Professional Documents

Culture Documents

10.1515ijcre 2017 0229

10.1515ijcre 2017 0229

Uploaded by

NarinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10.1515ijcre 2017 0229

10.1515ijcre 2017 0229

Uploaded by

NarinCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/329655942

Synthesis and Modification of Zeolite ZSM-5 Catalyst with Solutions of

Calcium Carbonate (CaCO3)and Sodium Carbonate(Na2CO3)for Methanol to

Gasoline Conversion

Article in International Journal of Chemical Reactor Engineering · December 2018

CITATION READS

1 193

1 author:

Ehsan Kianfar

200 PUBLICATIONS 787 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Nanozeolites: synthesized, properties, applications View project

Modified ZSM-5 Zeolite for Conversion of Liquefied Petroleum Gas (LPG) to Aromatics View project

All content following this page was uploaded by Ehsan Kianfar on 22 December 2018.

The user has requested enhancement of the downloaded file.

DE GRUYTER International Journal of Chemical Reactor Engineering. 2018; 20170229

Ehsan Kianfar1 / Mahmoud Salimi1 / Vahid Pirouzfar2 / Behnam Koohestani1

Synthesis and Modification of Zeolite ZSM-5

Catalyst with Solutions of Calcium Carbonate

(CaCO3) and Sodium Carbonate (Na2CO3) for

Methanol to Gasoline Conversion

1 Department of Chemical Engineering, Arak Branch, Islamic Azad University, Arak, Iran, E-mail: m-salimi@iau-arak.ac.ir

2 Department of Chemical Engineering, Central Tehran Branch, Islamic Azad University, Tehran, Iran

Abstract:

In this article, the ZSM-5 catalyst was used as the base catalyst and its structure was modified for conducting

Methanol to Gasoline reactions. ZSM-5 catalyst reacts to the solutions with diverse concentrations of calcium

carbonate (CaCO3 ) and sodium carbonate (Na2 CO3 ), and consequently, some changes were applied to its in-

ternal structure. Thus, Methanol to Gasoline (MTG) process was carried out under pressure of 1 atm, the tem-

perature of 400°C, and specific surface area of 300 m2g-1 on synthetic zeolite ZSM-5 catalyst by a fixed-bed

reactor. Structure and morphology of the synthesized catalyst were investigated by XRD, FT-IR, SEM, XRF and

BET analyses. The effect of CaCO3 and Na2 CO3 solutions used for catalyst modification on the distribution of

hydrocarbon products were studied and compared to ZSM-5 catalyst. The result of catalyst activity evaluation

tests shows that the modified catalyst with a 0.1 molar solution of CaCO3 and Na2 CO3 provides the highest

selectivity and efficiency compared to the hydrocarbons in boiling point range of C6+ gasoline.

Keywords: modification of ZSM-5 catalyst, structure and morphology, Methanol to Gasoline

DOI: 10.1515/ijcre-2017-0229

Received: November 26, 2017; Revised: January 14, 2018; Accepted: March 12, 2018

1 Introduction

The evidence indicates that the limited petroleum resources are not able to supply global energy demands.

Automatically generated rough PDF by ProofCheck from River Valley Technologies Ltd

The general fuel consumption is about 133 million tons per day which are being increased with a growth of

higher than 3 %. Given this consumption rate, it will reach 162 million tons per day in 2020 (Mena Subiranas

and Schaub 2007; Hagey and de Lasa 2004; Ferreira, Al-Bogami, and de Lasa 2015; Sengupta, Ghosal, and Basu

2012). Conventional methods for gasoline production typically include distillation of crude oil and processes

such as alkylation, isomerization, and catalytic cracking. However, fuel production by coal (coal to liquid) is

also attracted by some countries with coal resources. Given the critical importance and urgent need of the fuel

as well as increased demand for fuel, some alternative methods should be sought. Methanol to Gasoline (MTG)

process that is a part of general Gas to Liquid process, is a suitable alternative process which recently has been

considerably paid attention to. MTG process was used for the first time in the 1970s by petroleum research

group of Mobil Co (Aghaei and Haghighi 2014; Amereh, Haghighi, and Estifaee 2018; Estifaee et al. 2014; Ra-

hemi et al. 2014). Since the late 1970s, plenty of studies has been conducted in the process. In 1982, production

of aromatics, light olefins and gasoline through methanol was studied on ZSM-5 catalyst (Svelle et al. 2006; Tes-

sonnier et al. 2008). Inui (1984) studied the relationship between the acidic characteristic of ZSM-5 catalyst and

catalyst performance in MTG process (Zhang et al. 2014). Production of fuel and other chemical compounds

through methanol by ZSM-5 catalyst was also investigated (Bjorgen et al. 2007). Joensen et al. studied the appli-

cation of soda for ZSM-5 catalyst modification in MTG reaction (Fellah and Onal 2011). The effect of acids on the

performance of MTG process catalysts and impact of phosphoric acid on acidic sites of ZSM-5 catalyst was spec-

ified (Rownaghi and Hedlund 2011). Rownaghi et al. examined the efficiency of hydrocarbons within gasoline

boiling point range and impact of ZSM-5 catalyst crystals size on the efficiency of the products (Bi et al. 2014).

The studies conducted so far include assessment of the process and catalysts as well as their modification and

optimization of operational conditions for doing MTG reactions. Among zeolite catalysts, ZSM-5 and SAPO-

34 are suitable to conduct the process reactions and were further studied. The main mechanism recognized

Mahmoud Salimi is the corresponding author.

© 2018 Walter de Gruyter GmbH, Berlin/Boston.

Brought to you by | Umea University Library - invalid, see 15197 -

Authenticated 1

Download Date | 4/6/18 10:22 PM

Kianfar et al. DE GRUYTER

for MTG process includes equilibrium reaction of methanol dehydration to dimethyl ether after which light

olefins (e. g., ethylene and propylene) are produced by rehydrating dimethyl ether. These olefins are converted

to hydrocarbons inside the pores and then the greater hydrocarbons and such aromatics as Xylene, Toluene and

Benzene are produced (Du et al. 2014; Liu et al. 2015; Vo et al. 2012; Yan and Le Van Mao 2010; Al-Yassir and Le

Van Mao 2006; Li et al. 2007; Gregg and Sing 1982; 1967; Sing 1985; Shirazi and Jamshidi 2008; Fathi, Sohrabi,

and Falamaki 2014; Zaidi and Pant 2004; Kianfar et al. 2017). The present study employed ZSM-5 catalyst as

the base catalyst whose structure was modified for the accomplishment of MTG reactions. Performance of the

catalysts derived from the fixed-bed reactor was investigated and production of diverse hydrocarbons by them

was approved. The effect of the concentration of calcium carbonate (CaCO3 ) and sodium carbonate (Na2 CO3 )

solutions for modification of catalyst on conversion rate and efficiency of the hydrocarbons in gasoline boiling

point range was determined and compared to the conventional ZSM-5 catalyst. The modified ZSM-5 catalyst

with CaCO3 and Na2 CO3 solution leads to decrease Si/A1 ratio, namely, CaCO3 and Na2 CO3 solution cause to

remove Si from the catalyst structure. This is used due to the alkali properties of the solution which is able to

partly solve silicon catalyst structure and remove it. Moreover, with increased CaCO3 and Na2 CO3 concentra-

tion, Si/Al would be decreased in the catalyst which is a factor to increase heavier hydrocarbons production.

However, with decreased Si/Al, the specific surface of catalyst will also be decreased. The cause of specific

surface reduction following the increased concentration of CaCO3 and Na2 CO3 may be catalyst pores blockage

by deposits of CaCO3 and Na2 CO3.

2 Materials and methods

For modification of zeolite ZSM-5 catalyst, 30 ml of 0.05 and 0.1 molar solution of calcium carbonate (CaCO3 )

or sodium carbonate (Na2 CO3 ) (per 3 g of catalyst) was added to zeolite ZSM-5 catalyst and was completely

mixed for 3 h at a temperature of 70 °C. Then, the solution was separated from the catalyst by evaporation

under vacuum and the solid sample was dried in an oven. This operation was carried out once more and after

drying the catalyst, final acidification operation was also redone by ammonium nitrate solution (NH4 NO3 ).

Since some of the H+ s may have been missed while contact of catalyst to the solution of calcium carbonate

(CaCO3 ) and sodium carbonate (Na2 CO3 ), re-acidification may bring back them. Finally, calcination process

was carried for 3 h at a temperature of 550 °C. The obtained catalysts are named according to concentration of

solution of calcium carbonate CaCO3 and sodium carbonate Na2 CO3 and ion exchange in such a way that Z-0.05

is a catalyst modified by 0.05 molar solution of calcium carbonate CaCO3 and sodium carbonate Na2 CO3 and

Z-0.1 is the one modified by 0.1 molar solution of calcium carbonate CaCO3 and sodium carbonate Na2 CO3 .

Details on the reactor test characteristic methods are reported elsewhere.

Automatically generated rough PDF by ProofCheck from River Valley Technologies Ltd

2.1 Experimental setup

Efficiency and stability in a specific reaction are of the most important criteria for catalyst selection. In this

regard, MTG reaction was simulated in a fixed-bed reactor to evaluate reactive performance of the generated

catalyst. Figure 1 shows a schema of the relevant experimental system.

Figure 1: Scheme of the reactor, and testing and analysis system.

Brought to you by | Umea University Library - invalid, see 15197 -

2 Authenticated

Download Date | 4/6/18 10:22 PM

DE GRUYTER Kianfar et al.

3 Results and discussion

3.1 XRD analysis

Figure 2 indicates the spectra associated with XRD analysis for Zeolite ZSM-5. The relative crystalline mode of

this catalyst was calculated according to a reference, considering prominent peaks within angles of 22–25°.

Figure 2: XRD pattern and results for ZSM-5 and modified catalysts.

3.2 FT-IR analysis

Figure 3 shows FT-IR spectroscopy analysis for ZSM-5 sample. Generally, in FT-IR spectrum of zeolites two

type of peaks are observed. One is dedicated to internal vibrations of TO4 in which T are the elements inside

the zeolite structure (e. g. Si and Al) which are linked to oxygen. Such peaks are typically in the range of 950–

Automatically generated rough PDF by ProofCheck from River Valley Technologies Ltd

1250 cm−1 and 420–500 cm−1 which are attributed to T-O and O-T-O stretching vibrations, respectively. Other

one is the vibrations associated with tetrahedral connections. These peaks are appeared in the range of 500–

600 cm−1 and 1300–1700 cm−1 .

Figure 3: FT-IR results and analysis pattern for ZSM-5 and modified catalysts.

3.3 SEM analysis

Figure 4 shows SEM analysis results for a calcined catalyst which were photographed. As it can be seen from

micrograph, the sample crystals have a suitable dispersion and regular morphology.

Brought to you by | Umea University Library - invalid, see 15197 -

Authenticated 3

Download Date | 4/6/18 10:22 PM

Kianfar et al. DE GRUYTER

Figure 4: SEM images of ZSM-5 and modified catalysts with various percentage of CaCO3 and Na2 CO3 .

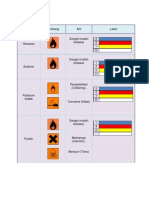

3.4 BET-XRF- NH3-TPD analysis results

Table 1 report physical and chemical characteristics of ZSM-5 using BET, XRF, NH3 -TPD analyses. Acidity of

Zeolite ZSM-5 linearly depends on concentration of aluminum at composition of the zeolite. Results of NH3 -

TPD analysis are compatible with the presence of aluminum at composition of zeolite.

Table 1: Results of surface area, Si/Al, Temperature programmed desorption, pore volume of various modified catalysts.

Catalysts SiO2/Al2O3 Si/Al BET Pore vol- NH3 capac-

surface ume(cm3/g) ity(mmol/g)

area(m2/g)

ZSM-5 30 15 300 0.379 0.8594

ZSM-5/CaCO3 (Z-0.05) 22 11 290 0.273 0.7058

ZSM-5/CaCO3 (Z-0.1) 20 10 284 0.177 0.7287

ZSM-5/Na2 CO3 (Z-0.05) 24 12 290 0.273 0.7428

ZSM-5/Na2 CO3 (Z-0.1) 22 11 292 0.281 0.7587

Automatically generated rough PDF by ProofCheck from River Valley Technologies Ltd

Given the BET analysis results, the specific surface of calcium carbonate with the increased concentration of

calcium carbonate from 0 to 0.1 % while the total volume of pores was decreased from 0.379 to 0.177 cm3/g with

increased calcium carbonate from 0 to 0.1 %. Also, specific surface of catalyst ZSM-5/Na2 CO3 with increased

sodium carbonate from 0 to 0.1 %, initially decreased concentration of 0.05 % solution of sodium carbonate

and then increased 0.1 % sodium carbonate solution. In addition, volume of pores with increased amount of

sodium carbonate from 0 to 0.1 %, initially decreased concentration of 0.05 % solution of sodium carbonate and

then increased 0.1 % sodium carbonate solution. Temperature Programmed Desorption analysis with ammonia

(NH3 -TPD) was used to specify acidity of catalyst sample. Results of these analyses are presented in Table 1.

Acidity of Zeolite ZSM-5 linearly depends on concentration of aluminum at composition of the zeolite. Results

of NH3 -TPD analysis are compatible with presence of aluminum at composition of zeolite. Given the results,

acidity distribution approaches the sites with medium acidity (peak in a temperature of 400 °C) by adding

improver CaCO3 and Na2 CO3 . Accordingly, the rate of high-acidity sites (peak in a temperature of 400 °C) and

poor-acidity ones (peak in a temperature of about 200°C) was decreased (Sing).

3.5 Evaluation of modified calcium carbonate and sodium carbonate catalyst to convert methanol to

gasoline

As shown in Table 1, modified ZSM-5 catalyst with CaCO3 and Na2 CO3 solution leads to decrease Si/A1 ratio,

namely, CaCO3 and Na2 CO3 solution causes to remove Si from the catalyst structure. This is used due to the

alkali properties of the solution which is able to partly solve silicon of catalyst structure and remove it (Fathi,

Sohrabi, and Falamaki 2014; Shirazi and Jamshidi 2008). Moreover, with increased CaCO3 and Na2 CO3 concen-

tration, Si/Al would be decreased in the catalyst which is a factor to increase heavier hydrocarbons production.

However, with decreased Si/Al, the specific surface of catalyst will also be decreased. The cause of specific sur-

Brought to you by | Umea University Library - invalid, see 15197 -

4 Authenticated

Download Date | 4/6/18 10:22 PM

DE GRUYTER Kianfar et al.

face reduction following the increased concentration of CaCO3 and Na2 CO3 may be catalyst pores blockage by

deposits of CaCO3 and Na2 CO3 . Therefore, it makes sense to use a concentration which optimises these two

acidity increase factors along with decreased specific surface in order to produce the desired product. Figure 5,

Figure 6 and Table 2 present methanol conversion rates for diverse catalysts. Table 1 and Table 2 show that de-

creased Si/Al gives rise to relatively increase methanol conversion rate. Figure 5, Figure 6 and Table 2 indicate

the efficiency of the produced hydrocarbons within C6+ gasoline boiling point range among diverse catalyst

samples. Efficiency is more frequently seen in Z-0.1 sample compared to additional catalysts. This can be at-

tributed to the higher acidity of such a catalyst which leads to boost accomplishing oligomerization reactions.

Hence, the Z-0.1 catalyst was considered and studied under more experiments. The rate of the hydrocarbons

produced by catalyst Z-0.1 within C6+ gasoline boiling point range is higher than additional hydrocarbons. As

pointed out, the reason for the increased production of heavier hydrocarbons is the increased acidity of the

catalyst that results from the decreased Si/Al which leads to increase oligomerization reactions and produc-

tion of heavy hydrocarbons. The studies show that performance of modified catalyst was enhanced with alkali

solution for BTX production compared to the initial catalyst. The authors believe that Meso pores structure in

the Z-0.1 catalyst is the main cause of such behaviour (Zaidi and Pant 2004). Accordingly, given BET analysis

results, the contribution of Meso pores was relatively increased in this sample of the catalyst. The produced

BTXs are valuable with a high octane number. In some cases, BTX is separated from the products and is used

as the feed of petrochemical plants.

Figure 5: Products distribution on the catalysts surface for MTG reactions with consideration of CaCO3 .

Automatically generated rough PDF by ProofCheck from River Valley Technologies Ltd

Figure 6: Products distribution on the catalysts surface for MTG reactions with consideration of Na2 CO3 .

Table 2: Distribution of hydrocarbons in synthesized gasoline.

Brought to you by | Umea University Library - invalid, see 15197 -

Authenticated 5

Download Date | 4/6/18 10:22 PM

Kianfar et al. DE GRUYTER

Catalysts Conversion CH4 C2 H4 C2 H6 C3 H6 C3 H8 i-C5 n-C5 C6+ -

(%) C7+ -

C8+

ZSM-5 99.5 4 % 20 % 3 % 21 % 15 % 13 % 3 % 20.5 %

ZSM-5/(0.05) CaCO3 84 3 % 17 % 1 % 35 % 2 % 8 % 3 % 15 %

ZSM-5/(0.1) CaCO3 99.65 7 % 18 % 2 % 20 % 5 % 5 % 4 % 38.65 %

ZSM-5/(0.05) Na2 CO3 79 3 % 16 % 1 % 35 % 2 % 8 % 3 % 11 %

ZSM-5/(0.1) Na2 CO3 99.8 6.90 % 17.95 % 2.70 % 19.80 % 4.93 % 4.97 % 3.95 % 38.6 %

4 Conclusion

ZSM-5 catalyst is used to carry out Methanol to Gasoline process reactions. Since the increased acidity of the

catalyst results in the increased oligomerization reactions and production of heavy hydrocarbons, the ZSM-

5 catalyst is applied with carbonate calcium and sodium carbonate solutions which provide alkali properties

to partly remove the silicones existing in catalyst structure. Results indicate that decrease of Si/Al affects the

catalyst performance and C6+ heavy hydrocarbons production was significantly increased. The results analysis

shows that Z-0.1 catalyst has a better performance to produce hydrocarbons with in C6+ gasoline boiling point

range.

NOMENCLATURE

T: temperature [°C]

id: internal diameter [mm]

FA0: molar flowrate of methanol [cc/min]

W: weight of catalyst [g]

References

Amereh, M., M. Haghighi, and P. Estifaee. 2018. “The Potential Use of HNO3- Treated Clinoptilolite in the Preparation of Pt/CeO2-

Automatically generated rough PDF by ProofCheck from River Valley Technologies Ltd

Clinoptilolite Nanostructured Catalyst Used in Toluene Abatement from Waste Gas Stream at Low Temperature.” Arabian Journal of

Chemistry 11: 81–90.

Aghaei, E., and M. Haghighi. 2014. “Enhancement of Catalytic Lifetime of Nanostructured SAPO-34 in Conversion of Biomethanol to Light

Olefins.” Microporous and Mesoporous Materials 196: 179–190.

Al-Yassir, N., and R. Le Van Mao. 2006. “Physico-Chemical Properties of Mixed Molybdenum and Cerium Oxides Supported on Silica-

Alumina and Their Use as Catalysts in the Thermal-Catalytic Cracking (TCC) of n-Hexane.” Applied Catalysis A: General 305: 130.

Bi, Y., Y. Wang, Y. Wei, Y. He, Z. Yu, Z. Liu, and L. Xu. 2014. “Toluene with Methanol Over the Modified HZSM‐5 Catalyst.” ChemCatChem 6:

713–718.

Bjorgen, M., S. Svelle, F. Joensen, J. Nerlov, S. Kolboe, F. Bonino, L. Palumbo, S. Bordiga, and U. Olsbye. 2007. “Conversion of Methanol to

Hydrocarbons over Zeolite H-ZSM-5: On the Origin of the Olefinic Species.” Journal of Catalysis 249: 195–207.

Du, X., L. J. France, V. L. Kuznetsov, T. Xiao, P. P. Edwards, H. Al Megren, and A. Bagabas. 2014. “Dry Reforming of Methane over ZrO2-

Supported Co–Mo Carbide Catalyst.” Applications Petrochem Researcher 4: 137–144.

Estifaee, P., M. Haghighi, A. A. Babaluo, N. Rahemi, and M. F. Jafari. 2014. “The Beneficial Use of Non-Thermal Plasma in Synthesis of

Ni/Al2O3eMgO Nanocatalyst Used in Hydrogen Production from Reforming of CH4/CO2 Greenhouse Gases.” Journal Power Sources 257:

364e373.

Fathi, S., M. Sohrabi, and C. Falamaki. 2014. “Improvement of HZSM-5 Performance by Alkaline Treatments: Comparative Catalytic Study in

the MTG Reactions.” Fuel 116: 529–537.

Fellah, M. F., and I. Onal. 2011. “C–H Bond Activation of Methane on M- and MO-ZSM-5 (M = Ag, Au, Cu, Rh and Ru) Clusters: A Density Func-

tional Theory Study.” Catalysis Today 171: 52–59.

Ferreira, M., S. Al-Bogami, and H. de Lasa. 2015. “Self Diffusivity of n-Dodecane and Benzothiophene in ZSM-5 Zeolites. Its Significance for a

New Catalytic Light Diesel Desulfurization Process.” International Journal of Chemical Reactor Engineering 14 (3): 737–748.

Gregg, SJ, and KSW. Sing. 1967. Adsorption, Surface Area, and Porosity. London: Academic Press.

Gregg, S. J., and K. S. W. Sing. 1982. Adsorption, Surface Area and Porosity., 2nd ed. London: Academic Press.

Hagey, L., and H. de Lasa. 2004. “Conversion of Synthesis Gas into Light Hydrocarbons. Modelling of the Catalytic Reaction Network.” Inter-

national Journal of Chemical Reactor Engineering 2 (1): Article A9. DOI: 10.2202/1542-6580.1103.

Brought to you by | Umea University Library - invalid, see 15197 -

6 Authenticated

Download Date | 4/6/18 10:22 PM

DE GRUYTER Kianfar et al.

Kianfar, E, M Salimi, V Pirouzfar, and B. Koohestani. 2017. “Synthesis of Modified Catalyst and Stabilization of CuO/NH4-ZSM-5 for Conver-

sion of Methanol to Gasoline.” International Journal Applications Ceram Technological 1–8. doi:10.1111/ijac.12830.

Li, X., B. Shen, Q. Guo, and J. Gao. 2007. “Effects of Large Pore Zeolite Additions in the Catalytic Pyrolysis Catalyst on the Light Olefins Pro-

duction.” Catalysis Today 125: 270.

Liu, Bonan, Liam France, Chen Wu, Zheng Jiang, Vladimir L. Kuznetsov, Hamid A. Al-Megren, Mohammed Al-Kinany, Saud A. Aldrees, Tian-

cun Xiaoa, and Peter P. Edwards. 2015. “Methanol-to-Hydrocarbons Conversion over MoO3/H-ZSM-5 Catalysts Prepared via Lower Tem-

perature Calcination: Route to Tailor the Distribution and Evolution of Promoter Mo Species, and their Corresponding Catalytic Proper-

ties.” Journal of Chemical Sciences 6: 5152.

Mena Subiranas, A., and G. Schaub. 2007. “Combining Fischer-Tropsch (FT) and Hydrocarbon Reactions under FT Reaction Conditions –

Catalyst and Reactor Studies with Co or Fe and Pt/ZSM-5.” International Journal of Chemical Reactor Engineering 5 (1): Article A78. DOI:

10.2202/1542-6580.1522.

Rahemi, N., M. Haghighi, A. A. Babaluo, and M. Fallah Jafari. 2014. “Syngas Production via CO2 Reforming of Methane over Plasma Assisted

Synthesized Ni-Co/Al2O3eZrO2 Nanocatalysts with Different Ni-Loadings.” International Journal Energy Researcher 38: 765–779.

Rownaghi, Ali A., and Jonas Hedlund. 2011. “Methanol to Gasoline-Range Hydrocarbons: Influence of Nanocrystal Size and Mesoporosity on

Catalytic Performance and Product Distribution of ZSM-5.” Industrial Engineering Chemical Researcher 50 (21): 11872–11878.

Sengupta, S., D. Ghosal, J. Basu, et al. 2012 . “Chemical Modification of HZSM-5 for Selective Methylation.” International Journal of Chemical

Reactor Engineering 10 (1): Article A22 . DOI: 10.1515/1542-6580.2607.

Shirazi, L., E. Jamshidi, et al. 2008. “The Effect of Si/Al Ratio of ZSM-5 Zeolite on Its Morphology, Acidity and Crystal Size.” Cryst Researcher

Technological 43 (12): 1300–1306.

Sing, K. S. W. 1985. “Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and

Porosity (Recommendations 1984).” Pure and Applied Chemistry 57 (4): 603–619. DOI: 10.1351/pac198557040603.

Svelle, S., F. Joensen, J. Nerlov, U. Olsbye, K. P. Lillerud, S. Kolboe, and M. Bjorgen. 2006. “Conversion of Methanol into Hydrocarbons over

Zeolite H-ZSM-5: Ethene Formation Is Mechanistically Separated from the Formation of Higher Alkenes.” Journal of the American Chemi-

cal Society 128: 14770–14771.

Tessonnier, J. P., B. Louis, S. Rigolet, M. J. Ledoux, and C. Pham-Huu. 2008. “Methane Dehydro-Aromatization on Mo/ZSM-5: About the Hid-

den Role of Brønsted Acid Sites.” Applications Catalysis A 336: 79–88.

Vo, D.-V. N., C. G. Cooper, T.-H. Nguyen, A. A. Adesina, and D. B. Bukur. 2012. “Evaluation of alumina-supported Mo carbide produced via

propane carburization for the Fischer–Tropsch synthesis.” Fuel 93: 105–116.

Yan, H. T., and R. Le Van Mao. 2010. “Hybrid Catalysts Used in the Catalytic Steam Cracking Process (CSC): Influence of the Pore Character-

istics and the Surface Acidity Properties of the ZSM-5Zeolite-Based Component on the Overall Catalytic Performance.” Applied Catalysis

A:General 375: 63.

Zaidi, H. A., and K. K. Pant. 2004. “Catalytic Conversion of Methanol to Gasoline Range Hydrocarbons.” Catalysis Today 96: 155–160.

Zhang, H., S. Shao, R. Xiao, D. Shen, and J. Zeng. 2014. “Characterization of Coke Deposition in the Catalytic Fast Pyrolysis of Biomass

Derivates.” Energy Fuels 28: 52–57.

Automatically generated rough PDF by ProofCheck from River Valley Technologies Ltd

Brought to you by | Umea University Library - invalid, see 15197 -

Authenticated 7

Download Date | 4/6/18 10:22 PM

View publication stats

You might also like

- Lurgi Mega Methanol by Combined ReformingDocument25 pagesLurgi Mega Methanol by Combined ReformingKeena Rahim100% (1)

- Final Internship Report and Project Paper: DeclarationDocument118 pagesFinal Internship Report and Project Paper: DeclarationAtefrachew SeyfuNo ratings yet

- Density of MeOH - Chemical Engineers Handbook, Perry Vol 1Document1 pageDensity of MeOH - Chemical Engineers Handbook, Perry Vol 1Jia Yuan ChngNo ratings yet

- Production of Propylene Oxide BY Hppo TechnologyDocument33 pagesProduction of Propylene Oxide BY Hppo Technologyramya tejaswiniNo ratings yet

- Experimental Paper15 AugDocument16 pagesExperimental Paper15 AugAhmad AliNo ratings yet

- Catalyst Optimization For Enhanced Propylene Formation in - 2015 - Comptes RenduDocument6 pagesCatalyst Optimization For Enhanced Propylene Formation in - 2015 - Comptes RendupaweenNo ratings yet

- Wasiur-Energy NexusDocument11 pagesWasiur-Energy Nexusazmiwasi_867013700No ratings yet

- 2008 - Catalysis Communication - Enhanced Octane Boosting Reactions of Light Naphtha On Mesoporous ZSM-5Document4 pages2008 - Catalysis Communication - Enhanced Octane Boosting Reactions of Light Naphtha On Mesoporous ZSM-5Sandeep Kumar SaxenaNo ratings yet

- Journal of CO2 Utilization: Cong Shi, Sha Wang, Xiang Ge, Shengxiang Deng, Bin Chen, Jun ShenDocument19 pagesJournal of CO2 Utilization: Cong Shi, Sha Wang, Xiang Ge, Shengxiang Deng, Bin Chen, Jun Shenfarah al-sudaniNo ratings yet

- Anekwe (2024) Anomali Impregnasi Zn10%Document11 pagesAnekwe (2024) Anomali Impregnasi Zn10%Saffanah YumnaNo ratings yet

- Dry ReformingDocument13 pagesDry ReformingDana MateiNo ratings yet

- Molecular Catalysis: Shivali Arora, Vijayalakshmi Gosu, Verraboina SubbaramaiahDocument14 pagesMolecular Catalysis: Shivali Arora, Vijayalakshmi Gosu, Verraboina SubbaramaiahSubba RamaiahNo ratings yet

- Fei Wang, Junming Xu, Jianchun Jiang, Peng Liu, Fanglin Li, Jun Ye, Minghao ZhouDocument9 pagesFei Wang, Junming Xu, Jianchun Jiang, Peng Liu, Fanglin Li, Jun Ye, Minghao ZhouNoviNo ratings yet

- From Synthesis Gas Production To Methanol Synthesi 2015 Journal of Natural GDocument14 pagesFrom Synthesis Gas Production To Methanol Synthesi 2015 Journal of Natural GRafael DamarNo ratings yet

- JGT Volume 6 Issue 2 Pages 4-19Document17 pagesJGT Volume 6 Issue 2 Pages 4-19조윤성No ratings yet

- S2 - (2016) Skala Et Al. Heterogeneous Kinetics of Vegtable Oil Transesterification at High TemperatureDocument11 pagesS2 - (2016) Skala Et Al. Heterogeneous Kinetics of Vegtable Oil Transesterification at High TemperatureJulian DavidNo ratings yet

- Kinetic Study of Autothermal Reforming of Glycerol in A Dual Layer Monolith CatalystDocument8 pagesKinetic Study of Autothermal Reforming of Glycerol in A Dual Layer Monolith CatalystElias ChiquiarNo ratings yet

- Journal of Environmental Chemical EngineeringDocument9 pagesJournal of Environmental Chemical Engineeringherdi sutanto adigunaNo ratings yet

- Synthesis and Characterization of A Graft-Modified Copolymer For EnhancedDocument10 pagesSynthesis and Characterization of A Graft-Modified Copolymer For Enhancedislam mohamedNo ratings yet

- Abbas. 2010. Hydrogen Production by Methane PDFDocument31 pagesAbbas. 2010. Hydrogen Production by Methane PDFHafiz Rama Devara100% (1)

- Arora 2021Document13 pagesArora 2021Subba RamaiahNo ratings yet

- Pyrolysis of Rice Husk, Coconut Shell, and Cladophora Glomerata Algae and Application of The Produced BiocharsDocument15 pagesPyrolysis of Rice Husk, Coconut Shell, and Cladophora Glomerata Algae and Application of The Produced BiocharsChristian DennisNo ratings yet

- A Review On The Catalytic Pyrolysis of Biomass For The Bio-Oil Production WithDocument15 pagesA Review On The Catalytic Pyrolysis of Biomass For The Bio-Oil Production WithDaniiela Melo RomeroNo ratings yet

- 10 1016@j Ijhydene 2020 05 201Document16 pages10 1016@j Ijhydene 2020 05 201kresna dwiNo ratings yet

- Synthesis, Characterization, and Application of Zno/Zsm-5 As Catalyst in The Cracking Process of Palm Methyl EstersDocument8 pagesSynthesis, Characterization, and Application of Zno/Zsm-5 As Catalyst in The Cracking Process of Palm Methyl EstersMiskine FilsNo ratings yet

- CatalystsDocument13 pagesCatalystsAlzahra AliNo ratings yet

- 2012 Uniform Mesoporous ZSM-5 Single Crystals Catalyst With High Resistance ToDocument8 pages2012 Uniform Mesoporous ZSM-5 Single Crystals Catalyst With High Resistance ToAmeen ShahidNo ratings yet

- Design and Comprehensive Optimization of C3MR Liquefaction Natural Gas Cycle by Considering Operational ConstraintsDocument13 pagesDesign and Comprehensive Optimization of C3MR Liquefaction Natural Gas Cycle by Considering Operational ConstraintsRishyavandhan VNo ratings yet

- Fenrg 07 00081Document10 pagesFenrg 07 00081SHUBHAMNo ratings yet

- 1 s2.0 S1876107012000107 MainDocument7 pages1 s2.0 S1876107012000107 MainBUREAU VERITAS BLOQUESNo ratings yet

- Mechanistic Study of Nanoparticles-Assisted XanthaDocument7 pagesMechanistic Study of Nanoparticles-Assisted XanthaAbooNo ratings yet

- High-Purity Hydrogen Production With in Situ CO2 Capture Based On Biomass GassificationDocument7 pagesHigh-Purity Hydrogen Production With in Situ CO2 Capture Based On Biomass GassificationNaveed RehmanNo ratings yet

- Optimal Design and Operation of An Industrial FluiDocument19 pagesOptimal Design and Operation of An Industrial Fluilalit meenaNo ratings yet

- Review On Effects of Gasifying Agents, TemperatureDocument10 pagesReview On Effects of Gasifying Agents, Temperature63011273No ratings yet

- Gong 2017Document26 pagesGong 2017EGI RISKIA MAULANANo ratings yet

- Ali Pour 2014Document6 pagesAli Pour 2014Marcus NguyễnNo ratings yet

- Direct Dimethyl Ether Synthesis From Syngas On Copper-Zeolite HybridDocument12 pagesDirect Dimethyl Ether Synthesis From Syngas On Copper-Zeolite HybridJulian De BedoutNo ratings yet

- Combined Dry Reforming and Partial Oxidation of Methane To Synthesis Gas On Noble Metal CatalystsDocument10 pagesCombined Dry Reforming and Partial Oxidation of Methane To Synthesis Gas On Noble Metal CatalystsLuiz Yamauchi JuniorNo ratings yet

- Biomass To BiofuelDocument9 pagesBiomass To BiofuelPallab RoyNo ratings yet

- 2021 - Odriozola - Bimetallic Ni-Ru and Ni-Re CatalystsDocument10 pages2021 - Odriozola - Bimetallic Ni-Ru and Ni-Re CatalystsArmonistasNo ratings yet

- Effect of Weak Base Modification On ZSM 5 Catalyst For Methanol To AromaticsDocument7 pagesEffect of Weak Base Modification On ZSM 5 Catalyst For Methanol To AromaticsArash AbbasiNo ratings yet

- 3.hydrogen Rich Products From Waste Plastic Over NiZSM-5 Catalysts Combined With DolomiteDocument9 pages3.hydrogen Rich Products From Waste Plastic Over NiZSM-5 Catalysts Combined With Dolomiteshamirah98No ratings yet

- Catalysts 11 01031 v2Document19 pagesCatalysts 11 01031 v2Edinilson Ramos Camelo RamosNo ratings yet

- Accepted Manuscript: Process Safety and Environment ProtectionDocument36 pagesAccepted Manuscript: Process Safety and Environment ProtectionMARTIN PINEDA TAVERANo ratings yet

- 1 s2.0 S0016236122033749 MainDocument15 pages1 s2.0 S0016236122033749 MaincemilNo ratings yet

- A Method For Characterization of BitumenDocument9 pagesA Method For Characterization of Bitumenzakiyah irfin100% (1)

- Biogas Fro SOfc APPLICATIONDocument7 pagesBiogas Fro SOfc APPLICATIONVikram UdayNo ratings yet

- Exposicion de ElectroquimicaDocument10 pagesExposicion de ElectroquimicaLIZETH PAOLA INSUASTY DELGADONo ratings yet

- Oil Shale CharacterizationDocument21 pagesOil Shale CharacterizationADEOLANo ratings yet

- Performance Analysis of DI Diesel Engine Fuelled With Diesel Along With Nano AdditivesDocument4 pagesPerformance Analysis of DI Diesel Engine Fuelled With Diesel Along With Nano Additivessatheeshsep24No ratings yet

- Characterization of Light Diesel Fraction Obtained From Upgraded HeavyDocument4 pagesCharacterization of Light Diesel Fraction Obtained From Upgraded HeavygiannsNo ratings yet

- 122Document10 pages122Bayangan HatiNo ratings yet

- Extraction of Transportation Grade Fuels From Waste LDPE Packaging Polymers Using Catalytic PyrolysisDocument8 pagesExtraction of Transportation Grade Fuels From Waste LDPE Packaging Polymers Using Catalytic PyrolysisPICHE MME SecretaryNo ratings yet

- 7 цитирований Impregnation vs. sol-gel and sol-gel-plasma dispersion of nickel nanoparticles over Al2O3 employed in combined dry reforming and partial oxidation of greenhouse gases to syngasDocument16 pages7 цитирований Impregnation vs. sol-gel and sol-gel-plasma dispersion of nickel nanoparticles over Al2O3 employed in combined dry reforming and partial oxidation of greenhouse gases to syngasПитон КиришевскийNo ratings yet

- Dynamic Optimization Strategies of A Heterogeneous Reactor For CO Conversion To MethanolDocument7 pagesDynamic Optimization Strategies of A Heterogeneous Reactor For CO Conversion To MethanolSarang GohNo ratings yet

- Catalytic Cracking of Palm Oil To Gasoline Over PRDocument15 pagesCatalytic Cracking of Palm Oil To Gasoline Over PRsyarif hidayatNo ratings yet

- Influence of Nanoparticles On Spray Performance of Alternative Jet FuelsDocument8 pagesInfluence of Nanoparticles On Spray Performance of Alternative Jet FuelsaruntnjNo ratings yet

- 10.1016@S1359 02860200108 0Document11 pages10.1016@S1359 02860200108 0Meita PratiwiNo ratings yet

- Effect of Modification ZSM-5 Catalyst in Upgrading Quality of Organic Liquid Product Derived From Catalytic Cracking of Indonesian Nyamplung Oil (Calophyllum Inophyllum)Document7 pagesEffect of Modification ZSM-5 Catalyst in Upgrading Quality of Organic Liquid Product Derived From Catalytic Cracking of Indonesian Nyamplung Oil (Calophyllum Inophyllum)Yusran KheryNo ratings yet

- The Performance and Exhaust Emissions Investigation of A Diesel Engine Using - Al O Nanoparticle Additives To BiodieselDocument10 pagesThe Performance and Exhaust Emissions Investigation of A Diesel Engine Using - Al O Nanoparticle Additives To BiodieselT Hari PrasadNo ratings yet

- Performance Investigation of Magnesiumechloride Hybrid Thermochemical Cycle For Hydrogen ProductionDocument10 pagesPerformance Investigation of Magnesiumechloride Hybrid Thermochemical Cycle For Hydrogen ProductionAdrián Lume HuayllaniNo ratings yet

- HDO-aducto-Catal Today 2016Document8 pagesHDO-aducto-Catal Today 2016cligcodiNo ratings yet

- ABSTRACTS 2021 WorkshopDocument8 pagesABSTRACTS 2021 WorkshopAbdullah AitaniNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Single Science End of Topic Assessment With MarkschemeDocument18 pagesSingle Science End of Topic Assessment With Markschemeerin mooreNo ratings yet

- What Is A Direct Methanol Fuel CellDocument25 pagesWhat Is A Direct Methanol Fuel Cellaisyahzafira26No ratings yet

- Calcination of Nickel-Alumina CatalystsDocument4 pagesCalcination of Nickel-Alumina CatalystsAnonymous 4PuFzAR100% (1)

- Biodiesel: Crown Iron Works CompanyDocument4 pagesBiodiesel: Crown Iron Works CompanyEthical ConspirestNo ratings yet

- Problemas Abiertos de FoglerDocument24 pagesProblemas Abiertos de FoglerHarold Fernando Guavita ReyesNo ratings yet

- Chm4701 Catalysis Methanol SynthesisDocument27 pagesChm4701 Catalysis Methanol SynthesisErwinnie EllyiaNo ratings yet

- Zuo 2016Document10 pagesZuo 2016Phạm NgânNo ratings yet

- Q1. (A) Hydrogen Used in The Haber Process Is Produced in The Following DynamicDocument84 pagesQ1. (A) Hydrogen Used in The Haber Process Is Produced in The Following Dynamicquoc hoangNo ratings yet

- Novel Process Technologies For Conversion of Carbon Dioxide From Industrial Flue Gas Streams Into MethanolDocument12 pagesNovel Process Technologies For Conversion of Carbon Dioxide From Industrial Flue Gas Streams Into Methanoltuan.huu2007No ratings yet

- Methanol Production Using Carbon Capture Technology: An OverviewDocument6 pagesMethanol Production Using Carbon Capture Technology: An OverviewmohdaizadahmadNo ratings yet

- Hayes Manufacturing AminesDocument9 pagesHayes Manufacturing AminesNNo ratings yet

- Selective Oxidation of Methylal As A New Catalytic Route To Concentrated FormaldehydeDocument5 pagesSelective Oxidation of Methylal As A New Catalytic Route To Concentrated FormaldehydeAnonymous vWSYmPNo ratings yet

- K3Document5 pagesK3Dani SetiawanNo ratings yet

- Methanol Project PDFDocument50 pagesMethanol Project PDFPaola Nair M ChNo ratings yet

- yokAcikBilim 10185403Document71 pagesyokAcikBilim 10185403gozdebstnciNo ratings yet

- Production of Biodiesel From Jatropha Curcas A ReviewDocument5 pagesProduction of Biodiesel From Jatropha Curcas A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 28350: Design Project For The Production of Dimethyl Carbonate From Ethylene OxideDocument76 pages28350: Design Project For The Production of Dimethyl Carbonate From Ethylene OxideRUANGLADDA LIMPONGSAWATNo ratings yet

- Xii OrganicDocument25 pagesXii OrganicArindam GoswamiNo ratings yet

- Chemistry Lab Report: Anchita AuroraDocument9 pagesChemistry Lab Report: Anchita AuroraAnchita AuroraNo ratings yet

- CHMT5011 Oil and Gas Engineering Design 2017 Lecture NotesDocument116 pagesCHMT5011 Oil and Gas Engineering Design 2017 Lecture NotesAbdulsalam JibrilNo ratings yet

- Quantitative ChemistryDocument32 pagesQuantitative ChemistryElena EngiNo ratings yet

- (PDF) Octane Rating of Gasoline and Octane Booster AdditivesDocument17 pages(PDF) Octane Rating of Gasoline and Octane Booster Additivesrabiya saeedNo ratings yet

- MSDS For MethanolDocument2 pagesMSDS For Methanolkagisokhoza000No ratings yet

- Journal of CO2 Utilization: Changsoo Kim, Chun-Jae Yoo, Hyung-Suk Oh, Byoung Koun Min, Ung LeeDocument22 pagesJournal of CO2 Utilization: Changsoo Kim, Chun-Jae Yoo, Hyung-Suk Oh, Byoung Koun Min, Ung Leeayemyattheint kyawNo ratings yet

- Perfume and Aromatic Raw Materials by INCIDocument412 pagesPerfume and Aromatic Raw Materials by INCIEkin OrhanNo ratings yet

- Previous HSE Questions From The Chapter "Alcohols, Phenols and Ethers"Document3 pagesPrevious HSE Questions From The Chapter "Alcohols, Phenols and Ethers"alan ChackoNo ratings yet