Professional Documents

Culture Documents

Roof Drain Data Sheet.

Roof Drain Data Sheet.

Uploaded by

rohitOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roof Drain Data Sheet.

Roof Drain Data Sheet.

Uploaded by

rohitCopyright:

Available Formats

INDIAN OIL CORPORATION LIMITED

Pipelines Division

Western Region Pipelines, Gauridad (Rajkot)

5.2 Modification of dip-hatch

5.2.1 The work may include dismantling (in part or full) of existing dip-hatch, design (if need be),

fabrication, assembly, testing (NDT etc.,) and installat

tackles, consumables, manpower, supervision and any other requisite resources necessary to

complete the works per contract specifications, drawing / existing design and instructions of EIC

/ Site engineer.

5.2.2 The scope shall also include (as per site requirement) supply of 8mm brass plates, 25mm thick

neoprene rubber sheet, brass rollers with brackets, neoprene rubber 20mm thick (1mx1m), guide

rollers, CAF gasket 3mm thick, nut and bolts.

5.3 Replacement of roof drain system

5.3.1 Existing system

5.3.1.1 The existing roof drain system consists of either swivel joint type with carbon steel piping or flexible

hose type. The same shall be dismantled and replaced with new flexible joint type roof drain and carbon

steel piping.

5.3.2 Specification of New system Flexible joint type

5.3.2.1 The new system shall consist of flexible composite hose type joint.

5.3.2.2 The composite hose shall use stainless steel wire helixes and fabric / film made up of polypropylene /

polyester materials. The hose materials shall be compatible for immersion service in crude oil and sea

water.

5.3.2.3 Side and connection plates and flanges shall be of stainless steel construction. Flanges shall conform to

ASME B 16.5 - ANSI 150 pressure class with raised face.

5.3.2.4 The pipe size of the flexible joint type roof drain shall be 6inch. Design pressure should be 150psi.

5.3.3 Approved suppliers

5.3.3.1 HMT - Pivot Master (Indian representative: SB TankServe Private Limited, Pune)

5.3.3.2 ATECO Tank Technologies Engineering Co. Ltd. Bend Master Flexible Roof Drain Joint (Indian

Representative: WADCO Business Solutions Pvt. Ltd., Mumbai)

5.3.3.3 CTS Netherlands B.V

5.3.3.4 In case bidder desires to supply & install any other roof drain apart from above, following criteria shall

be technical bid while bidding

and prior to supply of roof drains at site:

5.3.3.4.1 Track record for supply of roof drains to reputed oil companies in India.

5.3.3.4.2 Document in support of satisfactory performance of

18.1m.

5.3.3.4.3 Track records of satisfactory performance of flexible joint type roof drain of size 6 inch diameter and

above in tanks 13.5m.

5.3.3.4.4 History of roof drain failure or damage to tank due to roof drains will also be considered for

evaluation and acceptance of the technical bids of the bidders.

5.3.4 Scope of work

Page 17 of 73

INDIAN OIL CORPORATION LIMITED

Pipelines Division

Western Region Pipelines, Gauridad (Rajkot)

5.3.4.1 The scope of work in general shall include but not limited to supply of flexible joint type roof drain and

carrying out following activities including all requisite resources:

5.3.4.1.1 Dismantling of existing roof drain system (entire piping from roof sump to funnel outside shell

external except shell nozzle) and transportation to Owners scrap yard

5.3.4.1.2 Fabrication of new roof drain piping and interconnection to the required dimensions

5.3.4.1.3 Installation of flexible joint type roof drain and associated piping with proper alignment and plumb

under supervision of representative of roof drain manufacturer.

5.3.4.1.4 Carrying out hydrostatic testing; test pressure shall be as recommended by the manufacturer.

5.4 Piping dismantling works (all size at all elevations)

5.4.1 All piping such as water draw off, product draw off, TRV lines, sprinkler and foam lines of all

sizes (& up to Sch 80) including all its components (valves, fittings, steel supports etc) are

covered in the scope.

5.4.2 Dismantling may be in part or full as per decision of EIC/ Site engineer.

5.4.3 The scope shall include all works (cutting, dis-assembling, transportation and stacking at Owners

yard) as defined above. This shall be inclusive of supply of manpower, tools, equipment,

machinery, consumables and any other resources:

Note: The scope excludes dip-hatch piping and roof drain system which are covered separately.

5.5 Fabrication, erection and testing (Carbon steel)

5.5.1 All water drawoff, product draw off, TRV lines (NPS 1 / 6 / 8), sprinkler and foam lines at

ground level are considered for this item.

5.5.2 Fabrication, erection and testing shall be as defined in Cl.5.1 above. Testing include NDE only.

5.6 Fabrication, erection and testing (stainless steel)

5.6.1 Foam riser and sprinkler riser / rings (NPS 3 / 4 / 6 / 8) are considered for this item.

5.6.2 Fabrication, erection and testing shall be as defined in Cl.5.1 above

Note: The sprinkler and foam assembly shall be hydrostatic tested at 15kg/cm2 pressure by blocking

the vertical header / riser and spray nozzle openings (by providing Teflon bolts etc.) for minimum of

4hrs or as per the instructions of the E-I-C. The contractor should make all arrangements necessary

for testing i.e. pressure developing pumps, gauge etc. Calibration certificate of pressure gauge to be

used for hydro-test shall be submitted prior to start the testing

5.7 Structural shapes

5.7.1 Structural shapes / sections used in staircases, rolling ladder, trusses/ rafters in roof, supports of

sprinkler / foam lines etc., shall be supplied by the Contractor.

5.7.2 All steel for structural shapes / sections shall conform ASTM A36 / IS 2062.

5.7.3 Gratings used as staircase steps shall be hot dip galvanised. Thickness of zinc coating shall be

minimum 100µm. The molten metal in the working volume of the galvanizing bath shall contain

not less than an average value of 98.5 % zinc by weight. Quality checks at site shall be:

Page 18 of 73

You might also like

- GP 03 19 01Document12 pagesGP 03 19 01Anonymous fvO1W3100% (2)

- FRP Tank Specifications PDFDocument5 pagesFRP Tank Specifications PDFRagh100% (1)

- Pipeline WeldingDocument40 pagesPipeline WeldingVinoth kanna100% (1)

- Wehrhahn - AAC - Info Catalogue-EnDocument49 pagesWehrhahn - AAC - Info Catalogue-EnJavier F. Via Giglio100% (1)

- GRP Pipe For SeawaterDocument22 pagesGRP Pipe For Seawatersethu1091100% (2)

- E1300 - Corrosion and CoatingsDocument3 pagesE1300 - Corrosion and Coatingsgerrzen64No ratings yet

- Scope of SupplyDocument23 pagesScope of SupplymoodydoodyNo ratings yet

- 06 Modu rcn3Document16 pages06 Modu rcn3djodje1No ratings yet

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocument11 pages4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- Ves 5145 R3Document10 pagesVes 5145 R3danikakaNo ratings yet

- Annexure 2A - Prestressing - VOLUME 5-69-84Document16 pagesAnnexure 2A - Prestressing - VOLUME 5-69-84ManukantShrotriyaNo ratings yet

- IS784Document38 pagesIS784SHEIK AZFARNo ratings yet

- 3PS Gaw 002Document6 pages3PS Gaw 002ravi00098No ratings yet

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDocument48 pages4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterNo ratings yet

- Tender Specification - Potable WaterDocument12 pagesTender Specification - Potable WaterSuhas NatuNo ratings yet

- Allstate Specification For Astm PDFDocument12 pagesAllstate Specification For Astm PDFZaendals JepitNo ratings yet

- Saes L 470Document10 pagesSaes L 470abaanNo ratings yet

- Cement Coated Pipe PDFDocument29 pagesCement Coated Pipe PDFArjed Ali ShaikhNo ratings yet

- Specs Pre-Cast Segment LiningsDocument8 pagesSpecs Pre-Cast Segment Liningssatan007No ratings yet

- 3PS Gaw 006 - 03Document53 pages3PS Gaw 006 - 03Viveck VivekNo ratings yet

- C. Specifications For Cone Roof TKDocument21 pagesC. Specifications For Cone Roof TKFajar Sidiq AliwiyonoNo ratings yet

- Tender Specification - Sea WaterDocument12 pagesTender Specification - Sea WaterSuhas NatuNo ratings yet

- 3PS Gaw 005 - 06Document46 pages3PS Gaw 005 - 06Viveck VivekNo ratings yet

- Piping Design Plant LayoutDocument23 pagesPiping Design Plant Layoutluxvij100% (1)

- 1488 2 Technical Specification ANNEXURE IIDocument3 pages1488 2 Technical Specification ANNEXURE IIsushant shirsatNo ratings yet

- Technial Specification - Transformer and Reactor Part 4Document10 pagesTechnial Specification - Transformer and Reactor Part 4amulya00428No ratings yet

- Additional Requirements For Special Criteria Pressure VesselsDocument15 pagesAdditional Requirements For Special Criteria Pressure Vesselsbenedicto soto mestanza100% (1)

- Bored Cast in Place PilesDocument10 pagesBored Cast in Place Pilesmarufpwd442No ratings yet

- Fire Water System Design PDFDocument22 pagesFire Water System Design PDFktejankarNo ratings yet

- Inspection Check List 3Document22 pagesInspection Check List 3r.devendranNo ratings yet

- DG BusductDocument16 pagesDG BusductanandpurushothamanNo ratings yet

- Chapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinDocument8 pagesChapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinchatxxnoirNo ratings yet

- Assessment 1 API 570Document5 pagesAssessment 1 API 570Mohamed ZainNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- Materials System SpecificationDocument10 pagesMaterials System SpecificationMoustafa Bayoumi100% (1)

- Specification For HDPE MANHOLES PDFDocument4 pagesSpecification For HDPE MANHOLES PDFPipeline EngineerNo ratings yet

- General Conditions and Technical SpecificationsDocument20 pagesGeneral Conditions and Technical Specificationsravirawat15No ratings yet

- SECTION 13200 Specification For Bolted Tank UIGDocument11 pagesSECTION 13200 Specification For Bolted Tank UIGEman Ismail HalawiNo ratings yet

- Va Nca 23 13 23Document6 pagesVa Nca 23 13 23Ali AlomyNo ratings yet

- HPCL Cement Lined Spec PDFDocument167 pagesHPCL Cement Lined Spec PDFvenkateshwaranNo ratings yet

- Part-Vi MaterialsDocument43 pagesPart-Vi Materialsjoydeep_d3232No ratings yet

- Jgpd-Isf-t-sh-sa-1302-04-Ms For Placement of Light Weight Concrete For Roof Deck Areas Rev-04Document87 pagesJgpd-Isf-t-sh-sa-1302-04-Ms For Placement of Light Weight Concrete For Roof Deck Areas Rev-04gulzamanNo ratings yet

- 25-04 - Glazed Curtain WallingDocument9 pages25-04 - Glazed Curtain WallingCip ZerkopNo ratings yet

- TDI33 Tank Inspection Suitaility For Service API 653 Sec 4Document29 pagesTDI33 Tank Inspection Suitaility For Service API 653 Sec 4Faizal SattuNo ratings yet

- QT-09-2008 ConcreteDocument25 pagesQT-09-2008 ConcreteRichard WriteNo ratings yet

- 3PS Gaw 003Document5 pages3PS Gaw 003ravi00098No ratings yet

- Power Transformer Manual PDFDocument82 pagesPower Transformer Manual PDFamulya00428No ratings yet

- Fabrication Inspection ProcedureDocument11 pagesFabrication Inspection Procedurewill_herry100% (6)

- l2 Heat Shrink Sleeve DrawingDocument4 pagesl2 Heat Shrink Sleeve Drawingresp-ectNo ratings yet

- Iwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudDocument38 pagesIwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudPratik KharmateNo ratings yet

- LPG Blending Facilities - List of Documents For TenderDocument235 pagesLPG Blending Facilities - List of Documents For TenderManish MehtaNo ratings yet

- PART 1B Tech SpecificationDocument98 pagesPART 1B Tech SpecificationChandrashekar PatigeNo ratings yet

- Saes H 204Document34 pagesSaes H 204heartbreakkid132No ratings yet

- Method Statement RE Structures-Final-29052011Document5 pagesMethod Statement RE Structures-Final-29052011sanojevNo ratings yet

- 13230Document19 pages13230sidnowsheraNo ratings yet

- Bolt Torquing ReferenceDocument8 pagesBolt Torquing ReferenceDILSHAD AHEMADNo ratings yet

- 01 Samss 005Document5 pages01 Samss 005Moustafa BayoumiNo ratings yet

- Technical Specification For Micropile ConstructionDocument9 pagesTechnical Specification For Micropile ConstructionFFerideKochanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Ateco Bend Master PO Copies - India2Document9 pagesAteco Bend Master PO Copies - India2rohitNo ratings yet

- BPCL Kochi Refinery Order For Leg SocksDocument1 pageBPCL Kochi Refinery Order For Leg SocksrohitNo ratings yet

- Ateco Bend Master PO Copies - India1Document8 pagesAteco Bend Master PO Copies - India1rohitNo ratings yet

- Essar Project PO For 16 Nos 6inch Bend Master (Essar Oil Vadinar Terminal) - 1Document2 pagesEssar Project PO For 16 Nos 6inch Bend Master (Essar Oil Vadinar Terminal) - 1rohitNo ratings yet

- Ateco Bend Master PO Copies - IndiaDocument18 pagesAteco Bend Master PO Copies - IndiarohitNo ratings yet

- Approved Supplier of IFR For IOCL Vijayawada Tender.Document2 pagesApproved Supplier of IFR For IOCL Vijayawada Tender.rohitNo ratings yet

- IOCL Motihari IFR Order From NRP Projects.Document3 pagesIOCL Motihari IFR Order From NRP Projects.rohitNo ratings yet

- Approved Supplier of IFR For IOCL Solapur Tender.Document2 pagesApproved Supplier of IFR For IOCL Solapur Tender.rohitNo ratings yet

- BVL Dau Han NgoaiDocument1 pageBVL Dau Han NgoaiHanLe DuyNo ratings yet

- GouacheDocument3 pagesGouachecuatro sharedNo ratings yet

- Kolkata Police Training AcademyDocument77 pagesKolkata Police Training AcademyMonjit RoyNo ratings yet

- Tma Members List South Circle 2022-2023Document15 pagesTma Members List South Circle 2022-2023acube.printerNo ratings yet

- Certificado de Producto Swivel OPW 241TPSDocument4 pagesCertificado de Producto Swivel OPW 241TPSManuel david Gómez zapataNo ratings yet

- General Purpose and Blended Cements: Australian StandardDocument7 pagesGeneral Purpose and Blended Cements: Australian StandardKrist Jan Jimenez SeparaNo ratings yet

- t2 Chem Revision Ex 5Document7 pagest2 Chem Revision Ex 5Nicholas Ow100% (1)

- BS en 10028-1 - 2000Document3 pagesBS en 10028-1 - 2000raduono100% (1)

- Gypsum Products DR ZainabDocument8 pagesGypsum Products DR Zainabمحمد جاسم محمد عجاجNo ratings yet

- Empirical and Molecular Formala Practice With Answer - 1Document3 pagesEmpirical and Molecular Formala Practice With Answer - 1711635No ratings yet

- 9 Different Types of Sheet Metals and Their Uses For 2020Document17 pages9 Different Types of Sheet Metals and Their Uses For 2020rejoyraju3No ratings yet

- Clay Systems For Improved PerformanceDocument5 pagesClay Systems For Improved PerformanceDouglas Franco de Souza100% (1)

- Ch.9-Study Guide Chemical Reactions Teacher EditableDocument9 pagesCh.9-Study Guide Chemical Reactions Teacher EditableOrganize gnqNo ratings yet

- Management of Hot Spots in Refractory Lined High Temperature EquipmentDocument8 pagesManagement of Hot Spots in Refractory Lined High Temperature EquipmentALEJANDRO FIGUEROANo ratings yet

- GB175 2007Document14 pagesGB175 2007Muhammad RidwanNo ratings yet

- Thermal Properties of PolycarbonatesDocument20 pagesThermal Properties of PolycarbonatesThụy Thảo LinhNo ratings yet

- CMB 847Document107 pagesCMB 847ManuelNo ratings yet

- Specification For Filler Metals For Brazing and Braze WeldingDocument42 pagesSpecification For Filler Metals For Brazing and Braze WeldingJoão BatistaNo ratings yet

- Study of Components (Hydrogen Chloride) : Lab Preparation of HCLDocument4 pagesStudy of Components (Hydrogen Chloride) : Lab Preparation of HCLSANDEEP SINGHNo ratings yet

- Ellamera BI THIN 602Document2 pagesEllamera BI THIN 602Waides Silva PachecoNo ratings yet

- Designing Plastic Products Injection MouldingDocument123 pagesDesigning Plastic Products Injection MouldingSandeep PatilNo ratings yet

- JSPLDocument19 pagesJSPLAnkitNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormAbhinandan BastiNo ratings yet

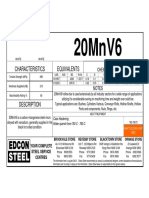

- Characteristics Equivalents: Chemical Analysis (%)Document1 pageCharacteristics Equivalents: Chemical Analysis (%)Ali TalebiNo ratings yet

- Use of The Other Ingredients in Cleaning Agents: By: Group 9Document56 pagesUse of The Other Ingredients in Cleaning Agents: By: Group 9Camille PasionNo ratings yet

- Standard Redox Potential Table PDFDocument10 pagesStandard Redox Potential Table PDFFercho LotudoNo ratings yet

- GurgaonDocument88 pagesGurgaonEkta Adlakha100% (3)

- Water Linelayout Sanitary Seweragelayout Septic TankDocument1 pageWater Linelayout Sanitary Seweragelayout Septic TankOwen Radaza PiranteNo ratings yet