Professional Documents

Culture Documents

J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998

J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998

Uploaded by

SvapneshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998

J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998

Uploaded by

SvapneshCopyright:

Available Formats

IS 1608: 2005

ISO 6892: 1998

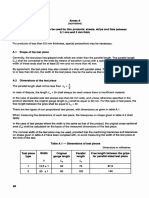

J.2.3 Total measurement uncertainty

The material-dependent response of proof strength over the permitted strain rate range specified in

table J.2 may be combined with the material independent parameters specified in table J.1 to give a total

estimate of uncertainty for the various materials indicated, as shown in table J.3.

For the purpose of this analysis, the total value of the variation in proof strength over the strain rate

range permitted in the standard has been halved and expressed as an equivalent tolerance, i.e, for

X5 Cr Ni Mo 17-12-2 stainless steel, the proof strength can vary by 6,8 % over the permitted strain rate

range so it is equivalent to a tolerance of ± 3,4 %. Therefore for X5 Cr Ni Mo 17-12-2 stainlesss steel,

the total uncertainty is given by:

Table J.3 - Examples of total expected measurement uncertainty for room temperature

proof strength determined in accordance with this International Standard

Material RpO,2 Values from Values from Total expected

Mean value table J.1 table J.2 measurement

uncertainty

MPa ±% 0/0 ±%

Ferritic steel

Pipe steel 680 2 0,05 .J4,0 =2,0

Plate steel 315 2 0,9 .J4,8 =2,2

Austenitic stHI

X5 Cr Ni Mo 17-12-2 235 2 3,4 .J15,6 =3,9

Nickel base alloys

Ni Cr20Ti 325 2 1,4 .J6,0 =2,4

Ni Cr Co Ti AI 25-20 790 2 0,95 J4,9 =2,2

J.3 Concluding remarks

A method of calculating the measurement uncertainty for room temperature tensile testing using an

"Error Budget" concept has been outlined and examples given for a few materials where the material

response to the testing parameters is known. It should be noted that the calculated uncertainties may

need to be modified to include a weighting factor in accordance with the guide to the expression of

uncertainty in measurement [2] and this will be undertaken when the Eurolab.and ISO working parties

finalise their recommendations on the optimum approach to be adopted. In addition, there are other

factors that can affect the measurement of tensile properties such as test piece bending, methods of

gripping the test piece, or the testing machine control mode, Le., extensometer control or loadlcrosshead

control which may affect the measured tensile properties (6]. However since there is insufficient

quantitative data available it is not possible to include their effects in error budgets at present. It should

also be recognised that this error budget approach only gives an estimate of the uncertainty due to the

measurement technique and does not make an allowance for the inherent scatter in experimental results

attributable to material inhomogeneity.

36

You might also like

- GB-T 4336-2016 - Carbon and Low-Alloy Steel-Determination of Multi-Element Contents-Spark Discharge Atomic Emission SpectrDocument37 pagesGB-T 4336-2016 - Carbon and Low-Alloy Steel-Determination of Multi-Element Contents-Spark Discharge Atomic Emission SpectrTrọng Đẹp Trai100% (3)

- Lab 3 TorsionDocument8 pagesLab 3 TorsionFarid NajandNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- Applsci 07 00338 v2 PDFDocument11 pagesApplsci 07 00338 v2 PDFNikhil KattiNo ratings yet

- 1 Paper 3135 PDFDocument10 pages1 Paper 3135 PDFSukhDeolNo ratings yet

- Metals 09 00568 PDFDocument16 pagesMetals 09 00568 PDFGNo ratings yet

- Nadia Hamzawy Mohamed - Nadia PaperDocument7 pagesNadia Hamzawy Mohamed - Nadia PaperchatgptuseregyptNo ratings yet

- JIS G5131ï š2008 High Manganese Steel Castings PDFDocument14 pagesJIS G5131ï š2008 High Manganese Steel Castings PDFsupendiNo ratings yet

- BWRA and Séférian Model For Preheating Temperature Calculation in Case of Low Alloyed and Unalloyed SteelDocument6 pagesBWRA and Séférian Model For Preheating Temperature Calculation in Case of Low Alloyed and Unalloyed SteelChokri AtefNo ratings yet

- Optimization of Process Parameters of Friction Stir Welding of Aa 6082-T6 Using Grey Based Taguchi MethodDocument8 pagesOptimization of Process Parameters of Friction Stir Welding of Aa 6082-T6 Using Grey Based Taguchi MethodTJPRC PublicationsNo ratings yet

- Draft SLS 26-2nd Revison - 2019-06-2811 00000003Document15 pagesDraft SLS 26-2nd Revison - 2019-06-2811 00000003Krishantha Jayawardene100% (1)

- Iiw - Ix-2058-03Document35 pagesIiw - Ix-2058-03pateta50No ratings yet

- Failure Analysis of SA-213TP347H High-TemperatureDocument6 pagesFailure Analysis of SA-213TP347H High-TemperatureLakshminarayanNo ratings yet

- Variations The Diameter Tip of Electrode On The ReDocument12 pagesVariations The Diameter Tip of Electrode On The ReThaharNo ratings yet

- Resistance Spot Welding Between Steel and Aluminum AlloyDocument5 pagesResistance Spot Welding Between Steel and Aluminum AlloyKIRANNo ratings yet

- Lab Description For Hardness Testing Procedures: Applicable StandardsDocument11 pagesLab Description For Hardness Testing Procedures: Applicable StandardsJaymin PatelNo ratings yet

- 2019 036 PeguesDocument8 pages2019 036 Peguesshweta shuklaNo ratings yet

- 2.25CR Mo VDocument9 pages2.25CR Mo VSangameswaran RamarajNo ratings yet

- Mathematical Modeling For Predicting Angular Distortion in Tig Welding of Stainless Steel 409L Butt WeldsDocument6 pagesMathematical Modeling For Predicting Angular Distortion in Tig Welding of Stainless Steel 409L Butt WeldsAnusua DasNo ratings yet

- Evaluation of Creep Properties of Steel P92 and Its Welded JointDocument4 pagesEvaluation of Creep Properties of Steel P92 and Its Welded Jointmahmoud_allam3No ratings yet

- Finite Element Simulation of Carbide Precipitation in Austenitic Stainless Steel 304Document7 pagesFinite Element Simulation of Carbide Precipitation in Austenitic Stainless Steel 304mangalraj900No ratings yet

- GB700-88 Carbon Structural SteelsDocument7 pagesGB700-88 Carbon Structural SteelsyuNo ratings yet

- Din 17177-79Document8 pagesDin 17177-79savanNo ratings yet

- Mechanical Response of Aluminium Alloy AA6061 Butt-Welded Joints Subjected To Two Initial Tempers and Different Heat TreatmentsDocument4 pagesMechanical Response of Aluminium Alloy AA6061 Butt-Welded Joints Subjected To Two Initial Tempers and Different Heat TreatmentsAnizahyatiNo ratings yet

- Electrochemical Behavior of Corrosion Resistance of X65/Inconel 625 Welded JointsDocument11 pagesElectrochemical Behavior of Corrosion Resistance of X65/Inconel 625 Welded JointsÉlida AlvesNo ratings yet

- Metallurgical and Micostructural Effect On CVN Impact Toughness in 2,25Cr1Mo Weld MetalDocument16 pagesMetallurgical and Micostructural Effect On CVN Impact Toughness in 2,25Cr1Mo Weld MetalMubeenNo ratings yet

- Brahim Belkessa, Djamel Miroud, Billel Cheniti, Naima Ouali, Maamar Hakem, Mustapha DjamaDocument7 pagesBrahim Belkessa, Djamel Miroud, Billel Cheniti, Naima Ouali, Maamar Hakem, Mustapha Djamasudish mishraNo ratings yet

- Metals 10 01481 v2Document15 pagesMetals 10 01481 v2Nirmal GhoshNo ratings yet

- Zhang 2020Document22 pagesZhang 2020peditopeditoaNo ratings yet

- Influence of Heat Input On The Content of Delta Ferrite in The Structure of 304L Stainless Steel Gta Welded JointsDocument7 pagesInfluence of Heat Input On The Content of Delta Ferrite in The Structure of 304L Stainless Steel Gta Welded JointsjinsthomasNo ratings yet

- Effect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelDocument9 pagesEffect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless Steelnaresh1272No ratings yet

- 2009 June ExamDocument6 pages2009 June ExamSurprise Presley SibiyaNo ratings yet

- Metallographic Investigations in The Diagnosis and Quality Control of Welded Joints of Austenitic SteelsDocument18 pagesMetallographic Investigations in The Diagnosis and Quality Control of Welded Joints of Austenitic SteelsДмитрий СтепановNo ratings yet

- Experimental Research in Smaw Parameter To Minimize The Residual Stress and Analysis For Eliminate Cold CracksDocument10 pagesExperimental Research in Smaw Parameter To Minimize The Residual Stress and Analysis For Eliminate Cold CracksTJPRC PublicationsNo ratings yet

- Evaluation of Optimal Parameters For Machining of SS 430 With Wire Cut EdmDocument5 pagesEvaluation of Optimal Parameters For Machining of SS 430 With Wire Cut EdmCüťièpie DipaNo ratings yet

- Effect of Austenite-To-Ferrite Phase TransformatioDocument13 pagesEffect of Austenite-To-Ferrite Phase TransformatioPablo PerdomoNo ratings yet

- EET 2000 Lab 1 ReportDocument11 pagesEET 2000 Lab 1 Reportyonatanfiseha2No ratings yet

- Nickel-Chromium-Iron-Molybdenum-Copper Alloy Rod: Standard Specification ForDocument4 pagesNickel-Chromium-Iron-Molybdenum-Copper Alloy Rod: Standard Specification ForLemir LopezNo ratings yet

- LinobDocument3 pagesLinobjayaramkrishnanNo ratings yet

- B574 Plfy402430879val PDFDocument6 pagesB574 Plfy402430879val PDFCarlosIkedaNo ratings yet

- Electrode Wear Rate of Graphite Electrode During Edm Process On Titanium Alloy M. A. R. Khan, M. M. Rahman and K. KadirgamaDocument6 pagesElectrode Wear Rate of Graphite Electrode During Edm Process On Titanium Alloy M. A. R. Khan, M. M. Rahman and K. KadirgamaNui Yuhu KuwNo ratings yet

- Models - Corr.galvanic Corrosion MG AlloyDocument10 pagesModels - Corr.galvanic Corrosion MG AlloyThiagoCarvalhoNo ratings yet

- Mathematical Model of Static and Dynamic Recrystallization, Roll Force and Mean Flow Stress of The Nb-Microalloyed Steels For Plain Steel Hot Roughing MillDocument10 pagesMathematical Model of Static and Dynamic Recrystallization, Roll Force and Mean Flow Stress of The Nb-Microalloyed Steels For Plain Steel Hot Roughing MillJJNo ratings yet

- Analysis The Sensitized WeldingDocument10 pagesAnalysis The Sensitized WeldingHatra MulyonoNo ratings yet

- Effects of Normalizing Processes On Microstructure and Impact Toughness in Ti-Bearing Weld Metal of Multilayer MAG Welded HSLA SteelDocument6 pagesEffects of Normalizing Processes On Microstructure and Impact Toughness in Ti-Bearing Weld Metal of Multilayer MAG Welded HSLA Steelarjun prajapatiNo ratings yet

- metals-09-00916Document8 pagesmetals-09-00916Abdul RafiNo ratings yet

- Estimation of Corrosion Kinetics ParametersDocument16 pagesEstimation of Corrosion Kinetics ParametersFelipe Cepeda SilvaNo ratings yet

- Optimization in Spheroidized Annealing of Two AISI 1022 Low Carbon Steels Used in Bolt IndustryDocument7 pagesOptimization in Spheroidized Annealing of Two AISI 1022 Low Carbon Steels Used in Bolt Industryenrico susantoNo ratings yet

- 03.phase Transformations in Creep Strength Enhanced Ferritic Steel WeldsDocument4 pages03.phase Transformations in Creep Strength Enhanced Ferritic Steel WeldsMohamed HatemNo ratings yet

- Translated A 5523Document20 pagesTranslated A 5523Pd ProxyNo ratings yet

- Models - Corr.corrosion Parameter EstimationDocument16 pagesModels - Corr.corrosion Parameter EstimationFelipe Cepeda SilvaNo ratings yet

- Characterisation of The Martensitic Chromium SteelDocument10 pagesCharacterisation of The Martensitic Chromium SteelskluxNo ratings yet

- Materials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangDocument5 pagesMaterials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangAntonio Alonso Diaz ArriagaNo ratings yet

- Study of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsDocument12 pagesStudy of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsMuhammad Fatka FirmansyahNo ratings yet

- Paper PublishedDocument7 pagesPaper PublishedNavlesh JamdarNo ratings yet

- Construction of Ag - AgCl Reference Electrode and ApplicationDocument3 pagesConstruction of Ag - AgCl Reference Electrode and ApplicationValentin-AngeloUzunovNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsFrom EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- (Rpo, 2) in The CaseDocument1 page(Rpo, 2) in The CaseSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Is 1608 - 2005 - 15Document1 pageIs 1608 - 2005 - 15SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- Is 1608 - 2005 - 11Document1 pageIs 1608 - 2005 - 11SvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inDocument1 pageIS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inSvapneshNo ratings yet

- Is 1608 - 2005 - 14Document1 pageIs 1608 - 2005 - 14SvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Lower Yield StrengthDocument1 pageIS 1608: 2005 ISO 6892: 1998: Lower Yield StrengthSvapneshNo ratings yet

- Pelaporan IKP Puskesmas Arjaty Daud 2022Document16 pagesPelaporan IKP Puskesmas Arjaty Daud 2022Fajar Slalu CeriaNo ratings yet

- Cooling System OperationDocument4 pagesCooling System OperationSRL MECHNo ratings yet

- Climate Action Incentive Payment Notice 2022 06 25 09 46 45 07823 PDFDocument3 pagesClimate Action Incentive Payment Notice 2022 06 25 09 46 45 07823 PDFalex mac dougallNo ratings yet

- SFDA Requirement For DEXADocument9 pagesSFDA Requirement For DEXAEhsan alwafaaNo ratings yet

- Electronic Reservation Slip (ERS) : 6617575281 12102/jananeswari Exp Ac 3 Tier Sleeper (3A)Document2 pagesElectronic Reservation Slip (ERS) : 6617575281 12102/jananeswari Exp Ac 3 Tier Sleeper (3A)Sparsh SharmaNo ratings yet

- Practical Bacteriology Laboratory Manual: Prepared byDocument37 pagesPractical Bacteriology Laboratory Manual: Prepared bysalamon2tNo ratings yet

- Env LawDocument16 pagesEnv LawHeena ShaikhNo ratings yet

- What Would You Be If You Were?Document2 pagesWhat Would You Be If You Were?oantaNo ratings yet

- Carbohydrates Reaction - KLP 5Document23 pagesCarbohydrates Reaction - KLP 5Putri SalsabilaNo ratings yet

- Eat Right Tip #1: Remove and Reduce The BadDocument4 pagesEat Right Tip #1: Remove and Reduce The BadPJK1-0619 Nurul Asyraf Bin Nurul AklaNo ratings yet

- (Download PDF) The Monstrous Feminine in Contemporary Japanese Popular Culture Raechel Dumas Online Ebook All Chapter PDFDocument42 pages(Download PDF) The Monstrous Feminine in Contemporary Japanese Popular Culture Raechel Dumas Online Ebook All Chapter PDFdavid.messer693100% (15)

- Aprelim - Purely CompensationDocument67 pagesAprelim - Purely CompensationAshley VasquezNo ratings yet

- Space Closing Mechanics - DIFFERENT LOOPSDocument147 pagesSpace Closing Mechanics - DIFFERENT LOOPSdrarjunvedvyas100% (18)

- Samsung DVM S Sales Brochure 20140729Document16 pagesSamsung DVM S Sales Brochure 20140729CARLOS ANDRES GONZALES BARRIOSNo ratings yet

- Study Guide: Lord of The FliesDocument3 pagesStudy Guide: Lord of The FliesLeo Christian Sixwillfix Villacortes-LauzonNo ratings yet

- Emergency Preparedness For Severe WeatherDocument2 pagesEmergency Preparedness For Severe WeatherRandy PedrozaNo ratings yet

- 57-Online Rejection Note, Material ReturnDocument3 pages57-Online Rejection Note, Material Returnananth100% (1)

- Clinical Nutrition: Paediatric Nutrition Risk Scores in Clinical Practice: Children With Inflammatory Bowel DiseaseDocument4 pagesClinical Nutrition: Paediatric Nutrition Risk Scores in Clinical Practice: Children With Inflammatory Bowel DiseaseMaggie S HungNo ratings yet

- COVID-19 and Disinfectants and Sanitizers in Food PremisesDocument5 pagesCOVID-19 and Disinfectants and Sanitizers in Food Premisesnur atiqah sobriNo ratings yet

- Requiem Bloodlines & PowersDocument16 pagesRequiem Bloodlines & PowersLuiz Henrique Matias MarcondesNo ratings yet

- 2007 06 08 OA FEA Kalaeloa Asphalt TerminalDocument255 pages2007 06 08 OA FEA Kalaeloa Asphalt TerminalEsteban Lopez ArboledaNo ratings yet

- Parole: Ca 2 - Non-Institutional CorrectionsDocument8 pagesParole: Ca 2 - Non-Institutional CorrectionsWena Mae Cristobal100% (5)

- Life Processes - CBSE Class 10 BiologyDocument7 pagesLife Processes - CBSE Class 10 BiologyGurukul24x775% (8)

- 2 Definition and Applications: Estimation of Physiological RequirementsDocument7 pages2 Definition and Applications: Estimation of Physiological RequirementsRj SantiagoNo ratings yet

- Construction and Installation of De-Icer BootsDocument11 pagesConstruction and Installation of De-Icer BootsPatrick dela rosaNo ratings yet

- Brick Work JSA HSE ProfessionalsDocument1 pageBrick Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNo ratings yet

- Product Risk Assessment Practices Regulatory AgenciesDocument19 pagesProduct Risk Assessment Practices Regulatory AgenciesAllyssa FernandezNo ratings yet

- Long Term LiabilitiesDocument21 pagesLong Term Liabilitiesnioriatti8924No ratings yet

- MSDS AltDocument6 pagesMSDS AltPuskesmas Tambakboyo TubanNo ratings yet

- From The Book "Key To Health"Document3 pagesFrom The Book "Key To Health"Raksha SharmaNo ratings yet