Professional Documents

Culture Documents

Titan T200 Spec Sheet

Titan T200 Spec Sheet

Uploaded by

Kim JunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Titan T200 Spec Sheet

Titan T200 Spec Sheet

Uploaded by

Kim JunCopyright:

Available Formats

Titan™ T200

Cone Crusher

Crusher TRAC10® Automation System (Optional)

- Full top service - Pre-wired automation system controls

- Patented Hybrid Bearings - Operator interface terminal - 12” full color touchscreen

o More stable cone head display

o Higher capacity - Remote crusher setting adjustment and tracking

o Less friction - Overload protection

o Allows easy, more frequent bearing - Dynamic Bowl Adjust System

inspection - Automatic liner calibration

- Re-usable Concave Collet - Liner wear tracking and compensation

o No wedges or sledge hammer required - Ability to modify settings while crushing

- Patented Thread Scraper - Parameter history, alarm logging, and PLC

- Thread Locking Mechanism communication

- Balanced Eccentric Assembly - Package can operate up to 4 crushers with one

o No socket or socket liner to remove display

- FEA Stress Analysis

- Cast Steel Frame with Bronze Radial and Thrust

Bearings Crusher Options

- Hydraulic Relief and Clearing System - Patented Anti-Spin System

- Hydraulic Bowl Adjust System o Fluid break

- Receiving hopper o Automatic reset (not mechanical)

- Manganese chamber liners - Transformer enclosure for basic alarm package

- Manual hydraulic controls - Electric motor

- Basic tool kit - Motor slide rails

- Operation and maintenance manuals - V-belt drive and guard

- Air-to-oil cooling system

Oil Lube System - High ambient/high altitude air-to-oil cooling system

- 10HP oil pump assembly - Cold weather package

- 55gal (208L) tank oil - Stationary feed basket

- Oil filter - Deluxe tool kit including all lifting devices

- (1) 3kW oil heaters - TRAC10® Automatic power adjust mode

- Pre-wired basic alarm package - TRAC10® Automatic feed control

- TRAC10® Wi-Fi connection

Hydraulic System - TRAC10® Remote diagnostics package

- 15HP pump assembly

- 20gal (76L) tank

- Pressure and return filters

- 1/3HP oil cooler

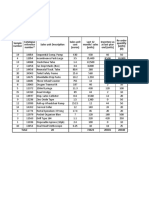

Dimensions

T200 T300 T400 T500

A 66.20” 74.85” 80.05” 88.68”

(1,682 mm) (1,902 mm) (2,034 mm) (2,253 mm)

B 59.20” 67.85” 73.05” 81.68”

(1,504 mm) (1,724 mm) (1,856 mm) (2,075 mm)

C 18.11” 19.29” 20.58

(460 mm) (490 mm) (523mm)

D 39.76” 44.49” 48.82” 57.25”

(1,010 mm) (1,131 mm) (1,241 mm) (1,455 mm)

E 46.85” 55.75” 65.11” 74.69”

(1,190 mm) (1,417 mm) (1,654 mm) (1,898 mm)

F 62.60” 74.80” 92.52” 107.09”

(1,591 mm) (1,900 mm) (2,351 mm) (2,721 mm)

H 77.08” 89.87” 105.75” 114.34”

(1,958 mm) (2,283 mm) (2,687 mm) (2,905 mm)

I 35.94” 45.37” 54.44” 57.09”

(913 mm) (1,153mm) (1,383 mm) (1,451 mm)

J 41.14” 44.49” 51.31” 57.25”

(1,045 mm) (1,131 mm) (1,304 mm) (1,455 mm)

L 42.91” 51.97” 65.35” 69.5”

(1,090 mm) (1,321 mm) (1,660 mm) (1,766 mm)

M 21.46” 25.98” 32.68” 34.75”

(546 mm) (660 mm) (831 mm) (883 mm)

N 51.57” 62.99” 74.41” 83.45”

(1,310 mm) (1,600 mm) (1,891 mm) (2,120 mm)

O 21.46” 25.98” 32.68” 34.75”

(546 mm) (660mm) (831 mm) (883 mm)

P 42.91” 51.97” 65.35” 69.50”

(1,090 mm) (1,321 mm) (1,660 mm) (1,766 mm)

Crusher Specifications

T200 T300 T400 T500

Head Diameter 36” (915 mm) 44” (1,120 mm) 52” (1,321 mm) 57” (1,450 mm)

Operating Range 900 - 1,100 RPM 850 - 1,050 RPM 825 - 1,050 RPM 825 - 1,050 RPM

Maximum Feed Size* 8.70” (220 mm) 11.20” (285 mm) 12.30” (314 mm) 14.20” (361mm)

Clearing Stroke 7” (178 mm) 7” (178 mm) 7” (178 mm) 7” (178 mm)

Horsepower 200 (150kw) 300 (225kw) 400 (300kw) 500 (375kw)

Total Weight 22,000 lbs 35,800 lbs 51,800 lbs 75,100lbs

(9,979 kgs) (16,239 kgs) (23,496 kgs) (34,065 kgs)

Upper Frame Assembly 8,000 lbs 12,900 lbs 18,000 lbs 26,500 lbs

with Liner (3,629 kgs) (5,851kgs) (8,165 kgs) (12,020 kgs)

Main Frame Assembly with 8,790 lbs 12,200 lbs 17,800 lbs 26,900 lbs

Main Shaft and Liners (3,987 kgs) (5,534 kgs) (8,074 kgs) (12,202 kgs)

*Feed sizes and the minimum operating CSS is affected by the feed gradation, type of material, fines content, feed distribution, moisture content, feed rate and other site specific operating

conditions.

NOTE: CONSULT FACTORY FOR EXACT DIMENSIONS, specifications are subject to change without notice. Continuous

design progress makes it necessary that specifications be subject to change without notice. All sales of the products of Telsmith,

Inc. are subject to the provisions of their standard warranty. Telsmith, Inc do not warrant or represent that their products meet any

federal, state, or local statutes, codes, ordinances, rules, standards or other regulations, including OSHA and MSHA, covering

Telsmith, Inc. safety, pollution, electrical wiring, etc. Compliance with these statutes and regulations is the responsibility of the user and will

10910 N. Industrial Dr. be dependent upon the area and the use to which the product is put by the user. In some photographs, guards may have been

Mequon, WI 53092 USA

(262) 242-6600 removed for illustrative purposes only. This equipment should not be operated without all guards attached in their normal position.

sales@telsmith.com Placement of guards and other safety equipment is often dependent upon the area and how the product is used. A safety study

www.telsmith.com should be made by the user of the application, and, if required additional guards, warning signs and other safety devices should

be installed by the user, wherever appropriate before operating the products.

4/20

You might also like

- Correas Cat..EquivalenciasDocument8 pagesCorreas Cat..EquivalenciasAbdul Zapata Escobar100% (6)

- SEBF8034 - Valve and Valve Spring Specifications (1Document21 pagesSEBF8034 - Valve and Valve Spring Specifications (1mohamed aliNo ratings yet

- IMPCO Model CA100 CaburetorDocument6 pagesIMPCO Model CA100 CaburetorMaxiSanchezNo ratings yet

- Netstal SYNERGY 800-230: Injection Moulding MachineDocument9 pagesNetstal SYNERGY 800-230: Injection Moulding MachinePiman MiriNo ratings yet

- Manual de Armado de Motor Volvo D6ADocument32 pagesManual de Armado de Motor Volvo D6Amarcos astete100% (4)

- Valve and Valve Spring SpecificationsDocument21 pagesValve and Valve Spring Specificationsbetoven8437100% (1)

- 3.0L EngineDocument182 pages3.0L EnginewawanNo ratings yet

- Kodiak Cone Crusher k300 Spec Sheet EnglishDocument2 pagesKodiak Cone Crusher k300 Spec Sheet Englishbrayansaucedo1993No ratings yet

- New Holland L 185 1Document20 pagesNew Holland L 185 1Daniel MechetteNo ratings yet

- Kidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Document6 pagesKidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Isa KumNo ratings yet

- Cat Fonte Segura Correias 2008 - 2009Document8 pagesCat Fonte Segura Correias 2008 - 2009Lyon Tratorpecas ITBNo ratings yet

- Emco e 300Document1 pageEmco e 300robalitojgpNo ratings yet

- Wirtgen W 2000 DatasheetDocument8 pagesWirtgen W 2000 DatasheetBeltazor HellboyNo ratings yet

- 400B Product Guide ImperialDocument20 pages400B Product Guide ImperialChiheb BEN ABDALLAHNo ratings yet

- S550 SpecificationsDocument6 pagesS550 SpecificationsMohamed ZakiNo ratings yet

- D4-12 Four-Post Lift - 5175317 - DannmarDocument1 pageD4-12 Four-Post Lift - 5175317 - DannmarJose A. Basanta H.No ratings yet

- 1.2 Sohc Engine Mechanical: SpecificationsDocument4 pages1.2 Sohc Engine Mechanical: SpecificationsAlejandro Muñoz PatiñoNo ratings yet

- PDF文档 8Document1 pagePDF文档 8Cuan HappyNo ratings yet

- Dynomax Shock Tool E-BrochureDocument2 pagesDynomax Shock Tool E-BrochureLeonardo BarriosNo ratings yet

- Hydraulic Mining Excavator - RH 200: General Data: FeaturesDocument8 pagesHydraulic Mining Excavator - RH 200: General Data: FeaturesEduardo Andres Contreras LetelierNo ratings yet

- Impco Carburetors-MixersDocument100 pagesImpco Carburetors-MixersLuis Ramón Argüello RealNo ratings yet

- CRC Evans Standard 32 60Document4 pagesCRC Evans Standard 32 60goomishNo ratings yet

- Nissan CD17Document3 pagesNissan CD17jose luis calixto requisNo ratings yet

- rh400 PDFDocument4 pagesrh400 PDFIvanNo ratings yet

- Engine - 1.6l GtdiDocument158 pagesEngine - 1.6l GtdiCRISTIAN DAVIDNo ratings yet

- Conveyor Chain. Web 4185 en - 0416 New LayoutDocument130 pagesConveyor Chain. Web 4185 en - 0416 New Layoutphong nguyenNo ratings yet

- CD500 CD600 CentrifugesDocument2 pagesCD500 CD600 Centrifugesharishkaushal1114No ratings yet

- Cat 345 CDocument8 pagesCat 345 CKaptan LeventcumNo ratings yet

- Auger Boring BrochureDocument5 pagesAuger Boring BrochureojuanibosasoNo ratings yet

- Nissan CD17Document3 pagesNissan CD17jose luis calixto requisNo ratings yet

- Carburetors & Mixers Model Ca100 CarburetorDocument6 pagesCarburetors & Mixers Model Ca100 CarburetorCarlos Chumbiauca MorenoNo ratings yet

- Engine Mechanical SystemDocument7 pagesEngine Mechanical SystemJavier AntonioNo ratings yet

- Nissan QR20DE (2.0 L) Engine Specs and Review, Horsepower and Torque, Service Data PDFDocument1 pageNissan QR20DE (2.0 L) Engine Specs and Review, Horsepower and Torque, Service Data PDFKareem Kelly100% (5)

- BN68-13695A-01 - QSG - QN85B 75-85inch - WW - L06 - 220113.0Document2 pagesBN68-13695A-01 - QSG - QN85B 75-85inch - WW - L06 - 220113.0Francisco OrtizNo ratings yet

- Ts90, Ts100, Ts110 Repair ManualDocument34 pagesTs90, Ts100, Ts110 Repair Manualclayden1955No ratings yet

- Kia K2500 Service Manual - Engine Mechanical System-1Document100 pagesKia K2500 Service Manual - Engine Mechanical System-1Arnev SalvianNo ratings yet

- Serie 740Document4 pagesSerie 740Mabeli MartinezNo ratings yet

- td10554 Compare Tormach Mills 1219a - mxCNCmasineDocument1 pagetd10554 Compare Tormach Mills 1219a - mxCNCmasineНикола ПетровићNo ratings yet

- Mustang 2010 PDFDocument310 pagesMustang 2010 PDFTaller 3L100% (2)

- Westco Product Catalog 2019Document16 pagesWestco Product Catalog 2019DiegoCaicedo1982100% (2)

- Service - Specifications Toyota ProboxDocument85 pagesService - Specifications Toyota Proboxcpgmotors83% (6)

- Cylinder Name Lift Cylinder Bucket Cylinder: Tube FosDocument11 pagesCylinder Name Lift Cylinder Bucket Cylinder: Tube FosSandipTakalikarNo ratings yet

- DMAX - SS - 0006 Shock Rev 5Document4 pagesDMAX - SS - 0006 Shock Rev 5Rovilson RibeiroNo ratings yet

- Carbs Mixers PDFDocument105 pagesCarbs Mixers PDFAnkush SehgalNo ratings yet

- MDDEDocument4 pagesMDDEThanh DuyNo ratings yet

- Qaapx20a100s - TimkenDocument1 pageQaapx20a100s - Timkenm.fadel.stNo ratings yet

- Manual CarryDocument720 pagesManual CarrydiegoNo ratings yet

- Kodiak Cone Crushers Specification Sheet: - Crusher - Lube AssemblyDocument6 pagesKodiak Cone Crushers Specification Sheet: - Crusher - Lube Assemblydeddy ariyantoNo ratings yet

- Super Long Front: Application & AttachmentDocument8 pagesSuper Long Front: Application & AttachmentAkhmad SebehNo ratings yet

- Rogrind SKS - 13.45Document2 pagesRogrind SKS - 13.45joshNo ratings yet

- SY305C LC Flyer-102955Document2 pagesSY305C LC Flyer-102955IMAM PUTRA PRABU, PTNo ratings yet

- CY6266/C6266Y Lathe: Model NoDocument2 pagesCY6266/C6266Y Lathe: Model NomillerNo ratings yet

- Section Guillotine: Title SawDocument4 pagesSection Guillotine: Title SawIsabel TorresNo ratings yet

- Cold Milling Machine W 2100: Technical SpecificationDocument8 pagesCold Milling Machine W 2100: Technical SpecificationAliNo ratings yet

- TransmissionDrivetrain TransmisionTrendePotencia TransmissionSystemedUniteDocument58 pagesTransmissionDrivetrain TransmisionTrendePotencia TransmissionSystemedUniteGiovanny ValenzuelaNo ratings yet

- The Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairFrom EverandThe Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairRating: 5 out of 5 stars5/5 (1)

- 6003 Series 6403 and 6603 Tractors Mexico South Africa and Asian Edition Replacement Parts GuideDocument3 pages6003 Series 6403 and 6603 Tractors Mexico South Africa and Asian Edition Replacement Parts GuidePedro ValerioNo ratings yet

- Lab Report 1Document5 pagesLab Report 1jvelezdanielaNo ratings yet

- Q& A Operation Management CaseDocument4 pagesQ& A Operation Management CaseAbdullah Al MunirNo ratings yet

- Abdominal Case Study CompiledDocument392 pagesAbdominal Case Study CompiledIshak IzharNo ratings yet

- Palladio Door Collection Brochure Edition 4 Oct 2021Document68 pagesPalladio Door Collection Brochure Edition 4 Oct 2021Focus WindowsNo ratings yet

- Asian33 112009Document40 pagesAsian33 112009irmuhidinNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- Gut Health Mindfulness Guide FREEBIEDocument11 pagesGut Health Mindfulness Guide FREEBIERaquel Orozco VargasNo ratings yet

- CH 02Document48 pagesCH 02miathegirl9No ratings yet

- Lab 5 - Ring AC DistributorDocument6 pagesLab 5 - Ring AC DistributorMuhammad AnasNo ratings yet

- To Calculate Monetary Saving by Changing Ex-Works Vendors From OM Logistics To Free Delivery Through Alternate TransporterDocument53 pagesTo Calculate Monetary Saving by Changing Ex-Works Vendors From OM Logistics To Free Delivery Through Alternate TransporterpeednaskNo ratings yet

- Secondary 6 FCE ExamPack SEVENDocument3 pagesSecondary 6 FCE ExamPack SEVENamtenistaNo ratings yet

- Abstract Number: 191 Finite Element Analysis of Geotextile Reinforced Highway Embankment Using Plaxis 3DDocument13 pagesAbstract Number: 191 Finite Element Analysis of Geotextile Reinforced Highway Embankment Using Plaxis 3DAnjali SharmaNo ratings yet

- Druids: A Basic Fantasy RPG SupplementDocument10 pagesDruids: A Basic Fantasy RPG SupplementR_J_ValdebenitoNo ratings yet

- EASA FTL Members GuideDocument18 pagesEASA FTL Members Guideabdul haNo ratings yet

- Emily Gerard Transylvanian SuperstitionsDocument4 pagesEmily Gerard Transylvanian SuperstitionsErzsebet HeghyekNo ratings yet

- wph11 01 Rms 20230817Document17 pageswph11 01 Rms 20230817Nirmani RodrigoNo ratings yet

- Gsmintelligentalarmsystem Installation and User ManualDocument8 pagesGsmintelligentalarmsystem Installation and User ManualPierfrancesco FravoliniNo ratings yet

- Automotive Servicing NC I CG - Spideylab - Com - 2017Document45 pagesAutomotive Servicing NC I CG - Spideylab - Com - 2017Cristy Pearl S. GarciaNo ratings yet

- IV Set Calibration ManualDocument5 pagesIV Set Calibration ManualGarollfailNo ratings yet

- Belt Reeler BrochureDocument4 pagesBelt Reeler BrochureRestuNo ratings yet

- Module 5Document13 pagesModule 5let's skip this100% (1)

- DC/DC Converters: FeaturesDocument3 pagesDC/DC Converters: FeaturesPustinjak SaharicNo ratings yet

- Position, Leverage and Opportunity: A Typology of Strategic Logics Linking Resources With Competitive AdvantageDocument16 pagesPosition, Leverage and Opportunity: A Typology of Strategic Logics Linking Resources With Competitive AdvantageEdgar LL.CNo ratings yet

- Expt - 11: JFET CharacteristicsDocument8 pagesExpt - 11: JFET CharacteristicssamarthNo ratings yet

- The Statistical Distribution of The Maxima of A Random Function by Cartwright and Longuet HigginsDocument22 pagesThe Statistical Distribution of The Maxima of A Random Function by Cartwright and Longuet Higginsadaniliu13No ratings yet

- Biological Disaster: InformationDocument4 pagesBiological Disaster: InformationBarani DharanNo ratings yet

- Your Space 1 Skills Test 10Document2 pagesYour Space 1 Skills Test 10Maxi ComasNo ratings yet

- Physical Sciences P1 Feb March 2018 EngDocument20 pagesPhysical Sciences P1 Feb March 2018 EngKoketso LetswaloNo ratings yet

- Aviation Indutry in IndiaDocument20 pagesAviation Indutry in IndiayuktimNo ratings yet