Professional Documents

Culture Documents

Patent 03

Patent 03

Uploaded by

fatemeh afari0 ratings0% found this document useful (0 votes)

18 views6 pagesOriginal Title

patent-03

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

18 views6 pagesPatent 03

Patent 03

Uploaded by

fatemeh afariCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

Canadian

Intellectual Property

Office

(19) +

‘An Agency of

Industry Canada

Office de la Propriété (1) CA 281984 (13) A

Intellectuelle

du Canada (40) 24.07.1928,

Un organisme

dindustrie Canada

(12)

(21) Application number. 2819840

(2) Date of ling

(51) Int. ct

(71) Applicant’ IcILTD.

(72) Inventor; MOORE JOSEPH WILLIAM ()

POLACK WILFRID G ().

(64) AMMONIUM CHLORIDE MANUFACTURE

(67) Abstract:

(54) FABRICATION DE CHLORURE D'AMMONIUM

This First Page has been artificially created and is not part of the CIPO Official Publication

X 281984

This invention relates to improvements in the manufacture

of ammonium chloride crystals.

It is the primary object of tho invention to provide

a simpler and cheaper method for the manufacture of the

tough fibrous crystals, similar to those usually produced

by sublimation of solid smmonium chloride using heat from

an external source.

These are valvable for certain purposes, and ordinarily

command & higher price than fine powder.

Tey are usually obtained by using heat from an

external source, and a separate and distinct process involving

expensive and troublesome methods of sublimation and conden-

sation.

According to the present invention we effect the

Interaction of gaseous ammonia and gaseous hydrochloric acid

under such therm@l conditions (particularly with regara to

velocity or thermal insulation) that very considerable

reaction temperature is developed when it is found that

combination occurs with the. simtaneous formation of the more

valuable crystalline form of ammonium chloride. &

‘The ammonia, whether liquid or gassous, may be sub-

stantially anhydrous and may 1f desired be used 4m the Liquid

form to prevent excessive generation of heat. Alternatively

the gases may contain moisture provided the quantity of

moisture is not so great as to cause deposition of water on

the solid salt.

Preferably we employ gaseous synthetic ammonia and

synthetic hydrochloric acid gas containing a controlled

C

28198

y 4

proportion of hydrogen. When these aro passed into one

end of @ reaction chamber s0 that the hydrochloric acid

preferably enters from the top and ammonia from the bottom,

4b is found that at a slow rate of flow amoninm chloride is

precipitated in the form of snow-like erystals.

A similar result 1s obtained when these casos are

caused to react on a laboratory scale. We do not claim

such a process in this application.

We find however ~ and this is the essential feature

of the Invention - that if the gases are allowed to react

ata higher rate of output in such a manner as to develop and

conserve the heat of the reaction to a substantial extent,

ammonium chloride is formed as cellular structure which, which

removed from the reaction chamber, appears as a mass of

extremely pure tough fibrous crystals, similar to those

ordinarily produced by a separate and distinct sublimation

process, using heat from an external source.

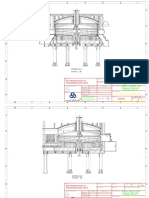

Example

Gaseous synthetic ammonia and an equivalent quantity

of gaseous synthetic hydrochloric acid (containing Sof free

ny@rogen) at atmospheric temperature are passed through a

suitably constructed cast iron cylinder 1 lined with glazed

earthenware tiles 2, and having an internal diameter of 21

inches and a length of 15 feet. ‘The gases are introduced

throiigh inlet pipes 5 and 4 and the residual gases pass

through the filter 5, the pipe 6 and the outlet pipe 7.

Moe cylinder is provided with doors 8 for removal of solids.

he gases are introduced at a rate sufficient to produce 6

pounds of ammonium chloride por hour. A reaction temperature

3

\y 281984

of about 500°C is thus attained and the resulting solid is

deposited at this high temperature so that the product is in

part, or all, a mass of touch fibrous crystals similar to

these usually obtained by sublimation and condensation, using

heat from an external source.

The product is chemically pure or practically so.

obviously the conditions will vary with different

sizes of apparatus.

In tho above example, concentrated gases are employed

and this naturally assists In maintaining a high temperature

4n the reaction vessel. ey

281984

We CLAIM AS. OUR INVENTION ¢

The process of manufacturing crystals of

ammonium chloride which consists in allowing gaseous

ammonia to react with gaseous hydrochloric acid under

such thermal conditions that the solid is deposited at

a high temperature sufficiently high to produce a mass

of tough fibrous crystals.

The process of manufacturing chloride crystals

which consists in allowing gaseous concentrated synthetic

ammonia to react with gaseous concentrated hydrochloric

acid at such a rate of flow that a reaction temperature

4s developed sufficiently high to produce tough fibrous

crystals.

3. Chemically pure tough fibrous crystals of

ammonium chloride.

~5-

281984

fu Droore

droning ster © 0.4, Glee

IAF, Inventor

” By

ao,

. (Attorney

Gersifie 40 be the

Gn the specification,

the2 doy of

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Crystallization and Separation of KCL From Carnallite Ore: Process Development, Simulation and Economic FeasibilityDocument11 pagesCrystallization and Separation of KCL From Carnallite Ore: Process Development, Simulation and Economic Feasibilityfatemeh afariNo ratings yet

- Ammonium Chloride-Reaction EquilibriumDocument6 pagesAmmonium Chloride-Reaction Equilibriumfatemeh afariNo ratings yet

- Patent 01Document3 pagesPatent 01fatemeh afariNo ratings yet

- Vehring AAPS 2006 Particle Design Via Spray DryingDocument27 pagesVehring AAPS 2006 Particle Design Via Spray Dryingfatemeh afariNo ratings yet

- Heat and Mass Transfer Study in The Spray Drying of Tomato JuiceDocument6 pagesHeat and Mass Transfer Study in The Spray Drying of Tomato Juicefatemeh afariNo ratings yet

- Pharmaceutical Spray DryingDocument16 pagesPharmaceutical Spray DryingLBNo ratings yet

- 1spray Dryer - 1Document10 pages1spray Dryer - 1fatemeh afariNo ratings yet

- Method For Improving Spray Drying Equipment and Product PropertiesDocument5 pagesMethod For Improving Spray Drying Equipment and Product Propertiesfatemeh afariNo ratings yet

- Ir - Ac - Yaghoub@Shirazu: A A A A C KGK J G G H HDocument12 pagesIr - Ac - Yaghoub@Shirazu: A A A A C KGK J G G H Hfatemeh afariNo ratings yet

- Process Report For Saturator Blow Down Drum D-6002: Marjan Petrochemical CompanyDocument9 pagesProcess Report For Saturator Blow Down Drum D-6002: Marjan Petrochemical Companyfatemeh afariNo ratings yet

- Chart Performance ENDocument1 pageChart Performance ENfatemeh afariNo ratings yet

- Ebook Computational OptimizationDocument237 pagesEbook Computational Optimizationfatemeh afariNo ratings yet

- Iran Mineral Salts Co. Potassium Sulfate Plant: Section A-A Scale 1: 50Document2 pagesIran Mineral Salts Co. Potassium Sulfate Plant: Section A-A Scale 1: 50fatemeh afariNo ratings yet

- Crystals: Reactive Crystallization Kinetics of K So From Picromerite-Based Mgso and KCLDocument24 pagesCrystals: Reactive Crystallization Kinetics of K So From Picromerite-Based Mgso and KCLfatemeh afariNo ratings yet