Professional Documents

Culture Documents

Magnafloc 10: Technical Information Mining Chemicals

Magnafloc 10: Technical Information Mining Chemicals

Uploaded by

Michael muludyangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnafloc 10: Technical Information Mining Chemicals

Magnafloc 10: Technical Information Mining Chemicals

Uploaded by

Michael muludyangCopyright:

Available Formats

Technical Information Mining Chemicals

TI/EVH 0050 e

June 2010 Page 1 of 2

Magnafloc® 10

® = registered Trademark of BASF SE

Anionic flocculant

Description Magnafloc 10 is a very high molecular weight, slightly anionic polyacrylamide

flocculant supplied as a free flowing granular powder.

Principal uses Magnafloc 10 has found application in a wide variety of mineral processing

operations including the following:

1. Acid leach CCD (uranium)

2. Potash slimes clarification and dewatering

3. Acid leach CCD (copper)

4. Acid leach (zinc)

5. Iron ore tailings clarification

6. Base metal concentrates thickenings and filtration

7. Thickening of coal tailings

Dosage depends on application but normally lies in the range

2 – 200 g/tonne of dry substrate flocculated.

Typical properties Physical form: Off-white granular powder

Particle size: 98 % < 1000 μm

Bulk density: 0.7 g/cm3

pH of 1 % solution at 25 °C: 6.5

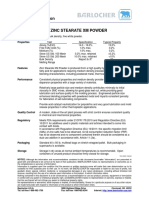

Viscosity at 25 °C: See graph and table

Apparent Viscosity-Concentration Graph

(Fann Viscometer-Shear Rate 5.11 sec-¹)

1200 cP

1000

800

600

400

200

0

0 0.2 0.4 0.6 0.8 1

Magnafloc 10 Concentration (%)

TI/EVH 0050 e June 2010 Page 2 of 2 Magnafloc 10

Application & Storage Recommended solution concentrations:

Stock solution: 0.25 – 0.5 % max.

Feed solution: 0.025 – 0.1 % max.

Shelf life 2 years from receipt of goods

Stock solution: 1 – 2 days

Storage of polymer should be in a cool, dry place.

Details on preparation and application can be obtained from a BASF SE

representative.

Solution viscosity data

(Fann viscometer – 25 °C – solvent – deionised water)

Magnafloc 10 Shear rate (sec-1)

concentration (%) 5.11 10.22 170 340 511 1022

Viscosity (cP)

1.0 1100 700 126 87 74 63

0.5 350 250 48 35 29 24

0.25 200 125 24 18 15 12

0.10 100 63 12 9 7 6

Shipping & Handling Magnafloc 10 is supplied in 25 kg nett plastic bags shrinkwrapped onto a

pallet suitable for export shipment. The product can also be supplied via

intermediate big bags or bulk tanker. Specific details of bag and tanker sizes

can be obtained on request.

Corrosivity towards most standard materials of construction is low, but

aluminium and galvanised equipment should be avoided.

Technical service Advice and assistance in the running of laboratory and plant tests to

select the correct flocculant and determine the best application is given by

representatives of BASF SE, who are experienced in mineral processing

applications.

Health & Safety Magnafloc 10 exhibits a very low order of oral toxicity and does not

present any abnormal problems in its handling or general use.

Detailed information on handling and any precautions to be observed in the

use of the product(s) described in this leaflet can be found in our relevant

health and safety information sheet.

Note The data contained in this publication are based on our current knowledge

and experience. In view of the many factors that may affect processing

and application of our product, these data do not relieve processors from

carrying out their own investigations and tests; neither do these data imply

any guarantee of certain properties, nor the suitability of the product for

a specific purpose. Any descriptions, drawings, photographs, data, pro-

portions, weights etc. given herein may change without prior information

and do not constitute the agreed contractual quality of the product. It is

the responsibility of the recipient of our products to ensure that any

proprietary rights and existing laws and legislation are observed.

June 2010

BASF SE

Oilfield & Mining Chemicals

67056 Ludwigshafen, Germany

www.performancechemicals.basf.com

You might also like

- Sanaa PDFDocument68 pagesSanaa PDFLjiljana Pucelj50% (4)

- Halil İnalcık - The Ottoman Economic Mind and Aspects of The Ottoman Economy PDFDocument10 pagesHalil İnalcık - The Ottoman Economic Mind and Aspects of The Ottoman Economy PDFA Seven HasdemirNo ratings yet

- KsacCA989819uascACApdf - coASCcam LeaaCsctherindia OrACScag RaascsCwDocument1,009 pagesKsacCA989819uascACApdf - coASCcam LeaaCsctherindia OrACScag RaascsCwRupesh Gurav100% (1)

- Natech Kolseal MO2Document8 pagesNatech Kolseal MO2marlon_3gsNo ratings yet

- Magnafloc 10 BASFDocument2 pagesMagnafloc 10 BASFwan-yu.linNo ratings yet

- MagnaflocDocument3 pagesMagnaflocfrancsanchezNo ratings yet

- Magnafloc 338 TI EVH 0056 eDocument2 pagesMagnafloc 338 TI EVH 0056 eHenry MaytaNo ratings yet

- Dokumen - Tips - Registered Trademark of Basf Se Magnafloc Magnafloc 155 Is A High Molecular WeightDocument2 pagesDokumen - Tips - Registered Trademark of Basf Se Magnafloc Magnafloc 155 Is A High Molecular WeightMahmoud HakimNo ratings yet

- Magnafloc 336 (HT)Document2 pagesMagnafloc 336 (HT)FirdausNo ratings yet

- RheomaxDocument2 pagesRheomaxlouza8100% (2)

- Magnafloc 5250 TI EVH 0033Document2 pagesMagnafloc 5250 TI EVH 0033JCL ROmanos100% (1)

- Magna FlocDocument2 pagesMagna FlocmatiasNo ratings yet

- Product Information: CODE 5925Document1 pageProduct Information: CODE 5925Noni NoniNo ratings yet

- Vitrebond Tech ProfileDocument21 pagesVitrebond Tech ProfilePapun ScribdNo ratings yet

- Ind 3003 2104eDocument2 pagesInd 3003 2104eRafael Flores HNo ratings yet

- DSM-0201.0 Hydroxyapatite PowderDocument3 pagesDSM-0201.0 Hydroxyapatite PowderJaideepNo ratings yet

- Glo Mica FMCDocument2 pagesGlo Mica FMCVikash KumarNo ratings yet

- Polypro VC 17Document2 pagesPolypro VC 17hauvuNo ratings yet

- RHOPLEX™ EC-3000: 100% Acrylic Polymer For The Roof Coatings MarketDocument4 pagesRHOPLEX™ EC-3000: 100% Acrylic Polymer For The Roof Coatings MarketLong An DoNo ratings yet

- DOW FILMTEC™ SW30HRLE-400 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HRLE-400 Element: Descriptiongvnks90No ratings yet

- Filmtec SW30HRLE-400Document3 pagesFilmtec SW30HRLE-400PT Deltapuro IndonesiaNo ratings yet

- Membrana Filmtec Sw30xle-400iDocument3 pagesMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake Specialmajmor-1No ratings yet

- NF FilmTec LiNE XD PDS 45 D04532 enDocument3 pagesNF FilmTec LiNE XD PDS 45 D04532 enHuynh le ManNo ratings yet

- 5.1 KATALOG Toray - TM800M - v1 - 202201Document2 pages5.1 KATALOG Toray - TM800M - v1 - 202201Diana SulardiNo ratings yet

- 767 Viscofluidscc 10 GBDocument2 pages767 Viscofluidscc 10 GBArjay PlataNo ratings yet

- Genapol PF 10Document2 pagesGenapol PF 10Mohamed HalemNo ratings yet

- CRP 100NDocument2 pagesCRP 100NbaharehestekiNo ratings yet

- Brochure Nouryon Hydrogenperoxide Product Information ManualDocument30 pagesBrochure Nouryon Hydrogenperoxide Product Information ManualUtpalNo ratings yet

- Licowax S FlakesDocument1 pageLicowax S Flakes王偉仲No ratings yet

- Techncal Data Sheet Vinylester 702-A: DescriptionDocument2 pagesTechncal Data Sheet Vinylester 702-A: DescriptionGokulnath Kongunadu SingamNo ratings yet

- TDS ICOM Vinylester-702-A EN2016UU PDFDocument2 pagesTDS ICOM Vinylester-702-A EN2016UU PDFGokulnath Kongunadu SingamNo ratings yet

- Sika Bond LA SubmittalDocument17 pagesSika Bond LA SubmittalmkNo ratings yet

- HYDRACoRe10 and 50 LD SeriesDocument1 pageHYDRACoRe10 and 50 LD SeriesSathishNo ratings yet

- Fosroc Nitocote EP405: Solvent-Free Epoxy Resin Coating For Water Retaining and Water Excluding Structures UsesDocument3 pagesFosroc Nitocote EP405: Solvent-Free Epoxy Resin Coating For Water Retaining and Water Excluding Structures UsesGer ShorttNo ratings yet

- Genapol PF 20Document2 pagesGenapol PF 20Mohamed HalemNo ratings yet

- Polymer 101-Fundamental of FlocculationDocument41 pagesPolymer 101-Fundamental of FlocculationAmmar Radzi AzmiNo ratings yet

- Surfactant EORDocument43 pagesSurfactant EORLê Công100% (1)

- Selective Recovery of Volatile Flavour Compounds Using Reversed-Phase Polystyrene AdsorbentsDocument7 pagesSelective Recovery of Volatile Flavour Compounds Using Reversed-Phase Polystyrene AdsorbentsРусланNo ratings yet

- Kollicoat ProtectDocument12 pagesKollicoat ProtectMd.ali-bin-saifullahNo ratings yet

- Mitsui (United) - Accofloc N-100 - TDSDocument2 pagesMitsui (United) - Accofloc N-100 - TDSaldivaindraNo ratings yet

- H.T MIBC Metil Isobutil Carbinol QADocument4 pagesH.T MIBC Metil Isobutil Carbinol QAMelissa Dávila KinNo ratings yet

- TDS Chemflake Glass Flake SuggestedDocument5 pagesTDS Chemflake Glass Flake SuggestedShankar Pl GowdaNo ratings yet

- F.T Polygel CaDocument2 pagesF.T Polygel CaMaría José NicolaldeNo ratings yet

- Ti-ExR04 PDSDocument2 pagesTi-ExR04 PDSBorja AzkargortaNo ratings yet

- DOW FILMTEC™ SW30HR-380 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HR-380 Element: DescriptionAnonymous zUsOCUNo ratings yet

- Pulp ProtectionDocument13 pagesPulp ProtectionmirfanulhaqNo ratings yet

- Pulp ProtectionDocument13 pagesPulp ProtectionmirfanulhaqNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- Lithium Base With Molybdenum Disulfide GreaseDocument2 pagesLithium Base With Molybdenum Disulfide GreaseYoong TanNo ratings yet

- Masterroc MP 355 1k TdsDocument3 pagesMasterroc MP 355 1k TdsAgung RiyandaNo ratings yet

- Membrane SW30XLE-440iDocument3 pagesMembrane SW30XLE-440iecrNo ratings yet

- Mos Pu Foam CompleteDocument4 pagesMos Pu Foam Completeyusnan yazidNo ratings yet

- GICDocument26 pagesGICJyotsna vaishnavNo ratings yet

- Zetag - 7563 1Document2 pagesZetag - 7563 1David GüellNo ratings yet

- Lubricool AcDocument3 pagesLubricool AcMarco PoloNo ratings yet

- United Initiators KPSDocument2 pagesUnited Initiators KPSxaviercarriNo ratings yet

- Sinopec Crystal GreaseDocument2 pagesSinopec Crystal GreaseImran ImranNo ratings yet

- 2 23 Ab Polyglass Vef May 19Document3 pages2 23 Ab Polyglass Vef May 19srinivasansscNo ratings yet

- TDS - Tankguard Zinc - Issued 01.08.2014Document5 pagesTDS - Tankguard Zinc - Issued 01.08.2014Arya Kemal Pratama PutraNo ratings yet

- TechnicalDataSheet (TDS) 7RELEASECOMPOUND English 08012019Document2 pagesTechnicalDataSheet (TDS) 7RELEASECOMPOUND English 08012019krlalitNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Fillet Welded JointsDocument4 pagesFillet Welded Jointsjocelyn beltranNo ratings yet

- Rohith R Fouress Report 1Document22 pagesRohith R Fouress Report 1Nithish ChandrashekarNo ratings yet

- CWNP Message of The DayDocument179 pagesCWNP Message of The DayLawrence OrewaNo ratings yet

- Radial Fan Conical Vs Parallel Impeller Casing AnalysisDocument10 pagesRadial Fan Conical Vs Parallel Impeller Casing AnalysisvirgilioNo ratings yet

- 11.2 - Introduction To Particle Physics - Physics LibreTexts PDFDocument4 pages11.2 - Introduction To Particle Physics - Physics LibreTexts PDFpappuNo ratings yet

- Ranger Archetypes: DervishDocument1 pageRanger Archetypes: DervishI love you Evans PeterNo ratings yet

- Module-8 - Hydrocyclone AdjustmentsDocument184 pagesModule-8 - Hydrocyclone AdjustmentsizotreyNo ratings yet

- P1-F Revision For Midyear - Listening - The Sydney Opera HouseDocument4 pagesP1-F Revision For Midyear - Listening - The Sydney Opera HouseYusuf Can SözerNo ratings yet

- Age Frequency Percentage %Document9 pagesAge Frequency Percentage %Jolly Mae CatabayNo ratings yet

- Turning RedDocument3 pagesTurning RedGaluh940% (2)

- Septic Tank DetailsDocument1 pageSeptic Tank DetailsEdciel EbuenNo ratings yet

- STG-Final 4th Edtion 2021 - PDF - Doctor of Medicine - Sexually Transmitted InfectionDocument512 pagesSTG-Final 4th Edtion 2021 - PDF - Doctor of Medicine - Sexually Transmitted InfectionAbenezer AbrahamNo ratings yet

- TO Bus Rapid Transit (BRT) System: Hemant TiwariDocument48 pagesTO Bus Rapid Transit (BRT) System: Hemant TiwariHemant Tiwari100% (2)

- Lorentz PS1800 CS-36-1Document4 pagesLorentz PS1800 CS-36-1SINES FranceNo ratings yet

- Assignment: Embedded SystemsDocument6 pagesAssignment: Embedded SystemsSudarshanNo ratings yet

- Lantul de Aprovizionare (Chain Supply)Document59 pagesLantul de Aprovizionare (Chain Supply)tamasraduNo ratings yet

- Diagnostic Test - Gen. Ed. (No. 4)Document7 pagesDiagnostic Test - Gen. Ed. (No. 4)Alemor AlviorNo ratings yet

- Tds Cassida Grease Rls Series EngDocument2 pagesTds Cassida Grease Rls Series Engmussawer hasnainNo ratings yet

- Corrosion Probe TypeDocument26 pagesCorrosion Probe TypeFirman MuttaqinNo ratings yet

- Valve Shutoff Classifications - Process PipingDocument4 pagesValve Shutoff Classifications - Process Pipingdragon2065No ratings yet

- Probelm SetsDocument57 pagesProbelm SetsAllison N. MillarNo ratings yet

- ITMO 2017 - Keystage III - Individual PDFDocument6 pagesITMO 2017 - Keystage III - Individual PDFzarifNo ratings yet

- 9-5 Complex Numbers and de Moivre - S TheoremDocument45 pages9-5 Complex Numbers and de Moivre - S Theorembinode100% (1)

- A Review of The Energy Tax On Electric Power Consumption 8rh054uiDocument31 pagesA Review of The Energy Tax On Electric Power Consumption 8rh054uiSheena Lynne AntalanNo ratings yet

- Science 3 TestDocument4 pagesScience 3 TestPatrick Jerome SilvanoNo ratings yet

- CID Foundation Only PermitDocument1 pageCID Foundation Only PermitOsvaldo CalderonUACJNo ratings yet

- Installation Manual of The Solar Weather Monitoring StationDocument40 pagesInstallation Manual of The Solar Weather Monitoring Stationsamwel kariukiNo ratings yet