Professional Documents

Culture Documents

Hirarc Atap Pipa

Hirarc Atap Pipa

Uploaded by

koco totok sugiartoCopyright:

Available Formats

You might also like

- COBIT 2019 - RACI by Role - April 2020Document295 pagesCOBIT 2019 - RACI by Role - April 2020gaston6711100% (1)

- HIRARC For Plastering WorkDocument2 pagesHIRARC For Plastering WorkShirako Takamoto100% (5)

- Risk Assesment Form - Ball MillingDocument6 pagesRisk Assesment Form - Ball Millingbc150100% (1)

- Generic Hirac - Risk Assessment Level 1Document3 pagesGeneric Hirac - Risk Assessment Level 1Anonymous dFaBw2O7KM100% (1)

- Olifantsvlei: General Site Operations - Flame CuttingDocument4 pagesOlifantsvlei: General Site Operations - Flame CuttinggrantNo ratings yet

- Examples of Positive Language PDFDocument2 pagesExamples of Positive Language PDFkalpesh100% (2)

- RA FormatDocument12 pagesRA FormatShibinNo ratings yet

- TGPL-AD-HSE01-TEM-HIRA X-Ray 02-1Document2 pagesTGPL-AD-HSE01-TEM-HIRA X-Ray 02-1Shubham ShuklaNo ratings yet

- Task Risk Assessment (TRA) : Project Name: Area On Site: Task Description: BTD InstallationDocument6 pagesTask Risk Assessment (TRA) : Project Name: Area On Site: Task Description: BTD InstallationADEEL SHAHZADNo ratings yet

- Demolitipon of Parapet Wall Risk Assessment (0075) - Rev-01Document7 pagesDemolitipon of Parapet Wall Risk Assessment (0075) - Rev-01Muhammad OsamaNo ratings yet

- Hazard Identification, Risk Assessment and Risk Control (Hirarc)Document2 pagesHazard Identification, Risk Assessment and Risk Control (Hirarc)Khaty JahNo ratings yet

- IM-08-B EHS Risk Assessment DC WorkDocument4 pagesIM-08-B EHS Risk Assessment DC WorkAndrés PacompíaNo ratings yet

- JRA 10-001 Devlopment of Barrow AreaDocument5 pagesJRA 10-001 Devlopment of Barrow AreaAijaz AhmedNo ratings yet

- OHS Risk Register-OldDocument24 pagesOHS Risk Register-OldMohamed Rizwan100% (1)

- JRA No 11-192 Manual Excavation For Construction of New FoundationsDocument4 pagesJRA No 11-192 Manual Excavation For Construction of New FoundationsAijaz AhmedNo ratings yet

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- 346 - Element 5.02 Baseline Risk Assessment 2013Document13 pages346 - Element 5.02 Baseline Risk Assessment 2013contrax8No ratings yet

- JRA 10-007 Refuelling at Deson Site CmapDocument5 pagesJRA 10-007 Refuelling at Deson Site CmapAijaz AhmedNo ratings yet

- Element 5 02 Baseline Risk Assessment 2013Document14 pagesElement 5 02 Baseline Risk Assessment 2013grantNo ratings yet

- Risk Assessment Form: Contracting W.L.LDocument7 pagesRisk Assessment Form: Contracting W.L.Lbelhareth seifeddineNo ratings yet

- JRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampDocument4 pagesJRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampAijaz AhmedNo ratings yet

- JRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaDocument5 pagesJRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaAijaz AhmedNo ratings yet

- JRA 10-005 Insttalation of New Dodo GateDocument9 pagesJRA 10-005 Insttalation of New Dodo GateAijaz AhmedNo ratings yet

- JRA 10-002 Contruction of Two Septic TanksDocument7 pagesJRA 10-002 Contruction of Two Septic TanksAijaz AhmedNo ratings yet

- HIRA-Underground WaterproofingDocument5 pagesHIRA-Underground WaterproofingBhagat DeepakNo ratings yet

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- RA Hot Works in Enclosed SpaceDocument2 pagesRA Hot Works in Enclosed SpaceMartinNo ratings yet

- HIRA WORK SHEET Blasting and Painting.Document10 pagesHIRA WORK SHEET Blasting and Painting.Madhu Electricals & Engineering100% (3)

- Demolitipon of Parapet Wall Risk Assessment (0075) - Rev-00Document5 pagesDemolitipon of Parapet Wall Risk Assessment (0075) - Rev-00Muhammad OsamaNo ratings yet

- Hira Aruisom - 2Document67 pagesHira Aruisom - 2Hemant PatilNo ratings yet

- NDT HiraDocument3 pagesNDT Hiragoswami editing zoneNo ratings yet

- Risk Assessment - Foam SystemDocument8 pagesRisk Assessment - Foam SystemJhOichriz Reginaldo CuevasNo ratings yet

- JRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomDocument5 pagesJRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomAijaz AhmedNo ratings yet

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinNo ratings yet

- JRA No 10-107 Installation of Nitrogen ReceiverDocument7 pagesJRA No 10-107 Installation of Nitrogen ReceiverAijaz AhmedNo ratings yet

- Risk Assessment - Plumbing Pump SetDocument8 pagesRisk Assessment - Plumbing Pump SetJhOichriz Reginaldo Cuevas100% (1)

- Excavation RA d5chvjDocument4 pagesExcavation RA d5chvjmurasolimaranNo ratings yet

- Hazard Identificaton and Risk Assessment ForDocument3 pagesHazard Identificaton and Risk Assessment ForLemuel PetronioNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Risk Assessment - BanDocument8 pagesRisk Assessment - Bankarthikeyan subramanianNo ratings yet

- JRA No 10-106 Installation of Dry Air Receiver VesselDocument6 pagesJRA No 10-106 Installation of Dry Air Receiver VesselAijaz AhmedNo ratings yet

- Copy of pحفر يدوي ترنشات 6135 وDocument10 pagesCopy of pحفر يدوي ترنشات 6135 وserag alwraqNo ratings yet

- JRA No 10-112 Grouting of Rebar in Foundation.Document6 pagesJRA No 10-112 Grouting of Rebar in Foundation.Aijaz AhmedNo ratings yet

- DOC-EHS-003 HIRA Environmental Aspect Impact RegisterDocument1 pageDOC-EHS-003 HIRA Environmental Aspect Impact RegisterJennifer JosenNo ratings yet

- JHA Dryer Hot CommissioningDocument5 pagesJHA Dryer Hot CommissioningJowel MercadoNo ratings yet

- JRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomDocument5 pagesJRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomAijaz AhmedNo ratings yet

- JRA No 10-108 Internal and External Painting of FEC Switch Room BuildingDocument5 pagesJRA No 10-108 Internal and External Painting of FEC Switch Room BuildingAijaz AhmedNo ratings yet

- Hazard-Database Mining BAGUS SEKALIDocument1,156 pagesHazard-Database Mining BAGUS SEKALIherikNo ratings yet

- RA Excavation For Hot WorkDocument4 pagesRA Excavation For Hot WorkSasi KumarNo ratings yet

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- Transition Duck Risk AnalysisDocument3 pagesTransition Duck Risk AnalysisAnıl AKÇANo ratings yet

- TRA FOR FRT - Rev.S2-2 (Recovered)Document31 pagesTRA FOR FRT - Rev.S2-2 (Recovered)rodman823No ratings yet

- Your Safety Is Our Business: Safetyman InternationalDocument3 pagesYour Safety Is Our Business: Safetyman Internationalg5nbNo ratings yet

- 22-RA FORM OP-20-01 FrezzingDocument1 page22-RA FORM OP-20-01 Frezzingelnaas1993No ratings yet

- Risk Assessment - Hvac SystemDocument8 pagesRisk Assessment - Hvac SystemJhOichriz Reginaldo Cuevas100% (1)

- Hazard DatabaseDocument1,140 pagesHazard DatabaseVero ColladoNo ratings yet

- JRA 10-009 Concrete of Foundation FEC Switch RoomDocument5 pagesJRA 10-009 Concrete of Foundation FEC Switch RoomAijaz AhmedNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- TRA Strainer Cleaning 01Document7 pagesTRA Strainer Cleaning 01Ijaz Hussain50% (2)

- JRA No 10-105 Installation of Distribution Panels at FEC AREADocument7 pagesJRA No 10-105 Installation of Distribution Panels at FEC AREAAijaz AhmedNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Safety Matrix Master - Rev 1Document5 pagesSafety Matrix Master - Rev 1praagthishNo ratings yet

- Journal of Art, Architecture and Built Environment (JAABE)Document15 pagesJournal of Art, Architecture and Built Environment (JAABE)UMT JournalsNo ratings yet

- Aide Memoire On UtilitiesDocument11 pagesAide Memoire On UtilitiesFaress RabiNo ratings yet

- Teachers' Classroom Assessment PracticesDocument12 pagesTeachers' Classroom Assessment PracticesDaniel BarnesNo ratings yet

- Benefits of Being Bilingual Lesson PlanDocument4 pagesBenefits of Being Bilingual Lesson PlanCristina BoantaNo ratings yet

- Instruction Manual: HF TransceiverDocument88 pagesInstruction Manual: HF TransceiverRahadianNo ratings yet

- File DisksDocument22 pagesFile DisksAlana PetersonNo ratings yet

- TM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMDocument308 pagesTM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMIbrahim Med100% (1)

- 2022 Cloud Native Security and Usage ReportDocument30 pages2022 Cloud Native Security and Usage ReportAnand SarmaNo ratings yet

- Carbon Dioxide CO2 SensorDocument4 pagesCarbon Dioxide CO2 SensorgouttNo ratings yet

- Test Series Vikas RaDocument32 pagesTest Series Vikas RaChampakNo ratings yet

- One Love Executive Business Plan 4Document62 pagesOne Love Executive Business Plan 4Rocio CarrascalNo ratings yet

- String/Arrays in JavaDocument7 pagesString/Arrays in JavaSaif HassanNo ratings yet

- ADT Service ManualDocument152 pagesADT Service ManualZakhele MpofuNo ratings yet

- Apollo Valves: 94A / 95A SeriesDocument1 pageApollo Valves: 94A / 95A Seriesmaruthappan sundaramNo ratings yet

- Xu and Zhang (2009) (ASCE) GT.1943-5606 - Dam BreachDocument14 pagesXu and Zhang (2009) (ASCE) GT.1943-5606 - Dam BreachCharumitra YadavNo ratings yet

- Bovaird Loeffler 2016Document13 pagesBovaird Loeffler 2016coolchannel26No ratings yet

- Schema Refinement and Normal Forms: Database Management Systems, 3ed, R. Ramakrishnan and J. Gehrke 1Document19 pagesSchema Refinement and Normal Forms: Database Management Systems, 3ed, R. Ramakrishnan and J. Gehrke 1PRADNYA KASHIKARNo ratings yet

- LOPC-mech Seal FailureDocument26 pagesLOPC-mech Seal FailureSanjeevi Kumar SpNo ratings yet

- Detecting Unseen Malicious VBA Macros With NLPTechniquesDocument9 pagesDetecting Unseen Malicious VBA Macros With NLPTechniquesPrakash ChandraNo ratings yet

- Unit 5 - Event Driven ProgrammingDocument22 pagesUnit 5 - Event Driven ProgrammingdharanyaNo ratings yet

- SS 113 QuizDocument2 pagesSS 113 QuizAlbette Amor Improgo SeposoNo ratings yet

- Installation and Operation Manual: VRV IV+ Heat Pump For High Ambient TemperaturesDocument44 pagesInstallation and Operation Manual: VRV IV+ Heat Pump For High Ambient Temperaturesahmadgce04No ratings yet

- Manual Magnum400 Rev.05 15 EngDocument53 pagesManual Magnum400 Rev.05 15 EngRobert AnthonyNo ratings yet

- Task Force ProposalDocument8 pagesTask Force ProposalForkLogNo ratings yet

- DLP in IctDocument3 pagesDLP in Ictreyna.sazon001No ratings yet

- Tata Motors's AchivementsDocument105 pagesTata Motors's AchivementsSunny SinghNo ratings yet

- Shellscriptingbook-Sample - Steves Bourne-Bash Scripting Tutorial PDFDocument16 pagesShellscriptingbook-Sample - Steves Bourne-Bash Scripting Tutorial PDFAnonymous Wu14iV9dqNo ratings yet

Hirarc Atap Pipa

Hirarc Atap Pipa

Uploaded by

koco totok sugiartoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hirarc Atap Pipa

Hirarc Atap Pipa

Uploaded by

koco totok sugiartoCopyright:

Available Formats

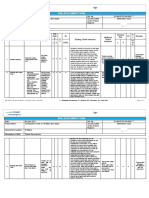

HIRARC

(Hazard Identification, Risk Assesment and Risk Control)

Project Name : Reconstruction of Islamic University of Palu Activity Name : Install Pipe Roof

No Hazard Effect X Frequency = Risk Action to be taken to reduce Risk

Task of Work / Action by Evaluation *)

R/N ( HE X F = R ) (Measures to reduce risk)

Location of Work

TR/A Hazard Analisys Action to be taken

Hazard effect Legal requirement Residual Risk

(Occupation / Location / E (Hazard / Aspect Analysis) Risk Category (action taken) (Responsibilit (Evaluation after

Product / Service.) (Danger / Impact Effect) (Regulations) ● Hierarchy: Elimination (i) to PPE (v) or Risk of Being y by) work is completed)

HE F R ● Reference: procedure / standard / program HE F R

1 Pipe Fabrication R/N Chemical hazard On Environment - M L M3 - Provide hazardous waste bag L L R1

- - Land Pollution PP NO.18/1999 Jo PP No.85/1999

Waste welding electrodes about Hazardous waste management

Welding smoke On Heath - Minister of Health decree M L M3 - Use welding clothes L L R1

- No.1407/Menkes/SK/XI/2002 about - Use chemical mask

Welder exposed by Guidelines for controlling the effect of

Welding smoke air pollution

Minister of Manpower decree

Welding spark on environment - No.Kep.186/MEN/1999 about Fire H L M5 Provide portable fire extinguisher and fire L L R1

-

- exposed to flammable - Fire prevention on working place blanket on welding location and

material

- Exposed to body part on Safety Government Regulation M L M3 PPE appropiate must be worn L L R1

- Burns No.08/MEN/VII/2010 about Personal

Protective Equipmen

Welding rays on Safety Per.02/MEN/1982 about welder M L M3 PPE appropiate must be worn L L R1

- Exposed to body part - Eye hurt qualification

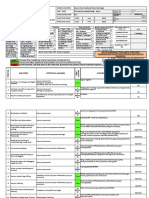

2 Grinding machine operated R/N Mechanical hazard H L M5 L L R1

contact with - cut Per.04/MEN/1985 about poer and Impact rated goggles to be worn during

- disc/entanglement machine production

-

grinding

- severe leceration

Guard in place on grinders – not to be

-

removed under any circumstances

shattering discs or flying - Eye Irritation Government Regulation M L M3 Ensure correct disc type selected for the L L R1

- No.08/MEN/VII/2010 about Personal -

particles task

Protective Equipmen

L L R1

as noise may exceed 80dB

- Hearing protection to be worn at all times

- Damage to hearing M L M3 -

- (A) for short period of time when grinding is being carried out.

when cutting, grinding or

polishing.

3 Arrangement pipe to R/N Install pipe at a height On Safety H H T9 - L L R1

Per.01/MEN/1980 about Occupational Provide manual handling procedure and

installation location - falll from a height - Broken bone - Health & Safety on Buildinding ensure all of manual handling job be

construction observe by safety officers

- Fatallity

- PPE appropiate must be worn

4 Oksigen Cutting torch R/N Cutting spark on environment - Minister of Manpower decree H L M5 - Provide portable fire extinguisher and fire L L R1

operated No.Kep.186/MEN/1999 about Fire blanket on welding location and

- exposed to flammable - Fire prevention on working place

material

- Exposed to body part on Safety Government Regulation M L M3 - PPE appropiate must be worn L L R1

No.08/MEN/VII/2010 about Personal

- Burn Protective Equipmen

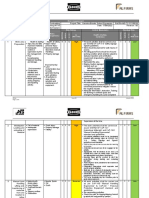

R/N = Routine / Normal

TR/A = Not a routine / Abnormal Note

28 Maret 2022

E = Emergency Date ……………………..………………… Things :

Risk Level & Frequency.

H = HIGH FREQUENCY Created by : Aprroved by

HE = HAZARD

M = MEDIUM H M L HSE Officer Site Manager Project Manager

EFFECT

L = LOW H T9 T8 M5

Note *) In the Evaluation column, no M T7 M6 M3

L M4 M2 R1 Ali Irwan

Revision Number : ………

You might also like

- COBIT 2019 - RACI by Role - April 2020Document295 pagesCOBIT 2019 - RACI by Role - April 2020gaston6711100% (1)

- HIRARC For Plastering WorkDocument2 pagesHIRARC For Plastering WorkShirako Takamoto100% (5)

- Risk Assesment Form - Ball MillingDocument6 pagesRisk Assesment Form - Ball Millingbc150100% (1)

- Generic Hirac - Risk Assessment Level 1Document3 pagesGeneric Hirac - Risk Assessment Level 1Anonymous dFaBw2O7KM100% (1)

- Olifantsvlei: General Site Operations - Flame CuttingDocument4 pagesOlifantsvlei: General Site Operations - Flame CuttinggrantNo ratings yet

- Examples of Positive Language PDFDocument2 pagesExamples of Positive Language PDFkalpesh100% (2)

- RA FormatDocument12 pagesRA FormatShibinNo ratings yet

- TGPL-AD-HSE01-TEM-HIRA X-Ray 02-1Document2 pagesTGPL-AD-HSE01-TEM-HIRA X-Ray 02-1Shubham ShuklaNo ratings yet

- Task Risk Assessment (TRA) : Project Name: Area On Site: Task Description: BTD InstallationDocument6 pagesTask Risk Assessment (TRA) : Project Name: Area On Site: Task Description: BTD InstallationADEEL SHAHZADNo ratings yet

- Demolitipon of Parapet Wall Risk Assessment (0075) - Rev-01Document7 pagesDemolitipon of Parapet Wall Risk Assessment (0075) - Rev-01Muhammad OsamaNo ratings yet

- Hazard Identification, Risk Assessment and Risk Control (Hirarc)Document2 pagesHazard Identification, Risk Assessment and Risk Control (Hirarc)Khaty JahNo ratings yet

- IM-08-B EHS Risk Assessment DC WorkDocument4 pagesIM-08-B EHS Risk Assessment DC WorkAndrés PacompíaNo ratings yet

- JRA 10-001 Devlopment of Barrow AreaDocument5 pagesJRA 10-001 Devlopment of Barrow AreaAijaz AhmedNo ratings yet

- OHS Risk Register-OldDocument24 pagesOHS Risk Register-OldMohamed Rizwan100% (1)

- JRA No 11-192 Manual Excavation For Construction of New FoundationsDocument4 pagesJRA No 11-192 Manual Excavation For Construction of New FoundationsAijaz AhmedNo ratings yet

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- 346 - Element 5.02 Baseline Risk Assessment 2013Document13 pages346 - Element 5.02 Baseline Risk Assessment 2013contrax8No ratings yet

- JRA 10-007 Refuelling at Deson Site CmapDocument5 pagesJRA 10-007 Refuelling at Deson Site CmapAijaz AhmedNo ratings yet

- Element 5 02 Baseline Risk Assessment 2013Document14 pagesElement 5 02 Baseline Risk Assessment 2013grantNo ratings yet

- Risk Assessment Form: Contracting W.L.LDocument7 pagesRisk Assessment Form: Contracting W.L.Lbelhareth seifeddineNo ratings yet

- JRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampDocument4 pagesJRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampAijaz AhmedNo ratings yet

- JRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaDocument5 pagesJRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaAijaz AhmedNo ratings yet

- JRA 10-005 Insttalation of New Dodo GateDocument9 pagesJRA 10-005 Insttalation of New Dodo GateAijaz AhmedNo ratings yet

- JRA 10-002 Contruction of Two Septic TanksDocument7 pagesJRA 10-002 Contruction of Two Septic TanksAijaz AhmedNo ratings yet

- HIRA-Underground WaterproofingDocument5 pagesHIRA-Underground WaterproofingBhagat DeepakNo ratings yet

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- RA Hot Works in Enclosed SpaceDocument2 pagesRA Hot Works in Enclosed SpaceMartinNo ratings yet

- HIRA WORK SHEET Blasting and Painting.Document10 pagesHIRA WORK SHEET Blasting and Painting.Madhu Electricals & Engineering100% (3)

- Demolitipon of Parapet Wall Risk Assessment (0075) - Rev-00Document5 pagesDemolitipon of Parapet Wall Risk Assessment (0075) - Rev-00Muhammad OsamaNo ratings yet

- Hira Aruisom - 2Document67 pagesHira Aruisom - 2Hemant PatilNo ratings yet

- NDT HiraDocument3 pagesNDT Hiragoswami editing zoneNo ratings yet

- Risk Assessment - Foam SystemDocument8 pagesRisk Assessment - Foam SystemJhOichriz Reginaldo CuevasNo ratings yet

- JRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomDocument5 pagesJRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomAijaz AhmedNo ratings yet

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinNo ratings yet

- JRA No 10-107 Installation of Nitrogen ReceiverDocument7 pagesJRA No 10-107 Installation of Nitrogen ReceiverAijaz AhmedNo ratings yet

- Risk Assessment - Plumbing Pump SetDocument8 pagesRisk Assessment - Plumbing Pump SetJhOichriz Reginaldo Cuevas100% (1)

- Excavation RA d5chvjDocument4 pagesExcavation RA d5chvjmurasolimaranNo ratings yet

- Hazard Identificaton and Risk Assessment ForDocument3 pagesHazard Identificaton and Risk Assessment ForLemuel PetronioNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Risk Assessment - BanDocument8 pagesRisk Assessment - Bankarthikeyan subramanianNo ratings yet

- JRA No 10-106 Installation of Dry Air Receiver VesselDocument6 pagesJRA No 10-106 Installation of Dry Air Receiver VesselAijaz AhmedNo ratings yet

- Copy of pحفر يدوي ترنشات 6135 وDocument10 pagesCopy of pحفر يدوي ترنشات 6135 وserag alwraqNo ratings yet

- JRA No 10-112 Grouting of Rebar in Foundation.Document6 pagesJRA No 10-112 Grouting of Rebar in Foundation.Aijaz AhmedNo ratings yet

- DOC-EHS-003 HIRA Environmental Aspect Impact RegisterDocument1 pageDOC-EHS-003 HIRA Environmental Aspect Impact RegisterJennifer JosenNo ratings yet

- JHA Dryer Hot CommissioningDocument5 pagesJHA Dryer Hot CommissioningJowel MercadoNo ratings yet

- JRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomDocument5 pagesJRA No 11-194 Repairing of Water Spouts With The Help of Cherry Picker & Scaffolding Platform at FEC Switch RoomAijaz AhmedNo ratings yet

- JRA No 10-108 Internal and External Painting of FEC Switch Room BuildingDocument5 pagesJRA No 10-108 Internal and External Painting of FEC Switch Room BuildingAijaz AhmedNo ratings yet

- Hazard-Database Mining BAGUS SEKALIDocument1,156 pagesHazard-Database Mining BAGUS SEKALIherikNo ratings yet

- RA Excavation For Hot WorkDocument4 pagesRA Excavation For Hot WorkSasi KumarNo ratings yet

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- Transition Duck Risk AnalysisDocument3 pagesTransition Duck Risk AnalysisAnıl AKÇANo ratings yet

- TRA FOR FRT - Rev.S2-2 (Recovered)Document31 pagesTRA FOR FRT - Rev.S2-2 (Recovered)rodman823No ratings yet

- Your Safety Is Our Business: Safetyman InternationalDocument3 pagesYour Safety Is Our Business: Safetyman Internationalg5nbNo ratings yet

- 22-RA FORM OP-20-01 FrezzingDocument1 page22-RA FORM OP-20-01 Frezzingelnaas1993No ratings yet

- Risk Assessment - Hvac SystemDocument8 pagesRisk Assessment - Hvac SystemJhOichriz Reginaldo Cuevas100% (1)

- Hazard DatabaseDocument1,140 pagesHazard DatabaseVero ColladoNo ratings yet

- JRA 10-009 Concrete of Foundation FEC Switch RoomDocument5 pagesJRA 10-009 Concrete of Foundation FEC Switch RoomAijaz AhmedNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- TRA Strainer Cleaning 01Document7 pagesTRA Strainer Cleaning 01Ijaz Hussain50% (2)

- JRA No 10-105 Installation of Distribution Panels at FEC AREADocument7 pagesJRA No 10-105 Installation of Distribution Panels at FEC AREAAijaz AhmedNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Safety Matrix Master - Rev 1Document5 pagesSafety Matrix Master - Rev 1praagthishNo ratings yet

- Journal of Art, Architecture and Built Environment (JAABE)Document15 pagesJournal of Art, Architecture and Built Environment (JAABE)UMT JournalsNo ratings yet

- Aide Memoire On UtilitiesDocument11 pagesAide Memoire On UtilitiesFaress RabiNo ratings yet

- Teachers' Classroom Assessment PracticesDocument12 pagesTeachers' Classroom Assessment PracticesDaniel BarnesNo ratings yet

- Benefits of Being Bilingual Lesson PlanDocument4 pagesBenefits of Being Bilingual Lesson PlanCristina BoantaNo ratings yet

- Instruction Manual: HF TransceiverDocument88 pagesInstruction Manual: HF TransceiverRahadianNo ratings yet

- File DisksDocument22 pagesFile DisksAlana PetersonNo ratings yet

- TM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMDocument308 pagesTM-Editor 25.04.2016 Seite 1 050-Meteorology - LTMIbrahim Med100% (1)

- 2022 Cloud Native Security and Usage ReportDocument30 pages2022 Cloud Native Security and Usage ReportAnand SarmaNo ratings yet

- Carbon Dioxide CO2 SensorDocument4 pagesCarbon Dioxide CO2 SensorgouttNo ratings yet

- Test Series Vikas RaDocument32 pagesTest Series Vikas RaChampakNo ratings yet

- One Love Executive Business Plan 4Document62 pagesOne Love Executive Business Plan 4Rocio CarrascalNo ratings yet

- String/Arrays in JavaDocument7 pagesString/Arrays in JavaSaif HassanNo ratings yet

- ADT Service ManualDocument152 pagesADT Service ManualZakhele MpofuNo ratings yet

- Apollo Valves: 94A / 95A SeriesDocument1 pageApollo Valves: 94A / 95A Seriesmaruthappan sundaramNo ratings yet

- Xu and Zhang (2009) (ASCE) GT.1943-5606 - Dam BreachDocument14 pagesXu and Zhang (2009) (ASCE) GT.1943-5606 - Dam BreachCharumitra YadavNo ratings yet

- Bovaird Loeffler 2016Document13 pagesBovaird Loeffler 2016coolchannel26No ratings yet

- Schema Refinement and Normal Forms: Database Management Systems, 3ed, R. Ramakrishnan and J. Gehrke 1Document19 pagesSchema Refinement and Normal Forms: Database Management Systems, 3ed, R. Ramakrishnan and J. Gehrke 1PRADNYA KASHIKARNo ratings yet

- LOPC-mech Seal FailureDocument26 pagesLOPC-mech Seal FailureSanjeevi Kumar SpNo ratings yet

- Detecting Unseen Malicious VBA Macros With NLPTechniquesDocument9 pagesDetecting Unseen Malicious VBA Macros With NLPTechniquesPrakash ChandraNo ratings yet

- Unit 5 - Event Driven ProgrammingDocument22 pagesUnit 5 - Event Driven ProgrammingdharanyaNo ratings yet

- SS 113 QuizDocument2 pagesSS 113 QuizAlbette Amor Improgo SeposoNo ratings yet

- Installation and Operation Manual: VRV IV+ Heat Pump For High Ambient TemperaturesDocument44 pagesInstallation and Operation Manual: VRV IV+ Heat Pump For High Ambient Temperaturesahmadgce04No ratings yet

- Manual Magnum400 Rev.05 15 EngDocument53 pagesManual Magnum400 Rev.05 15 EngRobert AnthonyNo ratings yet

- Task Force ProposalDocument8 pagesTask Force ProposalForkLogNo ratings yet

- DLP in IctDocument3 pagesDLP in Ictreyna.sazon001No ratings yet

- Tata Motors's AchivementsDocument105 pagesTata Motors's AchivementsSunny SinghNo ratings yet

- Shellscriptingbook-Sample - Steves Bourne-Bash Scripting Tutorial PDFDocument16 pagesShellscriptingbook-Sample - Steves Bourne-Bash Scripting Tutorial PDFAnonymous Wu14iV9dqNo ratings yet