Professional Documents

Culture Documents

Result of Inspection: Conclusion

Result of Inspection: Conclusion

Uploaded by

Bayu Aringga putraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Result of Inspection: Conclusion

Result of Inspection: Conclusion

Uploaded by

Bayu Aringga putraCopyright:

Available Formats

RESULT OF INSPECTION

Customer / User PT Elnusa Tbk Report Number LDS-JKT-0370-ELN-3

P.O Number / Project No. - / LDS-JKT-0370-ELN Date of Inspection January 29, 2022

Location of Inspection PT Elnusa Yard Cakung Next of Inspection July 29, 2022

Jakarta - Indonesia Other / Division HWU EHR#08

EQUIPMENT DETAILS

Description Skid BOP 4-1/16" Date of last examination :

Serial Number / Aset No. SKID-20 / 100000032838 05-Aug-19

Dimension 1140 (L) x 740 (W) x 1440 (H) mm Tested by of last exam. : Type of last examination :

Manufacture N/A Visual (V)

Date of Mnf N/A PT SES Visual & NDT (VN)

Colour Code Solid Blue Visual, NDT & Loadtest (T)

Tare Mass - Kg NOTE (If any comments) :

Payload - Kg

Max. Gross Mass 1500 Kg

Load Test - Kg

LIFTING SET DETAILS

Wire rope sling Shackle

Four Legged Wire Rope Slings Serial No : 14/5207 Serial No. Manufacture

Bow Anchor Shackle Bolt and

Thimble eyes type, with ferrule Dimensional : Ø 18 x (L) 1520 mm - FJ21F 0741 - Van Beest

Nut Type With Safety Pin

secure each end sling c/w WLL : 8.9 Tons at 0 - 45º - FJ21F 0738 - Van Beest

Master Link Assembly at Manufacture : WAL Size : 7/8 Inch - FJ21F 0696 - Van Beest

Upper End Date of Mnf. : N/A WLL : 6.50 Tons - FJ21F 2172 - Van Beest

INSPECTION SUMMARY

Inspection Type Document Review Proof Load Test

Visual Inspection DropTest

Dimensional check Deformation Record

NDT (Non Destructive Test) Color code / Stamping Name Plate

Magnetic Particle Test Marking Information

Dye Penterant Test Other

Applicable Ref. Code DNV 2.7-1 BS EN 13414-1 & BS EN 13414-2

BS EN 12079 BS EN 13889

BS 7072 Customer Requirement

Internal Procedure MPI-LDS-02 Rev. 01 LPT-LDS-06 Rev. 01

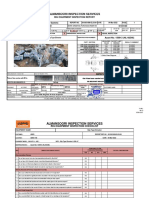

PICTURE OF EQUIPMENT

INSPECTION RESULTS

The unit should be periodically examined and tested at interval not exceeding 6 (six) month, but more frequent interval is needed with the objectives of

enviromental condition, result of previous examination, length of service time and statutory requirements.

No apparent discountinuities were detected through Magnetic Particle Inspection in welds of the critical areas of lifting points.

There is no apparent discountinuities were detected along critical area of lifting point during Magnetic Particle Inspection after Drop Test

Conclusion :

Based on document evaluation and field inspection PT LD Servis concluded that the lifting equipment can be used according to codes and standards and we

recommend the lifting equipment to be used for operations with safe workloads and Max Gross Mass. as stated above.

Name of person inspect and Client's Representative

Reviewed By

making this report Approved

Rahmat Febriansyah Khoirul Mashuda

ASNT NDT Lv. II QA/QC Representative PT Elnusa Tbk

PT LD SERVIS - MT Haryono Street Gg. PLN RT 38 No 15 - Balikpapan, East Kalimantan.

Telp.No : +62542 – 7204212 & +6542 - 878709 & +62812-5558-245

Email: marketing@ldservis.com website : www.ldservis.com

Document code: LD-F-OPR-L-04.01 Revision: 03 Effective date: 10 Januari 2022

VISUAL & DIMENSIONAL REPORT

Customer / User PT Elnusa Tbk Report Number LDS-JKT-0370-ELN-3

P.O Number / Project No. - / LDS-JKT-0370-ELN Date of Inspection January 29, 2022

Location of Inspection PT Elnusa Yard Cakung Next Of Inspection July 29, 2022

Jakarta - Indonesia Other / Division HWU EHR#08

EQUIPMENT DETAILS

Description Skid BOP 4-1/16" Manufacture N/A

Serial Number SKID-20 / 100000032838 Date of Manufacture N/A

Dimension 1140 (L) x 740 (W) x 1440 (L) mm Colour Code Solid Blue

GENERAL CONDITION

Essntial and Non Redundanct Availabelity Corrosion Deformation Crack Result Remarks

Top & bottom side rails Yes No Yes No Yes No Yes No Accepted

Top & bottom end rails Yes No Yes No Yes No Yes No Accepted

Primary Structures

Corner post Yes No Yes No Yes No Yes No Accepted

Pad eye Yes No Yes No Yes No Yes No Accepted

Forklift Pocket Yes No Yes No Yes No Yes No Accepted

Non Essential

Floor Plate Yes No Yes No Yes No Yes No Accepted

Coverage Area

Deflector plate Yes No Yes No Yes No Yes No - N/A

Stacking fitting Yes No Yes No Yes No Yes No - N/A

End plate Yes No Yes No Yes No Yes No - N/A

Door, wall & roof panel Yes No Yes No Yes No Yes No - N/A

Secondary Structure

Panel stiffeners Yes No Yes No Yes No Yes No - N/A

Corrugations Yes No Yes No Yes No Yes No - N/A

Tank protection Yes No Yes No Yes No Yes No - N/A

Internal securing point Yes No Yes No Yes No Yes No - N/A

Draining hole Yes No Yes No Yes No Yes No - N/A

Door Closure Yes No Yes No Yes No Yes No - N/A

cover on skid Yes No Yes No Yes No Yes No - N/A

INSPECTION SUMMARY

PAD EYE-1 PAD EYE-1 PAD EYE-1 PAD EYE-1

PAD EYES DIMENSIONS REMARK

( mm ) ( mm ) ( mm ) ( mm )

Hole Diameter ( A ) 30 30 30 30

Thickness at Pin Hole ( B ) 20 20 20 20

Thickness Check Plate (Total Thickness) ( C ) 23 23 23 23

Distance from Hole to top Pad eye ( D ) 37 37 37 37

Height ( E ) 110 110 110 110

Length Plate Pad eyes ( F ) 176 176 176 176

INSPECTION RESULTS

The dimensional examination (s) have been satisfactorily completed in accordance with standard reference used and customer requirement, Dimensional check

were done based on above reference standard

Conclusion :

Based on document evaluation and field inspection PT LD Servis concluded that the lifting equipment can be used according to codes and standards and we

recommend the lifting equipment to be used for operations with safe workloads and Max Gross Mass. as stated above.

Name of person inspect and Client's Representative

Reviewed By

making this report Approved

Rahmat Febriansyah Khoirul Mashuda

ASNT NDT Lv. II QA/QC Representative PT Elnusa Tbk

PT LD SERVIS - MT Haryono Street Gg. PLN RT 38 No 15 - Balikpapan, East Kalimantan.

Telp.No : +62542 – 7204212 & +6542 - 878709 & +62812-5558-245

Email: marketing@ldservis.com website : www.ldservis.com

Document code: LD-F-OPR-L-04.02 Revision: 03 Effective date: 10 Januari 2022

WIRE ROPE SLING INSPECTION REPORT

Customer / User PT Elnusa Tbk Report Number LDS-JKT-0370-ELN-3

P.O Number / Project No. - / LDS-JKT-0370-ELN Date of Inspection January 29, 2022

Location of Inspection PT Elnusa Yard Cakung Next Of Inspection July 29, 2022

Jakarta - Indonesia Other / Division HWU EHR#08

EQUIPMENT DETAILS

Description Type of Inspection :

Four Legged Wire Rope Slings Thimble eyes type, with ferrule

Visual Inspection NDT NDT (Non Destructive Test)

secure each end sling c/w Master Link Assembly at Upper End

Function Test Magnetic Particle Test

Serial Number 14/5207 Dimensional check Dye Penterant Test

Manufacture WAL Last of examination

Date of Manufacture N/A • Date : August 5, 2019

Work. Load Limit (WLL) 8.9 Tons @ 0 - 45º • Tested by : PT SES

Colour Code Solid Blue • Type examination :

Internal Procedure LDS-LT-20 LDS-LT-07 Visual NDT NDT (Non Destructive Test)

Ref. Code BS EN 13414 ANSI B30.9 Dimensional check Magnetic Particle Test

BS EN 1677 ANSI B30.20 Function Test Dye Penterant Test

GENERAL CONDITION

WIRE ROPE SLINGS MASTER LINK AND SUB. LINKS

Broken wire >1 wire Yes No Reduction of rope diameter > 10% Yes No Missing / Illegible Identification Yes No Pitting

External wear Yes No Basket or lantern deformation Yes No Exessive Wear Yes No Yes No

Decrease elasticity Yes No Wire protrusion Yes No Nick Yes No Weld Spater

Fracture of strand Yes No Local increase in rope diameter Yes No Gouges Yes No Yes No

Defect

Defect

Flattened protion Yes No Core of strand protrusion Yes No Stretched Link or Component Yes No 10% Reduction dim.

Waviness Yes No distorsion Yes No Bend Yes No Yes No

Kink Yes No Corrosion Yes No Twisted Yes No

Damage Yes No Severe Rust Yes No Deformation Yes No

Bend Yes No Other : Yes No Heat Damage Yes No

INSPECTION SUMMARY

Dimension

Evaluation

Diameter Length Width

Wire Rope Data REMARK

(A) (B) (C)

Accepted Rejected

mm mm mm

Wire Rope 18 1520 N/A √ -

Master Link 27 271 146 √ -

Ordinary Link 22 183 95 √ -

INSPECTION RESULTS

The dimensional examination (s) have been satisfactorily completed in accordance with standard reference used and customer requirement, Dimensional check were done based on

above reference standard

Conclusion :

Based on document evaluation and field inspection PT LD Servis concluded that the lifting equipment can be used according to codes and standards and we recommend the lifting

equipment to be used for operations with working load limit as stated above.

Name of person inspect and making

Reviewed By Client's Representative Approved

this report

Rahmat Febriansyah Khoirul Mashuda

ASNT NDT Lv. II QA/QC Representative PT Elnusa Tbk

PT LD SERVIS - MT Haryono Street Gg. PLN RT 38 No 15 - Balikpapan, East Kalimantan.

Telp.No : +62542 – 7204212 & +6542 - 878709 & +62812-5558-245

Email: marketing@ldservis.com website : www.ldservis.com

Document code: LD-F-OPR-L-04.03 Revision: 03 Effective date: 10 Januari 2022

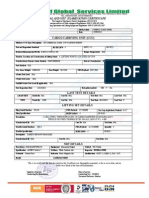

SHACKLE INSPECTION REPORT

Customer / User PT Elnusa Tbk Report Number LDS-JKT-0370-ELN-3

P.O Number / Project No. - / LDS-JKT-0370-ELN Date of Inspection January 29, 2022

Location of Inspection PT Elnusa Yard Cakung Next Of Inspection July 29, 2022

Jakarta - Indonesia Other / Division HWU EHR#08

EQUIPMENT DETAILS

Description Bow Anchor Shackle Bolt and Nut Type With Safety Pin Ref. Code : BS EN 13889 ANSI B30.26

Serial Number See Table BS 3551 ANSI B30.20

Manufacture Crosby Vanbeest Gunnebo Internal Procedure : LDS-LT-02

Other Type of Inspection :

Size 7/8 Inch Visual Inspection NDT NDT (Non Destructive Test)

Work. Load Limit (WLL) 6.5 Tons Function Test Magnetic Particle Test

Type Bolt & Nut Anchor Screw Pin Dimensional check Dye Penterant Test

Model G-2130 G-4163 855 Colour Code : Solid Blue

GENERAL CONDITION

Missing / Illegible Identification Exessive Wear Weld Spater Last of examination

Yes No Yes No Yes No Date : August 5, 2019

Stretched Component Twisted Pitting Tested by : PT SES

Yes No Yes No Yes No Type examination :

Defect

10% Reduction dimesional Nick Other Visual NDT NDT (Non Destructive Test)

Yes No Yes No Dimensional check Magnetic Particle Test

Exessive Wear Gouges Function Test Dye Penterant Test

Yes No Yes No NOTE (If any comments) :

Heat Damage Bend

Yes No Yes No

INSPECTION SUMMARY

Shackle Dimension Evaluation

Serial Number Width Inside (D) Length Inside Remarks

Ø Bow (A) mm Ø Pin (B) mm Ø Eye (C) mm Accepted Rejected

mm (E) mm

FJ21F 0741 22 25 52 36 83 √ - -

FJ21F 0738 22 25 52 36 83 √ - -

FJ21F 0696 22 25 52 36 83 √ - -

FJ21F 2172 22 25 52 36 83 √ - -

INSPECTION RESULTS

The dimensional examination (s) have been satisfactorily completed in accordance with standard reference used and customer requirement, Dimensional check were done

based on above reference standard

Conclusion :

Based on document evaluation and field inspection PT LD Servis concluded that the lifting equipment can be used according to codes and standards and we recommend the

lifting equipment to be used for operations with working load limit as stated above.

Name of person inspect and making

Reviewed By Client's Representative Approved

this report

Rahmat Febriansyah Khoirul Mashuda

ASNT NDT Lv. II QA/QC Representative PT Elnusa Tbk

PT LD SERVIS - MT Haryono Street Gg. PLN RT 38 No 15 - Balikpapan, East Kalimantan.

Telp.No : +62542 – 7204212 & +6542 - 878709 & +62812-5558-245

Email: marketing@ldservis.com Website : www.ldservis.com

Document code: LD-F-OPR-L-04.04 Revision: 03 Effective date: 10 Januari 2022

MAGNETIC PARTICLE INSPECTION REPORT

Customer / User PT Elnusa Tbk Report Number LDS-JKT-0370-ELN-3

P.O Number / Project No. - Date of Inspection January 29, 2022

Location of Inspection PT Elnusa Yard Cakung Next Date Inspection July 29, 2022

Jakarta - Indonesia Other / Division HWU EHR#08

GENERAL DATA

Description Skid BOP 4-1/16" Date of last examination :

Serial Number SKID-20 / 1000000328 June 19, 2020

Dimension ( L x W x H ) 1140 x 740 x 1440 mm Tested by of last exam. : Type of last examination :

Manufacture N/A Visual (V)

Date of Manufacture N/A PT SES Visual & NDT (VN)

Colour Code Solid Blue Visual, NDT & Loadtest (T)

EQUIPMENT USED

Magnetic Equip. Used Yoke Other Particle Visible Fluorescent

Current Type AC DC Permanent Wet Dry

Light Intensity 1076 Lux Particle application Spray Other

Lifting Force 40 Lb / 18.2 Kg 10 Lb / 4.5 Kg Particle Brand's / Type : White Contrast

Light Source Sun Light Magnaflux / WCP-2 Oikosh / M-47

Serial Number 1112 2876 3278 Particle

11200 15084 Magnaflux / 7HF Oikosh / I-72

Temperature Ambient Pole Spacing 6 Inch

Verification Cal. Block CB-LD-40LB CB-LD-10LB Other -

INSPECTION SUMMARY

Examination Method Continuous Field strength check Minimum twice in each area, right angle each other

Surface Prep. / cleaning Wire Brush As machined As ground Solvent Wipe

Stage of Examination As welded After Heat treated Before Load Test After Load Test

Scope of Examination Base Metal Edge Prep Back Chipping

Weld Area Weld Repair Others

Acceptance criteria ASME SEC V Article 7 Internal Procedure MPI-LDS 02 Rev. 1

AWS D1.1 MPI-LDS 03 Rev. 1

Customer Requirement MPI-LDS 04 Rev. 1

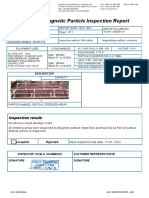

PICTURES AND ACCOMPLISHMENT

NDT AREA ACCEPTED REJECTED REMARKS

Pad Eyes 1 √ - No permanent defect

Pad Eyes 2 √ - No permanent defect

Pad Eyes 3 √ - No permanent defect

Pad Eyes 4 √ - No permanent defect

Other Structural Weld (Critical Area) - - -

NDE Before Load Test on : N/A NDE After Load Test on : N/A

INSPECTION RESULTS

No apparent discontinuities defect were detected through Magnetic Particle Inspection in welds of the critical areas of lifting points both was performed

No permanent defect or damage issue was detected at the time of process - The unit FIT for its intended use

Name of person inspect and Client's Representative

Reviewed By:

making this report: Approved

Rahmat Febriansyah Khoirul Mashuda

ASNT NDT Lv. II QA/QC Representative PT Elnusa Tbk

PT LD SERVIS - MT Haryono Street Gg. PLN RT 38 No 15 - Balikpapan, East Kalimantan.

Telp.No : +62542 – 7204212 & +6542 - 878709 & +62812-5558-245

Email: marketing@ldservis.com website : www.ldservis.com

Document code: LD-F-OPR-NDT-01.02 Revision: 03 Effective date: 10 Januari 2022

You might also like

- Indra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)Document57 pagesIndra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)med chabaneNo ratings yet

- Elevator Spider Maintenance Inspection & Wear DataDocument2 pagesElevator Spider Maintenance Inspection & Wear DataHector BarriosNo ratings yet

- Load Restraint - Safe Transport 5X5 Rev 2Document2 pagesLoad Restraint - Safe Transport 5X5 Rev 2Hortencio SamuelNo ratings yet

- 1A03 - Lab 2 - A2L. Quiz Answers - Lab Sections 10,11,15,16Document4 pages1A03 - Lab 2 - A2L. Quiz Answers - Lab Sections 10,11,15,16Bobby Rap73% (11)

- MPI Report SWL 5 Ton BoxDocument2 pagesMPI Report SWL 5 Ton BoxYusuf bagewadiNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putra100% (1)

- Slip Type Elevator Cat. IVDocument2 pagesSlip Type Elevator Cat. IVRanjithNo ratings yet

- VT ReportDocument1 pageVT ReportAbhishek SharmaNo ratings yet

- Wall Thickness - ReportDocument1 pageWall Thickness - ReportPetro100% (1)

- Pt. Sispum Sarana GrahaDocument2 pagesPt. Sispum Sarana GrahaMochammad AriefNo ratings yet

- North Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5Document3 pagesNorth Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5farshid KarpasandNo ratings yet

- Elevator Link Ears MPIDocument1 pageElevator Link Ears MPIRanjithNo ratings yet

- Ra Elevatorr Maintenance ManualDocument8 pagesRa Elevatorr Maintenance ManualBahman MatouriNo ratings yet

- 8689-2018 Sixco Chain SlingDocument2 pages8689-2018 Sixco Chain SlingAnonymous wuugFvOBjZNo ratings yet

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- Rigging Platform 25-05-2022-1Document1 pageRigging Platform 25-05-2022-1dele jimohNo ratings yet

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Document17 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Ulviyye ElesgerovaNo ratings yet

- Almansoori Inspection Services: Travelling Block AssemblyDocument1 pageAlmansoori Inspection Services: Travelling Block AssemblyRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Internal Dispatch Clearance ChecklistDocument54 pagesInternal Dispatch Clearance ChecklistMahesh2101No ratings yet

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- Factory Original MTCDocument1 pageFactory Original MTCSamir AjiNo ratings yet

- 3576 Erbil MergedDocument4 pages3576 Erbil MergedAli AlahmaNo ratings yet

- Eye Bolt Inspection Report: Last of ExaminationDocument7 pagesEye Bolt Inspection Report: Last of ExaminationRonniNo ratings yet

- Ultrasonic Test Report: Probe: Frequency: Type: Size: Angle: Reference Sensitivity (DB) ScanDocument1 pageUltrasonic Test Report: Probe: Frequency: Type: Size: Angle: Reference Sensitivity (DB) ScanZafar BhiwandiwalaNo ratings yet

- Pressure Form Test RecordDocument1 pagePressure Form Test RecordMUHAMMAD SALIM KhanNo ratings yet

- Crane DEMAG Cert 03-08-2022Document1 pageCrane DEMAG Cert 03-08-2022Omar ZarrougNo ratings yet

- Mobile Cranes Check ListDocument6 pagesMobile Cranes Check ListBanesco TemplarisNo ratings yet

- Mpi Pipe Rack PR 03-1.Document1 pageMpi Pipe Rack PR 03-1.Khalil ChabbouhNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Document2 pagesMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNo ratings yet

- Inspection CertifcatesDocument44 pagesInspection Certifcatesabdalrhman alqatawnehNo ratings yet

- M-Storm Drainage System - IC-M-SDS-00Document2 pagesM-Storm Drainage System - IC-M-SDS-00achusanachuNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- MarcoDocument1 pageMarcobimboNo ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- 1.transformer Maintenance Inspection Checklist - 001 - Uo - TSCDocument3 pages1.transformer Maintenance Inspection Checklist - 001 - Uo - TSCAnonymous mNQq7ojNo ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- Ultrasonic Wall Thickness Report Feb.27-28,20062 - 2Document32 pagesUltrasonic Wall Thickness Report Feb.27-28,20062 - 2Endickk Screamo PoreperrNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Tubecare Broucher PDFDocument16 pagesTubecare Broucher PDFRama Manikanta DondapatiNo ratings yet

- Table 5: Requirements For Drill Pipe Inspection ReportingDocument1 pageTable 5: Requirements For Drill Pipe Inspection ReportingJosue FishNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- CNC Lathe Calibration Procedure: 1.0 Standards and EquipmentDocument4 pagesCNC Lathe Calibration Procedure: 1.0 Standards and EquipmentTri SetiaNo ratings yet

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- Sertifikat SlingDocument1 pageSertifikat SlingHendra SaputraNo ratings yet

- Verticality Report.Document2 pagesVerticality Report.Gajanan R Ghatage100% (1)

- Visual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Document1 pageVisual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Michael OkwuwaNo ratings yet

- Vacuum Box Test PDFDocument3 pagesVacuum Box Test PDFWilson RodriguezNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putra100% (1)

- Emergency EyewashDocument2 pagesEmergency EyewashBayu Aringga putraNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putra100% (1)

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putra100% (1)

- Safety Data Sheet Sodium Bicarbonate: Section: 1. Product and Company IdentificationDocument9 pagesSafety Data Sheet Sodium Bicarbonate: Section: 1. Product and Company IdentificationBayu Aringga putraNo ratings yet

- MSDS Oli CompressorDocument4 pagesMSDS Oli CompressorBayu Aringga putraNo ratings yet

- Daily Hse Report: NO Item Description of Activity RemarksDocument3 pagesDaily Hse Report: NO Item Description of Activity RemarksBayu Aringga putraNo ratings yet

- Ampacimon Presentation STH AmDocument34 pagesAmpacimon Presentation STH AmDouglas RibeiroNo ratings yet

- Low RCS Microstrip Patch Antenna Using Frequency Selective Surface and Microstrip ResonatorDocument4 pagesLow RCS Microstrip Patch Antenna Using Frequency Selective Surface and Microstrip Resonatornguyễn đắc huyNo ratings yet

- BIOSPECT 21 Model 2013Document47 pagesBIOSPECT 21 Model 2013OBERON-INTROSPECT-BIOSPECT50% (2)

- HMT Senthil CompressDocument515 pagesHMT Senthil Compresssathiyapriyan2003No ratings yet

- Test To PassDocument7 pagesTest To Passayushbhardwaj181820No ratings yet

- ProjectDocument17 pagesProjectRavi ChotaliyaNo ratings yet

- Bus Duct - Catalog - GERS ViejoDocument12 pagesBus Duct - Catalog - GERS Viejo123peniscolaNo ratings yet

- Statistical Tolerance AnalysisDocument6 pagesStatistical Tolerance AnalysisbmvinayNo ratings yet

- Still Life Painting Lesson PlanDocument2 pagesStill Life Painting Lesson PlanGevy CamachoNo ratings yet

- DETECTOR - Service ManualDocument40 pagesDETECTOR - Service ManualOrlando Velado100% (1)

- DESMODUR MTX6076BAYTEC D24BAYTEC XL B SD2 4MF 2 60A 76D Ang Ind1Document2 pagesDESMODUR MTX6076BAYTEC D24BAYTEC XL B SD2 4MF 2 60A 76D Ang Ind1Алексей ПанасюгинNo ratings yet

- Aquaflair: Technical Cooling ChillersDocument27 pagesAquaflair: Technical Cooling ChillersmanuelNo ratings yet

- PIPE STRESS - PresentationDocument23 pagesPIPE STRESS - PresentationRavi Agarwal100% (1)

- Chemistry 311 Physical ChemistryDocument3 pagesChemistry 311 Physical ChemistryJosef CatiggayNo ratings yet

- Din 7984Document12 pagesDin 7984Nikola MilovanovićNo ratings yet

- S9 Q4 Week 2Document10 pagesS9 Q4 Week 2Mary Grace CatubiganNo ratings yet

- Chapter 3-Thermodynamic ProcessesDocument107 pagesChapter 3-Thermodynamic ProcessesRatu Dorji WangchukNo ratings yet

- SA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewDocument6 pagesSA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewdwarakababuNo ratings yet

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocument4 pagesSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadNo ratings yet

- The VSL Discussion: What Does Variable Speed of Light Mean and Should We Be Allowed To Think About ?Document4 pagesThe VSL Discussion: What Does Variable Speed of Light Mean and Should We Be Allowed To Think About ?muffinmule4No ratings yet

- Oster Halo PureDocument2 pagesOster Halo Purefederico3309538No ratings yet

- 2 Stage One Physics Design Practical InvestigationDocument10 pages2 Stage One Physics Design Practical Investigationg6z8fr6bysNo ratings yet

- Seal Ball ValvesDocument45 pagesSeal Ball Valvesmetasoniko2014No ratings yet

- Anchor Presentation Hilti 2011 PDFDocument8 pagesAnchor Presentation Hilti 2011 PDFNelsonDay100% (1)

- Class VIII I.I.T.foundation, N.T.S.E.& Science Olympiad Curriculum & Chapter NotesDocument83 pagesClass VIII I.I.T.foundation, N.T.S.E.& Science Olympiad Curriculum & Chapter NotesYo83% (6)

- Open Quantum System Dynamics - S41534-019-0235-YDocument10 pagesOpen Quantum System Dynamics - S41534-019-0235-YKaushik NandiNo ratings yet

- 1 2 Advantages Types of PrestressingDocument11 pages1 2 Advantages Types of PrestressingAlbyNo ratings yet

- 30GS Service ManualDocument28 pages30GS Service ManualarodassanchezNo ratings yet

- 25 Feb Shift 1 JEE Main 2021Document64 pages25 Feb Shift 1 JEE Main 2021Devchand BothraNo ratings yet