Unit - 4 Vapour Power Cycles Session 4 NotesDocument19 pagesUnit - 4 Vapour Power Cycles Session 4 NotesFlamboyantAttittudeNo ratings yet

- CON2910 Project B Basic Wood Joinery NotesDocument8 pagesCON2910 Project B Basic Wood Joinery NotesEd PawliwNo ratings yet

- Durafix Easyweld Flyer EnglishDocument2 pagesDurafix Easyweld Flyer EnglishDavid Assumpção da SilvaNo ratings yet

- 2014 How To Deal With Halen EstateDocument6 pages2014 How To Deal With Halen EstateChiara NaderNo ratings yet

- Tropical DesignDocument30 pagesTropical DesignJohn Lerry Estabillo100% (1)

- Refrigerant Piping Handbook Part I Engineering: Garth DenisonDocument72 pagesRefrigerant Piping Handbook Part I Engineering: Garth Denisonjm sausaNo ratings yet

- Quick Reference Guide: Section VIII, Division I - 2017 EditionDocument1 pageQuick Reference Guide: Section VIII, Division I - 2017 EditionVenicio AchermanNo ratings yet

- Types of Roof Trusses: King Post TrussDocument3 pagesTypes of Roof Trusses: King Post TrussjashndeepNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- Static Recrystalization TextureDocument11 pagesStatic Recrystalization Texture于大放No ratings yet

- Specification For Brick MasonryDocument6 pagesSpecification For Brick Masonrysri10888No ratings yet

- Part B-Arch ExreciseDocument2 pagesPart B-Arch Exrecisestudio surfaceNo ratings yet

- Band Gap Engineering - Lecture 7Document15 pagesBand Gap Engineering - Lecture 7ldaukiyaNo ratings yet

- 200 E 2 Floating Head Heat Exchanger MaintenanceDocument16 pages200 E 2 Floating Head Heat Exchanger Maintenancesubha50% (2)

- Issues To Address... : Chapter 14/15-1Document11 pagesIssues To Address... : Chapter 14/15-1Alex Nico JhoentaxsNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Mohd Said Mohd ZakariaNo ratings yet

- CE 437 - 0014-Compression-Members-2Document6 pagesCE 437 - 0014-Compression-Members-2Md Mufazzel Hossain ChowdhuryNo ratings yet

- Ime Module 4Document32 pagesIme Module 4Prakhyath MNo ratings yet