Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 viewsWhy It Pays To Maintain Your Boiler

Why It Pays To Maintain Your Boiler

Uploaded by

Omar KhaledWhile modern boilers have self-monitoring features, following a strict maintenance schedule can reduce fuel costs by 7% on average. The document recommends establishing regular inspection schedules, keeping maintenance records, and following boiler maintenance tips such as knowing equipment manuals, maintaining good housekeeping, and emphasizing safety. It provides a sample maintenance schedule that includes daily, weekly, monthly, semi-annual and annual checks and cleaning tasks to maximize boiler uptime.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- Emergency Drill ReportDocument6 pagesEmergency Drill ReportDirga Delonix Regia100% (4)

- Official History of 86th DivisionDocument344 pagesOfficial History of 86th DivisionFilipNo ratings yet

- Centrifugal Chiller Maintenance ChecklistDocument1 pageCentrifugal Chiller Maintenance Checklistosama alabsiNo ratings yet

- Chapter 13 SERVICE DATA: 13.1 Maintenance ScheduleDocument62 pagesChapter 13 SERVICE DATA: 13.1 Maintenance ScheduleAuxiliar Mantenimiento EcaNo ratings yet

- Boiler Chiller ChecklistDocument5 pagesBoiler Chiller ChecklistSyed Haider Abbas KazmiNo ratings yet

- Equipment O&M ChecklistsDocument11 pagesEquipment O&M ChecklistsAsebaho BadrNo ratings yet

- Boilers: Dail y Week Ly Mont Hly Annu AllyDocument3 pagesBoilers: Dail y Week Ly Mont Hly Annu AllyYonas AyeleNo ratings yet

- RMS - Boiler Maintenance & Periodic Testing ChecklistDocument5 pagesRMS - Boiler Maintenance & Periodic Testing ChecklistERplant RefinersNo ratings yet

- ABMA Boiler Maintenance ScheduleDocument1 pageABMA Boiler Maintenance Schedulesthefany whiteNo ratings yet

- Preventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceDocument1 pagePreventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceMohammad Anwar0% (1)

- PM ProgramDocument29 pagesPM Programemad youssefNo ratings yet

- Boiler Checklist Electrical Equipment Checklist Burner ChecklistDocument1 pageBoiler Checklist Electrical Equipment Checklist Burner Checklistحمودي معزNo ratings yet

- Boiler Checklist A4Document1 pageBoiler Checklist A4Yudha KurniawanNo ratings yet

- Week 7-8 Diesel Engine DiagnosisDocument122 pagesWeek 7-8 Diesel Engine Diagnosisعمر محمد عبدالرحمن عليNo ratings yet

- Maintenance ApproachDocument4 pagesMaintenance ApproachBarathNo ratings yet

- Gas TurbineDocument14 pagesGas TurbineBouazza100% (1)

- Generator Set Start-Up Checklist: Open Enclosed Generator SetsDocument2 pagesGenerator Set Start-Up Checklist: Open Enclosed Generator SetsEng Mamon StiNo ratings yet

- L136 - 65.99897-8080 Operating ManualDocument1 pageL136 - 65.99897-8080 Operating ManualYann LejardNo ratings yet

- Adobe Scan 04 Aug 2023Document1 pageAdobe Scan 04 Aug 2023Samuel DinkuNo ratings yet

- Listas C172SP BHCDocument8 pagesListas C172SP BHCKarla QuiñonezNo ratings yet

- Cashman EM Solutions Brochure 3 16Document2 pagesCashman EM Solutions Brochure 3 16jov100% (1)

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Inspection Form PM0007 Grader DailyDocument1 pageInspection Form PM0007 Grader DailyMalik RizwanNo ratings yet

- 8 Tobia - Maintenance of DEG (Mechanical)Document38 pages8 Tobia - Maintenance of DEG (Mechanical)Epeli RokodrokayaNo ratings yet

- The Maintenance Approach Used For The Hydraulic Press.: Submit By: Amira Sabry Submit To: Dr. Saber SokarDocument5 pagesThe Maintenance Approach Used For The Hydraulic Press.: Submit By: Amira Sabry Submit To: Dr. Saber SokarMohamed IbrahimNo ratings yet

- PSA PDT Tasking Report - Tasking ReportDocument3 pagesPSA PDT Tasking Report - Tasking Reportalf_haroNo ratings yet

- 250PMDocument1 page250PMAyub ardiNo ratings yet

- Maintenance-All in OneDocument13 pagesMaintenance-All in Onetarek ali ahmedNo ratings yet

- Parker Steam Boiler Quarterly Inspection Report: QTR 101-5Document2 pagesParker Steam Boiler Quarterly Inspection Report: QTR 101-5Danu KautsarNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- (From CAT Maintenance Guide) (From CAT Maintenance Guide) : No Information: To Be CompletedDocument1 page(From CAT Maintenance Guide) (From CAT Maintenance Guide) : No Information: To Be CompletedVicNo ratings yet

- SpringchecklistDocument1 pageSpringchecklistmcjuddyNo ratings yet

- Check List For Boiler MaintenanceDocument3 pagesCheck List For Boiler MaintenanceHasnain AfzalNo ratings yet

- Maintenance Schedule Surface MinerDocument8 pagesMaintenance Schedule Surface MinerSUBHASHNo ratings yet

- TEKTON TCX Test FormsDocument36 pagesTEKTON TCX Test FormsNorman CanlasNo ratings yet

- BR Generator Maintenance ChecklistDocument1 pageBR Generator Maintenance Checklistahmad fasfous100% (1)

- Monthly Maintenance Report For Steam GeneratorDocument1 pageMonthly Maintenance Report For Steam GeneratorArsalan AhmadNo ratings yet

- Gas TurbineDocument14 pagesGas Turbinevasanth11kv100% (3)

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- MHC Checklist04Document13 pagesMHC Checklist04Tawfiq ZidanNo ratings yet

- Maintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyDocument1 pageMaintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyGaurav JhaNo ratings yet

- Industrial Resources, Inc.: Solar Taurus 60 Gas TurbineDocument28 pagesIndustrial Resources, Inc.: Solar Taurus 60 Gas TurbineIsabel PaixaoNo ratings yet

- Maintenance Engine Mitsubishi S16RDocument20 pagesMaintenance Engine Mitsubishi S16RElyas Nur FridayanaNo ratings yet

- CH-17 Boiler Protections and InterlocksDocument22 pagesCH-17 Boiler Protections and InterlocksMourya DevuNo ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- AKSA Generator Startup Checklist - Editable PDFDocument2 pagesAKSA Generator Startup Checklist - Editable PDFTama42gmail.com AzryNo ratings yet

- MHC Checklist05Document4 pagesMHC Checklist05Tawfiq ZidanNo ratings yet

- DEZUMIDIFICATORDocument5 pagesDEZUMIDIFICATORviltermNo ratings yet

- Poeb107 YeoDocument2 pagesPoeb107 Yeomcalidonio5656No ratings yet

- Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingDocument4 pagesCustomer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- CH-17 Boiler Protections and InterlocksDocument21 pagesCH-17 Boiler Protections and InterlocksRavi ShankarNo ratings yet

- 303-00 Diagnosis and TestingDocument10 pages303-00 Diagnosis and TestingFerhan SerdarogluNo ratings yet

- TOM Training Centrifugal Compressors: TroubleshootingDocument5 pagesTOM Training Centrifugal Compressors: TroubleshootingAhmedNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- X15 Maintenance GuidelinesDocument1 pageX15 Maintenance GuidelinesAll Haul TransportNo ratings yet

- MOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityDocument2 pagesMOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityJaadi 786No ratings yet

- Maintenance Schedule Checklist: Check and Correct As NecessaryDocument1 pageMaintenance Schedule Checklist: Check and Correct As NecessaryLeonardo RamirezNo ratings yet

- Operational ChecksDocument9 pagesOperational Checkssmart_eng2009100% (3)

- General InformationDocument111 pagesGeneral Informationkhaledserag23No ratings yet

- Boiler - Steam GeneratorDocument19 pagesBoiler - Steam GeneratormarlpatsNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- 06 Report DataDocument7 pages06 Report DataOmar KhaledNo ratings yet

- 04 CalibrationDocument7 pages04 CalibrationOmar KhaledNo ratings yet

- Npcs Afouad 8kpm GtcaDocument16 pagesNpcs Afouad 8kpm GtcaOmar KhaledNo ratings yet

- Comp DGS Investigation and OJT - Cont.Document11 pagesComp DGS Investigation and OJT - Cont.Omar KhaledNo ratings yet

- Ibrahim T60CS Commissioning ContinuedDocument18 pagesIbrahim T60CS Commissioning ContinuedOmar Khaled100% (1)

- 6.2.1b 8000 Hours Maintenance - Comp MetricDocument17 pages6.2.1b 8000 Hours Maintenance - Comp MetricOmar KhaledNo ratings yet

- MS 13 151Document109 pagesMS 13 151Omar KhaledNo ratings yet

- RCM XXXDocument11 pagesRCM XXXOmar KhaledNo ratings yet

- 6.2.1a 8000 Hours Maintenance - Comp ImperialDocument15 pages6.2.1a 8000 Hours Maintenance - Comp ImperialOmar KhaledNo ratings yet

- Product CatalogsDocument5 pagesProduct CatalogsOmar KhaledNo ratings yet

- Reactive Capability Limitation of Synchronous MachinesDocument12 pagesReactive Capability Limitation of Synchronous MachinesOmar KhaledNo ratings yet

- Qasr - Alfy - Inhibit SD Caused by Spare ModulesDocument4 pagesQasr - Alfy - Inhibit SD Caused by Spare ModulesOmar KhaledNo ratings yet

- VCR Metal Gasket Face Seal Fittings and Micro-Fit Weld FittingsDocument34 pagesVCR Metal Gasket Face Seal Fittings and Micro-Fit Weld FittingsOmar KhaledNo ratings yet

- FMEADocument5 pagesFMEAOmar Khaled100% (1)

- Power Swager Manual: and Thermoplastic Hose Assembly InstructionsDocument12 pagesPower Swager Manual: and Thermoplastic Hose Assembly InstructionsOmar KhaledNo ratings yet

- Heating Single-Phase: Turbine-Generator During CircuitsDocument6 pagesHeating Single-Phase: Turbine-Generator During CircuitsOmar KhaledNo ratings yet

- Bench Top Tube Bender: User's ManualDocument14 pagesBench Top Tube Bender: User's ManualOmar KhaledNo ratings yet

- Reliability Centered Maintenance: DescriptionDocument2 pagesReliability Centered Maintenance: DescriptionOmar KhaledNo ratings yet

- Study of Existing RCM Approaches, Tools and Databases Used in Different IndustriesDocument10 pagesStudy of Existing RCM Approaches, Tools and Databases Used in Different IndustriesOmar KhaledNo ratings yet

- The "R" IN RCM-Pertinent Reliability Theory & Application: RCM Methodology: Based UponDocument24 pagesThe "R" IN RCM-Pertinent Reliability Theory & Application: RCM Methodology: Based UponOmar KhaledNo ratings yet

- PM Type Ann. Freq. Duration Down Time No. of Workersman - Day SP.P Cost PM SP.P CostDocument5 pagesPM Type Ann. Freq. Duration Down Time No. of Workersman - Day SP.P Cost PM SP.P CostOmar KhaledNo ratings yet

- System Effectiveness: Efficiency AvailabilityDocument5 pagesSystem Effectiveness: Efficiency AvailabilityOmar KhaledNo ratings yet

- Review of Predictive Maintenance MethodsDocument15 pagesReview of Predictive Maintenance MethodsOmar KhaledNo ratings yet

- Safety of Existing LiftsDocument13 pagesSafety of Existing LiftsOmar KhaledNo ratings yet

- 01 Part 1 - Maintenance Management OverviewDocument72 pages01 Part 1 - Maintenance Management OverviewOmar Khaled100% (1)

- 00 Maintenance Planning Cover 18 04 2004Document3 pages00 Maintenance Planning Cover 18 04 2004Omar KhaledNo ratings yet

- 000 Impact of TPM 11 9 05Document32 pages000 Impact of TPM 11 9 05Omar KhaledNo ratings yet

- 00 MMM Screens - Dr. Attia GomaaDocument11 pages00 MMM Screens - Dr. Attia GomaaOmar KhaledNo ratings yet

- Predictive Maintenance Sheet For Pump Bearing:: AssumeDocument3 pagesPredictive Maintenance Sheet For Pump Bearing:: AssumeOmar KhaledNo ratings yet

- 4 System Installation & MaintenanceDocument8 pages4 System Installation & MaintenanceOmar KhaledNo ratings yet

- Major 7F & Minor 7F AccountsDocument64 pagesMajor 7F & Minor 7F AccountsShaik Arif BashaNo ratings yet

- Barbell Medicine 12wk Press v2Document924 pagesBarbell Medicine 12wk Press v2Wen YNo ratings yet

- Test Partnership Numerical Reasoning Test 3: AssessmentdayDocument20 pagesTest Partnership Numerical Reasoning Test 3: AssessmentdayThanh Phu TranNo ratings yet

- MAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesDocument29 pagesMAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesSrinivas GopisettiNo ratings yet

- Anaesthetic and Respiratory Equipment - Laryngoscopes For Tracheal IntubationDocument2 pagesAnaesthetic and Respiratory Equipment - Laryngoscopes For Tracheal IntubationAisha MughalNo ratings yet

- HGTD Data Analysis For June2018Document12 pagesHGTD Data Analysis For June2018Shahzad AliNo ratings yet

- Chapter Four Non-Isothermal Reactors DesignDocument16 pagesChapter Four Non-Isothermal Reactors Designمصطفى العباديNo ratings yet

- Appendix 1: I. Exercise ToleranceDocument5 pagesAppendix 1: I. Exercise Tolerancejfcule1No ratings yet

- Multi Versio Reverb Multi Versio Resonator Multi Versio FilterDocument3 pagesMulti Versio Reverb Multi Versio Resonator Multi Versio FilterDistant AnimalsNo ratings yet

- Impact of Artificial "Gummy Fingers" On Fingerprint SystemDocument17 pagesImpact of Artificial "Gummy Fingers" On Fingerprint SystemDevika PadmanabhanNo ratings yet

- Fire Phenomena of Rigid Polyurethane FoamsDocument22 pagesFire Phenomena of Rigid Polyurethane FoamsNicola MelaNo ratings yet

- MATLAB-Simulink Based Analysis ofDocument4 pagesMATLAB-Simulink Based Analysis ofAmare KassawNo ratings yet

- PDF Oxford Textbook of Neuropsychiatry Niruj Agrawal Ebook Full ChapterDocument53 pagesPDF Oxford Textbook of Neuropsychiatry Niruj Agrawal Ebook Full Chapterjames.fahey314100% (1)

- A Case Study of Holiday Homes Biclatan Subdivision in General Trias, Cavite: Subdivision Planning and LandscapingDocument11 pagesA Case Study of Holiday Homes Biclatan Subdivision in General Trias, Cavite: Subdivision Planning and LandscapingKatrina ManriqueNo ratings yet

- Sustainable Development Meaning and Scope PDFDocument12 pagesSustainable Development Meaning and Scope PDFVaibhavi Modi100% (1)

- Arunpreet Kaur (800941004) Final ThesisDocument62 pagesArunpreet Kaur (800941004) Final ThesisrajeshwariNo ratings yet

- BLEPT 09-2016 Room Assignment Rosales-SecDocument114 pagesBLEPT 09-2016 Room Assignment Rosales-SecPRC Baguio50% (2)

- R S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsDocument29 pagesR S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsTushar RanaNo ratings yet

- Laserjet Professional M1130/M1210: MFP SeriesDocument16 pagesLaserjet Professional M1130/M1210: MFP SeriesDhanesh RamachandramNo ratings yet

- Smart Note Taker: A Seminar Report OnDocument32 pagesSmart Note Taker: A Seminar Report Onpavan kumar aretiNo ratings yet

- Third Periodical Test in English 5.Document7 pagesThird Periodical Test in English 5.Emil Nayad ZamoraNo ratings yet

- Proposal Rev 02Document30 pagesProposal Rev 02suronocaturatmojo100% (1)

- Analysis On CornDocument39 pagesAnalysis On CornKath Hidalgo100% (1)

- Literature in English 1798-1914-FinalDocument537 pagesLiterature in English 1798-1914-FinalAditya Prakash100% (1)

- Skin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsDocument10 pagesSkin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsCarolina RodriguezNo ratings yet

- EP-501, Evolution of Indian Economy Midterm: Submitted By: Prashun Pranav (CISLS)Document8 pagesEP-501, Evolution of Indian Economy Midterm: Submitted By: Prashun Pranav (CISLS)rumiNo ratings yet

- Paik I Expose The Music EN HHDocument4 pagesPaik I Expose The Music EN HHHanna B. HöllingNo ratings yet

- SEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Document4 pagesSEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Pilar Villanueva86% (7)

Why It Pays To Maintain Your Boiler

Why It Pays To Maintain Your Boiler

Uploaded by

Omar Khaled0 ratings0% found this document useful (0 votes)

11 views2 pagesWhile modern boilers have self-monitoring features, following a strict maintenance schedule can reduce fuel costs by 7% on average. The document recommends establishing regular inspection schedules, keeping maintenance records, and following boiler maintenance tips such as knowing equipment manuals, maintaining good housekeeping, and emphasizing safety. It provides a sample maintenance schedule that includes daily, weekly, monthly, semi-annual and annual checks and cleaning tasks to maximize boiler uptime.

Original Description:

Original Title

Why It Pays to Maintain Your Boiler

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWhile modern boilers have self-monitoring features, following a strict maintenance schedule can reduce fuel costs by 7% on average. The document recommends establishing regular inspection schedules, keeping maintenance records, and following boiler maintenance tips such as knowing equipment manuals, maintaining good housekeeping, and emphasizing safety. It provides a sample maintenance schedule that includes daily, weekly, monthly, semi-annual and annual checks and cleaning tasks to maximize boiler uptime.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views2 pagesWhy It Pays To Maintain Your Boiler

Why It Pays To Maintain Your Boiler

Uploaded by

Omar KhaledWhile modern boilers have self-monitoring features, following a strict maintenance schedule can reduce fuel costs by 7% on average. The document recommends establishing regular inspection schedules, keeping maintenance records, and following boiler maintenance tips such as knowing equipment manuals, maintaining good housekeeping, and emphasizing safety. It provides a sample maintenance schedule that includes daily, weekly, monthly, semi-annual and annual checks and cleaning tasks to maximize boiler uptime.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 2

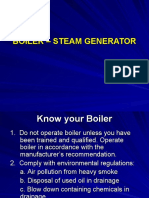

Why It Pays to Maintain Your Boiler

While modern boiler

installations tend to be

highly sophisticated

with many self-

monitoring and self-

regulating features, it

pays to maintain and

follow a rigid

maintenance and

inspection schedule.

Studies have shown that,

on average, 7% of boiler

fuel costs are a direct

result of poor

maintenance.

The following boiler maintenance tips have been adapted from the Cleaver-Brooks

Boiler Room Guide, an extensive document referring to various topics including

General Boiler Description; Inspections; Start-up; Routine Operations; Shutting Down;

and Theory of Combustion and Thermodynamics.

Boiler maintenance tips

Know your equipment. Keep the boiler manufacturer’s manual and data in a

special file and ensure that staff consult this information whenever in doubt.

Maintain complete records. Individual components should be listed on indexed

cards or computer data base by model, serial number and date of installation.

Establish a regular boiler inspection schedule.

Establish and use boiler log sheets.

Establish and keep written operating procedures updated. A detailed start-up

procedure is essential in standardizing boiler room routine.

Emphasize good housekeeping.

Keep electrical equipment clean.

Maintain adequate fresh air supply. Filters must be kept clean. In severe winter

weather, the room may need to be heated to an acceptable ambient temperature.

Keep accurate fuel records.

Emphasize safety in all aspects of boiler operation.

Recommended Gas/Oil Fired Boiler Inspection Schedules

It is very important that preventive maintenance be performed on an established

schedule. Following are recommendations on schedules as well as suggestions

to assist in maximizing the uptime of your boiler and associated equipment.

Daily* Weekly Monthly Semi-Annually Annually

Check water Check for tight Inspect burner Clean low water Clean fireside

level closing of fuel cut-off(s) surfaces

valves

Blowdown Check fuel and Analyze Check oil Clean

boiler air linkage combustion preheater breeching

Check

Blowdown Inspect Clean waterside

indicating lights Check cams

water column refractory surfaces

and alarms

Check Check Clean oil pump

Inspect for flue Check oil

combustion operating and strainer and

gas leaks storage tanks

visually limit controls filter

Treat water

Check safety Clean air Check fluid

according to the Inspect for hot

and interlock cleaner and levels on

established spots

controls air/oil separator hydraulic valves

program

Record boiler

Check low Review boiler Check pump

operating Check gauge

water cutoff(s) blowdown coupling

pressure/ glass

operation procedures alignment

temperature

Record Check for leaks,

Check Remove and

feedwater noise, vibration, Reset

combustion air recondition

pressure/ unusual combustion

supply safety valves

temperature conditions

Check

Record flue gas Check all filter Inspect mercury Check oil

operation of all

temperature elements switches pumps

motors

Record oil Check general

Check fuel Check boiler

pressure and burner

systems feed pumps

temperature operation

Check Check

Record gas Check belt

lubricating oil condensate

pressure drives

levels receivers

Record Check flame Check

Check chemical

atomizing scanner lubrication

feed systems

pressure assembly requirements

Check general Tighten all

Check packing

boiler/burner electrical

glands

operation terminals

*Daily items may be performed more than once daily.

Reproduced with kind permission of the Ontario Natural Gas Association.

You might also like

- Emergency Drill ReportDocument6 pagesEmergency Drill ReportDirga Delonix Regia100% (4)

- Official History of 86th DivisionDocument344 pagesOfficial History of 86th DivisionFilipNo ratings yet

- Centrifugal Chiller Maintenance ChecklistDocument1 pageCentrifugal Chiller Maintenance Checklistosama alabsiNo ratings yet

- Chapter 13 SERVICE DATA: 13.1 Maintenance ScheduleDocument62 pagesChapter 13 SERVICE DATA: 13.1 Maintenance ScheduleAuxiliar Mantenimiento EcaNo ratings yet

- Boiler Chiller ChecklistDocument5 pagesBoiler Chiller ChecklistSyed Haider Abbas KazmiNo ratings yet

- Equipment O&M ChecklistsDocument11 pagesEquipment O&M ChecklistsAsebaho BadrNo ratings yet

- Boilers: Dail y Week Ly Mont Hly Annu AllyDocument3 pagesBoilers: Dail y Week Ly Mont Hly Annu AllyYonas AyeleNo ratings yet

- RMS - Boiler Maintenance & Periodic Testing ChecklistDocument5 pagesRMS - Boiler Maintenance & Periodic Testing ChecklistERplant RefinersNo ratings yet

- ABMA Boiler Maintenance ScheduleDocument1 pageABMA Boiler Maintenance Schedulesthefany whiteNo ratings yet

- Preventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceDocument1 pagePreventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceMohammad Anwar0% (1)

- PM ProgramDocument29 pagesPM Programemad youssefNo ratings yet

- Boiler Checklist Electrical Equipment Checklist Burner ChecklistDocument1 pageBoiler Checklist Electrical Equipment Checklist Burner Checklistحمودي معزNo ratings yet

- Boiler Checklist A4Document1 pageBoiler Checklist A4Yudha KurniawanNo ratings yet

- Week 7-8 Diesel Engine DiagnosisDocument122 pagesWeek 7-8 Diesel Engine Diagnosisعمر محمد عبدالرحمن عليNo ratings yet

- Maintenance ApproachDocument4 pagesMaintenance ApproachBarathNo ratings yet

- Gas TurbineDocument14 pagesGas TurbineBouazza100% (1)

- Generator Set Start-Up Checklist: Open Enclosed Generator SetsDocument2 pagesGenerator Set Start-Up Checklist: Open Enclosed Generator SetsEng Mamon StiNo ratings yet

- L136 - 65.99897-8080 Operating ManualDocument1 pageL136 - 65.99897-8080 Operating ManualYann LejardNo ratings yet

- Adobe Scan 04 Aug 2023Document1 pageAdobe Scan 04 Aug 2023Samuel DinkuNo ratings yet

- Listas C172SP BHCDocument8 pagesListas C172SP BHCKarla QuiñonezNo ratings yet

- Cashman EM Solutions Brochure 3 16Document2 pagesCashman EM Solutions Brochure 3 16jov100% (1)

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Inspection Form PM0007 Grader DailyDocument1 pageInspection Form PM0007 Grader DailyMalik RizwanNo ratings yet

- 8 Tobia - Maintenance of DEG (Mechanical)Document38 pages8 Tobia - Maintenance of DEG (Mechanical)Epeli RokodrokayaNo ratings yet

- The Maintenance Approach Used For The Hydraulic Press.: Submit By: Amira Sabry Submit To: Dr. Saber SokarDocument5 pagesThe Maintenance Approach Used For The Hydraulic Press.: Submit By: Amira Sabry Submit To: Dr. Saber SokarMohamed IbrahimNo ratings yet

- PSA PDT Tasking Report - Tasking ReportDocument3 pagesPSA PDT Tasking Report - Tasking Reportalf_haroNo ratings yet

- 250PMDocument1 page250PMAyub ardiNo ratings yet

- Maintenance-All in OneDocument13 pagesMaintenance-All in Onetarek ali ahmedNo ratings yet

- Parker Steam Boiler Quarterly Inspection Report: QTR 101-5Document2 pagesParker Steam Boiler Quarterly Inspection Report: QTR 101-5Danu KautsarNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- (From CAT Maintenance Guide) (From CAT Maintenance Guide) : No Information: To Be CompletedDocument1 page(From CAT Maintenance Guide) (From CAT Maintenance Guide) : No Information: To Be CompletedVicNo ratings yet

- SpringchecklistDocument1 pageSpringchecklistmcjuddyNo ratings yet

- Check List For Boiler MaintenanceDocument3 pagesCheck List For Boiler MaintenanceHasnain AfzalNo ratings yet

- Maintenance Schedule Surface MinerDocument8 pagesMaintenance Schedule Surface MinerSUBHASHNo ratings yet

- TEKTON TCX Test FormsDocument36 pagesTEKTON TCX Test FormsNorman CanlasNo ratings yet

- BR Generator Maintenance ChecklistDocument1 pageBR Generator Maintenance Checklistahmad fasfous100% (1)

- Monthly Maintenance Report For Steam GeneratorDocument1 pageMonthly Maintenance Report For Steam GeneratorArsalan AhmadNo ratings yet

- Gas TurbineDocument14 pagesGas Turbinevasanth11kv100% (3)

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- MHC Checklist04Document13 pagesMHC Checklist04Tawfiq ZidanNo ratings yet

- Maintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyDocument1 pageMaintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyGaurav JhaNo ratings yet

- Industrial Resources, Inc.: Solar Taurus 60 Gas TurbineDocument28 pagesIndustrial Resources, Inc.: Solar Taurus 60 Gas TurbineIsabel PaixaoNo ratings yet

- Maintenance Engine Mitsubishi S16RDocument20 pagesMaintenance Engine Mitsubishi S16RElyas Nur FridayanaNo ratings yet

- CH-17 Boiler Protections and InterlocksDocument22 pagesCH-17 Boiler Protections and InterlocksMourya DevuNo ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- AKSA Generator Startup Checklist - Editable PDFDocument2 pagesAKSA Generator Startup Checklist - Editable PDFTama42gmail.com AzryNo ratings yet

- MHC Checklist05Document4 pagesMHC Checklist05Tawfiq ZidanNo ratings yet

- DEZUMIDIFICATORDocument5 pagesDEZUMIDIFICATORviltermNo ratings yet

- Poeb107 YeoDocument2 pagesPoeb107 Yeomcalidonio5656No ratings yet

- Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingDocument4 pagesCustomer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- CH-17 Boiler Protections and InterlocksDocument21 pagesCH-17 Boiler Protections and InterlocksRavi ShankarNo ratings yet

- 303-00 Diagnosis and TestingDocument10 pages303-00 Diagnosis and TestingFerhan SerdarogluNo ratings yet

- TOM Training Centrifugal Compressors: TroubleshootingDocument5 pagesTOM Training Centrifugal Compressors: TroubleshootingAhmedNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- X15 Maintenance GuidelinesDocument1 pageX15 Maintenance GuidelinesAll Haul TransportNo ratings yet

- MOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityDocument2 pagesMOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityJaadi 786No ratings yet

- Maintenance Schedule Checklist: Check and Correct As NecessaryDocument1 pageMaintenance Schedule Checklist: Check and Correct As NecessaryLeonardo RamirezNo ratings yet

- Operational ChecksDocument9 pagesOperational Checkssmart_eng2009100% (3)

- General InformationDocument111 pagesGeneral Informationkhaledserag23No ratings yet

- Boiler - Steam GeneratorDocument19 pagesBoiler - Steam GeneratormarlpatsNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- 06 Report DataDocument7 pages06 Report DataOmar KhaledNo ratings yet

- 04 CalibrationDocument7 pages04 CalibrationOmar KhaledNo ratings yet

- Npcs Afouad 8kpm GtcaDocument16 pagesNpcs Afouad 8kpm GtcaOmar KhaledNo ratings yet

- Comp DGS Investigation and OJT - Cont.Document11 pagesComp DGS Investigation and OJT - Cont.Omar KhaledNo ratings yet

- Ibrahim T60CS Commissioning ContinuedDocument18 pagesIbrahim T60CS Commissioning ContinuedOmar Khaled100% (1)

- 6.2.1b 8000 Hours Maintenance - Comp MetricDocument17 pages6.2.1b 8000 Hours Maintenance - Comp MetricOmar KhaledNo ratings yet

- MS 13 151Document109 pagesMS 13 151Omar KhaledNo ratings yet

- RCM XXXDocument11 pagesRCM XXXOmar KhaledNo ratings yet

- 6.2.1a 8000 Hours Maintenance - Comp ImperialDocument15 pages6.2.1a 8000 Hours Maintenance - Comp ImperialOmar KhaledNo ratings yet

- Product CatalogsDocument5 pagesProduct CatalogsOmar KhaledNo ratings yet

- Reactive Capability Limitation of Synchronous MachinesDocument12 pagesReactive Capability Limitation of Synchronous MachinesOmar KhaledNo ratings yet

- Qasr - Alfy - Inhibit SD Caused by Spare ModulesDocument4 pagesQasr - Alfy - Inhibit SD Caused by Spare ModulesOmar KhaledNo ratings yet

- VCR Metal Gasket Face Seal Fittings and Micro-Fit Weld FittingsDocument34 pagesVCR Metal Gasket Face Seal Fittings and Micro-Fit Weld FittingsOmar KhaledNo ratings yet

- FMEADocument5 pagesFMEAOmar Khaled100% (1)

- Power Swager Manual: and Thermoplastic Hose Assembly InstructionsDocument12 pagesPower Swager Manual: and Thermoplastic Hose Assembly InstructionsOmar KhaledNo ratings yet

- Heating Single-Phase: Turbine-Generator During CircuitsDocument6 pagesHeating Single-Phase: Turbine-Generator During CircuitsOmar KhaledNo ratings yet

- Bench Top Tube Bender: User's ManualDocument14 pagesBench Top Tube Bender: User's ManualOmar KhaledNo ratings yet

- Reliability Centered Maintenance: DescriptionDocument2 pagesReliability Centered Maintenance: DescriptionOmar KhaledNo ratings yet

- Study of Existing RCM Approaches, Tools and Databases Used in Different IndustriesDocument10 pagesStudy of Existing RCM Approaches, Tools and Databases Used in Different IndustriesOmar KhaledNo ratings yet

- The "R" IN RCM-Pertinent Reliability Theory & Application: RCM Methodology: Based UponDocument24 pagesThe "R" IN RCM-Pertinent Reliability Theory & Application: RCM Methodology: Based UponOmar KhaledNo ratings yet

- PM Type Ann. Freq. Duration Down Time No. of Workersman - Day SP.P Cost PM SP.P CostDocument5 pagesPM Type Ann. Freq. Duration Down Time No. of Workersman - Day SP.P Cost PM SP.P CostOmar KhaledNo ratings yet

- System Effectiveness: Efficiency AvailabilityDocument5 pagesSystem Effectiveness: Efficiency AvailabilityOmar KhaledNo ratings yet

- Review of Predictive Maintenance MethodsDocument15 pagesReview of Predictive Maintenance MethodsOmar KhaledNo ratings yet

- Safety of Existing LiftsDocument13 pagesSafety of Existing LiftsOmar KhaledNo ratings yet

- 01 Part 1 - Maintenance Management OverviewDocument72 pages01 Part 1 - Maintenance Management OverviewOmar Khaled100% (1)

- 00 Maintenance Planning Cover 18 04 2004Document3 pages00 Maintenance Planning Cover 18 04 2004Omar KhaledNo ratings yet

- 000 Impact of TPM 11 9 05Document32 pages000 Impact of TPM 11 9 05Omar KhaledNo ratings yet

- 00 MMM Screens - Dr. Attia GomaaDocument11 pages00 MMM Screens - Dr. Attia GomaaOmar KhaledNo ratings yet

- Predictive Maintenance Sheet For Pump Bearing:: AssumeDocument3 pagesPredictive Maintenance Sheet For Pump Bearing:: AssumeOmar KhaledNo ratings yet

- 4 System Installation & MaintenanceDocument8 pages4 System Installation & MaintenanceOmar KhaledNo ratings yet

- Major 7F & Minor 7F AccountsDocument64 pagesMajor 7F & Minor 7F AccountsShaik Arif BashaNo ratings yet

- Barbell Medicine 12wk Press v2Document924 pagesBarbell Medicine 12wk Press v2Wen YNo ratings yet

- Test Partnership Numerical Reasoning Test 3: AssessmentdayDocument20 pagesTest Partnership Numerical Reasoning Test 3: AssessmentdayThanh Phu TranNo ratings yet

- MAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesDocument29 pagesMAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesSrinivas GopisettiNo ratings yet

- Anaesthetic and Respiratory Equipment - Laryngoscopes For Tracheal IntubationDocument2 pagesAnaesthetic and Respiratory Equipment - Laryngoscopes For Tracheal IntubationAisha MughalNo ratings yet

- HGTD Data Analysis For June2018Document12 pagesHGTD Data Analysis For June2018Shahzad AliNo ratings yet

- Chapter Four Non-Isothermal Reactors DesignDocument16 pagesChapter Four Non-Isothermal Reactors Designمصطفى العباديNo ratings yet

- Appendix 1: I. Exercise ToleranceDocument5 pagesAppendix 1: I. Exercise Tolerancejfcule1No ratings yet

- Multi Versio Reverb Multi Versio Resonator Multi Versio FilterDocument3 pagesMulti Versio Reverb Multi Versio Resonator Multi Versio FilterDistant AnimalsNo ratings yet

- Impact of Artificial "Gummy Fingers" On Fingerprint SystemDocument17 pagesImpact of Artificial "Gummy Fingers" On Fingerprint SystemDevika PadmanabhanNo ratings yet

- Fire Phenomena of Rigid Polyurethane FoamsDocument22 pagesFire Phenomena of Rigid Polyurethane FoamsNicola MelaNo ratings yet

- MATLAB-Simulink Based Analysis ofDocument4 pagesMATLAB-Simulink Based Analysis ofAmare KassawNo ratings yet

- PDF Oxford Textbook of Neuropsychiatry Niruj Agrawal Ebook Full ChapterDocument53 pagesPDF Oxford Textbook of Neuropsychiatry Niruj Agrawal Ebook Full Chapterjames.fahey314100% (1)

- A Case Study of Holiday Homes Biclatan Subdivision in General Trias, Cavite: Subdivision Planning and LandscapingDocument11 pagesA Case Study of Holiday Homes Biclatan Subdivision in General Trias, Cavite: Subdivision Planning and LandscapingKatrina ManriqueNo ratings yet

- Sustainable Development Meaning and Scope PDFDocument12 pagesSustainable Development Meaning and Scope PDFVaibhavi Modi100% (1)

- Arunpreet Kaur (800941004) Final ThesisDocument62 pagesArunpreet Kaur (800941004) Final ThesisrajeshwariNo ratings yet

- BLEPT 09-2016 Room Assignment Rosales-SecDocument114 pagesBLEPT 09-2016 Room Assignment Rosales-SecPRC Baguio50% (2)

- R S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsDocument29 pagesR S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsTushar RanaNo ratings yet

- Laserjet Professional M1130/M1210: MFP SeriesDocument16 pagesLaserjet Professional M1130/M1210: MFP SeriesDhanesh RamachandramNo ratings yet

- Smart Note Taker: A Seminar Report OnDocument32 pagesSmart Note Taker: A Seminar Report Onpavan kumar aretiNo ratings yet

- Third Periodical Test in English 5.Document7 pagesThird Periodical Test in English 5.Emil Nayad ZamoraNo ratings yet

- Proposal Rev 02Document30 pagesProposal Rev 02suronocaturatmojo100% (1)

- Analysis On CornDocument39 pagesAnalysis On CornKath Hidalgo100% (1)

- Literature in English 1798-1914-FinalDocument537 pagesLiterature in English 1798-1914-FinalAditya Prakash100% (1)

- Skin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsDocument10 pagesSkin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsCarolina RodriguezNo ratings yet

- EP-501, Evolution of Indian Economy Midterm: Submitted By: Prashun Pranav (CISLS)Document8 pagesEP-501, Evolution of Indian Economy Midterm: Submitted By: Prashun Pranav (CISLS)rumiNo ratings yet

- Paik I Expose The Music EN HHDocument4 pagesPaik I Expose The Music EN HHHanna B. HöllingNo ratings yet

- SEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Document4 pagesSEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Pilar Villanueva86% (7)