Professional Documents

Culture Documents

04 Sayah

04 Sayah

Uploaded by

Clemente CurnisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Sayah

04 Sayah

Uploaded by

Clemente CurnisCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/324190922

Wasserkraftwerk Cerro del Águila in Peru • Planung und Bau in komplexer

Geologie Cerro del Águila Hydro Power Plant in Peru: Design and Construction

of 12 km Waterways and Utility...

Article · June 2016

CITATIONS READS

0 128

4 authors:

Selim M. Sayah Thüring Manfred

École Polytechnique Fédérale de Lausanne Lombardi SA

39 PUBLICATIONS 50 CITATIONS 13 PUBLICATIONS 220 CITATIONS

SEE PROFILE SEE PROFILE

Marco Braghini Roger Bremen

5 PUBLICATIONS 1 CITATION

Lombardi ltd

38 PUBLICATIONS 424 CITATIONS

SEE PROFILE

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Cerro Del Águila hydro Plant View project

Snowy 2.0- 2100 MW Pump Storage Plant View project

All content following this page was uploaded by Selim M. Sayah on 04 April 2018.

The user has requested enhancement of the downloaded file.

Wasserkraftwerk Cerro del Águila in Peru • Planung und Bau in komplexer Geologie

Selim M. Sayah, Dr. ès sciences, Project Manager, Lombardi Eng. Ltd., Minusio/CH

Manfred Thüring, Dr. phil. nat., Geologist, Lombardi Eng. Ltd., Minusio/CH

Marco Braghini, Engineer, Head of Hydraulic Section, Lombardi Eng. Ltd., Minusio/CH

Roger Bremen, Dr. ès sciences techniques, CEO, Lombardi Eng. Ltd., Minusio/CH

Cerro del Águila Hydro Power Plant in Peru

Design and Construction of 12 km Waterways and Utility Tunnels

in complex Geology

The Cerro del Águila project in Peru is a major hydropower scheme presently being commissioned and

scheduled to be opened in July 2016. This new 520 MW scheme includes a 90 m high roller-compacted

concrete (RCC) gravity dam, around 12 km of hydraulic and utility tunnels and two underground caverns

for turbines/generators and transformers/GIS, all excavated by drill and blast. This article deals with the

design and construction of the tunnels, highlighting several construction issues.

• The Guitarra Project, a short distance downstream from

1 Background the eponymous Guitarra curve. After almost 25 years of

1.1 Project History consideration, this Guitarra Project (1983) was redefined

The Cerro del Águila project in Peru [1] is the third hydro pro- and renamed Cerro del Águila Project.

ject cascade scheme to be constructed on the Mantaro river.

It is situated downstream from the existing SAM/Restitución After its acquisition by Kallpa Generación S.A., the elabora-

hydro plants. Originally, another project was planned to de- tion of the pre-feasibility study of the project and prelimi-

velop the second curve practically down to its confluence nary geological investigations and analyses were commis-

with the Apurimac River. This project would have included sioned in about 2008 from the Peruvian Consultancy firm

a long low pressure tunnel and a 250 m high dam situated JByA (Julio Bustamante y Asociados EIRL) with a view to

downstream of the Colcabamba river confluence in order inviting tenders for an Engineering, Procurement and Con-

to include the discharge provided by the additional catch- struction (EPC) contract. In November 2011, Astaldi S.p.A

ment area and the additional head between the SAM HPP from Italy and their joint venture partner Graña y Montero

tail water level and the Mantaro river. SAA from Peru won the EPC contract to build the scheme.

Lombardi SA was chosen later as the main designer for the

After a large scale landslide occurred in the Mayunmarca project.

area in 1974 [2–3], which demonstrated the apparent vulner-

ability of the valley side stability, the idea of implementing a 1.2 Location

very high dam was abandoned and partially substituted by The project area is situated around 270 km from the capital

the following scheme: Lima, at the second curve of the Mantaro River in a stretch,

• The Restitución Project to develop the remaining 250 m where the river flanks are relatively steep, between 1,600

head between the SAM HPP tailrace and the Mantaro river. and 1,200 m above sea level. It lies in the jurisdiction of the

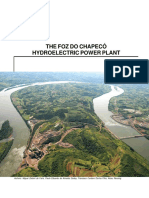

Quelle/credit: Selim M. Sayah

Quelle/credit: Selim M. Sayah

1 (a) Dam axis in the Mantaro River, headrace tunnel located on the right-hand side; (b) Valley formation downstream, location of the

underground powerhouse and tailrace tunnel on the right-hand side

2 S WIS S T UNNEL CONGRE SS 2 01 6

Cerro del Águila Hydro Power Plant in Peru • Design and Construction in complex Geology

Wasserkraftwerk Cerro del Águila in Peru

Planung und Bau von 12 km Wasserstrassen und Versorgungstunnel

in komplexer Geologie

Das Wasserkraftwerk Cerro del Águila mit einer Leistung von 520 MW wird derzeit in den peruanischen Anden in Betrieb

genommen und soll im Juli 2016 ans Netz gehen. Das Projekt umfasst den Bau einer 90 m hohen Schwergewichtsstaumauer

aus Walzbeton, eines 7,6 km langen Systems aus Zu- und Ablauftunneln mit etwas mehr als 90 m² Hufeisen-Querschnitt,

eines 242 m hohen Druckschachtes, eines Komplexes mit zwei unterirdischen Kavernen sowie mehrere Wasserschlösser,

Zugangs- und Bautunnel. Alle unterirdischen Bauten wurden im Sprengvortrieb ausgeführt. Besondere Herausforderungen

traten auf durch Gebirgsschlag, Abplatzungen, extreme Konvergenzen im Druckstollen durch mehr als 1600 m Überdeckung

sowie weitere bautechnische Einschränkungen.

Centrale hydroélectrique de Centrale idroelettrica

Cerro del Águila au Pérou Cerro del Águila in Perù

Étude et construction de 12 km de Progettazione e costruzione di 12 km

voies d’eau et d’un tunnel de service di vie navigabili e gallerie di riforni-

en milieu géologique complexe mento con una geologia complessa

D’une capacité de 520 MW, la centrale hydroélectrique Cerro La centrale idroelettrica di Cerro del Águila con un rendi-

del Águila, dans les Andes péruviennes, est actuellement en mento di 520 MW che viene attualmente messa in servi-

phase de mise en route et doit être raccordée au réseau en zio nelle Ande peruviane, sarà collegata alla rete elettrica

juillet 2016. Le projet comprend la construction d’un barrage- nel luglio 2016. Il progetto include la costruzione di una

poids en béton compacté au rouleau (BCR), d’un système de diga a gravità mediante calcestruzzo rullato e compattato

7,6 km de longueur comprenant une galerie d’amenée et une (RCC) alta 90 m, di un sistema gallerie di affluenza e di

galerie de restitution, dont la section en forme de fer à cheval scolo con sezione a ferro di cavallo da più di 90 m², una

est d’un peu plus de 90 m², d’un puits vertical de 242 m de condotta forzata alta 242 m e un complesso formato

haut, d’un complexe composé de deux cavernes souterraines da due caverne sotterranee come anche da vari torrini

ainsi que de plusieurs châteaux d’eau, tunnel d’accès et tun- piezometrici, gallerie di accesso e gallerie artificiali. Tutte

nel de chantier. Tous les ouvrages souterrains ont été exécu- le costruzioni sotterranee sono state eseguite con avan-

tés en excavation à l’explosif. La réalisation a été confrontée zamento per mezzo di esplosioni. Particolari difficoltà

à des défis particuliers, générés par des éboulements de sono insorte a causa di improvvise fratturazioni, carbona-

masses rocheuses, fissures, convergences extrêmes dans la tazione di calcestruzzi, estreme convergenze in condotte

galerie d’amenée du fait d’une couverture de plus de 1600 m di pressione con una copertura di più di 1600 m, come

et autres conditions limitatives en termes de construction. anche altre tipologie costruttive.

Pampas, Colcabamba and Salcabamba districts belonging to ites/granodiorites (Figs. 2a and 2b) [4]. The high grade meta-

Tayacaja Province in the Huancavelica region. morphic rocks belong to the Ambo-Copacabana group of

probably Paleozoic age and are composed of hornfelses,

With regard to the morpho-structural aspects that character- skarns and marbles. The granites/granodiorites belong

ize Peruvian territory, the area is located on the western slopes to the Villa Azul Batholith group, intrusives dated around

of the Oriental Cordillera de los Andes in central Peru on the Cretaceous to Tertiary.

Amazonian watershed (Figs. 1a and 1b). The area can be

reached from Lima along the Central Highway to the town of The intrusive contact between the two bedrock lithologies

Pampas. From this location, an unpaved road passing through is likely to be crossed by the headrace tunnel under an over-

the Colcabamba District and the localities of Andaymarca and burden of 900 m. The dam and the major part of the head-

Durasnuyoc reaches the site area. The powerhouse area is race tunnel are thus in granites/granodiorites, whereas the

accessible on the unpaved road of the Salcabamba District. remaining project structures (smaller part of headrace tun-

nel, pressure shaft, power house, and tailrace tunnel) are in

metamorphic rocks.

2 Site Geology

The tunnels are located in the pre-mesozoic basement of The granites/granodiorites are white to rose coloured with

metamorphic, pelitic to calcareous rocks, intruded by gran- good intact rock properties, but generally of lower quality

S WIS S T UNNEL CONGRE SS 2 01 6 3

Wasserkraftwerk Cerro del Águila in Peru • Planung und Bau in komplexer Geologie

Quelle/credit: Selim M. Sayah

Quelle/credit: Selim M. Sayah

2 The two bedrock lithologies: (a) Granites/granodiorites and (b) metamorphic rocks

Quelle/credit: Selim M. Sayah

3 Up to 100 m high remnants of colluvial material, left over from erosion

than the metamorphic rocks. The rock mass can show a con- or terraces. Particular colluvial deposits, most likely of re-

siderable degree of fracturing and alteration at depth, dete- mobilized slope debris and glacial deposits, of impressive

riorating the rock mass quality. thickness (up to 150 m) can be found in the power house/

tailrace area (Fig. 3). These deposits are organized in a series

The metamorphic rocks are aluminosilicate-rich to carbon- of terraces and composed of a mixture of boulders, cobbles

ate-rich rocks (paragneisses, hornfelses, skarns) with less fre- and gravel in a silty-sandy matrix showing high (short-term)

quent interlayers of amphibolites. These high strength rocks slope stability. The deposits are interlayered by rockslides

of very good intact rock quality generally show good rock at the frontal part of the terraces located at the right bank

mass quality, which in some cases is deteriorated by the local of Río Mantaro, in the area of the initial part of the tailrace

structural conditions. tunnel.

The Quaternary deposits are predominantly of colluvial Fig. 4 shows the geological situation at the project site. The

or alluvial nature. Alluvial deposits are organized as fans dam site and 75 % of the headrace tunnel are in granites/

4 S WIS S T UNNEL CONGRE SS 2 01 6

Cerro del Águila Hydro Power Plant in Peru • Design and Construction in complex Geology

granodiorites. The headrace tunnel crosses the original intru- underground works and excavation have been com pleted.

sive contact of the granites to the surrounding metamorphic Two adits were built for the headrace tunnel and two

rocks at roughly 4.25 km. The remaining part (25 %) of the adits for the tailrace tunnel. Table 1 shows the main char-

headrace tunnel, the power house, and tailrace tunnel are all acteristics of each scheme. This table also illustrates the

in metamorphic rocks. excavation advance rates for each tunnel. An average rate

of 6.8 m/day was achieved in the main headrace tunnel.

Although the tailrace tunnel has the same section, it was

3 Waterway System and Access Tunnels excavated at a faster rate of around 8.1 m/day. This differ-

3.1 Main Characteristics and Rock Support ence is mainly explained by the fact that the headrace tun-

The main tunnels and schemes of the project are illustrat- nel has sections with more than 1600 m rock overburden

ed in Fig. 5. This corresponds to around 12 km of tunnels and is thus prone to rockburst. This slowed the excavation

excavated using the conventional drill and blast method. rate due to all the support measures that were taken dur-

The project is presently being commissioned and all the ing excavation.

Quelle/credit: Selim M. Sayah

4 Geological profile along the main waterway system

Quelle/credit: Selim M. Sayah

5 Waterway system and utility tunnels/shaft of Cerro del Águila HPP

S WIS S T UNNEL CONGRE SS 2 01 6 5

Wasserkraftwerk Cerro del Águila in Peru • Planung und Bau in komplexer Geologie

Excavation rate

Waterway Length [m] Section [m2] Rock type

[m/day]

Headrace tunnel 5738 91.5 Granite/Granodiorite/Gneiss 6.8

Upper surge tunnel 483 60 Gneiss 1.8

Pressure shaft (raise bored, D = 4 m) 242 12.56 Gneiss 12.7

Pressure shaft (D & B, D = 10 m) 242 78.5 Gneiss 1.3

High pressure penstock 140 57.3 Gneiss 3.5

Draft tubes (3 tunnels) 280 32 Gneiss –

Lower surge tunnel 647 35.2–91.5 Gneiss –

Tailrace tunnel 1891 91.5 Gneiss 8.1

Derivation tunnel 326 104 Granite 2.7

Access tunnels/cable ways

Adit 1 headrace 95 46.7 Granite 0.8

Quelle/credit: Selim M. Sayah

Adit 2 headrace 452 46.7 Gneiss 1.7

Powerhouse access tunnel 606 46.7 Gneiss 1.7

Cable shaft (raise bored, D = 4 m) 191 12.56 Gneiss 3.8

Cable tunnel 166 35 Gneiss 1.8

Adit 1 tailrace 264 35 Gneiss 1.8

Table 1 Tunnels and shafts characteristics of Cerro del Águila project, lithology and excavation rate

The pressurized headrace tunnel conveys the water dis- tunnel is similar to that of the headrace tunnel though with a

charge of 210.5 m3/s from the power intake to the pressure smaller area (Table 1). It has a 13 % slope and it is 483 m long.

shaft. It is almost 5.7 km long, with a slope of 0.34 %. The

cross section of the headrace tunnel is illustrated in Fig. 6. The pressure shaft is the vertical connecting element between

It is a simplified horseshoe shape with a horizontal invert. the low pressure headrace tunnel and the high pressure mani-

Fig. 6 also shows the support system of rock type B. fold section. It is 242 m high with an 8 m internal diameter

and a 10 m excavation diameter. Based on several concluding

The excavation of the unlined headrace tunnel was carried hydrojacking tests carried out along the entire height of the

out simultaneously from two adits. The first one is situated shaft, the steel lining of this shaft was omitted. The final lining

at the first Mantaro River curve downstream of the dam axis consists of 1 m thick watertight reinforced concrete.

while the second adit is close to the downstream end of the

tunnel at the connection with the pressure shaft. This adit The manifold is the set of steel-lined high pressure tunnels

was also used to access the upper surge tunnel and the verti- between the vertical shaft and the 3-turbine system. The

cal shaft. Only permanent support measures were applied, internal tunnel diameter decreases from 6.00 m to 3.385 m.

depending on rock quality. This included grouted anchors, The total length of the manifold is around 140 m.

shotcrete and steel ribs. Special protection provisions were

applied in case of rockburst due to the high overburden The tailrace tunnel is about 1.9 km long, sloping down at

(around 1,600 m and the centre of the tunnel). All the rock 0.21 % (Figs. 5 and 7). The typical section of this tunnel is

support classification followed the Q System of Barton. This a replica of the headrace tunnel section. This tunnel is de-

rock classification system was specified in the contract by signed to be a pressurized scheme with a submerged outlet

the owner. Since the tunnel arch is more than 10 m high, a structure. This solution provides better protection of the en-

protective shotcrete layer with a thickness of at least 5 cm tire tailrace system during the passage of floods and allows

was always applied to the arch, even in rock of very good an increase of net head.

quality.

In order to avoid depressurized sections in the upstream part

The aim of the upper surge tunnel (Fig. 7) is to allow free of the tailrace tunnel close to the draft tube outlet during

water oscillation in the tunnel during emergency shut-down simultaneous emergency shut-down of the turbine system,

or start-up of the turbines. During mass oscillation, the a lower surge tunnel was built. The aim of this tunnel is to

maximum and minimum surge levels are 1,570.00 m asl and ensure sufficient head during emergency shut-down of the

1,537.00 m asl, respectively. The tunnel is equipped with an turbine in such a way that the piezometric level in the draft

orifice consisting of a 7 m long and 3.3 x 3.3 m steel-lined tube outlet section connecting to the tailrace tunnel remains

cross section, which enables a reduction of the maximum within an acceptable range. The required surface for mass

surge level by around 10 m. The typical section of the surge oscillation is around 3,000 m².

6 S WIS S T UNNEL CONGRE SS 2 01 6

Cerro del Águila Hydro Power Plant in Peru • Design and Construction in complex Geology

In this test, water is injected into borehole sections de limited

by packers. The water pressure is increased until existing

joints are opened. To ensure proper functioning, these pres-

sures must stay below the operating pressures, otherwise the

pressure shaft would have to be waterproofed with a lining.

Fig. 8 shows the measured hydrojacking pressures together

with the static pressures imposed by the water conveyance

system. As can be seen, the rock mass is subject to open-

ing of existing joints at pressures in the range of the opera-

tional pressures down to a certain depth. This indicates the

Quelle/credit: Selim M. Sayah

presence of a superficial zone of reduced rock mass quality

where fractures may open and water may circulate freely,

resulting in water loss. Waterproofing of the pressure shaft

is thus necessary down to a certain depth, especially at the

fault crossings and also close to the powerhouse.

6 Typical section of the headrace/tailrace system Fig. 9 depicts the grouting scheme that was applied along

the pressure shaft. In the lower high pressure section, around

In the following section, a few highlights of the pressure shaft 76 m of grouting was applied at a high pressure of 40 bar.

design are described. This scheme is of special importance The grouting of this section was independent of rock qual-

since it allows vertical water transfer from the low-pressure ity. The main purpose was to limit water infiltration during

to the high-pressure system where turbines are installed. operation from the shaft to the powerhouse cavern situated

at around 50 m. Moreover, in the middle of the shaft, where

3.2 Pressure Shaft a crossing fault was observed during the primary investiga-

The water tightness of the 242 m high pressure shaft was tion, another section was grouted at a slightly lower pres-

tested by hydrojacking tests in nearby boreholes, which sure of 35 bar. The grouting of this section was intended to

crossed the pressure shaft down to its bottom. increase the rock quality. It should also be mentioned that

Quelle/credit: Selim M. Sayah

7 Close-up of the downstream complex underground schemes

S WIS S T UNNEL CONGRE SS 2 01 6 7

Wasserkraftwerk Cerro del Águila in Peru • Planung und Bau in komplexer Geologie

4 Rockburst

4.1 Rockburst Analysis and proposed Rock Support

A major concern for the excavation of the headrace tun-

nel was the risk of spalling and rockburst. The tunnel passes

under a maximum overburden of more than 1600 m. The rock

burst risk had been evaluated using the classical approaches,

which relate the compressive strength of the intact rock to the

overburden stress, accounting for the excavation geometry

and the expected in-situ stress condition [6–7].

Fig. 10 shows the first estimate based only on the ratio of the

intact compressive strength and overburden stress for both

lithologies, granites/granodiorites and metamorphic rocks.

According to this and a more detailed evaluation, there was

a considerable risk of rockburst in intact sections, particu-

larly in the granites/granodiorites. For this bedrock lithology,

damage initiation may occur under an overburden of 500 m,

and will then develop to spalling. Rockburst may be present

with an overburden in excess of 1,150 m.

The section of the headrace tunnel in metamorphic rocks

is less vulnerable. Due to the higher compressive strength

Quelle/credit: Selim M. Sayah

and lower overburden, damage initiation may occur under

600 m overburden, and the condition for rockburst may not

be reached. Consequently, excavations needed to be accom-

panied by a monitoring concept and protective measures in

case of elevated rockburst risk.

8 Results of the hydrojacking tests made along the entire height Fig. 11 shows the support system (C2) suggested for the sec-

of the pressure shaft tions of the headrace tunnel susceptible to rockburst. This

support system includes systematic cement grouted rock

bolting in the arch as well as in the tunnel walls, reinforce-

ment of the roof with cone bolts and wire mesh, 15 cm of

shotcrete in the entire section and 5 cm of shotcrete to the

tunnel face. This protection was applied systematically when

the rock overburden was above 900 to 1,000 m and rock UCS

higher than 100 MPa. This reduced rockburst and thus avoid-

ed total collapse of the roof and tunnel walls.

4.2 Rockburst Events and Protection

Several events of mild to strong rockburst (3 to 4) were en-

countered during the excavation of the headrace tunnel.

One of the strongest events occurred during the evening of

November 14, 2014. A strong explosion-like noise was heard

at around 9 pm. The damage report indicated a 10 m extent

of limited collapse of the tunnel arch. Rock and protective

Quelle/credit: Selim M. Sayah

shotcrete were projected and the installed rock bolts were

destroyed (Fig. 12). This event occurred at a shallow overbur-

den of around 830 m. After this event, the application of rock

support C2 as mentioned before was adopted.

Concerning the protection and support measures that were

9 Grouting and concrete lining scheme of the pressure shaft adopted, some of the main actions applied during the exca-

vation are listed below:

the reinforced concrete lining and the water infiltration rate • Rock de-tension blasting: before carrying out the main

estimation were carried out using the theory developed by blasting, low charged blasting carried out deep behind the

Schleiss (1997) [5]. main blasting hole.

8 S WIS S T UNNEL CONGRE SS 2 01 6

Cerro del Águila Hydro Power Plant in Peru • Design and Construction in complex Geology

Quelle/credit: Diederichs M.S., Kaiser P.K., Eberhardt E.

10 Rockburst risk applied to the headrace tunnel conditions

• Rock bolts are only grouted after several days. A mechanical • Curved face excavation (convex).

head was used to grip the bolt. • It was noticed that the next 8 hours after the blasting are the

• Steel cages for workers working close to the tunnel most dangerous and when rockburst has mostly occurred.

(shotcrete nozzle man, topography, etc.).

• Areas with limited access (Fig. 13): no access allowed sev- Table 2 lists a detailed description for rockburst identifica-

eral metres from the newly blasted face or to the walls, etc. tion and the measures adopted.

Quelle/credit: Selim M. Sayah

Quelle/credit: Selim M. Sayah

11 Proposed rock support of tunnel sections prone to rock burst 12 Rockburst event in the headrace tunnel

S WIS S T UNNEL CONGRE SS 2 01 6 9

Wasserkraftwerk Cerro del Águila in Peru • Planung und Bau in komplexer Geologie

5 Conclusions and Acknowledgments race tunnel, and all the support and protection measures

In this article a description of all the waterway system and that were introduced.

utility tunnels has been provided with some highlights of

construction procedures and excavation. An analysis has The authors acknowledge the assistance of the contractor

been given of the pressure shaft, which is considered a key Consorcio Rio Mantaro (Astaldi S.p.A. and Graña y Montero

scheme. Also highlighted were the rockbust theory and SAA.) and the owner of the scheme Cerro del Águila S.A.

events that occurred during the excavation of the headrace (Kallpa S.A.) for their fruitful collaboration.

Quelle/credit: Selim M. Sayah

13 Protection measures adopted against rockburst during tunnel excavation

10 S WIS S T UNNEL CONGRE SS 2 01 6

Cerro del Águila Hydro Power Plant in Peru • Design and Construction in complex Geology

Behavior Q Phenomena Measures Support

RB0 • Cracking noise • Decree use of danger zones

Strain relief • Rumbling noise • Shotcrete to excavation face

• Poss. curved excavation face, –

leave excavated material at face

• Poss. anchors to excavation face

RB1 • Popping noise • Anchors to excavation face

Spalling • Dust formation • Poss. curved excavation face

• laty detachments < 5 m3 at face with depth

P • Leave excavated material at face

C1

< 1 m during cleaning • Use cone bolts according to

structural condition

• Apply protection mesh locally

RB2 • Strong popping noise • Systematically use cone bolts

0.5 to 40

Minor rockburst • Popping noises 3–6 hours after blasting • Systematic application of

• Dust clouds from crown protection mesh

• Detachments from face before cleaning • Anchors to excavation face

(< 5m3) • Curved excavation face

• Previously set anchor plates deform • Leave excavation material at face

RB3 • V

ery strong, explosion-like noise with several A

dditionally to previous measures:

C2

Heavy rockburst following noises • P oss. apply steel cable lacing

• Popping noises after > 3 hours

Quelle/credit: Selim M. Sayah

• Depending on damage situati-

• Detachment of formerly applied shotcrete on: densify systematic anchors,

• Detachment of shotcrete at face reinforce anchors to face

• Detachments at face > 5 m3 before cleaning • Apply relief blasts

• Overprofile • Document event

• T orn out anchor heads in side walls

Table 2 Different levels of rock spalling and rockburst and the support measures adopted

Literatur/References

[1] S. M. Sayah et al., 2013. Cerro del Águila 510 MW hydro power project of Cerro del Águila (Peru), World Tunnel

plant: The new Peruvian challenge, Hydropower and Congress 2014, Iguassu Falls, Brasil.

Dams, Innsbruck, Austria. [5] Schleiss, A.J., 1997. Design of reinforced concrete linings

[2] Hutchinson, J.N. and Kojan, E., 1975. The Mayunmarca of pressure tunnels and shafts.

Landslide of 25 April 1974, UNESCO report. [6] Diederichs M.S., Kaiser P.K., Eberhardt E., 2004. Damage

[3] S. M. Sayah et al., 2013. Cerro del Águila Gravity Dam in initiation and propagation in hard rock during tunnel-

Perú: Between Feasibility and Challenges, ICOLD Euro- ling and the influence of near-face stress rotation. Int. J.

pean Club Symposium, Venice, Italy. of R. Mech & Min. Sci., 41, 785–812.

[4] M. Thüring et al., 2014. Overcoming the geological [7] Hoek E. and Brown T.H., 1980. Underground excavations

and design related challenges of the 510 MW hydro- in rock. Inst. of Min. and Metall., London, 527 pp.

S WIS S T UNNEL CONGRE SS 2 01 6 11

View publication stats

You might also like

- Caculo Cabaça Hydropower Project: M. Cristina Costa, A. Amador, A. Santo, A. Morgado, A. ChicoDocument13 pagesCaculo Cabaça Hydropower Project: M. Cristina Costa, A. Amador, A. Santo, A. Morgado, A. ChicoMarcelo ProtzNo ratings yet

- Business PlanDocument7 pagesBusiness PlanEphrance100% (2)

- Urban Planning Nairobi Zones 3,4,5Document228 pagesUrban Planning Nairobi Zones 3,4,5musiomi2005No ratings yet

- Tax RemediesDocument16 pagesTax RemediesJoshua Catalla Mabilin100% (1)

- 04 SayahDocument11 pages04 SayahJulianaRpoNo ratings yet

- MohmandDocument52 pagesMohmandM Tanvir AbbasNo ratings yet

- Submitted To: Dr. Ali Shamim: Submitted By: Usman Naeem (11-CE-156)Document12 pagesSubmitted To: Dr. Ali Shamim: Submitted By: Usman Naeem (11-CE-156)KanjarvarNo ratings yet

- Sayah Et Al Hydro2015 FullpaperDocument13 pagesSayah Et Al Hydro2015 FullpaperFelipe AzevedoNo ratings yet

- Porto PrimaveraDocument36 pagesPorto PrimaveraaxeNo ratings yet

- Cana BravaDocument12 pagesCana BravaHelena LeonNo ratings yet

- 4 Carhuaquero Hydroelectric ProjectDocument24 pages4 Carhuaquero Hydroelectric ProjectAmar Pandey100% (1)

- Machadinho Hydropower Plant On The Pelotas RiverDocument26 pagesMachadinho Hydropower Plant On The Pelotas RiverPaula T. LimaNo ratings yet

- Teaser Colca Mining Project - Febrero2018Document12 pagesTeaser Colca Mining Project - Febrero2018chaxaimNo ratings yet

- Mambilla Hydroelectric Power Station ResearchDocument3 pagesMambilla Hydroelectric Power Station Researchajeyetanemmanuel1No ratings yet

- Development of The Geotechnical Baseline Report For The Snowy 2.0 Pumped Storage ProjectDocument19 pagesDevelopment of The Geotechnical Baseline Report For The Snowy 2.0 Pumped Storage ProjectDarshan Babu AdhikariNo ratings yet

- Gibe III Hydropower DamsDocument6 pagesGibe III Hydropower DamsYeison Torres100% (1)

- Upper Kotmale Field VisitDocument6 pagesUpper Kotmale Field VisitIsuru Kasthurirathne50% (2)

- Barra GrandeDocument12 pagesBarra GrandeHelena LeonNo ratings yet

- A Major Step For A Pipeline: Crossing The Serra Do Mar State Park in BrazilDocument11 pagesA Major Step For A Pipeline: Crossing The Serra Do Mar State Park in BrazilDheeraj Chowdary DhanekulaNo ratings yet

- Simplicio Hydroelectric Project On The Paraiba Do Sul RiverDocument30 pagesSimplicio Hydroelectric Project On The Paraiba Do Sul RiverRoberto CuestaNo ratings yet

- FunilDocument16 pagesFunilHelena LeonNo ratings yet

- Mangla Dam Raising ProjectDocument41 pagesMangla Dam Raising ProjectZiaullah100% (1)

- Kaigah HPP - Executive SummaryDocument27 pagesKaigah HPP - Executive SummaryAli Nawaz Khan100% (1)

- Tour Report HAMZADocument8 pagesTour Report HAMZAHamza KhanNo ratings yet

- Project Sheet: Boskalis' Energy Solutions FeaturesDocument2 pagesProject Sheet: Boskalis' Energy Solutions FeaturesZadeh NormanNo ratings yet

- Manampalli and Velamalai Tunnel ReportDocument11 pagesManampalli and Velamalai Tunnel Reportselvakumar subbuNo ratings yet

- Chapter-Ii: Surveys and InvestigationsDocument5 pagesChapter-Ii: Surveys and InvestigationsprakashNo ratings yet

- Yeywa Hydropower Project, An Overview: U. Win Kyaw, U. Myint Zaw, Alan Dredge, Paul Fischer, K. SteigerDocument8 pagesYeywa Hydropower Project, An Overview: U. Win Kyaw, U. Myint Zaw, Alan Dredge, Paul Fischer, K. SteigerNway Oo SaSa HmueNo ratings yet

- 2013 WTC2013Geneve-ChuquicamataUnderground PDFDocument9 pages2013 WTC2013Geneve-ChuquicamataUnderground PDFIvo FritzlerNo ratings yet

- Mangla Dam ReportDocument42 pagesMangla Dam ReportKashi Malik0% (3)

- Planning and Detailed Engineering Design of The 265-M-High Dudhkoshi Concrete Faced Rockfill Dam (CFRD) in NepalDocument12 pagesPlanning and Detailed Engineering Design of The 265-M-High Dudhkoshi Concrete Faced Rockfill Dam (CFRD) in NepalCamilo A PhillipsNo ratings yet

- Progress at The 11,233.1 MW Belo Monte HPP With Its Challenges and Achievements Keynote LectureDocument16 pagesProgress at The 11,233.1 MW Belo Monte HPP With Its Challenges and Achievements Keynote LectureMarcelo ProtzNo ratings yet

- Ba Is e Hydropower ProjectDocument10 pagesBa Is e Hydropower ProjectShreeya SNo ratings yet

- V Nathpa Jhakri HydroplantDocument12 pagesV Nathpa Jhakri HydroplantParth GhanekarNo ratings yet

- Implementation of Infrastructure Projects: 1.1 River RaviDocument37 pagesImplementation of Infrastructure Projects: 1.1 River RaviNavit MahajanNo ratings yet

- Ap Geography 19-9-2022Document9 pagesAp Geography 19-9-2022festivista.cessNo ratings yet

- TBM1Document9 pagesTBM1REDDYGAARI ABBAYINo ratings yet

- Terms and ConditionDocument42 pagesTerms and ConditionSUSOVAN BISWASNo ratings yet

- Hydrology AssignmentDocument9 pagesHydrology Assignmentafi khanNo ratings yet

- dw2018 Paper ArboletalDocument11 pagesdw2018 Paper ArboletalBrandon Jara PizarroNo ratings yet

- Design of The Misicuni Scheme in BoliviaDocument7 pagesDesign of The Misicuni Scheme in BoliviaNabucodonosor1980No ratings yet

- Foz ChapecoDocument26 pagesFoz ChapecoHelena LeonNo ratings yet

- Hydrauic Assg1Document4 pagesHydrauic Assg1Arslan RaoNo ratings yet

- Assignment #02 Irrigation and Hydraulic Structures: The University of Lahore Department of Technology (Civil Division)Document4 pagesAssignment #02 Irrigation and Hydraulic Structures: The University of Lahore Department of Technology (Civil Division)Arfat Naeem NajmiNo ratings yet

- Upgrading of Boundary Dam SpillwayDocument11 pagesUpgrading of Boundary Dam SpillwayJorge MagnoNo ratings yet

- PS-JG Ing-IABSE 291207Document6 pagesPS-JG Ing-IABSE 291207vinfinityindiaNo ratings yet

- (579390026) Caso 8 - Uso de Swellex en Grandes HidroelectricasDocument7 pages(579390026) Caso 8 - Uso de Swellex en Grandes Hidroelectricaskokolito192No ratings yet

- Yeywa RCC ProjectDocument12 pagesYeywa RCC Projectdce_40No ratings yet

- 002 Basha DamDocument6 pages002 Basha DamBilal Nawaz KiyaniNo ratings yet

- Appendix 8.4 - Engineering Method StatementDocument29 pagesAppendix 8.4 - Engineering Method Statementarega amareNo ratings yet

- Geotechnical Design of Underground Infrastructure Works For The Mine Chuquicamata in ChileDocument9 pagesGeotechnical Design of Underground Infrastructure Works For The Mine Chuquicamata in ChileIvonne CalderaNo ratings yet

- Annex 1 - SOW - Mutema-Tanganda Weir and Gravity PipelineDocument32 pagesAnnex 1 - SOW - Mutema-Tanganda Weir and Gravity PipelinekadjididieNo ratings yet

- Published Tunnelling Article in Construction TimesDocument6 pagesPublished Tunnelling Article in Construction TimesDEBASIS BARMANNo ratings yet

- Reporte Tecnico de Hidroituango: Obras HidraulicasDocument7 pagesReporte Tecnico de Hidroituango: Obras HidraulicasNESTOR ALAN GONZALEZ BUCIONo ratings yet

- Railways Tunnels and Airport Case StudyDocument9 pagesRailways Tunnels and Airport Case Study1DS20CV446 Sai Vinay GNo ratings yet

- Cable-Stayed Bridges Across The Panama Canal and The OrinocoDocument8 pagesCable-Stayed Bridges Across The Panama Canal and The Orinocosiva_civil4051100% (1)

- Training ReportDocument35 pagesTraining ReportManisha SharmaNo ratings yet

- Javier Mendoza - ANDDES - RELAVES PERU 20 DEEVDocument23 pagesJavier Mendoza - ANDDES - RELAVES PERU 20 DEEVrolandoh1No ratings yet

- Tunnelling in Weak Zone - A Case Study of Tunnel Construct Ion at Allain Duhangan Hydroelectric ProjectDocument19 pagesTunnelling in Weak Zone - A Case Study of Tunnel Construct Ion at Allain Duhangan Hydroelectric ProjectAnanda Sen100% (1)

- Upper Khimti-2 HPP Desk StudyDocument11 pagesUpper Khimti-2 HPP Desk StudyManoj BaralNo ratings yet

- PFR ReportDocument69 pagesPFR ReportsimplyfabkleanerzNo ratings yet

- Tunnels & Caverns: Looking Back at Forty Years in Underground Construction & EstimatingFrom EverandTunnels & Caverns: Looking Back at Forty Years in Underground Construction & EstimatingNo ratings yet

- Pressure Distribution in Steel-Lined Rock Tunnels and ShaftsDocument5 pagesPressure Distribution in Steel-Lined Rock Tunnels and ShaftsClemente CurnisNo ratings yet

- ThesiS-Ext - Pressure Shell Reinforsed RST PDFDocument171 pagesThesiS-Ext - Pressure Shell Reinforsed RST PDFClemente CurnisNo ratings yet

- $) Xoo') LQLWH (Ohphqw0Rghoiru%Xfnolqj$Qdo/Vlvri6Wliihqhg6Whho/Lqhuv Lq+/Gurhohfwulf3Uhvvx Uh7XqqhovDocument10 pages$) Xoo') LQLWH (Ohphqw0Rghoiru%Xfnolqj$Qdo/Vlvri6Wliihqhg6Whho/Lqhuv Lq+/Gurhohfwulf3Uhvvx Uh7XqqhovClemente CurnisNo ratings yet

- Hydro 2017-Document - HBP-Hot Banded PenstocksDocument11 pagesHydro 2017-Document - HBP-Hot Banded PenstocksClemente CurnisNo ratings yet

- Dr. C. Curnis Bronzetti Amberg Hydro2017 - AbstractDocument1 pageDr. C. Curnis Bronzetti Amberg Hydro2017 - AbstractClemente CurnisNo ratings yet

- #Winyourgame: Amdavad, Let'S Be A Part of The Best Running Experience in This Monsoon SeasonDocument14 pages#Winyourgame: Amdavad, Let'S Be A Part of The Best Running Experience in This Monsoon SeasonDheeraj JOSHI -AWSINDIA-No ratings yet

- Bock, de L.L.M. 4179781, BA Thesis 2017Document29 pagesBock, de L.L.M. 4179781, BA Thesis 2017DutraNo ratings yet

- HTTP Oh - PN Visa Visa-Free Travel For IndiansDocument4 pagesHTTP Oh - PN Visa Visa-Free Travel For IndiansSubratNo ratings yet

- Mock Test in Professional EducationDocument42 pagesMock Test in Professional EducationPrincess LucasNo ratings yet

- Equal Pay For Equal WorkDocument38 pagesEqual Pay For Equal WorkKanish JindalNo ratings yet

- IvatanDocument5 pagesIvatanNerinel CoronadoNo ratings yet

- Annex C.1Document1 pageAnnex C.1Eric OlayNo ratings yet

- CDIS CV PL.1 EcosystemDocument39 pagesCDIS CV PL.1 EcosystemIvanildo CostaNo ratings yet

- Course Outline - FIP - 2023Document5 pagesCourse Outline - FIP - 2023Hiền NguyễnNo ratings yet

- Test Unit 1 Project 4Document3 pagesTest Unit 1 Project 4larakorvinovaNo ratings yet

- Summary of Sons and LoversDocument8 pagesSummary of Sons and Loversachissalud50% (2)

- Fisa Tehnica Buton de Incendiu Adresabil UniPOS FD7150Document2 pagesFisa Tehnica Buton de Incendiu Adresabil UniPOS FD7150Augustin CatineanNo ratings yet

- HR DirectorDocument2 pagesHR DirectorAlvesNo ratings yet

- The Deficienies of Women in The Eyes of Imam Ali in Nahjul BalaghaDocument33 pagesThe Deficienies of Women in The Eyes of Imam Ali in Nahjul BalaghaSaleem BhimjiNo ratings yet

- Cover LetterDocument1 pageCover LetterZeeshan KhatriNo ratings yet

- Wall Mounted Attendance SystemDocument2 pagesWall Mounted Attendance SystemTooba SamiNo ratings yet

- Show Your Work Chapter 3Document2 pagesShow Your Work Chapter 3api-582076623No ratings yet

- GCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBODocument2 pagesGCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBOKickingEdgarAllenPoeNo ratings yet

- Paragraph WritingDocument2 pagesParagraph Writingrajput shreyaNo ratings yet

- Full Download Deviance Conformity and Social Control in Canada Canadian 4th Edition Bereska Solutions ManualDocument36 pagesFull Download Deviance Conformity and Social Control in Canada Canadian 4th Edition Bereska Solutions Manualwaywayqayemb100% (31)

- Thesis ProposalDocument6 pagesThesis ProposalSurender SinghNo ratings yet

- 68th BPSC Pre-1-64-95Document32 pages68th BPSC Pre-1-64-95MOHIT KUMARNo ratings yet

- The Cosy 131 User GuideDocument30 pagesThe Cosy 131 User GuidePhát Triển TháiNo ratings yet

- Bailment and PledgeDocument3 pagesBailment and PledgeGarima GarimaNo ratings yet

- TugasDocument5 pagesTugasWidarysta NazwaNo ratings yet

- 4th Quarter Tle 6Document9 pages4th Quarter Tle 6Jorry Pavo NepalNo ratings yet

- FMDS0329 PDFDocument5 pagesFMDS0329 PDFStory LoveNo ratings yet