Professional Documents

Culture Documents

GFK50 Gas Filter GFK

GFK50 Gas Filter GFK

Uploaded by

Papaleguas gamesCopyright:

Available Formats

You might also like

- THE LTSPICE XVII SIMULATOR: Commands and ApplicationsFrom EverandTHE LTSPICE XVII SIMULATOR: Commands and ApplicationsRating: 5 out of 5 stars5/5 (1)

- Siemens Videomed Dic ManualDocument38 pagesSiemens Videomed Dic ManualDante NuevoNo ratings yet

- PIC Microcontroller Projects in C: Basic to AdvancedFrom EverandPIC Microcontroller Projects in C: Basic to AdvancedRating: 5 out of 5 stars5/5 (10)

- ModulanteDocument23 pagesModulanteVBPNo ratings yet

- QL Technical Manual LOWresDocument44 pagesQL Technical Manual LOWresajayNo ratings yet

- Service Manual US-C 16 N... C 30 NDocument80 pagesService Manual US-C 16 N... C 30 NAlfredo VMNo ratings yet

- Valve de FlujoDocument22 pagesValve de FlujoimpwrcNo ratings yet

- Gas Pressure Regulators VGBF: Technical InformationDocument25 pagesGas Pressure Regulators VGBF: Technical InformationLuis Enrique Vidal GachaNo ratings yet

- GX SeriesDocument198 pagesGX SeriescesarNo ratings yet

- Manual Compresor GX2-22Document85 pagesManual Compresor GX2-22alex romero100% (4)

- Sampson ControlerDocument52 pagesSampson Controlerpetar.petrov.111964No ratings yet

- Granville-Phillips® Series 385 Convectron®Document152 pagesGranville-Phillips® Series 385 Convectron®Bruce M SchallerNo ratings yet

- Hydac FAMH ManualDocument28 pagesHydac FAMH ManualDavid A. LópezNo ratings yet

- Operation ManualDocument18 pagesOperation ManualnawajhaNo ratings yet

- MagiCAD 2008.5 Users GuideDocument382 pagesMagiCAD 2008.5 Users GuideDaneliuc Simion100% (1)

- 320D PDT ComparisonDocument22 pages320D PDT Comparisonlalo11715No ratings yet

- CLCH-PRC026A-En - 072015 - Performance UCCA Outdoor CatalogDocument88 pagesCLCH-PRC026A-En - 072015 - Performance UCCA Outdoor CatalogVietHienNo ratings yet

- 06 B04 - Bucher - Qxeh-2 - 100-P-000096-EnDocument13 pages06 B04 - Bucher - Qxeh-2 - 100-P-000096-EnYanis Anis HabetNo ratings yet

- Regulador de Pressão Iti - VGBF - GBDocument19 pagesRegulador de Pressão Iti - VGBF - GBEDILSONNo ratings yet

- Ipro2500 Manual ENDocument28 pagesIpro2500 Manual ENDonato Di BariNo ratings yet

- MS 02 346Document24 pagesMS 02 346Joshua EkoNo ratings yet

- GOT1000 HandbookDocument220 pagesGOT1000 HandbookREDDYGAARI ABBAYI100% (1)

- Tech HBDocument32 pagesTech HBGreg ReynekeNo ratings yet

- TSC YSC 3 A 10 TR R410 PDFDocument220 pagesTSC YSC 3 A 10 TR R410 PDFJesus DavalosNo ratings yet

- OIML R 137-1&2: Nternational EcommendationDocument70 pagesOIML R 137-1&2: Nternational EcommendationcrosswordsguyNo ratings yet

- Quicklub: Centralized Lubrication Pump 203 VDCDocument24 pagesQuicklub: Centralized Lubrication Pump 203 VDCGilmar SantosNo ratings yet

- GP 275545Document54 pagesGP 275545victorlawNo ratings yet

- 3040SSB Kodak m6Document22 pages3040SSB Kodak m6Pepe GarciaNo ratings yet

- Xensiv Pas Co2: DescriptionDocument19 pagesXensiv Pas Co2: DescriptionAvs ElectronNo ratings yet

- Product Specification: Articulated RobotDocument48 pagesProduct Specification: Articulated RobotFrancisco CalderónNo ratings yet

- Champion Log Splitter 22tonDocument25 pagesChampion Log Splitter 22tonChuck CharlesNo ratings yet

- AP3000 ManualDocument12 pagesAP3000 ManualSineepa PLOYNo ratings yet

- Installation Instructions: G51Mp Series UnitsDocument56 pagesInstallation Instructions: G51Mp Series UnitsJames LoewenNo ratings yet

- SH (NA) - 080862ENG-M - GT Converter2 Version3 Operating Manual For GT Works3Document66 pagesSH (NA) - 080862ENG-M - GT Converter2 Version3 Operating Manual For GT Works3Daniel PedrosoNo ratings yet

- VAM-J EEDEN19A Data Books EnglishDocument37 pagesVAM-J EEDEN19A Data Books EnglishValentin MalihinNo ratings yet

- Capnoflex LF Co: Service ManualDocument30 pagesCapnoflex LF Co: Service ManualfatihNo ratings yet

- Crompton Ac MotorsDocument50 pagesCrompton Ac Motorspriyanshsingh97100% (1)

- Printer Driver: Operating ManualDocument92 pagesPrinter Driver: Operating Manualfransm88No ratings yet

- Valvulas Vickers Tn32Document40 pagesValvulas Vickers Tn32jairobosquetti100% (1)

- E+h Liquiphant FTL20HDocument24 pagesE+h Liquiphant FTL20HJoheNo ratings yet

- TS G8xx-transducersV1-1EN LeuDocument26 pagesTS G8xx-transducersV1-1EN LeumariamNo ratings yet

- CG LT Motor Catalogue-2Document25 pagesCG LT Motor Catalogue-2lightsonsNo ratings yet

- D2 - DCM Data Communications ModuleDocument70 pagesD2 - DCM Data Communications ModuleSilvia Del RioNo ratings yet

- ComNav Vector G2 G2B Installation Operation ManualDocument62 pagesComNav Vector G2 G2B Installation Operation ManualmansoorNo ratings yet

- Grid Code Version 13Document460 pagesGrid Code Version 13Rachel GrahamNo ratings yet

- Operation: Marine Generator SetsDocument152 pagesOperation: Marine Generator Setsabduallah muhammad100% (1)

- Toyota 1kd2kd Common Rail SystemDocument31 pagesToyota 1kd2kd Common Rail SystemMuhammad Sulaiman100% (3)

- Válvula Control de Flujo - Series FN - F (C) y FRGDocument22 pagesVálvula Control de Flujo - Series FN - F (C) y FRGAlejandroSierraVargasNo ratings yet

- Operacion y Mant. Instrument AirDocument305 pagesOperacion y Mant. Instrument AirJo alberto Uribe minierNo ratings yet

- Belimo Zonetight Zone Valves Technical DocumentationDocument29 pagesBelimo Zonetight Zone Valves Technical DocumentationJames WhyRick?No ratings yet

- McQuay - Air Cool SplitDocument24 pagesMcQuay - Air Cool Splitakaashmohan1No ratings yet

- Uawi110x enDocument104 pagesUawi110x enSiboneloNo ratings yet

- Pump 203 VDC 2.1EN-38002-K11 ENDocument24 pagesPump 203 VDC 2.1EN-38002-K11 ENArtemNo ratings yet

- Proservo NMS5Document38 pagesProservo NMS5abcNo ratings yet

- Deploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideFrom EverandDeploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideRating: 5 out of 5 stars5/5 (2)

- Embedded DSP Processor Design: Application Specific Instruction Set ProcessorsFrom EverandEmbedded DSP Processor Design: Application Specific Instruction Set ProcessorsNo ratings yet

- Triple Play: Building the converged network for IP, VoIP and IPTVFrom EverandTriple Play: Building the converged network for IP, VoIP and IPTVNo ratings yet

- DSA0059074ZGDocument5 pagesDSA0059074ZGPapaleguas gamesNo ratings yet

- 6SL3210-1PE31-1UL0 Datasheet enDocument2 pages6SL3210-1PE31-1UL0 Datasheet enPapaleguas gamesNo ratings yet

- TDS NITOSEAL MS600 Saudi Arabia2Document3 pagesTDS NITOSEAL MS600 Saudi Arabia2Papaleguas gamesNo ratings yet

- BSTe B405 EN Sensors 2018 Low PDFDocument4 pagesBSTe B405 EN Sensors 2018 Low PDFPapaleguas gamesNo ratings yet

- PlotterDocument2 pagesPlotterPapaleguas gamesNo ratings yet

- 1Document2 pages1Papaleguas gamesNo ratings yet

- Catalogo MINICARTUCHOS-CAPSULAS - INGLSDocument18 pagesCatalogo MINICARTUCHOS-CAPSULAS - INGLSPapaleguas gamesNo ratings yet

- General Specifica TionsDocument2 pagesGeneral Specifica TionsPapaleguas gamesNo ratings yet

- SARTOPUREdata Sartopureind sgk2006 e DataDocument2 pagesSARTOPUREdata Sartopureind sgk2006 e DataPapaleguas gamesNo ratings yet

- CODIGOS REXROTH ELEMENTOS LOGICOS ETC-codici - Fuori - Produzione - Codici - SostitutiviDocument435 pagesCODIGOS REXROTH ELEMENTOS LOGICOS ETC-codici - Fuori - Produzione - Codici - SostitutiviPapaleguas gamesNo ratings yet

- Despaletizadora AS 1 H - (2) - 1601-2000Document400 pagesDespaletizadora AS 1 H - (2) - 1601-2000Papaleguas gamesNo ratings yet

- DGMFNDocument22 pagesDGMFNPapaleguas gamesNo ratings yet

- VG 15Document6 pagesVG 15Papaleguas gamesNo ratings yet

- Hed8 Series 1xDocument10 pagesHed8 Series 1xPapaleguas gamesNo ratings yet

- As3-Rgs-Regulador Pressao PneumaticoDocument3 pagesAs3-Rgs-Regulador Pressao PneumaticoPapaleguas gamesNo ratings yet

- HH52, HH53, HH54 Series: Miniature Control RelaysDocument4 pagesHH52, HH53, HH54 Series: Miniature Control RelaysPapaleguas gamesNo ratings yet

- 649 Valvula PDFDocument45 pages649 Valvula PDFPapaleguas gamesNo ratings yet

- GTA-120シリーズ 取説 (2312)Document104 pagesGTA-120シリーズ 取説 (2312)Papaleguas gamesNo ratings yet

- DR30B5Document6 pagesDR30B5Papaleguas gamesNo ratings yet

- R 6 Catalogen Pcac2017a1Document2 pagesR 6 Catalogen Pcac2017a1Papaleguas gamesNo ratings yet

- Sterilfilter P SRFDocument3 pagesSterilfilter P SRFPapaleguas gamesNo ratings yet

- GTA-120 Series: Specifications and Instruction ManualDocument104 pagesGTA-120 Series: Specifications and Instruction ManualPapaleguas gamesNo ratings yet

- Protection Against Dirt, Sand and RustDocument2 pagesProtection Against Dirt, Sand and RustPapaleguas gamesNo ratings yet

- Donaldson Price List 2017Document499 pagesDonaldson Price List 2017Papaleguas gamesNo ratings yet

- Smart GuideDocument674 pagesSmart GuidePapaleguas gamesNo ratings yet

- Installation Instructions: Durametallic P-50Document12 pagesInstallation Instructions: Durametallic P-50Papaleguas gamesNo ratings yet

- S 40 45McCannalok Snow Brochure 6 - 6 - 18Document8 pagesS 40 45McCannalok Snow Brochure 6 - 6 - 18Papaleguas gamesNo ratings yet

- Bearing Supports-1Document145 pagesBearing Supports-1Papaleguas gamesNo ratings yet

- PV Elite - Pressure Vessel DesignDocument6 pagesPV Elite - Pressure Vessel Designbudy sinaga100% (4)

- Steel MembersDocument6 pagesSteel Membersalinaitwe shalifuNo ratings yet

- Is 6392 1971Document62 pagesIs 6392 1971Chandra SekharNo ratings yet

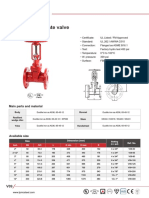

- Flanged OS&Y Gate Valve: Main Parts and MaterialDocument1 pageFlanged OS&Y Gate Valve: Main Parts and Materialmourad laatatNo ratings yet

- New Microsoft Office Word DocumentDocument5 pagesNew Microsoft Office Word Documentruhul43No ratings yet

- Fastwind 2014 200CC Parts Catalogue 2015 02 05Document32 pagesFastwind 2014 200CC Parts Catalogue 2015 02 05JeovannyAlexanderMatamorosSanchez100% (1)

- BBG200719ENDocument314 pagesBBG200719ENAbhinandan PadhaNo ratings yet

- Kawasaki KMX 125-A12 Parts ManualDocument113 pagesKawasaki KMX 125-A12 Parts ManualLarge Rice100% (4)

- 5.6 Execution 5.4 5.5: Ball ValvesDocument2 pages5.6 Execution 5.4 5.5: Ball ValvesMajid DixonNo ratings yet

- Grupo de Montagem Group Index Alpha Grupos de Montaje Groupes de MontageDocument437 pagesGrupo de Montagem Group Index Alpha Grupos de Montaje Groupes de MontagewanderNo ratings yet

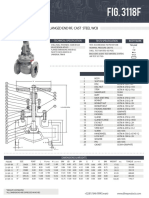

- 3118F 3318F 3618F-SeriesDocument6 pages3118F 3318F 3618F-SeriesDavid CandoNo ratings yet

- Piping Classes - Rev07Document39 pagesPiping Classes - Rev07Sali NdjiddaNo ratings yet

- Tank Drawings Example PDFDocument2 pagesTank Drawings Example PDFMiguel OrhlNo ratings yet

- S-00-1360-001 Rev.0 - FC (General Specification For Piping)Document11 pagesS-00-1360-001 Rev.0 - FC (General Specification For Piping)ajmainNo ratings yet

- Section 23 21 14 - Underground Pre-Insulated Hydronic PipingDocument7 pagesSection 23 21 14 - Underground Pre-Insulated Hydronic PipingaadsamudNo ratings yet

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutNo ratings yet

- Nordstrom Steel Plug Valves: Experience in MotionDocument60 pagesNordstrom Steel Plug Valves: Experience in MotionJorge Hanna AkouriNo ratings yet

- Dimension Flange AsmeDocument10 pagesDimension Flange AsmeHanif SaidonNo ratings yet

- Grove g4n Gate Valve BrochureDocument24 pagesGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Cobra-Tdc: Tilting Disc Check Valve With Lever and Counterweight/ Hydraulic Damper PN 10 / 16 / 25 DN 100 - 2200Document7 pagesCobra-Tdc: Tilting Disc Check Valve With Lever and Counterweight/ Hydraulic Damper PN 10 / 16 / 25 DN 100 - 2200GogyNo ratings yet

- Installation Manual Color Scanning Sonar FSV-30/FSV-30S: WWW - Furuno.co - JPDocument80 pagesInstallation Manual Color Scanning Sonar FSV-30/FSV-30S: WWW - Furuno.co - JPCali MelendezNo ratings yet

- Atmospheric Storage Tanks: 11-1-1 BP Oil Co. RPDocument54 pagesAtmospheric Storage Tanks: 11-1-1 BP Oil Co. RPHardik AcharyaNo ratings yet

- Specification For Fire MonitorDocument4 pagesSpecification For Fire Monitorromdhan88No ratings yet

- X Ride Part CatalogueDocument46 pagesX Ride Part CatalogueMahful Irvay MukhlisNo ratings yet

- Welded Tanks For Oil StorageDocument58 pagesWelded Tanks For Oil StorageDwi HermawanNo ratings yet

- Specification For Hot Water Boilers-9-10Document2 pagesSpecification For Hot Water Boilers-9-10Karthik AnandanNo ratings yet

- DANAIS MT II CL 150 ENDocument28 pagesDANAIS MT II CL 150 ENLasombra DelPatoNo ratings yet

- PP Lined Pipe PDFDocument27 pagesPP Lined Pipe PDFNILADRI BHATTACHARYYANo ratings yet

- Calculator ASME B31 4Document9 pagesCalculator ASME B31 4jleonos100% (3)

- CNC:DSTV & Pipe Profiling: Aaron LeacockDocument52 pagesCNC:DSTV & Pipe Profiling: Aaron Leacockraymond wilburnNo ratings yet

GFK50 Gas Filter GFK

GFK50 Gas Filter GFK

Uploaded by

Papaleguas gamesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GFK50 Gas Filter GFK

GFK50 Gas Filter GFK

Uploaded by

Papaleguas gamesCopyright:

Available Formats

Gas filters GFK

Technical Information · GB

1 Edition 06.14

• For the protection of downstream devices against blockage

• Very high throughput

• High purification efficiency

• Long service life

• Easy-to-replace filter pad

• EC type-tested and certified

Contents

Gas filters GFK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Examples of application . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Animation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Calculating the nominal size . . . . . . . . . . . . . . . . . . . . . 8

5 Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 T-products range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Project planning information . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

7.1 Filter pads with a separation rate of 50 µm . . . . . . . . . 11

7.2 Filter pads with a special separation rate of 10 µm . . . 11

8 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.1.1 GFK 15 to 250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.1.2 GFK 15T to 100T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9 Maintenance cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

GFK · Edition 06.14 ▼ = To be continued 2

1 Application

GFK..R

GFK..F

Suitable for filtration of the fuel gas and combustion air supply

to all gas consuming appliances.

GFK · Edition 06.14 3

Application

1.1 Examples of application

Gas pressure control system with GFK..F Pressure control system with GFK..R

Main gas shut-off device with GFK..F

GFK · Edition 06.14 4

2 Certification

EC type-tested and certified

pursuant to:

– Gas Appliances Directive (2009/142/EC)

GFK · Edition 06.14 5

3 Function

Gas filter GFK is used for cleaning fuel gases and air.

With clean filter pad 1 with a standard separation rate of 50 μm,

the pressure gradient over the filter pad must not exceed

10 mbar (4 “WC).

1 The pressure gradient will increase with soiling due to the

gas. The filter pad must be changed at a pressure gradient

≥ 20 mbar (8 "WC), see operating instructions. Otherwise, dust

may be forced through the pad.

GFK · Edition 06.14 6

Function

3.1 Animation Go to www.adobe.com, click on “Adobe Reader” at the bottom

The interactive animation shows the function of the gas filter of the page and follow the instructions.

GFK. If the animation does not start to play, you can download

Click on the picture. The animation can be controlled using the it from the document library (Docuthek) as an independent

control bar at the bottom of the window (as on a DVD player). application.

To play the animation, you will need Adobe Reader 9 or a newer

version. If you do not have Adobe Reader on your system, you

can download it from the Internet.

GFK · Edition 06.14 7

4 Flow rate Reading instructions:

When determining the pressure loss, operat-

ing cubic metres must be entered. Then the

20

8 pressure loss Δp read must be multiplied by

∆p [inch WC]

∆p [mbar]

GF 200

50

00

25

50

the absolute pressure in bar (positive pressure

0

0

0

6

K2

K2

K2

K3

K4

K5

K6

K8

K1

K1

K1

K1

5

K

+ 1) to account for the change in the medium’s

GF

GF

GF

GF

GF

GF

GF

GF

GF

GF

GF

GF

4 10

8 density.

3 ●

6 Example:

2 5

4

inlet pressure pu (positive pressure) = 4 bar,

3

gas type: natural gas,

1 operating flow rate Qb = 150 m3/h (b),

0,8 2 selected filter: GFK 65,

0,6 Δp in the diagram = 1.5 mbar,

0,5

Δp = 1.5 mbar x (1 + 4) = 7.5 mbar.

0,4 1

0,3 0,8 The GFK 65 has been selected correctly.

0,6

0,2 0,5

0,4 4.1 Calculating the nominal size

0,3 Standard T-product

1

0,8 0,2 Enter density

Natural gas 0.80 kg/m3

0,6

0,5 Flow rate Q (standard) 740 m3/h

0,4 1 0,1 Inlet pressure pu 4000 mbar

10 20 30 40 60 80 100 200 300 400 600 1000 2000 3000 5000

2

20 30 40 60 80 100 200 300 400 600 1000 2000 3000 5000 ∆pmax. 10.0 mbar

3

7 8 10 20 30 40 60 80 100 200 300 400 600 1000 2000 3000 Medium temperature 0 °C

4

8 10 20 30 40 60 80 100 200 300 400 600 1000 2000 3000

Q [m3/h (n)] Flow rate Q (operation) 150 m3/h

1

300 400 600 1000 2000 4000 6000 10000 20000 30000 50000 100000 Product ∆p v

Q [SCFH] [mbar] [m/s]

GFK 65 | 7,5 | 11

GFK 80 | 3,2 | 8

GFK 100 | 1,5 | 5

= natural gas (ρ = 0.80 kg/m3) A pressure loss of 10 mbar must not be ex- GFK 125 | 0,8 | 3

b = town gas (ρ = 0.58 kg/m3) ceeded. GFK 150 | 0,4 | 2

c = propane (ρ = 2.01 kg/m3) GFK 200 | 0,1 | 1

d = air (ρ = 1.29 kg/m3) GFK 250 | 0,1 | 1

GFK · Edition 06.14 8

5 Selection

5.1 Standard range 5.2 T-products range

10 40 60 -3 -6 N A 40 -3

GFK 15R GFK 15T

GFK 20R GFK 20T

GFK 25R GFK 25T

GFK 32R GFK 40T

GFK 40R GFK 50T

GFK 50R GFK 65T

GFK 65R GFK 80T

GFK 40F GFK 100T

GFK 50F

Order example

GFK 65F

GFK 40TN40-3

GFK 80F

GFK 100F

5.3 Type code

GFK 125F

Code Description

GFK 150F

GFK Gas filter

GFK 200F

15, 20, 25, 32, 40, 50, 65,

GFK 250F Nominal size

80, 100, 125, 150, 200, 250

Order example T T-product

GFK 32R10-6 R Rp internal thread

F Flanged connection to ISO 7005

N NPT internal thread

A ANSI flange

Max. inlet pressure pu max.

10 1 bar

40 4 bar (58 psig)

60 6 bar

-3 Screw plug at the inlet and outlet

-6 Pressure test point at the

inlet and outlet

GFK · Edition 06.14 9

6 Project planning information

6.1 Installation

Installation in horizontal and vertical pipework.

The housing cover should be detachable at the side so that

no dirt gets into the housing during maintenance.

GFK · Edition 06.14 10

7 Accessories 7.2 Filter pads with a special separation rate of

10 µm

7.1 Filter pads with a separation rate of 50 µm

For air or inert gases only.

Spare parts set GFK 15/20, 10 filter pads and 10 O-rings,

Order No.: 71935010. Spare parts set GFK 15+20R40-S10,

10 filter pads and 10 O-rings,

Spare parts set GFK 25/32, 10 filter pads and 10 O-rings,

Order No.: 74919810.

Order No.: 71937010.

Spare parts set GFK 25+32R40-S10,

Spare parts set GFK 40/50, 5 filter pads and 5 O-rings,

10 filter pads and 10 O-rings,

Order No.: 71939010.

Order No.: 74919811.

Spare parts set GFK 65, 1 filter pad and 1 O-ring,

Spare parts set GFK 40+50F40-S10,

Order No.: 74923284.

5 filter pads and 5 O-rings,

Spare parts set GFK 80, 1 filter pad and 1 O-ring, Order No.: 74919812.

Order No.: 74923285.

Spare parts set GFK 65..S10,

Spare parts set GFK 100, 1 filter pad and 1 O-ring, 1 filter pad and 1 O-ring,

Order No.: 74923286. Order No.: 74923281.

Filter pad GFK 125, Spare parts set GFK 80..S10,

Order No.: 35448581. 1 filter pad and 1 O-ring,

O-ring 308x8 for GFK 125/150, Order No.: 74923282.

Order No.: 03110013. Spare parts set GFK 100..S10,

Filter pad GFK 150, 1 filter pad and 1 O-ring,

Order No.: 35448583. Order No.: 74923283.

O-ring 308x8 for GFK 125/150,

Order No.: 03110013.

Filter pad GFK 200/250,

Order No.: 35448584.

O-ring 430x8 for GFK 200/250,

Order No.: 03109164.

GFK · Edition 06.14 11

8 Technical data

Gas type:

natural gas, town gas, LPG (gaseous), biologically produced

methane and air.

Max. inlet pressure pu:

1 bar GFK 15 to 250,

4 bar (60 psig) GFK 15R to 65R, GFK 15TN to 100TN,

6 bar GFK 40F to 100F.

Ambient temperature: -15 to +80°C (5 to 176°F).

Continuous operation at high temperatures accelerates the

ageing of elastomer materials.

Version to DIN 3386

Housing

GFK 15 to 100 made from AlSi.

GFK 125 to 250 made from sheet steel.

GFK..R: Rp internal thread connection to ISO 7-1.

GFK..F: flanged connection to ISO 7005, PN 16.

GFK..N: NPT internal thread.

GFK..A: ANSI 150 flanged connection.

Filter pad: polypropylene fleece (standard 50 µm).

Pressure test points on the cover

GFK 15 to 100:

Inlet side: Rp 1/8 pressure test nipple,

Outlet side: Rp 1/8 pressure test nipple.

GFK 125 to 250:

Inlet side: Rp 1/8 plug,

Outlet side: Rp 1/8 plug.

GFK 15T to 100T:

Inlet side: Rp 1/8 plug,

Outlet side: Rp 1/8 plug.

GFK · Edition 06.14 12

Technical data

8.1 Dimensions

8.1.1 GFK 15 to 250

H2

H2 k H1 GFK 200

D2 d2 GFK 250

H1 øD

L

L

GFK..R GFK..F

Type Dimensions Flange Drilling pu max. Weight Filter

L ØD H1 H2 D2 k d2 No.

DN Connection mm mm mm mm mm mm mm bar kg mm x mm

GFK 15 15 Rp ½ 92 88 69 33 – – – – 1+4 0.4 127 x 56

GFK 20 20 Rp ¾ 92 88 69 33 – – – – 1+4 0.4 127 x 56

GFK 25 25 Rp 1 135 134 69 43 – – – – 1+4 0.8 210 x 75

GFK 32 32 Rp 1¼ 135 134 69 43 – – – – 1+4 0.8 210 x 75

GFK 40 40 Rp 1½ 208 182 88 64 – – – – 1+4 2.0 323 x 114

GFK 50 50 Rp 2 208 182 88 64 – – – – 1+4 2.0 323 x 114

GFK 65 65 Rp 2½ 220 182 119 96 – – – – 1+4 3.3 323 x 177

GFK 40 40 40 256 182 88 63 150 110 18 4 1+6 3.9 323 x 114

GFK 50 50 50 250 182 88 63 165 125 18 4 1+6 4.2 323 x 114

GFK 65 65 65 250 182 118 97 185 145 18 4 1+6 5.5 323 x 177

GFK 80 80 80 330 262 133 87 200 160 18 8 1+6 9.6 489 x 177

GFK 100 100 100 350 262 137 120 228 180 18 8 1+6 11.5 437 x 209

GFK 125 125 125 470 355 133 125 250 210 18 8 1+4 45.0 675 x 226

GFK 150 150 150 470 355 181 167 285 240 23 8 1+4 55.0 675 x 316

GFK 200 200 200 630 500 310 202 340 295 23 12 1 120.0 908 x 417

GFK 250 250 250 630 500 310 202 355 355 27 12 1 130.0 908 x 417

GFK · Edition 06.14 13

Technical data > Dimensions

8.1.2 GFK 15T to 100T

H2

H2 k H1

D2 d2

H1 øD

L

GFK..N GFK..A

Type Connection Dimensions ANSI 150 flange Drilling Weight Filter pad

NPT L ØD H1 H2 D2 k d2 No. Dimensions

ANSI DN inch inch inch inch inch inch inch lbs inch2

GFK 15TN ½ 15 3.26 3.46 2.01 1.23 – – – – 0.8 9.3

GFK 20TN ¾ 20 3.62 3.46 2.01 1.23 – – – – 0.8 9.3

GFK 25TN 1 25 5.35 5.28 2.20 1.73 – – – – 1.7 21

GFK 40TN 1½ 40 8.19 5.28 2.99 2.52 – – – – 4.4 52

GFK 50TN 2 50 8.19 5.28 2.99 2.52 – – – – 4.9 52

GFK 65TN 2½ 65 8.66 5.28 4.17 3.78 – – – – 11.5 89

GFK 50TA 2 50 9.84 5.28 2.99 2.48 5.98 4.76 0.75 4 9.3 52

GFK 65TA 2½ 65 9.84 5.28 4.17 3.82 7.01 5.51 0.75 4 11.5 84

GFK 80TA 3 80 13.0 10.3 4.72 3.42 7.52 5.98 0.75 4 17.6 122

GFK 100TA 4 100 13.8 10.3 4.92 4.72 9.02 7.52 0.75 8 20.5 145

GFK · Edition 06.14 14

9 Maintenance cycles

Change filter pad once per annum, twice per annum for bio-

logically produced methane, or in case the pressure differential

on the gas filter has risen by 100% compared to when new,

Δpmax. = 20 mbar.

GFK · Edition 06.14 15

Feedback

Finally, we are offering you the opportunity to assess this “Technical Information (TI)” and to give us your opinion, so that we

can improve our documents further and suit them to your needs.

Clarity Comprehension Scope

Found information quickly Coherent Too little

Searched for a long time Too complicated Sufficient

Didn’t find information No answer Too wide

What is missing? No answer

No answer

Use Navigation My scope of functions

✔ To get to know the product I can find my way around Technical department

✔ To choose a product I got “lost” Sales

✔ Planning No answer No answer

✔ To look for information

Remarks

(Adobe Reader 7 or higher required)

Kromschröder AG

Michael Rehkamp

m.rehkamp@kromschroeder.com

www.adobe.com

Osnabrück

Contact

Elster GmbH The current addresses of our international agents are

Postfach 2809 · 49018 Osnabrück available on the Internet:

Strotheweg 1 · 49504 Lotte (Büren) www.kromschroeder.de/index.php?id=718&L=1

Germany

T +49 541 1214-0 We reserve the right to make technical modifications

03250819

F +49 541 1214-370 in the interests of progress.

info@kromschroeder.com Copyright © 2014 Elster GmbH

www.kromschroeder.com All rights reserved.

GFK · Edition 06.14

You might also like

- THE LTSPICE XVII SIMULATOR: Commands and ApplicationsFrom EverandTHE LTSPICE XVII SIMULATOR: Commands and ApplicationsRating: 5 out of 5 stars5/5 (1)

- Siemens Videomed Dic ManualDocument38 pagesSiemens Videomed Dic ManualDante NuevoNo ratings yet

- PIC Microcontroller Projects in C: Basic to AdvancedFrom EverandPIC Microcontroller Projects in C: Basic to AdvancedRating: 5 out of 5 stars5/5 (10)

- ModulanteDocument23 pagesModulanteVBPNo ratings yet

- QL Technical Manual LOWresDocument44 pagesQL Technical Manual LOWresajayNo ratings yet

- Service Manual US-C 16 N... C 30 NDocument80 pagesService Manual US-C 16 N... C 30 NAlfredo VMNo ratings yet

- Valve de FlujoDocument22 pagesValve de FlujoimpwrcNo ratings yet

- Gas Pressure Regulators VGBF: Technical InformationDocument25 pagesGas Pressure Regulators VGBF: Technical InformationLuis Enrique Vidal GachaNo ratings yet

- GX SeriesDocument198 pagesGX SeriescesarNo ratings yet

- Manual Compresor GX2-22Document85 pagesManual Compresor GX2-22alex romero100% (4)

- Sampson ControlerDocument52 pagesSampson Controlerpetar.petrov.111964No ratings yet

- Granville-Phillips® Series 385 Convectron®Document152 pagesGranville-Phillips® Series 385 Convectron®Bruce M SchallerNo ratings yet

- Hydac FAMH ManualDocument28 pagesHydac FAMH ManualDavid A. LópezNo ratings yet

- Operation ManualDocument18 pagesOperation ManualnawajhaNo ratings yet

- MagiCAD 2008.5 Users GuideDocument382 pagesMagiCAD 2008.5 Users GuideDaneliuc Simion100% (1)

- 320D PDT ComparisonDocument22 pages320D PDT Comparisonlalo11715No ratings yet

- CLCH-PRC026A-En - 072015 - Performance UCCA Outdoor CatalogDocument88 pagesCLCH-PRC026A-En - 072015 - Performance UCCA Outdoor CatalogVietHienNo ratings yet

- 06 B04 - Bucher - Qxeh-2 - 100-P-000096-EnDocument13 pages06 B04 - Bucher - Qxeh-2 - 100-P-000096-EnYanis Anis HabetNo ratings yet

- Regulador de Pressão Iti - VGBF - GBDocument19 pagesRegulador de Pressão Iti - VGBF - GBEDILSONNo ratings yet

- Ipro2500 Manual ENDocument28 pagesIpro2500 Manual ENDonato Di BariNo ratings yet

- MS 02 346Document24 pagesMS 02 346Joshua EkoNo ratings yet

- GOT1000 HandbookDocument220 pagesGOT1000 HandbookREDDYGAARI ABBAYI100% (1)

- Tech HBDocument32 pagesTech HBGreg ReynekeNo ratings yet

- TSC YSC 3 A 10 TR R410 PDFDocument220 pagesTSC YSC 3 A 10 TR R410 PDFJesus DavalosNo ratings yet

- OIML R 137-1&2: Nternational EcommendationDocument70 pagesOIML R 137-1&2: Nternational EcommendationcrosswordsguyNo ratings yet

- Quicklub: Centralized Lubrication Pump 203 VDCDocument24 pagesQuicklub: Centralized Lubrication Pump 203 VDCGilmar SantosNo ratings yet

- GP 275545Document54 pagesGP 275545victorlawNo ratings yet

- 3040SSB Kodak m6Document22 pages3040SSB Kodak m6Pepe GarciaNo ratings yet

- Xensiv Pas Co2: DescriptionDocument19 pagesXensiv Pas Co2: DescriptionAvs ElectronNo ratings yet

- Product Specification: Articulated RobotDocument48 pagesProduct Specification: Articulated RobotFrancisco CalderónNo ratings yet

- Champion Log Splitter 22tonDocument25 pagesChampion Log Splitter 22tonChuck CharlesNo ratings yet

- AP3000 ManualDocument12 pagesAP3000 ManualSineepa PLOYNo ratings yet

- Installation Instructions: G51Mp Series UnitsDocument56 pagesInstallation Instructions: G51Mp Series UnitsJames LoewenNo ratings yet

- SH (NA) - 080862ENG-M - GT Converter2 Version3 Operating Manual For GT Works3Document66 pagesSH (NA) - 080862ENG-M - GT Converter2 Version3 Operating Manual For GT Works3Daniel PedrosoNo ratings yet

- VAM-J EEDEN19A Data Books EnglishDocument37 pagesVAM-J EEDEN19A Data Books EnglishValentin MalihinNo ratings yet

- Capnoflex LF Co: Service ManualDocument30 pagesCapnoflex LF Co: Service ManualfatihNo ratings yet

- Crompton Ac MotorsDocument50 pagesCrompton Ac Motorspriyanshsingh97100% (1)

- Printer Driver: Operating ManualDocument92 pagesPrinter Driver: Operating Manualfransm88No ratings yet

- Valvulas Vickers Tn32Document40 pagesValvulas Vickers Tn32jairobosquetti100% (1)

- E+h Liquiphant FTL20HDocument24 pagesE+h Liquiphant FTL20HJoheNo ratings yet

- TS G8xx-transducersV1-1EN LeuDocument26 pagesTS G8xx-transducersV1-1EN LeumariamNo ratings yet

- CG LT Motor Catalogue-2Document25 pagesCG LT Motor Catalogue-2lightsonsNo ratings yet

- D2 - DCM Data Communications ModuleDocument70 pagesD2 - DCM Data Communications ModuleSilvia Del RioNo ratings yet

- ComNav Vector G2 G2B Installation Operation ManualDocument62 pagesComNav Vector G2 G2B Installation Operation ManualmansoorNo ratings yet

- Grid Code Version 13Document460 pagesGrid Code Version 13Rachel GrahamNo ratings yet

- Operation: Marine Generator SetsDocument152 pagesOperation: Marine Generator Setsabduallah muhammad100% (1)

- Toyota 1kd2kd Common Rail SystemDocument31 pagesToyota 1kd2kd Common Rail SystemMuhammad Sulaiman100% (3)

- Válvula Control de Flujo - Series FN - F (C) y FRGDocument22 pagesVálvula Control de Flujo - Series FN - F (C) y FRGAlejandroSierraVargasNo ratings yet

- Operacion y Mant. Instrument AirDocument305 pagesOperacion y Mant. Instrument AirJo alberto Uribe minierNo ratings yet

- Belimo Zonetight Zone Valves Technical DocumentationDocument29 pagesBelimo Zonetight Zone Valves Technical DocumentationJames WhyRick?No ratings yet

- McQuay - Air Cool SplitDocument24 pagesMcQuay - Air Cool Splitakaashmohan1No ratings yet

- Uawi110x enDocument104 pagesUawi110x enSiboneloNo ratings yet

- Pump 203 VDC 2.1EN-38002-K11 ENDocument24 pagesPump 203 VDC 2.1EN-38002-K11 ENArtemNo ratings yet

- Proservo NMS5Document38 pagesProservo NMS5abcNo ratings yet

- Deploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideFrom EverandDeploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideRating: 5 out of 5 stars5/5 (2)

- Embedded DSP Processor Design: Application Specific Instruction Set ProcessorsFrom EverandEmbedded DSP Processor Design: Application Specific Instruction Set ProcessorsNo ratings yet

- Triple Play: Building the converged network for IP, VoIP and IPTVFrom EverandTriple Play: Building the converged network for IP, VoIP and IPTVNo ratings yet

- DSA0059074ZGDocument5 pagesDSA0059074ZGPapaleguas gamesNo ratings yet

- 6SL3210-1PE31-1UL0 Datasheet enDocument2 pages6SL3210-1PE31-1UL0 Datasheet enPapaleguas gamesNo ratings yet

- TDS NITOSEAL MS600 Saudi Arabia2Document3 pagesTDS NITOSEAL MS600 Saudi Arabia2Papaleguas gamesNo ratings yet

- BSTe B405 EN Sensors 2018 Low PDFDocument4 pagesBSTe B405 EN Sensors 2018 Low PDFPapaleguas gamesNo ratings yet

- PlotterDocument2 pagesPlotterPapaleguas gamesNo ratings yet

- 1Document2 pages1Papaleguas gamesNo ratings yet

- Catalogo MINICARTUCHOS-CAPSULAS - INGLSDocument18 pagesCatalogo MINICARTUCHOS-CAPSULAS - INGLSPapaleguas gamesNo ratings yet

- General Specifica TionsDocument2 pagesGeneral Specifica TionsPapaleguas gamesNo ratings yet

- SARTOPUREdata Sartopureind sgk2006 e DataDocument2 pagesSARTOPUREdata Sartopureind sgk2006 e DataPapaleguas gamesNo ratings yet

- CODIGOS REXROTH ELEMENTOS LOGICOS ETC-codici - Fuori - Produzione - Codici - SostitutiviDocument435 pagesCODIGOS REXROTH ELEMENTOS LOGICOS ETC-codici - Fuori - Produzione - Codici - SostitutiviPapaleguas gamesNo ratings yet

- Despaletizadora AS 1 H - (2) - 1601-2000Document400 pagesDespaletizadora AS 1 H - (2) - 1601-2000Papaleguas gamesNo ratings yet

- DGMFNDocument22 pagesDGMFNPapaleguas gamesNo ratings yet

- VG 15Document6 pagesVG 15Papaleguas gamesNo ratings yet

- Hed8 Series 1xDocument10 pagesHed8 Series 1xPapaleguas gamesNo ratings yet

- As3-Rgs-Regulador Pressao PneumaticoDocument3 pagesAs3-Rgs-Regulador Pressao PneumaticoPapaleguas gamesNo ratings yet

- HH52, HH53, HH54 Series: Miniature Control RelaysDocument4 pagesHH52, HH53, HH54 Series: Miniature Control RelaysPapaleguas gamesNo ratings yet

- 649 Valvula PDFDocument45 pages649 Valvula PDFPapaleguas gamesNo ratings yet

- GTA-120シリーズ 取説 (2312)Document104 pagesGTA-120シリーズ 取説 (2312)Papaleguas gamesNo ratings yet

- DR30B5Document6 pagesDR30B5Papaleguas gamesNo ratings yet

- R 6 Catalogen Pcac2017a1Document2 pagesR 6 Catalogen Pcac2017a1Papaleguas gamesNo ratings yet

- Sterilfilter P SRFDocument3 pagesSterilfilter P SRFPapaleguas gamesNo ratings yet

- GTA-120 Series: Specifications and Instruction ManualDocument104 pagesGTA-120 Series: Specifications and Instruction ManualPapaleguas gamesNo ratings yet

- Protection Against Dirt, Sand and RustDocument2 pagesProtection Against Dirt, Sand and RustPapaleguas gamesNo ratings yet

- Donaldson Price List 2017Document499 pagesDonaldson Price List 2017Papaleguas gamesNo ratings yet

- Smart GuideDocument674 pagesSmart GuidePapaleguas gamesNo ratings yet

- Installation Instructions: Durametallic P-50Document12 pagesInstallation Instructions: Durametallic P-50Papaleguas gamesNo ratings yet

- S 40 45McCannalok Snow Brochure 6 - 6 - 18Document8 pagesS 40 45McCannalok Snow Brochure 6 - 6 - 18Papaleguas gamesNo ratings yet

- Bearing Supports-1Document145 pagesBearing Supports-1Papaleguas gamesNo ratings yet

- PV Elite - Pressure Vessel DesignDocument6 pagesPV Elite - Pressure Vessel Designbudy sinaga100% (4)

- Steel MembersDocument6 pagesSteel Membersalinaitwe shalifuNo ratings yet

- Is 6392 1971Document62 pagesIs 6392 1971Chandra SekharNo ratings yet

- Flanged OS&Y Gate Valve: Main Parts and MaterialDocument1 pageFlanged OS&Y Gate Valve: Main Parts and Materialmourad laatatNo ratings yet

- New Microsoft Office Word DocumentDocument5 pagesNew Microsoft Office Word Documentruhul43No ratings yet

- Fastwind 2014 200CC Parts Catalogue 2015 02 05Document32 pagesFastwind 2014 200CC Parts Catalogue 2015 02 05JeovannyAlexanderMatamorosSanchez100% (1)

- BBG200719ENDocument314 pagesBBG200719ENAbhinandan PadhaNo ratings yet

- Kawasaki KMX 125-A12 Parts ManualDocument113 pagesKawasaki KMX 125-A12 Parts ManualLarge Rice100% (4)

- 5.6 Execution 5.4 5.5: Ball ValvesDocument2 pages5.6 Execution 5.4 5.5: Ball ValvesMajid DixonNo ratings yet

- Grupo de Montagem Group Index Alpha Grupos de Montaje Groupes de MontageDocument437 pagesGrupo de Montagem Group Index Alpha Grupos de Montaje Groupes de MontagewanderNo ratings yet

- 3118F 3318F 3618F-SeriesDocument6 pages3118F 3318F 3618F-SeriesDavid CandoNo ratings yet

- Piping Classes - Rev07Document39 pagesPiping Classes - Rev07Sali NdjiddaNo ratings yet

- Tank Drawings Example PDFDocument2 pagesTank Drawings Example PDFMiguel OrhlNo ratings yet

- S-00-1360-001 Rev.0 - FC (General Specification For Piping)Document11 pagesS-00-1360-001 Rev.0 - FC (General Specification For Piping)ajmainNo ratings yet

- Section 23 21 14 - Underground Pre-Insulated Hydronic PipingDocument7 pagesSection 23 21 14 - Underground Pre-Insulated Hydronic PipingaadsamudNo ratings yet

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutNo ratings yet

- Nordstrom Steel Plug Valves: Experience in MotionDocument60 pagesNordstrom Steel Plug Valves: Experience in MotionJorge Hanna AkouriNo ratings yet

- Dimension Flange AsmeDocument10 pagesDimension Flange AsmeHanif SaidonNo ratings yet

- Grove g4n Gate Valve BrochureDocument24 pagesGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Cobra-Tdc: Tilting Disc Check Valve With Lever and Counterweight/ Hydraulic Damper PN 10 / 16 / 25 DN 100 - 2200Document7 pagesCobra-Tdc: Tilting Disc Check Valve With Lever and Counterweight/ Hydraulic Damper PN 10 / 16 / 25 DN 100 - 2200GogyNo ratings yet

- Installation Manual Color Scanning Sonar FSV-30/FSV-30S: WWW - Furuno.co - JPDocument80 pagesInstallation Manual Color Scanning Sonar FSV-30/FSV-30S: WWW - Furuno.co - JPCali MelendezNo ratings yet

- Atmospheric Storage Tanks: 11-1-1 BP Oil Co. RPDocument54 pagesAtmospheric Storage Tanks: 11-1-1 BP Oil Co. RPHardik AcharyaNo ratings yet

- Specification For Fire MonitorDocument4 pagesSpecification For Fire Monitorromdhan88No ratings yet

- X Ride Part CatalogueDocument46 pagesX Ride Part CatalogueMahful Irvay MukhlisNo ratings yet

- Welded Tanks For Oil StorageDocument58 pagesWelded Tanks For Oil StorageDwi HermawanNo ratings yet

- Specification For Hot Water Boilers-9-10Document2 pagesSpecification For Hot Water Boilers-9-10Karthik AnandanNo ratings yet

- DANAIS MT II CL 150 ENDocument28 pagesDANAIS MT II CL 150 ENLasombra DelPatoNo ratings yet

- PP Lined Pipe PDFDocument27 pagesPP Lined Pipe PDFNILADRI BHATTACHARYYANo ratings yet

- Calculator ASME B31 4Document9 pagesCalculator ASME B31 4jleonos100% (3)

- CNC:DSTV & Pipe Profiling: Aaron LeacockDocument52 pagesCNC:DSTV & Pipe Profiling: Aaron Leacockraymond wilburnNo ratings yet