Professional Documents

Culture Documents

Enclosed Impeller Centrifugal Electric Pumps: in AISI 304

Enclosed Impeller Centrifugal Electric Pumps: in AISI 304

Uploaded by

jorgeCopyright:

Available Formats

You might also like

- Maharashtra HSC Chemistry Paper 1-Target PublicationDocument54 pagesMaharashtra HSC Chemistry Paper 1-Target PublicationKhanAbdullah78% (18)

- Ammonia-Haldor Topsoe PDFDocument6 pagesAmmonia-Haldor Topsoe PDFShubham BansalNo ratings yet

- Komatsu Pc20 R 8Document6 pagesKomatsu Pc20 R 8Lilik TrisnayantiNo ratings yet

- BlockTec AAC PresentationDocument53 pagesBlockTec AAC Presentationluigi firmalinoNo ratings yet

- 1 Contents: Design Note On Level Crossing InletDocument12 pages1 Contents: Design Note On Level Crossing Inletsuranga dadallage100% (1)

- Tutorial MSEWDocument1 pageTutorial MSEWSUNDARAVELNo ratings yet

- Lesson Plan in Science Matter For Grade 3Document7 pagesLesson Plan in Science Matter For Grade 3fatimah aburomeh100% (2)

- LPC-LPCD E-Drive: In-Line Electronic Electric Pumps + InverterDocument5 pagesLPC-LPCD E-Drive: In-Line Electronic Electric Pumps + InverterVu DangNo ratings yet

- CDX (L) : Single Impeller Centrifugal Electric PumpsDocument8 pagesCDX (L) : Single Impeller Centrifugal Electric Pumpsdiego Uruguay 87No ratings yet

- Hollow Shaft Encoder WDG 100 HDocument5 pagesHollow Shaft Encoder WDG 100 HAntonio Carlos CardosoNo ratings yet

- 2CDX (L) : Dual Impeller Centrifugal Electric PumpsDocument6 pages2CDX (L) : Dual Impeller Centrifugal Electric PumpsBILLY CODYNo ratings yet

- In-Line Centrifugal Electric Pumps: in AISI 304 Stainless SteelDocument7 pagesIn-Line Centrifugal Electric Pumps: in AISI 304 Stainless SteelMuh. Arul RomadhonNo ratings yet

- 61-Clark-Reliance-TWIP-ELECTROPIERNA DE NIVELDocument4 pages61-Clark-Reliance-TWIP-ELECTROPIERNA DE NIVELMiguel ZeaNo ratings yet

- 2 VAG EKO Plus F4Document3 pages2 VAG EKO Plus F4Baris BoskanNo ratings yet

- Komatsu pc12-r8Document6 pagesKomatsu pc12-r8Doich BrothersNo ratings yet

- Anti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceDocument2 pagesAnti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceMehrzadNo ratings yet

- 1DB 10881 enDocument1 page1DB 10881 enFreddy MormontoyNo ratings yet

- Electrovalvulas de Control Filtro MangasDocument2 pagesElectrovalvulas de Control Filtro MangasJosé Emilio Vásquez CarrascoNo ratings yet

- JZ-500 / OZ-500: Technical DataDocument3 pagesJZ-500 / OZ-500: Technical Datademetrio lopezNo ratings yet

- JZ-500 / OZ-500: Technical DataDocument2 pagesJZ-500 / OZ-500: Technical DataMaynor PadillaNo ratings yet

- Manual ENDocument52 pagesManual ENJoão RigorNo ratings yet

- KV-5500/5000/3000 KV-DR1: Programmable ControllerDocument2 pagesKV-5500/5000/3000 KV-DR1: Programmable ControllerCatngoNo ratings yet

- Exp LG 419920 - 0Document1 pageExp LG 419920 - 0Juan Pablo Cisternas FortuneNo ratings yet

- RF JumperDocument1 pageRF JumperSheena Camille ManalangNo ratings yet

- Exp LG 419744 - 0Document1 pageExp LG 419744 - 0aissatyacineNo ratings yet

- Bu0250 6072502 en 3021 DeskDocument212 pagesBu0250 6072502 en 3021 Deskolivier.bigouretNo ratings yet

- Technical Data: 2-1/2" & 3" (DN65 & DN80) MODEL F Deluge Valve Vertical Conventional Trim ChartDocument4 pagesTechnical Data: 2-1/2" & 3" (DN65 & DN80) MODEL F Deluge Valve Vertical Conventional Trim ChartAli Osman100% (1)

- Exp LG 419917 - 0Document1 pageExp LG 419917 - 0aissatyacineNo ratings yet

- WebTec Pico BulletinDocument4 pagesWebTec Pico BulletinjnaveNo ratings yet

- Exp LG 419746 - 0Document1 pageExp LG 419746 - 0aissatyacineNo ratings yet

- Eibenstock PDB 250Document124 pagesEibenstock PDB 250Projects CortexNo ratings yet

- datasheet_model-dr857Document2 pagesdatasheet_model-dr857ivanNo ratings yet

- Valtek FlowpakDocument12 pagesValtek FlowpakRaphael AndradeNo ratings yet

- DS4510 5010Document2 pagesDS4510 5010Andie Hart100% (1)

- European Catalog Pilot Valve Boxes Series c20 Asco en 7028706Document2 pagesEuropean Catalog Pilot Valve Boxes Series c20 Asco en 7028706ChangHuiChuanNo ratings yet

- Valvula de Control Caracterizado de 2 ViasDocument4 pagesValvula de Control Caracterizado de 2 Viasjackpillaca4No ratings yet

- Exp LG 027109 - 0Document1 pageExp LG 027109 - 0aissatyacineNo ratings yet

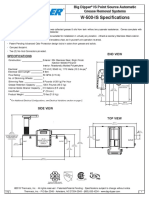

- W 500 Is SpecDocument2 pagesW 500 Is SpecdjukalNo ratings yet

- Lapp Kabel H05V-K: Power and Control CablesDocument1 pageLapp Kabel H05V-K: Power and Control CablesJemerald MagtanongNo ratings yet

- MCCB - DRX 125 - Thermal Magnetic - Icu 36 Ka - 415 V - 2P - 50 ADocument1 pageMCCB - DRX 125 - Thermal Magnetic - Icu 36 Ka - 415 V - 2P - 50 AJosé Luis Julca GarcíaNo ratings yet

- RKB Metals Industry LeafletDocument2 pagesRKB Metals Industry LeafletLuis Carlos FerréNo ratings yet

- Helukabel M11464 en GBDocument2 pagesHelukabel M11464 en GBDaniel ChangNo ratings yet

- DAB FK Pumpe Za Komunalne VodeDocument24 pagesDAB FK Pumpe Za Komunalne VodeBurazBurazNo ratings yet

- Magnetic Speed Pensor - 6732Document1 pageMagnetic Speed Pensor - 6732Jezrell JaravataNo ratings yet

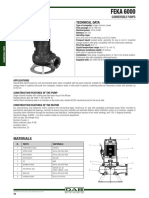

- FEKA 6000: Technical DataDocument3 pagesFEKA 6000: Technical DataAmir NooriNo ratings yet

- Systems Specifiers Guide Excerpt of Firestop Applications Products Technical Information ASSET DOC LOC 6168298Document38 pagesSystems Specifiers Guide Excerpt of Firestop Applications Products Technical Information ASSET DOC LOC 6168298Jaime LopezNo ratings yet

- Straight Shell D-1.0 & 0.7 M-LDocument1 pageStraight Shell D-1.0 & 0.7 M-LDeep SherawatNo ratings yet

- Model Ac/Tc-21: Belt Box ConfigurationDocument2 pagesModel Ac/Tc-21: Belt Box ConfigurationRiddhesh PatelNo ratings yet

- 400lpm Ebara Submersibe PumpDocument7 pages400lpm Ebara Submersibe PumpAddin Galih PrakosoNo ratings yet

- Biowatt Collaudo Svizzera GeDocument2 pagesBiowatt Collaudo Svizzera GeAhmed El-AdawyNo ratings yet

- Technical Bid For Electric Heat Tracing SystemDocument27 pagesTechnical Bid For Electric Heat Tracing SystemNaveed Ahmed MirNo ratings yet

- Technical Bid For Electric Heat Tracing SystemDocument27 pagesTechnical Bid For Electric Heat Tracing SystemNaveed Ahmed MirNo ratings yet

- MCB RX 6000 - 3P 400 V - 10 A - C Curve - Prong-Type Supply BusbarsDocument1 pageMCB RX 6000 - 3P 400 V - 10 A - C Curve - Prong-Type Supply BusbarsHenry Roger Sanchez AguilarNo ratings yet

- Intelocked Panel Switch Sockets & Plugs: CPSCP - FSQCP / BPDocument2 pagesIntelocked Panel Switch Sockets & Plugs: CPSCP - FSQCP / BPvenkatesh tekkaliNo ratings yet

- Assured Automation R-SeriesDocument2 pagesAssured Automation R-SeriesBrandon TrocNo ratings yet

- Megatorque Motor: PB SeriesDocument11 pagesMegatorque Motor: PB SeriesshahNo ratings yet

- Dep 1122 Type 270 270r en Web 0Document13 pagesDep 1122 Type 270 270r en Web 0Pablo SauNo ratings yet

- Signet 2819-2823 Conductivity/Resistivity Electrodes: FeaturesDocument4 pagesSignet 2819-2823 Conductivity/Resistivity Electrodes: FeaturesMagin Idelfonso TorreblancaNo ratings yet

- Exp LG 028647 - 0Document1 pageExp LG 028647 - 0Jose PalmaNo ratings yet

- Gate Valve VAGDocument5 pagesGate Valve VAGrosiNo ratings yet

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Jeffrey Calinao ManaloNo ratings yet

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Sonny LuuNo ratings yet

- Rgs Reflex Solenoid ActuatorDocument2 pagesRgs Reflex Solenoid ActuatorDaniel MarNo ratings yet

- SNM SNM V Close Coupled Centrifugal Pump EnglishDocument8 pagesSNM SNM V Close Coupled Centrifugal Pump EnglishInnovatech EnterpriseNo ratings yet

- Switching UnitDocument12 pagesSwitching UnitEdi PurwantoNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDocument12 pagesPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshNo ratings yet

- Heating Systems: 1-IntroductionDocument5 pagesHeating Systems: 1-IntroductionFlaw Lesş MisşNo ratings yet

- MSDS - GlobalpreneDocument5 pagesMSDS - GlobalprenealphadingNo ratings yet

- Ana ChemDocument14 pagesAna ChemSamuel MagannonNo ratings yet

- General Chemistry Q4 M4Document16 pagesGeneral Chemistry Q4 M4roxan clabria100% (1)

- COMTECH LIU Upto 144FDocument4 pagesCOMTECH LIU Upto 144Fparth mendirattaNo ratings yet

- DESERT Solar CellsDocument2 pagesDESERT Solar CellsAndrew AtotuomahNo ratings yet

- Nanotechnology in Temporary Anchorage Devices: Dr. Chelza X, Dr. Anand SivadasaDocument3 pagesNanotechnology in Temporary Anchorage Devices: Dr. Chelza X, Dr. Anand SivadasajayashreeNo ratings yet

- CatTod2015 CO2 To Olefins CatDocument8 pagesCatTod2015 CO2 To Olefins CatSolticiio DiieNo ratings yet

- Iqwq Ce1091 VPWLD D7 4556 - 0Document7 pagesIqwq Ce1091 VPWLD D7 4556 - 0jacksonbello34No ratings yet

- UNIT-3 Index Properties of Soil: Er. Shatrudhan Prasad Yadav Constructor Instructor LTS, LahanDocument14 pagesUNIT-3 Index Properties of Soil: Er. Shatrudhan Prasad Yadav Constructor Instructor LTS, Lahanajai chyNo ratings yet

- Heat Work AP Chem 1314Document4 pagesHeat Work AP Chem 1314karlaNo ratings yet

- Index 9th Edition PheurDocument34 pagesIndex 9th Edition Pheurpepilloelgrillo50% (2)

- Student Design Lab Report Comparison of Different Types of WeldsDocument26 pagesStudent Design Lab Report Comparison of Different Types of WeldsSylvester WafulaNo ratings yet

- Chap 2 WaterDocument34 pagesChap 2 WaterGlidilyn Castillo BarcelonNo ratings yet

- MS51830FDocument5 pagesMS51830FValentinNo ratings yet

- 4 Design and Operation of Landfills 1667309860593Document30 pages4 Design and Operation of Landfills 1667309860593Saran Raj SNo ratings yet

- Block Works & PlasteringDocument11 pagesBlock Works & PlasteringmrameshceNo ratings yet

- RydAir BPIDocument4 pagesRydAir BPIbhasker sharmaNo ratings yet

- Importance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsDocument18 pagesImportance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsJessel Galicia100% (1)

- Microstructures of Copper AlloysDocument71 pagesMicrostructures of Copper Alloysmauriciodom100% (7)

- Production of Maleic AnhydrideDocument8 pagesProduction of Maleic AnhydrideZafran AliNo ratings yet

- Material PDFDocument8 pagesMaterial PDFashoku24007No ratings yet

- Identifying Rocks Activity FormatDocument4 pagesIdentifying Rocks Activity FormatMike Lexter AndalNo ratings yet

Enclosed Impeller Centrifugal Electric Pumps: in AISI 304

Enclosed Impeller Centrifugal Electric Pumps: in AISI 304

Uploaded by

jorgeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enclosed Impeller Centrifugal Electric Pumps: in AISI 304

Enclosed Impeller Centrifugal Electric Pumps: in AISI 304

Uploaded by

jorgeCopyright:

Available Formats

DWC

ENCLOSED IMPELLER CENTRIFUGAL ELECTRIC PUMPS

in AISI 304

Enclosed impeller centrifugal electric pumps in AISI 304 stainless steel.

APPLICATIONS

• Cooling, air conditioning and heating systems

• Chiller

• Washing systems

• Industrial liquids

TECHNICAL DETAILS

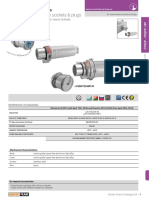

• Available in two different versions: with threaded (DWC-N) and

DWC-N Victaulic connections (DWC-V)

• Insulation as per standard for the Victaulic version (DWC-V)

PUMP TECHNICAL DATA

• Maximum working pressure: 8 bar

DWC-V • Maxim temperature of the liquid:

-15°C ÷ +90°C

-15°C ÷ +110°C for H-HS-HW-HSW versions

• Suction and discharge connection G2 for DWC-N

PERFORMANCE RANGE (according to ISO 9906 Attachment A) • Suction and discharge connection Ø2” (60.3 mm) for DWC-V

• For further information please see our Data Book on the web site

www.ebaraeurope.com

MOTOR TECHNICAL DATA

• High efficiency IE2 motors starting from 0.75kW up to 5.5kW

IE3 starting from 0.75kW

• Self-ventilated 2 pole asynchronous motor

• Class of insulation F

• IP55 protection degree

• 230/400V ±10% 50Hz three phase voltage

• Protection under user’s responsibility for the three phase version

MATERIALS

• Pump casing, casing cover, impeller and shaft (part in contact with

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

the liquid) in AISI 304

• Bracket and motor frame in aluminium

• Mechanical seal in:

- Ceramic/Carbon/EPDM (standard)

- special versions: see p. 32

ACCESSORIES (On request)

Insulation casing for DWC pump casing for applications with refrigerant

liquids or liquids with high thermal difference that may generate

condensate.

IDENTIFICATION CODE

DWC H - V 500 / 3.0

1.1

Power in kW 1.5

2.2

3.0

Type 300

500

H

HS

V Victaulic Connection HW

N Threaded connection HSW

Q1AVGG

Optional version AQ1EGG

VAEGG

Q1U3EGG

Model U3BEGG

Japanese Technology since 1912 28 Commercial

DWC

ENCLOSED IMPELLER CENTRIFUGAL ELECTRIC PUMPS

in AISI 304

PERFORMANCE CHART

Model P 2 Q = Flow Rate

Three phase l/min 100 150 200 250 300 350 400 500 600 700 750

230/400V [HP] [kW] m3/h 6 9 12 15 18 21 24 30 36 42 45

H=Head [m]

DWC 300/1.1 1.5 1.1 19.2 18.1 16.6 15.0 13.1 11.0 8.5 - - - -

DWC 300/1.5 2 1.5 22.5 21.4 20.1 18.5 16.7 14.6 12.0 - - - -

DWC 500/1.5 2 1.5 - - 17.0 16.4 15.7 14.9 14.0 12.0 9.8 7.4 6.2

DWC 500/2.2 3 2.2 - - 23.0 22.3 21.5 20.7 19.8 17.8 15.5 13.0 11.5

DWC 500/3.0 4 3 - - 25.0 24.4 23.7 22.9 22.0 20.0 17.6 15.0 13.6

PERFORMANCE CURVES DWC 300 series PERFORMANCE CURVES DWC 500 series

(according to ISO 9906 Attachment A) (according to ISO 9906 Attachment A)

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

THERMAL INSULATION

Model Insulating cover Insulating cover Joint

pump casing joint Victaulic

DWC-V 300/1.1

DWC-V 300/1.5

VICTAULIC JOINT

DWC-V 500/1.5 Standard On request On request

DWC-V 500/2.2

DWC-V 500/3.0

JOINT INSULATING COVER

DWC-N 300/1.1

DWC-N 300/1.5

PUMP BODY

PUMP BODY INSULATING COVER

DWC-N 500/1.5 On request Not applicable Not applicable

DWC-N 500/2.2

JOINT INSULATING COVER DWC-N 500/3.0

VICTAULIC JOINT

SEC. A-A

Japanese Technology since 1912 29 Commercial

DWC

ENCLOSED IMPELLER CENTRIFUGAL ELECTRIC PUMPS

in AISI 304

DIMENSIONS DWC-V (VICTAULIC CONNECTION)

DIMENSIONAL TABLE

Model Dimensions [mm] Weight [kg]

B B* C C* H3 H3* V V* *

DWC-V 300/1.1 372 397 197 197 239 239 PG11 M20x1.5 14.5 15.4

DWC-V 300/1.5 385 397.5 197 197 239 239 PG11 M20x1.5 16.0 16.9

DWC-V 500/1.5 385 397.5 197 197 239 239 PG11 M20x1.5 17.0 17.9

DWC-V 500/2.2 418 396.5 230 ÷ 241 197 244 239 PG 13.5 M20x1.5 20.3 20.3

DWC-V 500/3.0 457 457 230 ÷ 241 230 ÷ 241 244 244 PG 13.5 M20x1.5 22.3 22.3

* Models with IE3 motor only

DIMENSIONS VIEW DWC-N (THREADED CONNECTION)

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

DIMENSIONAL TABLE

Model Dimensions [mm] Weight [kg]

B B* C C* H3 H3* V V* *

DWC-N 300/1.1 372 397 197 197 239 239 PG11 M20x1.5 14.5 15.4

DWC-N 300/1.5 385 397.5 197 197 239 239 PG11 M20x1.5 16.0 16.9

DWC-N 500/1.5 385 397.5 197 197 239 239 PG11 M20x1.5 16.5 17.4

DWC-N 500/2.2 418 396.5 230 ÷ 241 197 244 239 PG 13.5 M20x1.5 20.3 20.3

DWC-N 500/3.0 457 457 230 ÷ 241 230 ÷ 241 244 244 PG 13.5 M20x1.5 22.3 22.3

* Models with IE3 motor only

Japanese Technology since 1912 30 Commercial

DWC

ENCLOSED IMPELLER CENTRIFUGAL ELECTRIC PUMPS

in AISI 304

SECTIONAL VIEW DWC-V (VICTAULIC CONNECTION) SECTIONAL VIEW DWC-N (THREADED CONNECTION)

MATERIALS TABLE

Ref. Name Materials Ref. Name Materials

1 Pump casing EN 1.4301 (AISI 304) 25 Plug EN 1.4301 (AISI 304)

3 Motor bracket Aluminium 26 O-Ring [1] EPDM

4 Casing cover EN 1.4301 (AISI 304) 32 Key EN 1.4401 (AISI 316)

6 Shaft EN 1.4301 (AISI 304) 34 Impeller nut EN 1.4301 (AISI 304)

Part in contact with the liquid

7 Impeller EN 1.4301 (AISI 304) 42 Motor support Aluminium / Galvanised steel

11 Mechanical seal Ceramic/Carbon/EPDM 50 Spacer -

12 Motor frame - 56 Terminal box cover gasket NBR

13 Motor cover Aluminium 73 Casing ring EN 1.4301 (AISI 304)

14 Fan PA 75 Washer EN 1.4301 (AISI 304)

15 Fan cover Galvanised Fe P04 76 Washer EN 1.4301 (AISI 304)

16 Terminal Box - 77 O-Ring [1] EPDM

17 Terminal box cover Aluminium 78 O-Ring [1] EPDM

19 Bearing (pump side) - 92 Seal ring -

20 Bearing (motor side) - 93 Seal ring -

21 Adjustment ring Steel C70 200 Screw (pump body) Stainless steel A2-70/1 class ISO 3506/1

22 Tie-rod Galvanised Fe 42 208 Screw Stainless steel A2-70/1 class ISO 3506/1

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

24 Plug EN 1.4301 (AISI 304)

[1]= FKM for H-HS-HW-HSW versions

Japanese Technology since 1912 31 Commercial

DWC

ENCLOSED IMPELLER CENTRIFUGAL ELECTRIC PUMPS

in AISI 304

MECHCANICAL SEAL standard MATERIALS TABLE

Ref. Name Materials

A Rotating part Ceramic

B Fixed part Carbon

C O-Ring EPDM

D O-Ring EPDM

E O-Ring EPDM

F Spring AISI 316

G Structure/frame AISI 304

SPECIAL MECHANICAL SEALS (on request)

Ref. Name Materials

H Version HS Version HW Version HSW Version

A Rotating part Ceramic Silicon Carbide Tungsten Carbide Silicon Carbide

B Fixed part Carbon Silicon Carbide Tungsten Carbide Tungsten Carbide

C O-Ring FKM FKM FKM FKM

D O-Ring FKM FKM FKM FKM

E O-Ring FKM FKM FKM FKM

F Spring AISI 316 AISI 316 AISI 316 AISI 316

G Structure/frame AISI 304 AISI 316 AISI 316 AISI 316

Ref. Name Materials

Q1AVGG Version AQ1EGG Version VAEGG Version Q1U3EGG Version U3BEGG Version

A Rotating part Silicon Carbide Metallised carbon Ceramic Silicon Carbide Tungsten Carbide

B Fixed part Metallised carbon Silicon Carbide Metallised carbon Tungsten Carbide Graphite

C O-Ring FKM EPDM EPDM EPDM EPDM

D O-Ring FKM EPDM EPDM EPDM EPDM

E O-Ring FKM EPDM EPDM EPDM EPDM

The content of this publication should not be considered mandatory. EBARA Pumps Europe S.p.A. reserves the right to change the content without prior notice.

F Spring AISI 316 AISI 316 AISI 316 AISI 316 AISI 316

G Structure/frame AISI 316 AISI 316 AISI 316 AISI 316 AISI 316

ELECTRIC DATA TABLE

Model P 2 Efficiency Efficiency (%) P 1 Absorbed Current

Three phase Three phase [A]

230/400V [HP] [kW] Three phase η% Three phase Three phase

50% 75% 100% [kW] 230V 400V

1.5 1.1 IE2 79.7 82.5 83.0 1.80 5.5 3.2

DWC 300/1.1 1.5 1.1 IE3 83.0 85.8 85.6 1.77 5.8 3.3

DWC 300/1.5 2 1.5 IE2 78.6 83.0 84.2 1.78 6.3 3.7

2 1.5 IE3 82.7 86.1 87.0 1.72 6.6 3.8

2 1.5 IE2 78.6 83.0 84.2 1.78 6.3 3.7

DWC 500/1.5 2 1.5 IE3 82.7 86.1 87.0 1.72 6.6 3.8

3 2.2 IE2 83.1 85.7 86.2 2.55 7.8 4.5

DWC 500/2.2

3 2.2 IE3 86.2 87.0 86.0 2.55 8.2 4.7

4 3 IE2 85.0 86.7 86.3 3.48 10.6 6.1

DWC 500/3.0

4 3 IE3 85.9 87.5 87.1 3.44 11.1 6.4

NOISE DATA TABLE

Model P 2

L - dB(A)*

pA

Three phase

230/400V [HP] [kW]

DWC 300/1.1 1.5 1.1 <70

DWC 300/1.5 2 1.5

DWC 500/1.5 2 1.5

DWC 500/2.2 3 2.2 <70

DWC 500/3.0 4 3

* Mean value of several measurements at 1 m distance around the pump.

Tolerance ± 2.5 dB.

Japanese Technology since 1912 32 Commercial

You might also like

- Maharashtra HSC Chemistry Paper 1-Target PublicationDocument54 pagesMaharashtra HSC Chemistry Paper 1-Target PublicationKhanAbdullah78% (18)

- Ammonia-Haldor Topsoe PDFDocument6 pagesAmmonia-Haldor Topsoe PDFShubham BansalNo ratings yet

- Komatsu Pc20 R 8Document6 pagesKomatsu Pc20 R 8Lilik TrisnayantiNo ratings yet

- BlockTec AAC PresentationDocument53 pagesBlockTec AAC Presentationluigi firmalinoNo ratings yet

- 1 Contents: Design Note On Level Crossing InletDocument12 pages1 Contents: Design Note On Level Crossing Inletsuranga dadallage100% (1)

- Tutorial MSEWDocument1 pageTutorial MSEWSUNDARAVELNo ratings yet

- Lesson Plan in Science Matter For Grade 3Document7 pagesLesson Plan in Science Matter For Grade 3fatimah aburomeh100% (2)

- LPC-LPCD E-Drive: In-Line Electronic Electric Pumps + InverterDocument5 pagesLPC-LPCD E-Drive: In-Line Electronic Electric Pumps + InverterVu DangNo ratings yet

- CDX (L) : Single Impeller Centrifugal Electric PumpsDocument8 pagesCDX (L) : Single Impeller Centrifugal Electric Pumpsdiego Uruguay 87No ratings yet

- Hollow Shaft Encoder WDG 100 HDocument5 pagesHollow Shaft Encoder WDG 100 HAntonio Carlos CardosoNo ratings yet

- 2CDX (L) : Dual Impeller Centrifugal Electric PumpsDocument6 pages2CDX (L) : Dual Impeller Centrifugal Electric PumpsBILLY CODYNo ratings yet

- In-Line Centrifugal Electric Pumps: in AISI 304 Stainless SteelDocument7 pagesIn-Line Centrifugal Electric Pumps: in AISI 304 Stainless SteelMuh. Arul RomadhonNo ratings yet

- 61-Clark-Reliance-TWIP-ELECTROPIERNA DE NIVELDocument4 pages61-Clark-Reliance-TWIP-ELECTROPIERNA DE NIVELMiguel ZeaNo ratings yet

- 2 VAG EKO Plus F4Document3 pages2 VAG EKO Plus F4Baris BoskanNo ratings yet

- Komatsu pc12-r8Document6 pagesKomatsu pc12-r8Doich BrothersNo ratings yet

- Anti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceDocument2 pagesAnti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceMehrzadNo ratings yet

- 1DB 10881 enDocument1 page1DB 10881 enFreddy MormontoyNo ratings yet

- Electrovalvulas de Control Filtro MangasDocument2 pagesElectrovalvulas de Control Filtro MangasJosé Emilio Vásquez CarrascoNo ratings yet

- JZ-500 / OZ-500: Technical DataDocument3 pagesJZ-500 / OZ-500: Technical Datademetrio lopezNo ratings yet

- JZ-500 / OZ-500: Technical DataDocument2 pagesJZ-500 / OZ-500: Technical DataMaynor PadillaNo ratings yet

- Manual ENDocument52 pagesManual ENJoão RigorNo ratings yet

- KV-5500/5000/3000 KV-DR1: Programmable ControllerDocument2 pagesKV-5500/5000/3000 KV-DR1: Programmable ControllerCatngoNo ratings yet

- Exp LG 419920 - 0Document1 pageExp LG 419920 - 0Juan Pablo Cisternas FortuneNo ratings yet

- RF JumperDocument1 pageRF JumperSheena Camille ManalangNo ratings yet

- Exp LG 419744 - 0Document1 pageExp LG 419744 - 0aissatyacineNo ratings yet

- Bu0250 6072502 en 3021 DeskDocument212 pagesBu0250 6072502 en 3021 Deskolivier.bigouretNo ratings yet

- Technical Data: 2-1/2" & 3" (DN65 & DN80) MODEL F Deluge Valve Vertical Conventional Trim ChartDocument4 pagesTechnical Data: 2-1/2" & 3" (DN65 & DN80) MODEL F Deluge Valve Vertical Conventional Trim ChartAli Osman100% (1)

- Exp LG 419917 - 0Document1 pageExp LG 419917 - 0aissatyacineNo ratings yet

- WebTec Pico BulletinDocument4 pagesWebTec Pico BulletinjnaveNo ratings yet

- Exp LG 419746 - 0Document1 pageExp LG 419746 - 0aissatyacineNo ratings yet

- Eibenstock PDB 250Document124 pagesEibenstock PDB 250Projects CortexNo ratings yet

- datasheet_model-dr857Document2 pagesdatasheet_model-dr857ivanNo ratings yet

- Valtek FlowpakDocument12 pagesValtek FlowpakRaphael AndradeNo ratings yet

- DS4510 5010Document2 pagesDS4510 5010Andie Hart100% (1)

- European Catalog Pilot Valve Boxes Series c20 Asco en 7028706Document2 pagesEuropean Catalog Pilot Valve Boxes Series c20 Asco en 7028706ChangHuiChuanNo ratings yet

- Valvula de Control Caracterizado de 2 ViasDocument4 pagesValvula de Control Caracterizado de 2 Viasjackpillaca4No ratings yet

- Exp LG 027109 - 0Document1 pageExp LG 027109 - 0aissatyacineNo ratings yet

- W 500 Is SpecDocument2 pagesW 500 Is SpecdjukalNo ratings yet

- Lapp Kabel H05V-K: Power and Control CablesDocument1 pageLapp Kabel H05V-K: Power and Control CablesJemerald MagtanongNo ratings yet

- MCCB - DRX 125 - Thermal Magnetic - Icu 36 Ka - 415 V - 2P - 50 ADocument1 pageMCCB - DRX 125 - Thermal Magnetic - Icu 36 Ka - 415 V - 2P - 50 AJosé Luis Julca GarcíaNo ratings yet

- RKB Metals Industry LeafletDocument2 pagesRKB Metals Industry LeafletLuis Carlos FerréNo ratings yet

- Helukabel M11464 en GBDocument2 pagesHelukabel M11464 en GBDaniel ChangNo ratings yet

- DAB FK Pumpe Za Komunalne VodeDocument24 pagesDAB FK Pumpe Za Komunalne VodeBurazBurazNo ratings yet

- Magnetic Speed Pensor - 6732Document1 pageMagnetic Speed Pensor - 6732Jezrell JaravataNo ratings yet

- FEKA 6000: Technical DataDocument3 pagesFEKA 6000: Technical DataAmir NooriNo ratings yet

- Systems Specifiers Guide Excerpt of Firestop Applications Products Technical Information ASSET DOC LOC 6168298Document38 pagesSystems Specifiers Guide Excerpt of Firestop Applications Products Technical Information ASSET DOC LOC 6168298Jaime LopezNo ratings yet

- Straight Shell D-1.0 & 0.7 M-LDocument1 pageStraight Shell D-1.0 & 0.7 M-LDeep SherawatNo ratings yet

- Model Ac/Tc-21: Belt Box ConfigurationDocument2 pagesModel Ac/Tc-21: Belt Box ConfigurationRiddhesh PatelNo ratings yet

- 400lpm Ebara Submersibe PumpDocument7 pages400lpm Ebara Submersibe PumpAddin Galih PrakosoNo ratings yet

- Biowatt Collaudo Svizzera GeDocument2 pagesBiowatt Collaudo Svizzera GeAhmed El-AdawyNo ratings yet

- Technical Bid For Electric Heat Tracing SystemDocument27 pagesTechnical Bid For Electric Heat Tracing SystemNaveed Ahmed MirNo ratings yet

- Technical Bid For Electric Heat Tracing SystemDocument27 pagesTechnical Bid For Electric Heat Tracing SystemNaveed Ahmed MirNo ratings yet

- MCB RX 6000 - 3P 400 V - 10 A - C Curve - Prong-Type Supply BusbarsDocument1 pageMCB RX 6000 - 3P 400 V - 10 A - C Curve - Prong-Type Supply BusbarsHenry Roger Sanchez AguilarNo ratings yet

- Intelocked Panel Switch Sockets & Plugs: CPSCP - FSQCP / BPDocument2 pagesIntelocked Panel Switch Sockets & Plugs: CPSCP - FSQCP / BPvenkatesh tekkaliNo ratings yet

- Assured Automation R-SeriesDocument2 pagesAssured Automation R-SeriesBrandon TrocNo ratings yet

- Megatorque Motor: PB SeriesDocument11 pagesMegatorque Motor: PB SeriesshahNo ratings yet

- Dep 1122 Type 270 270r en Web 0Document13 pagesDep 1122 Type 270 270r en Web 0Pablo SauNo ratings yet

- Signet 2819-2823 Conductivity/Resistivity Electrodes: FeaturesDocument4 pagesSignet 2819-2823 Conductivity/Resistivity Electrodes: FeaturesMagin Idelfonso TorreblancaNo ratings yet

- Exp LG 028647 - 0Document1 pageExp LG 028647 - 0Jose PalmaNo ratings yet

- Gate Valve VAGDocument5 pagesGate Valve VAGrosiNo ratings yet

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Jeffrey Calinao ManaloNo ratings yet

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Sonny LuuNo ratings yet

- Rgs Reflex Solenoid ActuatorDocument2 pagesRgs Reflex Solenoid ActuatorDaniel MarNo ratings yet

- SNM SNM V Close Coupled Centrifugal Pump EnglishDocument8 pagesSNM SNM V Close Coupled Centrifugal Pump EnglishInnovatech EnterpriseNo ratings yet

- Switching UnitDocument12 pagesSwitching UnitEdi PurwantoNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDocument12 pagesPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshNo ratings yet

- Heating Systems: 1-IntroductionDocument5 pagesHeating Systems: 1-IntroductionFlaw Lesş MisşNo ratings yet

- MSDS - GlobalpreneDocument5 pagesMSDS - GlobalprenealphadingNo ratings yet

- Ana ChemDocument14 pagesAna ChemSamuel MagannonNo ratings yet

- General Chemistry Q4 M4Document16 pagesGeneral Chemistry Q4 M4roxan clabria100% (1)

- COMTECH LIU Upto 144FDocument4 pagesCOMTECH LIU Upto 144Fparth mendirattaNo ratings yet

- DESERT Solar CellsDocument2 pagesDESERT Solar CellsAndrew AtotuomahNo ratings yet

- Nanotechnology in Temporary Anchorage Devices: Dr. Chelza X, Dr. Anand SivadasaDocument3 pagesNanotechnology in Temporary Anchorage Devices: Dr. Chelza X, Dr. Anand SivadasajayashreeNo ratings yet

- CatTod2015 CO2 To Olefins CatDocument8 pagesCatTod2015 CO2 To Olefins CatSolticiio DiieNo ratings yet

- Iqwq Ce1091 VPWLD D7 4556 - 0Document7 pagesIqwq Ce1091 VPWLD D7 4556 - 0jacksonbello34No ratings yet

- UNIT-3 Index Properties of Soil: Er. Shatrudhan Prasad Yadav Constructor Instructor LTS, LahanDocument14 pagesUNIT-3 Index Properties of Soil: Er. Shatrudhan Prasad Yadav Constructor Instructor LTS, Lahanajai chyNo ratings yet

- Heat Work AP Chem 1314Document4 pagesHeat Work AP Chem 1314karlaNo ratings yet

- Index 9th Edition PheurDocument34 pagesIndex 9th Edition Pheurpepilloelgrillo50% (2)

- Student Design Lab Report Comparison of Different Types of WeldsDocument26 pagesStudent Design Lab Report Comparison of Different Types of WeldsSylvester WafulaNo ratings yet

- Chap 2 WaterDocument34 pagesChap 2 WaterGlidilyn Castillo BarcelonNo ratings yet

- MS51830FDocument5 pagesMS51830FValentinNo ratings yet

- 4 Design and Operation of Landfills 1667309860593Document30 pages4 Design and Operation of Landfills 1667309860593Saran Raj SNo ratings yet

- Block Works & PlasteringDocument11 pagesBlock Works & PlasteringmrameshceNo ratings yet

- RydAir BPIDocument4 pagesRydAir BPIbhasker sharmaNo ratings yet

- Importance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsDocument18 pagesImportance and Methods of Enhancing and Decorating Bamboo Wood and Metal ProductsJessel Galicia100% (1)

- Microstructures of Copper AlloysDocument71 pagesMicrostructures of Copper Alloysmauriciodom100% (7)

- Production of Maleic AnhydrideDocument8 pagesProduction of Maleic AnhydrideZafran AliNo ratings yet

- Material PDFDocument8 pagesMaterial PDFashoku24007No ratings yet

- Identifying Rocks Activity FormatDocument4 pagesIdentifying Rocks Activity FormatMike Lexter AndalNo ratings yet