Professional Documents

Culture Documents

CCC HeadedReinforcement

CCC HeadedReinforcement

Uploaded by

Farja_ZzzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CCC HeadedReinforcement

CCC HeadedReinforcement

Uploaded by

Farja_ZzzCopyright:

Available Formats

C R E AT I V E C O N C R E T E C O N S T R U C T I O N

Headed Reinforcement

by Dr. Henry G. Russell, Henry G. Russell Inc.

T he traditional method of terminating

reinforcing bars in tension is to provide

a development length beyond the section where

reinforcing bar by means of a ferrous filler

medium.

• Using a separate threaded nut to secure the

the reinforcing bar is no longer needed. This head to the reinforcing bar.

development length may consist of a straight

length or a hooked anchorage. Hooks usually The head may be round, elliptical, or

have 90- or 180-degree bends. There are, rectangular, and it may be forged, machined

however, situations where there is insufficient from bar stock, or cut from steel plate. The

length available to accommodate a straight purchaser must either specify head dimensions

development length or a hook. There are also or accept head dimensions supplied by the

locations, such as column-to-bent connections, manufacturer prior to use. Headed deformed

where reinforcement can become very congested, reinforcing bar manufacturers may also offer

particularly where hooks are used. These are products made from a variety of stainless steel

ideal situations for considering the use of alloys, and some headed deformed bars are

headed reinforcement. The benefits of headed offered with epoxy or galvanic coatings.

reinforcement include:

• Simplified bar placement by reducing Structural Design

congestion The American Association of State Highway

• Easier concrete placement and Transportation Officials’ AASHTO LRFD

• Reduced detailing by using a standard product Bridge Design Specifications Article 5.10.8.3,

Development by Mechanical Anchorages, allows

Headed Bars Defined the use of mechanical anchorages if the device

The American Concrete Institute (ACI) defines is capable of developing the strength of the

a headed bar as “a steel reinforcing bar that reinforcement without damage to the concrete.3

has steel head(s) on one or both ends with the Performance of mechanical anchorages must be

purpose of anchoring the bar in concrete.”1 verified by laboratory testing, and complete details

must be shown in the contract documents.

ASTM A970, Standard Specification for

Headed Steel Bars for Concrete Reinforcement, The AASHTO LRFD specifications also allow

addresses deformed steel reinforcing bars with the development of reinforcing bars to consist of

a head attached to one or both ends.2 Various a combination of mechanical anchorage and the

methods are used to form the head. The scope of additional development length of reinforcement

ASTM A970 includes the following methods for between the point of maximum bar stress and

forming the head: the mechanical anchorage. In practice, most

• Welding according to the standards of the heads provide a strength greater than that of the

American Welding Society. reinforcing bar being anchored.

• Integrally hot forging the head from the

reinforcing bar. The AASHTO LRFD specifications provide few

• Attaching an internally threaded head to design details. However, design provisions for ASTM A970, Standard Specification

matching threads at the end of the bar. The headed deformed reinforcing bars are included for Headed Steel Bars for Concrete

threads may be straight or tapered. Thread in Section 25.4.4 of ACI’s Building Code Reinforcement, lists seven methods of

specifications and standards are generally Requirements for Structural Concrete (ACI 318- forming heads on headed reinforcing

selected by the manufacturer. 19).4 These requirements allow the use of headed bars. Examples of three forming methods

• Cold swaging an externally threaded or reinforcing bars in tension when the following are shown here: (top) heads integrally

plain coupling sleeve or headed sleeve onto conditions are satisfied: hot forged from the reinforcing bars,

the reinforcing bar. Radial compression of • Bars conform with ASTM A970. (middle) internally threaded heads

the swaged sleeve on the reinforcing bar • Bar size does not exceed size no. 11. attached to matching threads at the end

creates a mechanical interlock with the bar • Net bearing area of the head is at least four of the reinforcing bars, and (bottom) cold

deformations. times the area of the bar. swaged headed sleeves on reinforcing

• Cold extruding an external coupling sleeve • Normalweight concrete is used. bars. Photos: Headed Reinforcement Corp.

onto the reinforcing bar. • Clear cover for the bar is at least twice the bar (top); Dextra America (middle); BarSplice

• Attaching a coupling sleeve to the end of the diameter. Products Inc. (bottom).

ASPIRE Fall 2020 | 39

Concluding Remarks

Headed reinforcing bars provide a solution

to develop reinforcement in tension when the

use of straight bars or hooked bars is neither

practical nor economical. Further information

about their use is available from the Concrete

Reinforcing Steel Institute, ACI, ASTM

International, and manufacturers’ literature.

References

1. American Concrete Institute (ACI). 2018.

ACI Concrete Terminology (ACI CT-18).

Congestion in a pile-to-pile cap connection was eliminated by using field-installed Farmington Hills, MI: ACI.

heads to replace hooked bars. Photo: Headed Reinforcement Corp. 2. ASTM International. 2018. Standard

Specification for Headed Steel Bars for

• Center-to-center spacing between bars is at the minimum specified elongation of the Concrete Reinforcement (ASTM A970/

least three times the bar diameter. reinforcing bar A970M-18). West Conshohocken, PA: ASTM

• Class HA: Required to develop the minimum International.

The net bearing area is defined as the area specified tensile strength of the reinforcing 3. American Association of State Highway and

of the head projected onto a plane orthogonal bar and to satisfy specific requirements for Transportation Officials (AASHTO). 2020.

to the longitudinal axis of the bar minus the head dimensions AASHTO LRFD Bridge Design Specifications,

bar cross-sectional area. This area represents 9th ed. Washington, DC: AASHTO.

the contact surface between the head and the Note that ASTM A970 requires headed bars to 4. ACI Committee 318. 2019. Building Code

concrete where the bar tensile force is transferred develop 100% of the minimum specified tensile Requirements for Structural Concrete (ACI

to the concrete through compressive stress. strength of the reinforcing bar, whereas the 318-19) and Commentary (ACI 318R-19).

AASHTO LRFD specifications Article 5.10.8.4.2b Farmington Hills, MI: ACI.

ASTM A970 requires tensile testing of the full- requires mechanical couplers to develop 125% __________

size reinforcing bar with a head attached to one of the specified yield strength. ACI 318-19 Dr. Henry G. Russell is an engineering

end. The tensile properties of the headed bar Subsection 20.2.1.6 requires the use of Class HA consultant and former managing technical

shall conform to one of the following classes: head dimensions, but Subsection 25.4.5.1 also editor of ASPIRE®. He has been involved

• Class A: Required to develop the minimum permits the use of any other type of mechanical with applications of concrete for bridges

specified tensile strength of the reinforcing bar anchorage capable of developing the yield for over 45 years and has published

• Class B: Required to develop both the strength of the reinforcing bar, provided it is many papers on the applications of high-

minimum specified tensile strength and approved by the building official. performance concrete.

EPOXY INTEREST GROUP

® Information You Can Trust.

To learn more about the many benefits

Epoxy-Coated of epoxy-coated reinforcing steel visit . . .

www.epoxyinterestgroup.org

Reinforcing Steel

COST-EFFECTIVE

CORROSION

PROTECTION

Follow us on

18174_EIG_Aspire_Summer_2018_ad.indd 1 5/22/18 9:55 AM

40 | ASPIRE Fall 2020

You might also like

- Working Platform For Tracked Plant - BR470 Guideline and Revised ApproachDocument6 pagesWorking Platform For Tracked Plant - BR470 Guideline and Revised ApproachDanny LamNo ratings yet

- Astm F1554-18Document8 pagesAstm F1554-18Mohamad Arraj100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Diagrama Hydraulico Caterpillar 950 GCDocument11 pagesDiagrama Hydraulico Caterpillar 950 GCJose PichinteNo ratings yet

- Steel Interchange: Code of Standard Practice Hss Connections in OmfsDocument2 pagesSteel Interchange: Code of Standard Practice Hss Connections in Omfshector diazNo ratings yet

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDocument2 pagesSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazNo ratings yet

- CFSEI Tech Note X Bracing L001-09Document8 pagesCFSEI Tech Note X Bracing L001-09Jane EyreNo ratings yet

- EJ Fisher BracingwithJoistsDocument6 pagesEJ Fisher BracingwithJoistsGabby KenNo ratings yet

- Elementos de Conexión Pernos y SoldadurasDocument83 pagesElementos de Conexión Pernos y Soldadurasmiguel vilchez bachiaoNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- 2006v11 Si WebDocument2 pages2006v11 Si Webel.salumbidesNo ratings yet

- June2017-AnchorBoltsDocument4 pagesJune2017-AnchorBoltsAlireza RanjbarianNo ratings yet

- Design of Connections GateDocument25 pagesDesign of Connections GateShaik Mastan ValiNo ratings yet

- Ghali Et All - Headed Studs in Concrete State of The ArtDocument11 pagesGhali Et All - Headed Studs in Concrete State of The ArtbllldNo ratings yet

- 1 s2.0 S0950061818322256 MainDocument9 pages1 s2.0 S0950061818322256 MainVishal NaikNo ratings yet

- 2003v04 Si WebDocument2 pages2003v04 Si WebMohanNo ratings yet

- 2009 ACIStructJ LubellBentzCollins SpacingDocument10 pages2009 ACIStructJ LubellBentzCollins SpacingrohitNo ratings yet

- Reinforcing SteelDocument8 pagesReinforcing SteelPrittam Kumar JenaNo ratings yet

- Pre-Fabricated Punching Shear ReinfDocument4 pagesPre-Fabricated Punching Shear ReinfJose ManjooranNo ratings yet

- Boltingwelding January 2014Document84 pagesBoltingwelding January 2014SenthilNo ratings yet

- Aircraft RivetsDocument51 pagesAircraft Rivetsaanand.mce80% (10)

- Galvanized Slip-Critical ConnectionsDocument2 pagesGalvanized Slip-Critical Connectionsaams_sNo ratings yet

- FAQs About Headed Reinf Bars - ETN-M-3-14Document8 pagesFAQs About Headed Reinf Bars - ETN-M-3-14MukarramuddinNo ratings yet

- Site FixesDocument4 pagesSite FixesBalaji SampathNo ratings yet

- Barsplicer Brochure RevADocument4 pagesBarsplicer Brochure RevAaltipatlarNo ratings yet

- (Code) ACI 349.2R-97 Embedment Design Examples (ACI, 1997)Document26 pages(Code) ACI 349.2R-97 Embedment Design Examples (ACI, 1997)sungwgNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- High-Strength Reinforcement in Exterior Beam-Column Joints Under Cyclic LoadingDocument14 pagesHigh-Strength Reinforcement in Exterior Beam-Column Joints Under Cyclic LoadingRafie Itharani UlkhaqNo ratings yet

- Bar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsDocument11 pagesBar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- Irjet V8i1007Document5 pagesIrjet V8i1007Diwakar Singh RajputNo ratings yet

- 98 Tips: For DesigningDocument6 pages98 Tips: For DesigningKarthikeyan KrishNo ratings yet

- Pre-Pub FinalPaperDocument8 pagesPre-Pub FinalPaperZiyad KubbaNo ratings yet

- Si 10 2013 PDFDocument2 pagesSi 10 2013 PDFhector diazNo ratings yet

- Improve Design For Steel Reinforcement of The Traditional Design Used by Decreasing The Number of Steel TiesDocument4 pagesImprove Design For Steel Reinforcement of The Traditional Design Used by Decreasing The Number of Steel TiesEditor IJTSRDNo ratings yet

- Astm A970mDocument7 pagesAstm A970mKarma AlgorithmNo ratings yet

- UNIT-III Design of Fasteners and Welded Joints: Session - 1Document18 pagesUNIT-III Design of Fasteners and Welded Joints: Session - 1Narendra ChavdaNo ratings yet

- Designing With Structural TubingDocument9 pagesDesigning With Structural TubingrilopiyNo ratings yet

- Fasteners-Technical Data and ChartsDocument15 pagesFasteners-Technical Data and ChartsChrill DsilvaNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 33Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 33behnam fallahNo ratings yet

- Old Rebar EDR 48Document4 pagesOld Rebar EDR 48JimBobNo ratings yet

- AISC Steel Design Q&ADocument2 pagesAISC Steel Design Q&Astormyshen0920No ratings yet

- Cyclic Response of Exterior Beam-Column Joints With Different Anchorage MethodsDocument11 pagesCyclic Response of Exterior Beam-Column Joints With Different Anchorage MethodsErikEspinoNo ratings yet

- SQ 17Document2 pagesSQ 17Alparslan GureNo ratings yet

- C 955 Â " 00 QZK1NS0WMEEDocument4 pagesC 955 Â " 00 QZK1NS0WMEESebastián RodríguezNo ratings yet

- Design of Anchor Bolts in PedestalsDocument10 pagesDesign of Anchor Bolts in PedestalsVertical Starter100% (6)

- Stress-Strain Relationship of High-Strength Steel (HSS) Reinforcing BarsDocument9 pagesStress-Strain Relationship of High-Strength Steel (HSS) Reinforcing BarsAISWARYA K VIJAY M.Tech CASE 2021-2023No ratings yet

- Steel Monopoles Steel Monopoles: R. Balagopal and N. Prasad RaoDocument139 pagesSteel Monopoles Steel Monopoles: R. Balagopal and N. Prasad RaoSube OhNo ratings yet

- Slip Track Design Tn-W100-08aDocument4 pagesSlip Track Design Tn-W100-08aZebNo ratings yet

- Cyclic Response of Exterior Beam-Column Joints With Different Anchorage MethodsDocument11 pagesCyclic Response of Exterior Beam-Column Joints With Different Anchorage MethodspaulkohanNo ratings yet

- Lecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesDocument20 pagesLecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesSulabh GuptaNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- HSS Steel AvailabilityDocument2 pagesHSS Steel Availabilityaams_sNo ratings yet

- Perforated CoreDocument13 pagesPerforated Coreh.ezatisazehNo ratings yet

- ASTM BoltsDocument3 pagesASTM BoltsAnonymous IwqK1NlNo ratings yet

- 10 04 13Document55 pages10 04 13Edu HernándezNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- Brenner - Bridginess More of The Civil Engineering Life (2009)Document240 pagesBrenner - Bridginess More of The Civil Engineering Life (2009)Farja_ZzzNo ratings yet

- NCh3171 2017Document16 pagesNCh3171 2017Farja_ZzzNo ratings yet

- Technical Manual For Design and Construction of Road Tunnels. US Departmento of TransportationDocument30 pagesTechnical Manual For Design and Construction of Road Tunnels. US Departmento of TransportationFarja_ZzzNo ratings yet

- 117M 10Document81 pages117M 10Farja_Zzz0% (1)

- ProjectLibre ShortcutsDocument1 pageProjectLibre ShortcutsFarja_ZzzNo ratings yet

- Tilting Process PanelDocument225 pagesTilting Process PanelSäbrinä Shukrì100% (1)

- 2019 Book StateOfTheArtAndFutureTrendsIn PDFDocument530 pages2019 Book StateOfTheArtAndFutureTrendsIn PDFDionisis SpiliopoulosNo ratings yet

- Shear WallDocument119 pagesShear WallZuzar100% (3)

- Lecture 9 - Humidification and Water CoolingDocument2 pagesLecture 9 - Humidification and Water CoolingHirun ManujayaNo ratings yet

- Physics Lab Report 4 Circular Motion: FIE-School of Engineering Taylor's UniversityDocument12 pagesPhysics Lab Report 4 Circular Motion: FIE-School of Engineering Taylor's UniversityTaima GhNo ratings yet

- Derivation of Class x1 Part 2Document5 pagesDerivation of Class x1 Part 2Chittransh SharmaNo ratings yet

- Serge Abrate-Impact On Composite Structures (1998) PDFDocument301 pagesSerge Abrate-Impact On Composite Structures (1998) PDFShree Biradar0% (1)

- Datasheet Flygt 2201 012 HT-MT 60hz En-UsDocument2 pagesDatasheet Flygt 2201 012 HT-MT 60hz En-UsCristhian Vilca SilvestreNo ratings yet

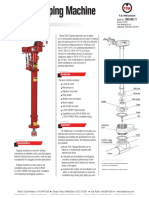

- Hot TappingMachine 760Document6 pagesHot TappingMachine 760Anonymous 7xbdR5No ratings yet

- Chapter 14 Kinetics of Particle - Work EnergyDocument37 pagesChapter 14 Kinetics of Particle - Work EnergyISLAMIC VOICENo ratings yet

- Linked PDFDocument43 pagesLinked PDFMarcelo AguirreNo ratings yet

- GNPHYS 1 - Worktext - WEEK 12 - Lab Activity - LLORENDocument3 pagesGNPHYS 1 - Worktext - WEEK 12 - Lab Activity - LLORENRussell JamesNo ratings yet

- Air/Hydraulic Bottle Jack: Operating Instructions and Parts ManualDocument8 pagesAir/Hydraulic Bottle Jack: Operating Instructions and Parts ManualMutiara DamayNo ratings yet

- Ferti JetDocument19 pagesFerti JetCèsar Daniel Linares QuirozNo ratings yet

- Sistema Inyección CR BoschDocument8 pagesSistema Inyección CR BoschRodolfo Leiva100% (1)

- 5.4 Design of Doubly Reinforced BeamsDocument17 pages5.4 Design of Doubly Reinforced BeamsMarcelo AbreraNo ratings yet

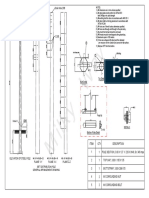

- 30FT 35FT 40FT 45FT DrawingsDocument4 pages30FT 35FT 40FT 45FT DrawingsPrefer Electrical Engineering And SupplyNo ratings yet

- NENMANIKARADocument143 pagesNENMANIKARAsandeep perumanaNo ratings yet

- Company Catalogue - Kaifeng Fantai FlowmeterDocument42 pagesCompany Catalogue - Kaifeng Fantai FlowmeterMark WangNo ratings yet

- Water Meter Guidelines & SpecificationsDocument19 pagesWater Meter Guidelines & SpecificationsSrujan GuptaNo ratings yet

- EP PlateDocument6 pagesEP Plateraghav abudhabiNo ratings yet

- Module 1. 3100 Fundamental ConceptsDocument16 pagesModule 1. 3100 Fundamental ConceptsTin VillalbaNo ratings yet

- Vehicle Suspension DesignDocument63 pagesVehicle Suspension DesignVenkatesh ChegireddyNo ratings yet

- Randomation Vehicle Physics ManualDocument36 pagesRandomation Vehicle Physics ManualbrokenNo ratings yet

- CraneDocument16 pagesCraneAdrian Franco MolinaNo ratings yet

- Introduction 2Document2 pagesIntroduction 2Ali DandamunNo ratings yet

- Ic Engine ThesisDocument8 pagesIc Engine Thesisafcmunxna100% (1)

- Data Sheet: Synchronous Motor and GearboxesDocument4 pagesData Sheet: Synchronous Motor and Gearboxespenulis kata penulis kataNo ratings yet

- Internal Misalignment SpecDocument12 pagesInternal Misalignment Specmegastar0604No ratings yet