Professional Documents

Culture Documents

SQ8167 - 03 - Reflux Condenser HTRI 6th Aug 21-CMTD

SQ8167 - 03 - Reflux Condenser HTRI 6th Aug 21-CMTD

Uploaded by

SRICopyright:

Available Formats

You might also like

- Mcquarrie and Simon Physical Chemistry Solutions Manual PDFPDF CompressDocument4 pagesMcquarrie and Simon Physical Chemistry Solutions Manual PDFPDF CompressLuis Felipe0% (2)

- Propane Storage TankDocument1 pagePropane Storage TankMarakanaMahesh100% (1)

- Quiz 1.4 - 2.2Document10 pagesQuiz 1.4 - 2.2Aideé LoraNo ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- Heat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Document15 pagesHeat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Joli SmithNo ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Accessen Plate Heat Exchanger Specification SheetDocument1 pageAccessen Plate Heat Exchanger Specification Sheetfakir mohammadNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Agitated VesselDocument8 pagesAgitated VesselBharatShethNo ratings yet

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- US Units Heat Exchanger Specification SheetDocument1 pageUS Units Heat Exchanger Specification SheetDwi PutraNo ratings yet

- Pharma Engg. Heat Transfer AreaDocument4 pagesPharma Engg. Heat Transfer AreamanojNo ratings yet

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Document9 pagesStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002mohan babuNo ratings yet

- Flat HeadsDocument11 pagesFlat HeadsToniNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Limpet Coil CalculationDocument2 pagesLimpet Coil CalculationYusuf DabhiyaNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- InputCOIL PDFDocument9 pagesInputCOIL PDFneelNo ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- Sop For Fan SizingDocument3 pagesSop For Fan SizingHsein Wang100% (1)

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 pagesHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Training Program On Petroleum Refining Technology: Session 5: Fouling - Causes, Consequences and MitigationDocument27 pagesTraining Program On Petroleum Refining Technology: Session 5: Fouling - Causes, Consequences and MitigationAtifNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Design of EquipmentDocument14 pagesDesign of EquipmentNaeem KhanNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 pagesAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNo ratings yet

- Arz 104 Wood 125141Document1 pageArz 104 Wood 125141youcef islaNo ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- Webinar FAQ - Shell and Tube Heat ExchangersDocument8 pagesWebinar FAQ - Shell and Tube Heat Exchangersrameshkarthik810No ratings yet

- Sizing Sheet of Vertical 2-Phase Separator As Per API 12JDocument5 pagesSizing Sheet of Vertical 2-Phase Separator As Per API 12JWickyNo ratings yet

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- Horizontal KO Pot V1.2Document6 pagesHorizontal KO Pot V1.2hk168No ratings yet

- Stack Gas Specification: Project Name Client Location GeneralDocument6 pagesStack Gas Specification: Project Name Client Location Generalbudi utomo0% (1)

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document15 pagesAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangNo ratings yet

- Physical Properties of FurfuralDocument16 pagesPhysical Properties of Furfuralalice.medeirosNo ratings yet

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Document31 pagesDesign of Shell & Tube HX (Unprotected For Expert Excel Users)Sameer ChaturvediNo ratings yet

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan Ramasamy100% (1)

- Heat Exchanger RatingDocument20 pagesHeat Exchanger RatingFareeha HasanNo ratings yet

- Is 14745 1999 Thermic FluidsDocument8 pagesIs 14745 1999 Thermic FluidsRajesh KumarNo ratings yet

- Weight Calculation For VesselDocument6 pagesWeight Calculation For VesselDesign SadhanaNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument2 pagesHeat Exchanger Specification Sheet SI UnitssalamrefighNo ratings yet

- Superheated Steam SeparatorDocument4 pagesSuperheated Steam SeparatorGanesh BhardwajNo ratings yet

- Aspen Exchanger Design and Rating Air Cooled V11Document1 pageAspen Exchanger Design and Rating Air Cooled V11HafidzAliyufaNo ratings yet

- 3 Ntu MethodDocument72 pages3 Ntu MethodPradyumna DhamangaonkarNo ratings yet

- HTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFDocument14 pagesHTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFSivi NallamothuNo ratings yet

- Film Temp Calculation For Thermic Fluid ApplicationDocument2 pagesFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuNo ratings yet

- 00000-JDS-015 (ERV Manhole) Rev 0Document10 pages00000-JDS-015 (ERV Manhole) Rev 0sithulibraNo ratings yet

- Dump CondenserDocument6 pagesDump CondensersakalidhasavasanNo ratings yet

- Storage Tank Heat Loss Calcs - 28.09.2009Document10 pagesStorage Tank Heat Loss Calcs - 28.09.2009Ali MoazamiNo ratings yet

- Relief Calculations Workbook Relief Load Calculations: Fire Case - Vessel With Partial Liquid Inventory WorksheetDocument2 pagesRelief Calculations Workbook Relief Load Calculations: Fire Case - Vessel With Partial Liquid Inventory Worksheetgopal krishnanNo ratings yet

- Flare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachDocument8 pagesFlare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachaltruismNo ratings yet

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- National Fire Protection Association-GoogleDocument2 pagesNational Fire Protection Association-GooglesandeepNo ratings yet

- Solved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsDocument21 pagesSolved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsAB RanaNo ratings yet

- PeristalticDocument12 pagesPeristalticAnonymous ItzBhUGoiNo ratings yet

- Pid Area 280Document21 pagesPid Area 280ATALAYNo ratings yet

- High Temperature ResinDocument2 pagesHigh Temperature ResinDILIGENT AM11No ratings yet

- Variable Head Type FlowmetersDocument32 pagesVariable Head Type FlowmetersAnuNarayan R100% (2)

- Corrosion and Its PreventionDocument28 pagesCorrosion and Its PreventionMehul Neha Bisht100% (2)

- GeneXpert TechnologyDocument30 pagesGeneXpert TechnologySukma EffendyNo ratings yet

- 5282syllabus (NEP2020) CSEDocument109 pages5282syllabus (NEP2020) CSEridhiNo ratings yet

- Saka - Company Profile and HSE Management SystemDocument11 pagesSaka - Company Profile and HSE Management SystemKaos DistroNo ratings yet

- Chemistry Viva QuestionsDocument3 pagesChemistry Viva QuestionsShivamNo ratings yet

- Agua para EspressoDocument5 pagesAgua para EspressoManuel MoraNo ratings yet

- Phthalic Anhydride Part 1Document6 pagesPhthalic Anhydride Part 1Ajay Yadav100% (1)

- Bioavailable Curcumin FormulationsDocument9 pagesBioavailable Curcumin Formulationsciprian72No ratings yet

- SSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFDocument586 pagesSSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFBhavani Gujjari0% (1)

- Soalan KimiaDocument6 pagesSoalan KimiaFatimah Abdul RahmanNo ratings yet

- Profile Star PDFDocument2 pagesProfile Star PDFAyahKenzieNo ratings yet

- Pengaruh Suhu Dan Waktu Pelapisan Tembaga Pada Baja Karbon Rendah Secara Elektroplating Terhadap Korosi Dewi SasmitaDocument7 pagesPengaruh Suhu Dan Waktu Pelapisan Tembaga Pada Baja Karbon Rendah Secara Elektroplating Terhadap Korosi Dewi SasmitaAndika SuryaNo ratings yet

- Kollidon 30 Technical InformationDocument10 pagesKollidon 30 Technical InformationhomarearisugawaNo ratings yet

- D4and5 Coulombs Law Worksheet SOLUTIONSDocument7 pagesD4and5 Coulombs Law Worksheet SOLUTIONSCss PursuerNo ratings yet

- Effect of Magnetizing Water and Seeds On The Production of Cucumber (Cucumis Sativus L.) Under Cooled Plastic TunnelsDocument71 pagesEffect of Magnetizing Water and Seeds On The Production of Cucumber (Cucumis Sativus L.) Under Cooled Plastic Tunnelssunziv19No ratings yet

- Intership 1Document28 pagesIntership 1Abhishek KhandekarNo ratings yet

- Topic 1 - Cement and Concrete Basics - GrayDocument86 pagesTopic 1 - Cement and Concrete Basics - GraysazedaNo ratings yet

- Fatigue Testing - Ignacio ArtamendiDocument26 pagesFatigue Testing - Ignacio ArtamendiRoque3RNo ratings yet

- Pharmacokinetics and Comparative Bioavailability of Allopurinol Formulations in Healthy SubjectsDocument5 pagesPharmacokinetics and Comparative Bioavailability of Allopurinol Formulations in Healthy SubjectsFajar NovendraNo ratings yet

- COOLANT Komatsu PDFDocument16 pagesCOOLANT Komatsu PDFdarwin100% (1)

- Diagonal RelationshipDocument16 pagesDiagonal RelationshipBaiye RandolfNo ratings yet

- 1 s2.0 S0378775320310120 MainDocument26 pages1 s2.0 S0378775320310120 MainRishabh KumarNo ratings yet

SQ8167 - 03 - Reflux Condenser HTRI 6th Aug 21-CMTD

SQ8167 - 03 - Reflux Condenser HTRI 6th Aug 21-CMTD

Uploaded by

SRIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SQ8167 - 03 - Reflux Condenser HTRI 6th Aug 21-CMTD

SQ8167 - 03 - Reflux Condenser HTRI 6th Aug 21-CMTD

Uploaded by

SRICopyright:

Available Formats

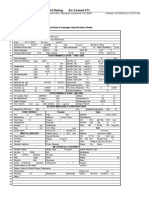

1 HEAT EXCHANGER SPECIFICATION SHEET Page 1

2 HES-SI Units

3

4 Job No.

5 Customer Reference No.

6 Address Proposal No.

7 Plant Location Date 5/8/2021 Rev 1

8 Service of Unit Reflux Condenser Item No. 46-HA-5526A/B

9 Size 850 x 5900 mm Type BEM Horizontal Connected In 1 Parallel 1 Series

10 Surf/Unit (Gross/Eff) / m2 Shell/Unit 1 Surf/Shell (Gross/Eff) / m2

11 PERFORMANCE OF ONE UNIT

12 Fluid Allocation Shell Side Tube Side

13 Fluid Name COOLING MEDIUM MEOTHANOL

14 Fluid Quantity, Total kg/hr 407884 32396

15 Vapor (In/Out) 32396 154.98

16 Liquid 407884 407884 32241

17 Steam

18 Water

19 Noncondensables

20 Temperature (In/Out) C 32.00 55.00 89.24 50.00

21 Specific Gravity 0.9949 0.9857 0.7774

22 Viscosity cP 0.7880 0.5150 0.0120 0.0150 V/L 0.4020

23 Molecular Weight, Vapor

24 Molecular Weight, Noncondensables

25 Specific Heat kJ/kg-C 4.1100 4.1100 1.5600 1.0225 V/L 2.8400

26 Thermal Conductivity W/m-C 0.6160 0.6430 0.0220 0.0190 V/L 0.1930

27 Latent Heat kJ/kg 1091.6 772.02

28 Inlet Pressure barG 7.000 1.471

29 Velocity m/s 0.56 6.07

30 Pressure Drop, Allow/Calc kPa 35.000 33.912 21.000 2.610

31 Fouling Resistance (min) m2-K/W 0.000000 0.000000

32 Heat Exchanged 10742. kW MTD (Corrected) 40.3 C

33 Transfer Rate, Service 951.89 W/m2-K Clean 1247.4 W/m2-K Actual 1247.4 W/m2-K

34 CONSTRUCTION OF ONE SHELL Sketch (Bundle/Nozzle Orientation)

35 Shell Side Tube Side

36 Design/Test Pressure barG 18.000 / 10.000 /

37 Design Temperature C 125.00 125.00

38 No Passes per Shell 1 1

39 Corrosion Allowance mm 3.000 0.000

40 Connections In mm 1 @ 202.72 1 @ 488.95

41 Size & Out mm 1 @ 202.72 1 @ 154.05

42 Rating Intermediate @ @

43 Tube No. OD 19.050 mm Thk(Avg) 1.651 mm Length 5.900 m Pitch mm

44 Tube Type Plain Material 316 Stainless steel (17 Cr, 12 Ni) Tube pattern

45 Shell Carbon steel ID 850.00 OD 872.23 mm Shell Cover

46 Channel or Bonnet 316 Stainless steel (17 Cr, 12 Ni) Channel Cover

47 Tubesheet-Stationary 316 Stainless steel (17 Cr, 12 Ni) Tubesheet-Floating

48 Floating Head Cover Impingement Plate Circular plate

49 Baffles-Cross Type NTIW-Seg. %Cut (Diam) Spacing(c/c) Inlet mm

50 Baffles-Long Seal Type None

51 Supports-Tube U-Bend Type None

52 Bypass Seal Arrangement pairs seal strips Tube-Tubesheet Joint Expanded and strength welded

53 Expansion Joint Type

54 Rho-V2-Inlet Nozzle kg/m-s2 Bundle Entrance 1034.0 Bundle Exit 911.73 kg/m-s2

55 Gaskets-Shell Side Tube Side

56 - Floating Head

57 Code Requirements ASME TEMA Class R

58 Weight/Shell 6286.8 kg Filled with Water 10568 kg Bundle 3819.8 kg

59 Remarks:

60 1. 31% additional surface area (in lieu of fouling factors) over the required surface area in clean condition

61 2.heat exchagner shall be suitable for 110% of specified condensate flowrate from thermal performance and tube vibration.

62

63 Reprinted with Permission (v7.3.2)

provide pressure pls reduce the tube

drop at clean side velocity and

utilize the

condition. at no increase the shell

maximum tube

case pressure drop side velocity.

side pressure drop.

at clean condition

shall exceed the

Item No.: 46-HA-5526A/B J:\Inquiry-Panfeng\8167_SLB\2021-07-28\SQ8167_03_Reflux Condenser(1).htri

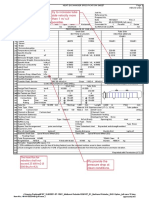

Vibration Analysis Page 2

Released to the following HTRI Member Company:

HES

HES

Xist 7.3.2 5/8/2021 11:47 SN: 00371-53375827 HES-SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With NTIW-Segmental Baffles

1 Shellside condition Sens. Liquid (Level 2.3000)

2 Axial stress loading (MPa) 0.000 Added mass factor 1.761

3 Beta 4.000

4 Position In The Bundle Inlet Center Outlet

5 Length for natural frequency (m) 0.828 0.828 0.828

6 Length/TEMA maximum span (--) 0.544 0.544 0.544

7 Number of spans (--) 7 7 7

8 Tube natural frequency (Hz) 56.2 + 56.3 56.3

9 Shell acoustic frequency (Hz) 0.0 0.0 0.0

10 Flow Velocities Inlet Center Outlet

11 Window parallel velocity (m/s) 1.19 1.19 1.20

12 Bundle crossflow velocity (m/s) 0.55 0.56 0.55

13 Bundle/shell velocity (m/s) 0.67 0.68 0.67

14 Fluidelastic Instability Check Inlet Center Outlet

15 Log decrement HTRI 0.099 0.098 0.095

16 Critical velocity (m/s) 2.48 2.47 2.44

17 Baffle tip cross velocity ratio (--) 0.2604 0.2649 0.2677

18 Average crossflow velocity ratio (--) 0.2215 0.2253 0.2277

19 Acoustic Vibration Check Inlet Center Outlet

20 Vortex shedding ratio (--) 0.000 0.000 0.000

21 Chen number (--) 0 0 0

22 Turbulent buffeting ratio (--) 0.000 0.000 0.000

23 Tube Vibration Check Inlet Center Outlet

24 Vortex shedding ratio (--) 0.094 0.095 0.095

25 Parallel flow amplitude (mm) 0.005 0.005 0.005

26 Crossflow amplitude (mm) 0.027 0.028 0.027

27 Tube gap (mm) 4.763 4.763 4.763

28 Crossflow RHO-V-SQ (kg/m-s2) 300.66 307.14 303.46

29 Bundle Entrance/Exit

30 (analysis at first tube row) Entrance Exit

31 Fluidelastic instability ratio (--) 0.411 0.395

32 Vortex shedding ratio (--) 0.175 0.165

33 Crossflow amplitude (mm) 0.09491 0.08340

34 Crossflow velocity (m/s) 1.02 0.96

35 Tubesheet to inlet/outlet support (mm) None None

36 Shell Entrance/Exit Parameters Entrance Exit

37 Impingement device Circular plate --

38 Flow area (m2) 0.095 0.110

39 Velocity (m/s) 1.20 1.05

40 RHO-V-SQ (kg/m-s2) 1430.3 1085.7

41 Shell type BEM Baffle type NTIW-Seg.

42 Tube type Plain Baffle layout Perpend.

43 Pitch ratio 1.2500 Tube diameter, (mm) 19.050

44 Layout angle 30 Tube material 316 Stainless steel (17 Cr, 12 Ni)

45 Number U-Bend supports Elastic modulus, (MPa) 190269

46 Use deresonating baffles No Supports/baffle space 0

47 Program Messages

48 + Frequency ratios are based upon lowest natural or acoustic frequency

49 * Items with asterisk exceed a conservative lower limit for vibration-free design. Review your case

50 using the procedure described in Online Help; You may find that a vibration problem is unlikely.

51

52

53

54

Item No.: 46-HA-5526A/B J:\Inquiry-Panfeng\8167_SLB\2021-07-28\SQ8167_03_Reflux Condenser(1).htri

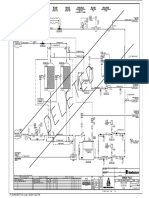

Drawings Page 5

Released to the following HTRI Member Company:

HES

HES

Xist 7.3.2 5/8/2021 11:47 SN: 00371-53375827 HES-SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With NTIW-Segmental Baffles

1

2 7911

3 mm

4 754 870 5394 470

5 mm mm mm mm

6

7 T1 S1 Pls add tubesheet

8

9 layout

10

11

872

12

mm

13

14

15

16

17 S2 Fixed Slotted T2

18 1808 3531

19 mm mm

20

21 T1 S1

22

23

735 735

24 mm

mm

25

26

27

28 691 680 691

mm mm mm

29

30

31 S2 T2

32

33 Front Channel Shell Rear Channel

34

35 Nozzles OD, mm Rating Design Shell Tube Weight kg Company HES

36 S1 Inlet 219.07 Pres (barG) 18 10 Bundle 3820 Customer Ref

S2 Outlet 219.07 Temp (C) 125 125 Dry 6287 Item 46-HA-5526A/B

37 T1 Inlet 508 Passes 1 1 Wet 10568 Service Reflux Condenser

38 T2 Outlet 168.28 Thick (mm) 11.112 1.651 TEMA BEM Setting Plan

39 Date 5/8/2021 By

Diagram Rev 1

40

41

42

Item No.: 46-HA-5526A/B J:\Inquiry-Panfeng\8167_SLB\2021-07-28\SQ8167_03_Reflux Condenser(1).htri

You might also like

- Mcquarrie and Simon Physical Chemistry Solutions Manual PDFPDF CompressDocument4 pagesMcquarrie and Simon Physical Chemistry Solutions Manual PDFPDF CompressLuis Felipe0% (2)

- Propane Storage TankDocument1 pagePropane Storage TankMarakanaMahesh100% (1)

- Quiz 1.4 - 2.2Document10 pagesQuiz 1.4 - 2.2Aideé LoraNo ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- Heat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Document15 pagesHeat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Joli SmithNo ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Accessen Plate Heat Exchanger Specification SheetDocument1 pageAccessen Plate Heat Exchanger Specification Sheetfakir mohammadNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Agitated VesselDocument8 pagesAgitated VesselBharatShethNo ratings yet

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- US Units Heat Exchanger Specification SheetDocument1 pageUS Units Heat Exchanger Specification SheetDwi PutraNo ratings yet

- Pharma Engg. Heat Transfer AreaDocument4 pagesPharma Engg. Heat Transfer AreamanojNo ratings yet

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Document9 pagesStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002mohan babuNo ratings yet

- Flat HeadsDocument11 pagesFlat HeadsToniNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Limpet Coil CalculationDocument2 pagesLimpet Coil CalculationYusuf DabhiyaNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- InputCOIL PDFDocument9 pagesInputCOIL PDFneelNo ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- Sop For Fan SizingDocument3 pagesSop For Fan SizingHsein Wang100% (1)

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 pagesHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Training Program On Petroleum Refining Technology: Session 5: Fouling - Causes, Consequences and MitigationDocument27 pagesTraining Program On Petroleum Refining Technology: Session 5: Fouling - Causes, Consequences and MitigationAtifNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Design of EquipmentDocument14 pagesDesign of EquipmentNaeem KhanNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 pagesAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNo ratings yet

- Arz 104 Wood 125141Document1 pageArz 104 Wood 125141youcef islaNo ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- Webinar FAQ - Shell and Tube Heat ExchangersDocument8 pagesWebinar FAQ - Shell and Tube Heat Exchangersrameshkarthik810No ratings yet

- Sizing Sheet of Vertical 2-Phase Separator As Per API 12JDocument5 pagesSizing Sheet of Vertical 2-Phase Separator As Per API 12JWickyNo ratings yet

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- Horizontal KO Pot V1.2Document6 pagesHorizontal KO Pot V1.2hk168No ratings yet

- Stack Gas Specification: Project Name Client Location GeneralDocument6 pagesStack Gas Specification: Project Name Client Location Generalbudi utomo0% (1)

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document15 pagesAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangNo ratings yet

- Physical Properties of FurfuralDocument16 pagesPhysical Properties of Furfuralalice.medeirosNo ratings yet

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Document31 pagesDesign of Shell & Tube HX (Unprotected For Expert Excel Users)Sameer ChaturvediNo ratings yet

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan Ramasamy100% (1)

- Heat Exchanger RatingDocument20 pagesHeat Exchanger RatingFareeha HasanNo ratings yet

- Is 14745 1999 Thermic FluidsDocument8 pagesIs 14745 1999 Thermic FluidsRajesh KumarNo ratings yet

- Weight Calculation For VesselDocument6 pagesWeight Calculation For VesselDesign SadhanaNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument2 pagesHeat Exchanger Specification Sheet SI UnitssalamrefighNo ratings yet

- Superheated Steam SeparatorDocument4 pagesSuperheated Steam SeparatorGanesh BhardwajNo ratings yet

- Aspen Exchanger Design and Rating Air Cooled V11Document1 pageAspen Exchanger Design and Rating Air Cooled V11HafidzAliyufaNo ratings yet

- 3 Ntu MethodDocument72 pages3 Ntu MethodPradyumna DhamangaonkarNo ratings yet

- HTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFDocument14 pagesHTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFSivi NallamothuNo ratings yet

- Film Temp Calculation For Thermic Fluid ApplicationDocument2 pagesFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuNo ratings yet

- 00000-JDS-015 (ERV Manhole) Rev 0Document10 pages00000-JDS-015 (ERV Manhole) Rev 0sithulibraNo ratings yet

- Dump CondenserDocument6 pagesDump CondensersakalidhasavasanNo ratings yet

- Storage Tank Heat Loss Calcs - 28.09.2009Document10 pagesStorage Tank Heat Loss Calcs - 28.09.2009Ali MoazamiNo ratings yet

- Relief Calculations Workbook Relief Load Calculations: Fire Case - Vessel With Partial Liquid Inventory WorksheetDocument2 pagesRelief Calculations Workbook Relief Load Calculations: Fire Case - Vessel With Partial Liquid Inventory Worksheetgopal krishnanNo ratings yet

- Flare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachDocument8 pagesFlare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachaltruismNo ratings yet

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- National Fire Protection Association-GoogleDocument2 pagesNational Fire Protection Association-GooglesandeepNo ratings yet

- Solved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsDocument21 pagesSolved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsAB RanaNo ratings yet

- PeristalticDocument12 pagesPeristalticAnonymous ItzBhUGoiNo ratings yet

- Pid Area 280Document21 pagesPid Area 280ATALAYNo ratings yet

- High Temperature ResinDocument2 pagesHigh Temperature ResinDILIGENT AM11No ratings yet

- Variable Head Type FlowmetersDocument32 pagesVariable Head Type FlowmetersAnuNarayan R100% (2)

- Corrosion and Its PreventionDocument28 pagesCorrosion and Its PreventionMehul Neha Bisht100% (2)

- GeneXpert TechnologyDocument30 pagesGeneXpert TechnologySukma EffendyNo ratings yet

- 5282syllabus (NEP2020) CSEDocument109 pages5282syllabus (NEP2020) CSEridhiNo ratings yet

- Saka - Company Profile and HSE Management SystemDocument11 pagesSaka - Company Profile and HSE Management SystemKaos DistroNo ratings yet

- Chemistry Viva QuestionsDocument3 pagesChemistry Viva QuestionsShivamNo ratings yet

- Agua para EspressoDocument5 pagesAgua para EspressoManuel MoraNo ratings yet

- Phthalic Anhydride Part 1Document6 pagesPhthalic Anhydride Part 1Ajay Yadav100% (1)

- Bioavailable Curcumin FormulationsDocument9 pagesBioavailable Curcumin Formulationsciprian72No ratings yet

- SSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFDocument586 pagesSSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFBhavani Gujjari0% (1)

- Soalan KimiaDocument6 pagesSoalan KimiaFatimah Abdul RahmanNo ratings yet

- Profile Star PDFDocument2 pagesProfile Star PDFAyahKenzieNo ratings yet

- Pengaruh Suhu Dan Waktu Pelapisan Tembaga Pada Baja Karbon Rendah Secara Elektroplating Terhadap Korosi Dewi SasmitaDocument7 pagesPengaruh Suhu Dan Waktu Pelapisan Tembaga Pada Baja Karbon Rendah Secara Elektroplating Terhadap Korosi Dewi SasmitaAndika SuryaNo ratings yet

- Kollidon 30 Technical InformationDocument10 pagesKollidon 30 Technical InformationhomarearisugawaNo ratings yet

- D4and5 Coulombs Law Worksheet SOLUTIONSDocument7 pagesD4and5 Coulombs Law Worksheet SOLUTIONSCss PursuerNo ratings yet

- Effect of Magnetizing Water and Seeds On The Production of Cucumber (Cucumis Sativus L.) Under Cooled Plastic TunnelsDocument71 pagesEffect of Magnetizing Water and Seeds On The Production of Cucumber (Cucumis Sativus L.) Under Cooled Plastic Tunnelssunziv19No ratings yet

- Intership 1Document28 pagesIntership 1Abhishek KhandekarNo ratings yet

- Topic 1 - Cement and Concrete Basics - GrayDocument86 pagesTopic 1 - Cement and Concrete Basics - GraysazedaNo ratings yet

- Fatigue Testing - Ignacio ArtamendiDocument26 pagesFatigue Testing - Ignacio ArtamendiRoque3RNo ratings yet

- Pharmacokinetics and Comparative Bioavailability of Allopurinol Formulations in Healthy SubjectsDocument5 pagesPharmacokinetics and Comparative Bioavailability of Allopurinol Formulations in Healthy SubjectsFajar NovendraNo ratings yet

- COOLANT Komatsu PDFDocument16 pagesCOOLANT Komatsu PDFdarwin100% (1)

- Diagonal RelationshipDocument16 pagesDiagonal RelationshipBaiye RandolfNo ratings yet

- 1 s2.0 S0378775320310120 MainDocument26 pages1 s2.0 S0378775320310120 MainRishabh KumarNo ratings yet