Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

70 viewsMain Sub-Main Distribution Boards Testing and Commissioning Procedure

Main Sub-Main Distribution Boards Testing and Commissioning Procedure

Uploaded by

Aleen Gamal Al-DinjiThe document outlines testing and commissioning procedures for main sub-main distribution boards, sub-main distribution boards, distribution boards, and consumer units. It details visual inspections, functional checks, insulation resistance tests, and switch-on processes to ensure equipment is properly installed and operating correctly before system acceptance. Key steps include verifying nameplate details and ratings, checking for damage, measuring insulation resistance, and energizing main and sub-main switches sequentially while monitoring for issues. Upon satisfactory completion of all tests, the engineer will sign an acceptance certificate.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Method of Statement - Electrical Power Supply Turn OnDocument2 pagesMethod of Statement - Electrical Power Supply Turn OnAlex Choong67% (3)

- CCTV Camera Testing & Commissioning ProcedureDocument2 pagesCCTV Camera Testing & Commissioning ProcedureAleen Gamal Al-Dinji100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Testing and Commissioning of SwitchgearDocument3 pagesTesting and Commissioning of SwitchgearkdmillerNo ratings yet

- Pre - Functional Checklist Documentation 9Document5 pagesPre - Functional Checklist Documentation 9renjithv_4No ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- PRE Commissioning Procedures TR Rev01 PGCILDocument52 pagesPRE Commissioning Procedures TR Rev01 PGCILkrishnamanikandan100% (3)

- Method of Statement Holiday TestingDocument4 pagesMethod of Statement Holiday TestingEdison Walit100% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- JW Marriot Abu Dhabi Resort & Spa Otak InternationalDocument15 pagesJW Marriot Abu Dhabi Resort & Spa Otak InternationalPeanut d. DestroyerNo ratings yet

- Emergency Lights Central Battery System Testing and Commissioning Method of StatementDocument12 pagesEmergency Lights Central Battery System Testing and Commissioning Method of StatementAleen Gamal Al-DinjiNo ratings yet

- Testing and Commissioning of Metal-Clad SwitchgearDocument3 pagesTesting and Commissioning of Metal-Clad SwitchgearJoel AlcantaraNo ratings yet

- Testing & Commissioning of Fire Suppression SystemDocument5 pagesTesting & Commissioning of Fire Suppression Systemmyanmarfire100% (2)

- T&C of Fire Supression SystemDocument5 pagesT&C of Fire Supression Systemamg007100% (1)

- Commissioning: Commissioning High Voltage EquipmentDocument14 pagesCommissioning: Commissioning High Voltage Equipment2091979No ratings yet

- Testing and Commissioning of Fire Alarm SystemDocument10 pagesTesting and Commissioning of Fire Alarm SystemRobin Oidem CaniedoNo ratings yet

- Testing & Commissioning of CCUDocument2 pagesTesting & Commissioning of CCUamg007100% (1)

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- Testing and Commissioning of MetalClad SwitchgearDocument3 pagesTesting and Commissioning of MetalClad SwitchgearPradeep Kumar MaraptlaNo ratings yet

- Thermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andDocument3 pagesThermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andCollen Noel MabasaNo ratings yet

- Introduction To Testing and Commissioning of Power System (2019, Elsevier) (10.1016 - B978-0-12-816858-5.00003-4) - Libgen - Li PDFDocument8 pagesIntroduction To Testing and Commissioning of Power System (2019, Elsevier) (10.1016 - B978-0-12-816858-5.00003-4) - Libgen - Li PDFMohammed A. AliNo ratings yet

- 16950Document16 pages16950uddinnadeemNo ratings yet

- g10 4thQ Commissioning Electrical SystemDocument12 pagesg10 4thQ Commissioning Electrical SystemLiyan PrettyNo ratings yet

- Sec16 - Electrical Construction Checkout and TestingDocument13 pagesSec16 - Electrical Construction Checkout and TestingYusufNo ratings yet

- Commn. Check ListDocument8 pagesCommn. Check ListsbpathiNo ratings yet

- Testing and Commissioning of Electrical EquipmentDocument6 pagesTesting and Commissioning of Electrical EquipmentGreeshma PuttannaNo ratings yet

- EDOC - 10 Critical Tests For New Power Circuit BreakersDocument7 pagesEDOC - 10 Critical Tests For New Power Circuit BreakersEl Comedor Benedict100% (1)

- Inspection and Test ProceduresDocument33 pagesInspection and Test Proceduresmrnoboby0407No ratings yet

- 05 EsuDocument2 pages05 EsuFernando BarbariniNo ratings yet

- Precommissioning, Commissioning and Start Up ExplainationDocument12 pagesPrecommissioning, Commissioning and Start Up ExplainationKevin Muhammad100% (1)

- Preventive MaintenanceDocument6 pagesPreventive MaintenanceMay Ann DuronNo ratings yet

- Method of Statement KPMG Fm200Document8 pagesMethod of Statement KPMG Fm200Manesh KariyadanNo ratings yet

- Visual and Technical Checking of Instrumentation and Control SystemDocument13 pagesVisual and Technical Checking of Instrumentation and Control SystemzhangyiliNo ratings yet

- Project Name: Yas Acres (North Yas) Development Phase 1 SurDocument17 pagesProject Name: Yas Acres (North Yas) Development Phase 1 SurARUNNo ratings yet

- Specification For Testing & CommissioningDocument7 pagesSpecification For Testing & CommissioningEric TaylorNo ratings yet

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssNo ratings yet

- Commissioning High Voltage EquipmentDocument13 pagesCommissioning High Voltage EquipmentJesus RodriguezNo ratings yet

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad Switchgearvijaydev75100% (1)

- Field Inspection of New Medium-Voltage SwitchgearDocument3 pagesField Inspection of New Medium-Voltage SwitchgearHamad GulNo ratings yet

- AC Circuit Breakers Routine Tests According To IEC 62271-100Document12 pagesAC Circuit Breakers Routine Tests According To IEC 62271-100sathishkannanNo ratings yet

- Field Inspection and Testing of Medium-Voltage Motor Control Centres (MCCS)Document3 pagesField Inspection and Testing of Medium-Voltage Motor Control Centres (MCCS)Sandro CuetoNo ratings yet

- Take Control of Your Systems With The Control Box AssemblyDocument5 pagesTake Control of Your Systems With The Control Box AssemblyjackNo ratings yet

- Commissioning of InstrumentationDocument16 pagesCommissioning of InstrumentationrajuNo ratings yet

- Test Guide InstructionDocument41 pagesTest Guide InstructionThức Võ100% (1)

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- MCC Test ProcedureDocument18 pagesMCC Test ProcedureAous H100% (1)

- 03 Pre-Commissioning and Commissioning 26 08 00 09022022011343Document13 pages03 Pre-Commissioning and Commissioning 26 08 00 09022022011343ibrahimsirpiNo ratings yet

- Edoc-Switchgear and Switchboard Inspection and Testing GuideDocument16 pagesEdoc-Switchgear and Switchboard Inspection and Testing GuideEl Comedor Benedict100% (1)

- Edoc-Switchgear and Switchboard Inspection and Testing GuideDocument16 pagesEdoc-Switchgear and Switchboard Inspection and Testing GuideEl Comedor Benedict100% (1)

- Wave Let TutorialDocument26 pagesWave Let TutorialBhavik PrajapatiNo ratings yet

- Aea 1305 WC El MS 0031Document7 pagesAea 1305 WC El MS 0031Adil HasanovNo ratings yet

- Substation Pre Commissioning TestsDocument13 pagesSubstation Pre Commissioning Testsrasheed313100% (2)

- General Information (Technical) : 1.1. Codes, Standards & RegulationsDocument6 pagesGeneral Information (Technical) : 1.1. Codes, Standards & RegulationsjayNo ratings yet

- Understanding Electrical Inspection and TestingDocument3 pagesUnderstanding Electrical Inspection and TestingI Wayan Aries DarmawanNo ratings yet

- Comprehensive Electrical System Maintenance ChecklistsDocument12 pagesComprehensive Electrical System Maintenance ChecklistsFarrukh Nadeem100% (1)

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad SwitchgearMohammed MadiNo ratings yet

- SLPG - HT Motor-4yDocument4 pagesSLPG - HT Motor-4yAshraf MohammedNo ratings yet

- Job Plan: Lead Craft Condition For Work Crafts Department Craft QTYDocument3 pagesJob Plan: Lead Craft Condition For Work Crafts Department Craft QTYMohsin YasinNo ratings yet

- Commissioning Documents For Instrumentation EngineersDocument7 pagesCommissioning Documents For Instrumentation EngineersVraja Kisori100% (1)

- Electrician's Troubleshooting and Testing Pocket Guide, Third EditionFrom EverandElectrician's Troubleshooting and Testing Pocket Guide, Third EditionRating: 5 out of 5 stars5/5 (1)

- Method Statement For Installation of CCTV Camera SystemDocument6 pagesMethod Statement For Installation of CCTV Camera SystemAleen Gamal Al-DinjiNo ratings yet

- Sequence of Operation For ElectricalDocument5 pagesSequence of Operation For ElectricalAleen Gamal Al-DinjiNo ratings yet

- Method of Statement For Installation of Earthing, Bonding & Lightning Protection SystemDocument6 pagesMethod of Statement For Installation of Earthing, Bonding & Lightning Protection SystemAleen Gamal Al-DinjiNo ratings yet

- Ring Main Unit Testing and Commissioning Method StatementDocument4 pagesRing Main Unit Testing and Commissioning Method StatementAleen Gamal Al-DinjiNo ratings yet

- Automatic Transfer SwitchDocument7 pagesAutomatic Transfer SwitchAleen Gamal Al-DinjiNo ratings yet

- Emergency Lights Central Battery System Testing and Commissioning Method of StatementDocument12 pagesEmergency Lights Central Battery System Testing and Commissioning Method of StatementAleen Gamal Al-DinjiNo ratings yet

- Installation of Access Control System Method of StatementDocument5 pagesInstallation of Access Control System Method of StatementAleen Gamal Al-DinjiNo ratings yet

- Installation of Marble and Granite Tiles On FloorDocument7 pagesInstallation of Marble and Granite Tiles On FloorAleen Gamal Al-Dinji100% (2)

- Method Statement For Fire Alarm System InstallationDocument7 pagesMethod Statement For Fire Alarm System InstallationAleen Gamal Al-Dinji100% (1)

- Method Statement For GIDocument9 pagesMethod Statement For GIAleen Gamal Al-DinjiNo ratings yet

- Statement of Purpose Name: Krishna Teja SwarnaDocument2 pagesStatement of Purpose Name: Krishna Teja SwarnaMohammadRahemanNo ratings yet

- Tuyển Sinh 10 - đề 1 -KeyDocument5 pagesTuyển Sinh 10 - đề 1 -Keynguyenhoang17042004No ratings yet

- CGF FPC Palm Oil RoadmapDocument31 pagesCGF FPC Palm Oil RoadmapnamasayanazlyaNo ratings yet

- Papper Referensi 2 - Using Warmth As The Visual Design of A Store - Intimacy, Relational Needs, and Approach IntentionsDocument11 pagesPapper Referensi 2 - Using Warmth As The Visual Design of A Store - Intimacy, Relational Needs, and Approach IntentionsBergodo PrajuritNo ratings yet

- Dbms Lab Dbms Lab: 23 March 202Document12 pagesDbms Lab Dbms Lab: 23 March 202LOVISH bansalNo ratings yet

- Safety Data Sheet Carbon Cathode SolutionDocument11 pagesSafety Data Sheet Carbon Cathode SolutionJeff BanasekNo ratings yet

- Taylor Swift LyricsDocument2 pagesTaylor Swift LyricsElsie DomeNo ratings yet

- Halimatus Islamiah Analisis Jurnal Internasional K3Document3 pagesHalimatus Islamiah Analisis Jurnal Internasional K3TussNo ratings yet

- Semantically Partitioned Object Sap BW 7.3Document23 pagesSemantically Partitioned Object Sap BW 7.3smiks50% (2)

- Comm 130 PortfolioDocument23 pagesComm 130 PortfolioSami MossNo ratings yet

- PCA TIME SAVING DESIGN AIDS - Two-Way SlabsDocument7 pagesPCA TIME SAVING DESIGN AIDS - Two-Way SlabsvNo ratings yet

- Sample Questions FinalDocument11 pagesSample Questions FinaldunyaNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- Electro-Chemiluminescence Immunoassay (ECLIA) For The Quantitative Determination of CA 15-3 in Human Serum and PlasmaDocument2 pagesElectro-Chemiluminescence Immunoassay (ECLIA) For The Quantitative Determination of CA 15-3 in Human Serum and PlasmayantuNo ratings yet

- GDPR ReportDocument84 pagesGDPR ReportKingPlaysNo ratings yet

- InnerFiles Current Year PDF 2023Document687 pagesInnerFiles Current Year PDF 2023shravanibagul04No ratings yet

- Department of Mechanical Engineering: Final Year Mini Project PresentationDocument22 pagesDepartment of Mechanical Engineering: Final Year Mini Project PresentationNaresh DamaNo ratings yet

- Shahetal.2022 TecGeomorpJhelumDocument21 pagesShahetal.2022 TecGeomorpJhelumAyesha EjazNo ratings yet

- Gershwin George Rhapsody in Blue For Sax Quartet 64734Document113 pagesGershwin George Rhapsody in Blue For Sax Quartet 64734Jessica HowardNo ratings yet

- Alarm Security Pic - Google ShoppingDocument1 pageAlarm Security Pic - Google Shoppingleeleeleebc123No ratings yet

- Inactive Volcanoes in The Philippine SDocument6 pagesInactive Volcanoes in The Philippine SChristian ParadoNo ratings yet

- 3HAC052610 AM Functional Safety and SafeMove2 RW 6-En PDFDocument236 pages3HAC052610 AM Functional Safety and SafeMove2 RW 6-En PDFlesnarjp jpNo ratings yet

- Rear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05Document46 pagesRear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05SergeyNo ratings yet

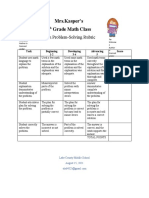

- Problemsolving RubricDocument1 pageProblemsolving Rubricapi-560491685No ratings yet

- Building 7Document1 pageBuilding 7Arshad AlamNo ratings yet

- C C P S: Lalit KumarDocument3 pagesC C P S: Lalit KumarAbhishek aby5No ratings yet

- Muac MunichaccDocument24 pagesMuac MunichaccDelavillièreNo ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseAhmad DaoodNo ratings yet

- SBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsDocument14 pagesSBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsAminNo ratings yet

- SPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesDocument24 pagesSPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesLulut Fitra FalaNo ratings yet

Main Sub-Main Distribution Boards Testing and Commissioning Procedure

Main Sub-Main Distribution Boards Testing and Commissioning Procedure

Uploaded by

Aleen Gamal Al-Dinji0 ratings0% found this document useful (0 votes)

70 views4 pagesThe document outlines testing and commissioning procedures for main sub-main distribution boards, sub-main distribution boards, distribution boards, and consumer units. It details visual inspections, functional checks, insulation resistance tests, and switch-on processes to ensure equipment is properly installed and operating correctly before system acceptance. Key steps include verifying nameplate details and ratings, checking for damage, measuring insulation resistance, and energizing main and sub-main switches sequentially while monitoring for issues. Upon satisfactory completion of all tests, the engineer will sign an acceptance certificate.

Original Description:

hi

Original Title

Main Sub

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines testing and commissioning procedures for main sub-main distribution boards, sub-main distribution boards, distribution boards, and consumer units. It details visual inspections, functional checks, insulation resistance tests, and switch-on processes to ensure equipment is properly installed and operating correctly before system acceptance. Key steps include verifying nameplate details and ratings, checking for damage, measuring insulation resistance, and energizing main and sub-main switches sequentially while monitoring for issues. Upon satisfactory completion of all tests, the engineer will sign an acceptance certificate.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

70 views4 pagesMain Sub-Main Distribution Boards Testing and Commissioning Procedure

Main Sub-Main Distribution Boards Testing and Commissioning Procedure

Uploaded by

Aleen Gamal Al-DinjiThe document outlines testing and commissioning procedures for main sub-main distribution boards, sub-main distribution boards, distribution boards, and consumer units. It details visual inspections, functional checks, insulation resistance tests, and switch-on processes to ensure equipment is properly installed and operating correctly before system acceptance. Key steps include verifying nameplate details and ratings, checking for damage, measuring insulation resistance, and energizing main and sub-main switches sequentially while monitoring for issues. Upon satisfactory completion of all tests, the engineer will sign an acceptance certificate.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

Main Sub-Main Distribution Boards

Testing and Commissioning Procedure

Method Statement For The Testing and Commissioning of Main Sub-

Main Distribution Boards (MSMDB) Sub-Main Distribution Boards

(SMDB) Distribution Boards (DB) and Consumer Units(CU)

TESTING, COMMISSIONING AND START UP PROCEDURES

Upon completion of equipment installation and prior to

carrying out test runs, the Contractor shall visually inspect

the installation and satisfy that the equipment has been

properly installed.

Ensure that all moving parts (if any) are free from

obstructions.

It should be ascertained that the system has been installed in

accordance with the design and installation drawings, and

that each piece of equipment operates properly.

Manufacturer’s instructions, where applicable, will be

followed for testing and commissioning of the system

components.

All recommendations as per standards and regulatory

requirements applicable to the project shall be followed.

Preparation

Prior to system operation the Contractor together with the Engineer

visually inspects and attests that the system is ready for operation.

The following shall be observed:

Punch list: The contractor shall see to it that all the punch list items

that may directly affect the system tests were all complied with and/

or resolved with the Engineer/ Client.

Notification: The Contractor shall notify the Engineer and/ or Client

representative of the time and date when the test/ inspection shall be

performed. The Contractor shall notify the Engineer and/ or Client

representative 48 hours before the actual inspection to enable them

to witness the tests. The values will be recorded and submitted for

further approval.

Testing procedure MSMDB’s and SMDB’s

The following tests are to be carried out in a distribution board:

Verification of nameplate details for rating in accordance

with approved General Arrangement (GA) drawings

Check for physical damage

General checks

Check for Electrical/ Functional checks

Insulation Resistance tests

Check earthing connection

Test equipment/ instruments:

Insulation resistance tester with variable voltage selections

Multi-meters

Insulation resistance test – Procedures

Check for the tightness of all connections

Clean all the supporting insulators

Isolate the cables on incoming and outgoing side

Apply a Megger voltage of 1000 Volts DC with Respective

Phases for one (1) minute and record the values

Similarly, continue the test and record the values for the

other phases

Electrical/ Functional Checks – Procedures

Switch on the main incoming control supply for the SMDB

Check the electrical operation of the switchgear using the

schemes

Check the operation of the indicating devices, voltmeters,

protective devices, etc. mounted in the panel using the

scheme

Testing procedure of DB’s & CU’s

The following tests are to carried out in a distribution board:

Verification of nameplate details for rating in accordance

with approved General Arrangement (GA) drawings

Check for physical damage and earthing connection

General checks

Check for Electrical/ Functional checks

Test equipment/ instruments:

Multi-meters

Electrical/ Functional Checks – Procedures

Switch on the main incoming control supply for the SMDB

Check the electrical operation of the circuit breaker

Check the availability of voltage on circuit breaker by using

Multi-meter

Check the operation of the indicating devices, Voltmeters,

protective devices, etc. mounted in the panel using the same

scheme

Before Energisation

Check:

Busbar chambers, main and sub-main switch connections i.e.

bolts and nuts tightness.

Earthing connections at compartments, all switches and earth

electrodes.

Clearance of live parts from direct contact with or any

likelihood of contact with tools, spurious bare conductors

remaining in switches, circuit breakers and switch cubicles.

Vacuum cleaning of switches and Breakers.

Provision of danger and warning signs.

Switch on Process

Whenever there is any break of time e.g. the next day, in

carrying out the switch on process, re-test of insulation

resistance is required.

Switch on the main incoming with all other out going

breakers off.

If normal, switch on other sub-main switches one by one with

all other outgoing switches off.

If normal, then switch on all other out-going switches one by

one.

Keep vigilance for about 30 minutes to see if any smell or

abnormal noise is being generated.

Acceptance:

After the system is thoroughly tested and inspected and all

comments have been duly complied and rectified, the Engineers shall

sign the Acceptance Certificate certifying that the system is fully

accepted and shall be ready for handing over to the owner.

You might also like

- Method of Statement - Electrical Power Supply Turn OnDocument2 pagesMethod of Statement - Electrical Power Supply Turn OnAlex Choong67% (3)

- CCTV Camera Testing & Commissioning ProcedureDocument2 pagesCCTV Camera Testing & Commissioning ProcedureAleen Gamal Al-Dinji100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Testing and Commissioning of SwitchgearDocument3 pagesTesting and Commissioning of SwitchgearkdmillerNo ratings yet

- Pre - Functional Checklist Documentation 9Document5 pagesPre - Functional Checklist Documentation 9renjithv_4No ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- PRE Commissioning Procedures TR Rev01 PGCILDocument52 pagesPRE Commissioning Procedures TR Rev01 PGCILkrishnamanikandan100% (3)

- Method of Statement Holiday TestingDocument4 pagesMethod of Statement Holiday TestingEdison Walit100% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- JW Marriot Abu Dhabi Resort & Spa Otak InternationalDocument15 pagesJW Marriot Abu Dhabi Resort & Spa Otak InternationalPeanut d. DestroyerNo ratings yet

- Emergency Lights Central Battery System Testing and Commissioning Method of StatementDocument12 pagesEmergency Lights Central Battery System Testing and Commissioning Method of StatementAleen Gamal Al-DinjiNo ratings yet

- Testing and Commissioning of Metal-Clad SwitchgearDocument3 pagesTesting and Commissioning of Metal-Clad SwitchgearJoel AlcantaraNo ratings yet

- Testing & Commissioning of Fire Suppression SystemDocument5 pagesTesting & Commissioning of Fire Suppression Systemmyanmarfire100% (2)

- T&C of Fire Supression SystemDocument5 pagesT&C of Fire Supression Systemamg007100% (1)

- Commissioning: Commissioning High Voltage EquipmentDocument14 pagesCommissioning: Commissioning High Voltage Equipment2091979No ratings yet

- Testing and Commissioning of Fire Alarm SystemDocument10 pagesTesting and Commissioning of Fire Alarm SystemRobin Oidem CaniedoNo ratings yet

- Testing & Commissioning of CCUDocument2 pagesTesting & Commissioning of CCUamg007100% (1)

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- Testing and Commissioning of MetalClad SwitchgearDocument3 pagesTesting and Commissioning of MetalClad SwitchgearPradeep Kumar MaraptlaNo ratings yet

- Thermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andDocument3 pagesThermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andCollen Noel MabasaNo ratings yet

- Introduction To Testing and Commissioning of Power System (2019, Elsevier) (10.1016 - B978-0-12-816858-5.00003-4) - Libgen - Li PDFDocument8 pagesIntroduction To Testing and Commissioning of Power System (2019, Elsevier) (10.1016 - B978-0-12-816858-5.00003-4) - Libgen - Li PDFMohammed A. AliNo ratings yet

- 16950Document16 pages16950uddinnadeemNo ratings yet

- g10 4thQ Commissioning Electrical SystemDocument12 pagesg10 4thQ Commissioning Electrical SystemLiyan PrettyNo ratings yet

- Sec16 - Electrical Construction Checkout and TestingDocument13 pagesSec16 - Electrical Construction Checkout and TestingYusufNo ratings yet

- Commn. Check ListDocument8 pagesCommn. Check ListsbpathiNo ratings yet

- Testing and Commissioning of Electrical EquipmentDocument6 pagesTesting and Commissioning of Electrical EquipmentGreeshma PuttannaNo ratings yet

- EDOC - 10 Critical Tests For New Power Circuit BreakersDocument7 pagesEDOC - 10 Critical Tests For New Power Circuit BreakersEl Comedor Benedict100% (1)

- Inspection and Test ProceduresDocument33 pagesInspection and Test Proceduresmrnoboby0407No ratings yet

- 05 EsuDocument2 pages05 EsuFernando BarbariniNo ratings yet

- Precommissioning, Commissioning and Start Up ExplainationDocument12 pagesPrecommissioning, Commissioning and Start Up ExplainationKevin Muhammad100% (1)

- Preventive MaintenanceDocument6 pagesPreventive MaintenanceMay Ann DuronNo ratings yet

- Method of Statement KPMG Fm200Document8 pagesMethod of Statement KPMG Fm200Manesh KariyadanNo ratings yet

- Visual and Technical Checking of Instrumentation and Control SystemDocument13 pagesVisual and Technical Checking of Instrumentation and Control SystemzhangyiliNo ratings yet

- Project Name: Yas Acres (North Yas) Development Phase 1 SurDocument17 pagesProject Name: Yas Acres (North Yas) Development Phase 1 SurARUNNo ratings yet

- Specification For Testing & CommissioningDocument7 pagesSpecification For Testing & CommissioningEric TaylorNo ratings yet

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssNo ratings yet

- Commissioning High Voltage EquipmentDocument13 pagesCommissioning High Voltage EquipmentJesus RodriguezNo ratings yet

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad Switchgearvijaydev75100% (1)

- Field Inspection of New Medium-Voltage SwitchgearDocument3 pagesField Inspection of New Medium-Voltage SwitchgearHamad GulNo ratings yet

- AC Circuit Breakers Routine Tests According To IEC 62271-100Document12 pagesAC Circuit Breakers Routine Tests According To IEC 62271-100sathishkannanNo ratings yet

- Field Inspection and Testing of Medium-Voltage Motor Control Centres (MCCS)Document3 pagesField Inspection and Testing of Medium-Voltage Motor Control Centres (MCCS)Sandro CuetoNo ratings yet

- Take Control of Your Systems With The Control Box AssemblyDocument5 pagesTake Control of Your Systems With The Control Box AssemblyjackNo ratings yet

- Commissioning of InstrumentationDocument16 pagesCommissioning of InstrumentationrajuNo ratings yet

- Test Guide InstructionDocument41 pagesTest Guide InstructionThức Võ100% (1)

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- MCC Test ProcedureDocument18 pagesMCC Test ProcedureAous H100% (1)

- 03 Pre-Commissioning and Commissioning 26 08 00 09022022011343Document13 pages03 Pre-Commissioning and Commissioning 26 08 00 09022022011343ibrahimsirpiNo ratings yet

- Edoc-Switchgear and Switchboard Inspection and Testing GuideDocument16 pagesEdoc-Switchgear and Switchboard Inspection and Testing GuideEl Comedor Benedict100% (1)

- Edoc-Switchgear and Switchboard Inspection and Testing GuideDocument16 pagesEdoc-Switchgear and Switchboard Inspection and Testing GuideEl Comedor Benedict100% (1)

- Wave Let TutorialDocument26 pagesWave Let TutorialBhavik PrajapatiNo ratings yet

- Aea 1305 WC El MS 0031Document7 pagesAea 1305 WC El MS 0031Adil HasanovNo ratings yet

- Substation Pre Commissioning TestsDocument13 pagesSubstation Pre Commissioning Testsrasheed313100% (2)

- General Information (Technical) : 1.1. Codes, Standards & RegulationsDocument6 pagesGeneral Information (Technical) : 1.1. Codes, Standards & RegulationsjayNo ratings yet

- Understanding Electrical Inspection and TestingDocument3 pagesUnderstanding Electrical Inspection and TestingI Wayan Aries DarmawanNo ratings yet

- Comprehensive Electrical System Maintenance ChecklistsDocument12 pagesComprehensive Electrical System Maintenance ChecklistsFarrukh Nadeem100% (1)

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad SwitchgearMohammed MadiNo ratings yet

- SLPG - HT Motor-4yDocument4 pagesSLPG - HT Motor-4yAshraf MohammedNo ratings yet

- Job Plan: Lead Craft Condition For Work Crafts Department Craft QTYDocument3 pagesJob Plan: Lead Craft Condition For Work Crafts Department Craft QTYMohsin YasinNo ratings yet

- Commissioning Documents For Instrumentation EngineersDocument7 pagesCommissioning Documents For Instrumentation EngineersVraja Kisori100% (1)

- Electrician's Troubleshooting and Testing Pocket Guide, Third EditionFrom EverandElectrician's Troubleshooting and Testing Pocket Guide, Third EditionRating: 5 out of 5 stars5/5 (1)

- Method Statement For Installation of CCTV Camera SystemDocument6 pagesMethod Statement For Installation of CCTV Camera SystemAleen Gamal Al-DinjiNo ratings yet

- Sequence of Operation For ElectricalDocument5 pagesSequence of Operation For ElectricalAleen Gamal Al-DinjiNo ratings yet

- Method of Statement For Installation of Earthing, Bonding & Lightning Protection SystemDocument6 pagesMethod of Statement For Installation of Earthing, Bonding & Lightning Protection SystemAleen Gamal Al-DinjiNo ratings yet

- Ring Main Unit Testing and Commissioning Method StatementDocument4 pagesRing Main Unit Testing and Commissioning Method StatementAleen Gamal Al-DinjiNo ratings yet

- Automatic Transfer SwitchDocument7 pagesAutomatic Transfer SwitchAleen Gamal Al-DinjiNo ratings yet

- Emergency Lights Central Battery System Testing and Commissioning Method of StatementDocument12 pagesEmergency Lights Central Battery System Testing and Commissioning Method of StatementAleen Gamal Al-DinjiNo ratings yet

- Installation of Access Control System Method of StatementDocument5 pagesInstallation of Access Control System Method of StatementAleen Gamal Al-DinjiNo ratings yet

- Installation of Marble and Granite Tiles On FloorDocument7 pagesInstallation of Marble and Granite Tiles On FloorAleen Gamal Al-Dinji100% (2)

- Method Statement For Fire Alarm System InstallationDocument7 pagesMethod Statement For Fire Alarm System InstallationAleen Gamal Al-Dinji100% (1)

- Method Statement For GIDocument9 pagesMethod Statement For GIAleen Gamal Al-DinjiNo ratings yet

- Statement of Purpose Name: Krishna Teja SwarnaDocument2 pagesStatement of Purpose Name: Krishna Teja SwarnaMohammadRahemanNo ratings yet

- Tuyển Sinh 10 - đề 1 -KeyDocument5 pagesTuyển Sinh 10 - đề 1 -Keynguyenhoang17042004No ratings yet

- CGF FPC Palm Oil RoadmapDocument31 pagesCGF FPC Palm Oil RoadmapnamasayanazlyaNo ratings yet

- Papper Referensi 2 - Using Warmth As The Visual Design of A Store - Intimacy, Relational Needs, and Approach IntentionsDocument11 pagesPapper Referensi 2 - Using Warmth As The Visual Design of A Store - Intimacy, Relational Needs, and Approach IntentionsBergodo PrajuritNo ratings yet

- Dbms Lab Dbms Lab: 23 March 202Document12 pagesDbms Lab Dbms Lab: 23 March 202LOVISH bansalNo ratings yet

- Safety Data Sheet Carbon Cathode SolutionDocument11 pagesSafety Data Sheet Carbon Cathode SolutionJeff BanasekNo ratings yet

- Taylor Swift LyricsDocument2 pagesTaylor Swift LyricsElsie DomeNo ratings yet

- Halimatus Islamiah Analisis Jurnal Internasional K3Document3 pagesHalimatus Islamiah Analisis Jurnal Internasional K3TussNo ratings yet

- Semantically Partitioned Object Sap BW 7.3Document23 pagesSemantically Partitioned Object Sap BW 7.3smiks50% (2)

- Comm 130 PortfolioDocument23 pagesComm 130 PortfolioSami MossNo ratings yet

- PCA TIME SAVING DESIGN AIDS - Two-Way SlabsDocument7 pagesPCA TIME SAVING DESIGN AIDS - Two-Way SlabsvNo ratings yet

- Sample Questions FinalDocument11 pagesSample Questions FinaldunyaNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- Electro-Chemiluminescence Immunoassay (ECLIA) For The Quantitative Determination of CA 15-3 in Human Serum and PlasmaDocument2 pagesElectro-Chemiluminescence Immunoassay (ECLIA) For The Quantitative Determination of CA 15-3 in Human Serum and PlasmayantuNo ratings yet

- GDPR ReportDocument84 pagesGDPR ReportKingPlaysNo ratings yet

- InnerFiles Current Year PDF 2023Document687 pagesInnerFiles Current Year PDF 2023shravanibagul04No ratings yet

- Department of Mechanical Engineering: Final Year Mini Project PresentationDocument22 pagesDepartment of Mechanical Engineering: Final Year Mini Project PresentationNaresh DamaNo ratings yet

- Shahetal.2022 TecGeomorpJhelumDocument21 pagesShahetal.2022 TecGeomorpJhelumAyesha EjazNo ratings yet

- Gershwin George Rhapsody in Blue For Sax Quartet 64734Document113 pagesGershwin George Rhapsody in Blue For Sax Quartet 64734Jessica HowardNo ratings yet

- Alarm Security Pic - Google ShoppingDocument1 pageAlarm Security Pic - Google Shoppingleeleeleebc123No ratings yet

- Inactive Volcanoes in The Philippine SDocument6 pagesInactive Volcanoes in The Philippine SChristian ParadoNo ratings yet

- 3HAC052610 AM Functional Safety and SafeMove2 RW 6-En PDFDocument236 pages3HAC052610 AM Functional Safety and SafeMove2 RW 6-En PDFlesnarjp jpNo ratings yet

- Rear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05Document46 pagesRear Drive Halfshafts: 2016.0 RANGE ROVER (LG), 205-05SergeyNo ratings yet

- Problemsolving RubricDocument1 pageProblemsolving Rubricapi-560491685No ratings yet

- Building 7Document1 pageBuilding 7Arshad AlamNo ratings yet

- C C P S: Lalit KumarDocument3 pagesC C P S: Lalit KumarAbhishek aby5No ratings yet

- Muac MunichaccDocument24 pagesMuac MunichaccDelavillièreNo ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseAhmad DaoodNo ratings yet

- SBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsDocument14 pagesSBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsAminNo ratings yet

- SPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesDocument24 pagesSPE 163723 Pressure Transient Analysis of Data From Permanent Downhole GaugesLulut Fitra FalaNo ratings yet