Professional Documents

Culture Documents

P1-Key Conepts of Supply Chain-1

P1-Key Conepts of Supply Chain-1

Uploaded by

Macayanan, Norlanie L.Copyright:

Available Formats

You might also like

- Elysian CycleDocument3 pagesElysian CycleMyrnil TilbeNo ratings yet

- Supply Chain Management Multiple Choice QuestionsDocument5 pagesSupply Chain Management Multiple Choice QuestionsZeynep Bülbüllü80% (5)

- Accounting For Materials: I. Opening Prayer III. Overview of The Topic IV. Discussion II. AnnouncementsDocument38 pagesAccounting For Materials: I. Opening Prayer III. Overview of The Topic IV. Discussion II. AnnouncementsJasmin ToqueNo ratings yet

- SCMDocument20 pagesSCMifaNo ratings yet

- Introduction To Supply Chain Management NotesDocument7 pagesIntroduction To Supply Chain Management NotesAnonymous wMppXCM0No ratings yet

- Production - Inventory - Location - Transportation - InformationDocument7 pagesProduction - Inventory - Location - Transportation - InformationKushal BagadiyaNo ratings yet

- Supply Chain ReviewerDocument7 pagesSupply Chain ReviewerAlexisNo ratings yet

- Introduction To Supply ChainDocument6 pagesIntroduction To Supply ChainAlexisNo ratings yet

- Introduction To SCMDocument11 pagesIntroduction To SCMMike DeeNo ratings yet

- Supply Chain Management - TQMDocument11 pagesSupply Chain Management - TQMsuriya kishoreNo ratings yet

- History and Key Concept of SCDocument9 pagesHistory and Key Concept of SCRoli RoliNo ratings yet

- Term Paper OF Operation Management (O.M) : TopicDocument15 pagesTerm Paper OF Operation Management (O.M) : TopicreyazmbaNo ratings yet

- BA 7051 Logistics and Supply Chain Management UNIT - 1Document13 pagesBA 7051 Logistics and Supply Chain Management UNIT - 1porseenaNo ratings yet

- Basic Concepts of Supply Chain ManagementDocument42 pagesBasic Concepts of Supply Chain ManagementMarcela BerrocalNo ratings yet

- LeslyDocument3 pagesLeslymickaellacson5No ratings yet

- Unit - IDocument100 pagesUnit - Irajeeeva100% (1)

- An Analysis of Global Supply Chain Management - Indian PerspectiveDocument58 pagesAn Analysis of Global Supply Chain Management - Indian PerspectiveujwaljaiswalNo ratings yet

- Supply Chain Management 22Document17 pagesSupply Chain Management 22mussamhsNo ratings yet

- P2-The Five Major Supply Chain Drivers-2Document3 pagesP2-The Five Major Supply Chain Drivers-2Macayanan, Norlanie L.No ratings yet

- LSCM Short Answers-PrapoornaDocument3 pagesLSCM Short Answers-PrapoornapraveenaNo ratings yet

- Supply Chain Management FinalDocument12 pagesSupply Chain Management FinalManJyot SinghNo ratings yet

- SCMDocument5 pagesSCMSenai21dragoNo ratings yet

- CH 1Document19 pagesCH 1mmithoo290No ratings yet

- Key Concepts of Supply Chain Management: Chapter - 1Document19 pagesKey Concepts of Supply Chain Management: Chapter - 1KateNo ratings yet

- Inventory ManagementDocument5 pagesInventory Managementmickaellacson5No ratings yet

- SCM NotesDocument23 pagesSCM NotesHari KrishnanNo ratings yet

- Supply Chain Management PDFDocument60 pagesSupply Chain Management PDFpurushothaman PurushothamanNo ratings yet

- INTT 356 Spring 2021 Ch11 HandoutsDocument26 pagesINTT 356 Spring 2021 Ch11 HandoutsbbilgicberkNo ratings yet

- 4-Supply Chain ManagementDocument13 pages4-Supply Chain ManagementabhishekNo ratings yet

- Supply Chain Management: Basic ConceptsDocument44 pagesSupply Chain Management: Basic ConceptsBharat GohilNo ratings yet

- SBAA7026Document74 pagesSBAA7026vishal ranaNo ratings yet

- Advanced Supply Chain ManagementDocument8 pagesAdvanced Supply Chain ManagementM AhmedNo ratings yet

- Supply Chain ManagementDocument37 pagesSupply Chain ManagementShefali SinghNo ratings yet

- Supply Chain MangtDocument72 pagesSupply Chain Mangtkaranij2No ratings yet

- Assignment - 1: Summary of Class 1 To Class 4Document2 pagesAssignment - 1: Summary of Class 1 To Class 4Hafis SayedNo ratings yet

- Assignment - 1: Summary of Class 1 To Class 4Document2 pagesAssignment - 1: Summary of Class 1 To Class 4Hafis SayedNo ratings yet

- CHP - 49 - Lean and Agile Supply ChainDocument14 pagesCHP - 49 - Lean and Agile Supply ChainSiddesh SiddappaNo ratings yet

- An Introduction To Supply Chain ManagementDocument5 pagesAn Introduction To Supply Chain Managementsukhbir24No ratings yet

- DTM Module IDocument55 pagesDTM Module Idangerous saifNo ratings yet

- 1 Key Concepts of SCMDocument19 pages1 Key Concepts of SCMIsha MittalNo ratings yet

- SCM Unit1Document13 pagesSCM Unit1classybanana06No ratings yet

- Subject: Logistics and Retail Information Credits: 4Document135 pagesSubject: Logistics and Retail Information Credits: 4AKASH JOEL DAVIDNo ratings yet

- Assignment - 1: Summary of Class 1 To Class 4Document2 pagesAssignment - 1: Summary of Class 1 To Class 4Hafis SayedNo ratings yet

- Best Notes On Supply Chain Management1Document72 pagesBest Notes On Supply Chain Management1yashvardhansinghisaalphalegendNo ratings yet

- Unit-4 Physical Distribution SystemDocument28 pagesUnit-4 Physical Distribution SystemSTEVEN OMARYNo ratings yet

- History & Evolution of Supply Chain ManagemantDocument41 pagesHistory & Evolution of Supply Chain ManagemantGreeshma100% (7)

- Basic Concepts of Supply Chain ManagementDocument21 pagesBasic Concepts of Supply Chain ManagementRamkumar KumarNo ratings yet

- Chapter 21Document19 pagesChapter 21Fire BoltNo ratings yet

- Importance of Reverse Logistics in Supply Chain ManagementDocument27 pagesImportance of Reverse Logistics in Supply Chain ManagementRenjith SdNo ratings yet

- SCM 1Document71 pagesSCM 1Abdul RasheedNo ratings yet

- Age of LogisticsDocument136 pagesAge of LogisticsManu JosephNo ratings yet

- Chapter 1-17 JamDocument25 pagesChapter 1-17 JamEmmaNo ratings yet

- 21NKU 29 - Class ReflectionDocument8 pages21NKU 29 - Class Reflectionyoha priyaNo ratings yet

- Supply Chain Management Is The Management of A Network of Interconnected Businesses Involved in The Ultimate Provision of SCMDocument8 pagesSupply Chain Management Is The Management of A Network of Interconnected Businesses Involved in The Ultimate Provision of SCMPankajNo ratings yet

- Key Concepts of Supply Chain ManagementDocument1 pageKey Concepts of Supply Chain ManagementToño VillalobosNo ratings yet

- Unit 1 - SCM - Introduction To Supply Chain ManagementDocument22 pagesUnit 1 - SCM - Introduction To Supply Chain Managementaman.raj2022No ratings yet

- Logistics ManagementDocument27 pagesLogistics Managementapi-375001183% (12)

- Week 2Document27 pagesWeek 2Muhammad YahyaNo ratings yet

- The Role of Supply Chain As A Value DriverDocument276 pagesThe Role of Supply Chain As A Value DriverRey SinNo ratings yet

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- Procedure and Documentation in Supply Chain Management: Business strategy books, #1From EverandProcedure and Documentation in Supply Chain Management: Business strategy books, #1No ratings yet

- P2-The Five Major Supply Chain Drivers-2Document3 pagesP2-The Five Major Supply Chain Drivers-2Macayanan, Norlanie L.No ratings yet

- M3 - New Trends in Supply Chain TechnologyDocument3 pagesM3 - New Trends in Supply Chain TechnologyMacayanan, Norlanie L.No ratings yet

- Creating Supply Chains in Competitive AdvantageDocument2 pagesCreating Supply Chains in Competitive AdvantageMacayanan, Norlanie L.No ratings yet

- Northwestern University Laoag City Registration For Graduate School (VJSSGS) Commencement Exercise July 29, 2022Document51 pagesNorthwestern University Laoag City Registration For Graduate School (VJSSGS) Commencement Exercise July 29, 2022Macayanan, Norlanie L.No ratings yet

- CH 8 - AnswerDocument58 pagesCH 8 - Answer金沛霓No ratings yet

- Week 8 Homework - Part 2 - Financial AccountingDocument5 pagesWeek 8 Homework - Part 2 - Financial Accountinglamvolamvo0912No ratings yet

- Chapter 67 01 InvDocument45 pagesChapter 67 01 Invhaymanotandualem2015No ratings yet

- Lily Window Glass CoDocument2 pagesLily Window Glass CoSITI SARAH JAUHARINo ratings yet

- Long Test Midterm Coverage - QDocument6 pagesLong Test Midterm Coverage - QMark IlanoNo ratings yet

- Module 5 Inventory ManagementDocument20 pagesModule 5 Inventory ManagementRyan Dave MalnegroNo ratings yet

- Ch.5 Process Costing - Questions AnswersDocument7 pagesCh.5 Process Costing - Questions Answersdhfbbbbbbbbbbbbbbbbbh88% (8)

- SAP MM OverviewDocument9 pagesSAP MM OverviewRoxanaNo ratings yet

- Hangyo ProjectDocument31 pagesHangyo ProjectJessica GlennNo ratings yet

- Ibrahim Jawed WAC Scietific GlassDocument4 pagesIbrahim Jawed WAC Scietific GlassIbrahim JawedNo ratings yet

- Systematic Risk Vs Unsystematic RiskDocument4 pagesSystematic Risk Vs Unsystematic Riskgaurav112011No ratings yet

- Activity 1 - Manufacturing Accounting Cycle: Problem 1Document2 pagesActivity 1 - Manufacturing Accounting Cycle: Problem 1AJ OrtegaNo ratings yet

- Advantages of The DFF Types of Stock ValuationsDocument1 pageAdvantages of The DFF Types of Stock ValuationsvolhenryNo ratings yet

- Arbitrary Allocations-Not Significant Determinants of The CostDocument2 pagesArbitrary Allocations-Not Significant Determinants of The CostOlga SîrbuNo ratings yet

- Part 2 PRE2Document3 pagesPart 2 PRE2School FilesNo ratings yet

- Inventory Management in Supply Chain 2Document208 pagesInventory Management in Supply Chain 2cfakhryNo ratings yet

- 605 Chapter 6Document26 pages605 Chapter 6阿锭No ratings yet

- Chapter 15Document13 pagesChapter 15Brian Duela100% (1)

- 07-QTDM Chapter SevenDocument8 pages07-QTDM Chapter SevenErit AhmedNo ratings yet

- Inventory Control-MBADocument46 pagesInventory Control-MBAVenkadesh JNo ratings yet

- Index: S. NO. Topic Page NoDocument228 pagesIndex: S. NO. Topic Page NoMuskan NarulaNo ratings yet

- Tally Course BrochureDocument2 pagesTally Course BrochureRaja SenguptaNo ratings yet

- Hoba 2Document3 pagesHoba 2mariaNo ratings yet

- Formulas! 0 Current Assets Current Liabilities: Working CapitalDocument9 pagesFormulas! 0 Current Assets Current Liabilities: Working CapitalMajoy BantocNo ratings yet

- Net Requirements Planned-Order ReceiptsDocument43 pagesNet Requirements Planned-Order Receiptsajeng.saraswatiNo ratings yet

- Chap 015Document53 pagesChap 015Bagas NullNo ratings yet

- Accounting Principles: 11 Edition - US GAAPDocument73 pagesAccounting Principles: 11 Edition - US GAAPPutu Deny WijayaNo ratings yet

P1-Key Conepts of Supply Chain-1

P1-Key Conepts of Supply Chain-1

Uploaded by

Macayanan, Norlanie L.Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P1-Key Conepts of Supply Chain-1

P1-Key Conepts of Supply Chain-1

Uploaded by

Macayanan, Norlanie L.Copyright:

Available Formats

KEY CONEPTS OF SUPPLY CHAIN

The practice of supply chain management is guided by some basic underlying concepts that

have not changed much over the centuries. Several hundred years ago, Napoleon made the

remark, “An army marches on its stomach.” Napoleon was a master strategist and a skilful

general and this remark shows that he clearly understood the importance of what we would

now call an efficient supply chain. Unless the soldiers are fed, the army cannot move.

Along these same lines, there is another saying that goes, “Amateurs talk strategy and

professionals talk logistics.” People can discuss all sorts of grand strategies and dashing

manoeuvres but none of that will be possible without first figuring out how to meet the day-

to-day demands of providing an army with fuel, spare parts, food, shelter, and ammunition.

The term “supply chain management” arose in the late 1980s and came into widespread use

in the 1990s. Prior to that time, businesses used terms such as “logistics” and “operations

management” instead. Here are some definition of a supply chain:

• “A supply chain is the alignment of firms that bring products or services to market.”—from

Lambert, Stock, and Ellram. (Lambert, Douglas M., James R. Stock, and Lisa M. Ellram,

1998, Fundamentals of Logistics Management, Boston, MA: Irwin/ McGraw-Hill, Chapter

14)

• “A supply chain consists of all stages involved, directly or indirectly, in fulfi lling a

customer request. The supply chain not only includes the manufacturer and suppliers, but also

transporters, warehouses, retailers, and customers themselves.”—from Chopra and Meindl

(Chopra, Sunil, and Peter Meindl, 2003, Supply Chain, Second Edition, Upper Saddle River,

NJ: Prentice-Hall, Inc., Chapter 1).

• “A supply chain is a network of facilities and distribution options that performs the

functions of procurement of materials, transformation of these materials into intermediate and

finished products, and the distribution of these finished products to customers.”—from

Ganeshan and Harrison (Ganeshan, Ram, and Terry P. Harrison, 1995, “An Introduction to

Supply Chain Management,” Department of Management Sciences and Information Systems,

303 Beam Business Building, Penn State University, University Park, Pennsylvania).

• “The systemic, strategic coordination of the traditional business functions and the tactics

across these business functions within a particular company and across businesses within the

supply chain, for the purposes of improving the long-term performance of the individual

companies and the supply chain as a whole.”—from Mentzer, DeWitt, Keebler, Min, Nix,

Smith, and Zacharia (Mentzer, John T., William DeWitt, James S. Keebler, Soonhong Min,

Nancy W. Nix, Carlo D. Smith, and Zach G. Zacharia, 2001, “Defi ning Supply Chain

Management,” Journal of Business Logistics, Vol. 22, No. 2, p. 18).

HPC 6 SUPPLY CHAIN MANAGEMENT IN HOSPITALITY MANAGEMENT

1

There is a basic pattern to the practice of supply chain management. Each supply chain has its

own unique set of market demands and operating challenges and yet the issues remain

essentially the same in every case. Companies in any supply chain must make decisions

individually and collectively regarding their actions in five areas:

1. Production— What products does the market want? How much of which products should

be produced and by when? This activity includes the creation of master production schedules

that take into account plant capacities, workload balancing, quality control, and equipment

maintenance.

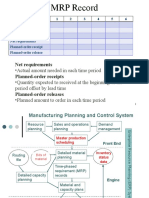

2. Inventory— What inventory should be stocked at each stage in a supply chain? How

much inventory should be held as raw materials, semi-finished, or finished goods? The

primary purpose of inventory is to act as a buffer against uncertainty in the supply chain.

However, holding inventory can be expensive.

3. Location— Where should facilities for production and inventory storage be located?

Where are the most cost efficient locations for production and for storage of inventory?

Should existing facilities be used or new ones built? Once these decisions are made they

determine the possible paths available for product to flow through for delivery to the final

consumer.

4. Transportation— How should inventory be moved from one supply chain location to

another? Air-freight and truck delivery are generally fast and reliable but they are expensive.

Shipping by sea or rail is much less expensive but usually involves longer transit times and

more uncertainty. This uncertainty must be compensated for by stocking higher levels of

inventory.

5. Information— How much data should be collected and how much information should be

shared? Timely and accurate information holds the promise of better coordination and better

decision making. With good information, people can make effective decisions about what to

produce and how much, about where to locate inventory, and how best to transport it.

HPC 6 SUPPLY CHAIN MANAGEMENT IN HOSPITALITY MANAGEMENT

2

You might also like

- Elysian CycleDocument3 pagesElysian CycleMyrnil TilbeNo ratings yet

- Supply Chain Management Multiple Choice QuestionsDocument5 pagesSupply Chain Management Multiple Choice QuestionsZeynep Bülbüllü80% (5)

- Accounting For Materials: I. Opening Prayer III. Overview of The Topic IV. Discussion II. AnnouncementsDocument38 pagesAccounting For Materials: I. Opening Prayer III. Overview of The Topic IV. Discussion II. AnnouncementsJasmin ToqueNo ratings yet

- SCMDocument20 pagesSCMifaNo ratings yet

- Introduction To Supply Chain Management NotesDocument7 pagesIntroduction To Supply Chain Management NotesAnonymous wMppXCM0No ratings yet

- Production - Inventory - Location - Transportation - InformationDocument7 pagesProduction - Inventory - Location - Transportation - InformationKushal BagadiyaNo ratings yet

- Supply Chain ReviewerDocument7 pagesSupply Chain ReviewerAlexisNo ratings yet

- Introduction To Supply ChainDocument6 pagesIntroduction To Supply ChainAlexisNo ratings yet

- Introduction To SCMDocument11 pagesIntroduction To SCMMike DeeNo ratings yet

- Supply Chain Management - TQMDocument11 pagesSupply Chain Management - TQMsuriya kishoreNo ratings yet

- History and Key Concept of SCDocument9 pagesHistory and Key Concept of SCRoli RoliNo ratings yet

- Term Paper OF Operation Management (O.M) : TopicDocument15 pagesTerm Paper OF Operation Management (O.M) : TopicreyazmbaNo ratings yet

- BA 7051 Logistics and Supply Chain Management UNIT - 1Document13 pagesBA 7051 Logistics and Supply Chain Management UNIT - 1porseenaNo ratings yet

- Basic Concepts of Supply Chain ManagementDocument42 pagesBasic Concepts of Supply Chain ManagementMarcela BerrocalNo ratings yet

- LeslyDocument3 pagesLeslymickaellacson5No ratings yet

- Unit - IDocument100 pagesUnit - Irajeeeva100% (1)

- An Analysis of Global Supply Chain Management - Indian PerspectiveDocument58 pagesAn Analysis of Global Supply Chain Management - Indian PerspectiveujwaljaiswalNo ratings yet

- Supply Chain Management 22Document17 pagesSupply Chain Management 22mussamhsNo ratings yet

- P2-The Five Major Supply Chain Drivers-2Document3 pagesP2-The Five Major Supply Chain Drivers-2Macayanan, Norlanie L.No ratings yet

- LSCM Short Answers-PrapoornaDocument3 pagesLSCM Short Answers-PrapoornapraveenaNo ratings yet

- Supply Chain Management FinalDocument12 pagesSupply Chain Management FinalManJyot SinghNo ratings yet

- SCMDocument5 pagesSCMSenai21dragoNo ratings yet

- CH 1Document19 pagesCH 1mmithoo290No ratings yet

- Key Concepts of Supply Chain Management: Chapter - 1Document19 pagesKey Concepts of Supply Chain Management: Chapter - 1KateNo ratings yet

- Inventory ManagementDocument5 pagesInventory Managementmickaellacson5No ratings yet

- SCM NotesDocument23 pagesSCM NotesHari KrishnanNo ratings yet

- Supply Chain Management PDFDocument60 pagesSupply Chain Management PDFpurushothaman PurushothamanNo ratings yet

- INTT 356 Spring 2021 Ch11 HandoutsDocument26 pagesINTT 356 Spring 2021 Ch11 HandoutsbbilgicberkNo ratings yet

- 4-Supply Chain ManagementDocument13 pages4-Supply Chain ManagementabhishekNo ratings yet

- Supply Chain Management: Basic ConceptsDocument44 pagesSupply Chain Management: Basic ConceptsBharat GohilNo ratings yet

- SBAA7026Document74 pagesSBAA7026vishal ranaNo ratings yet

- Advanced Supply Chain ManagementDocument8 pagesAdvanced Supply Chain ManagementM AhmedNo ratings yet

- Supply Chain ManagementDocument37 pagesSupply Chain ManagementShefali SinghNo ratings yet

- Supply Chain MangtDocument72 pagesSupply Chain Mangtkaranij2No ratings yet

- Assignment - 1: Summary of Class 1 To Class 4Document2 pagesAssignment - 1: Summary of Class 1 To Class 4Hafis SayedNo ratings yet

- Assignment - 1: Summary of Class 1 To Class 4Document2 pagesAssignment - 1: Summary of Class 1 To Class 4Hafis SayedNo ratings yet

- CHP - 49 - Lean and Agile Supply ChainDocument14 pagesCHP - 49 - Lean and Agile Supply ChainSiddesh SiddappaNo ratings yet

- An Introduction To Supply Chain ManagementDocument5 pagesAn Introduction To Supply Chain Managementsukhbir24No ratings yet

- DTM Module IDocument55 pagesDTM Module Idangerous saifNo ratings yet

- 1 Key Concepts of SCMDocument19 pages1 Key Concepts of SCMIsha MittalNo ratings yet

- SCM Unit1Document13 pagesSCM Unit1classybanana06No ratings yet

- Subject: Logistics and Retail Information Credits: 4Document135 pagesSubject: Logistics and Retail Information Credits: 4AKASH JOEL DAVIDNo ratings yet

- Assignment - 1: Summary of Class 1 To Class 4Document2 pagesAssignment - 1: Summary of Class 1 To Class 4Hafis SayedNo ratings yet

- Best Notes On Supply Chain Management1Document72 pagesBest Notes On Supply Chain Management1yashvardhansinghisaalphalegendNo ratings yet

- Unit-4 Physical Distribution SystemDocument28 pagesUnit-4 Physical Distribution SystemSTEVEN OMARYNo ratings yet

- History & Evolution of Supply Chain ManagemantDocument41 pagesHistory & Evolution of Supply Chain ManagemantGreeshma100% (7)

- Basic Concepts of Supply Chain ManagementDocument21 pagesBasic Concepts of Supply Chain ManagementRamkumar KumarNo ratings yet

- Chapter 21Document19 pagesChapter 21Fire BoltNo ratings yet

- Importance of Reverse Logistics in Supply Chain ManagementDocument27 pagesImportance of Reverse Logistics in Supply Chain ManagementRenjith SdNo ratings yet

- SCM 1Document71 pagesSCM 1Abdul RasheedNo ratings yet

- Age of LogisticsDocument136 pagesAge of LogisticsManu JosephNo ratings yet

- Chapter 1-17 JamDocument25 pagesChapter 1-17 JamEmmaNo ratings yet

- 21NKU 29 - Class ReflectionDocument8 pages21NKU 29 - Class Reflectionyoha priyaNo ratings yet

- Supply Chain Management Is The Management of A Network of Interconnected Businesses Involved in The Ultimate Provision of SCMDocument8 pagesSupply Chain Management Is The Management of A Network of Interconnected Businesses Involved in The Ultimate Provision of SCMPankajNo ratings yet

- Key Concepts of Supply Chain ManagementDocument1 pageKey Concepts of Supply Chain ManagementToño VillalobosNo ratings yet

- Unit 1 - SCM - Introduction To Supply Chain ManagementDocument22 pagesUnit 1 - SCM - Introduction To Supply Chain Managementaman.raj2022No ratings yet

- Logistics ManagementDocument27 pagesLogistics Managementapi-375001183% (12)

- Week 2Document27 pagesWeek 2Muhammad YahyaNo ratings yet

- The Role of Supply Chain As A Value DriverDocument276 pagesThe Role of Supply Chain As A Value DriverRey SinNo ratings yet

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- Procedure and Documentation in Supply Chain Management: Business strategy books, #1From EverandProcedure and Documentation in Supply Chain Management: Business strategy books, #1No ratings yet

- P2-The Five Major Supply Chain Drivers-2Document3 pagesP2-The Five Major Supply Chain Drivers-2Macayanan, Norlanie L.No ratings yet

- M3 - New Trends in Supply Chain TechnologyDocument3 pagesM3 - New Trends in Supply Chain TechnologyMacayanan, Norlanie L.No ratings yet

- Creating Supply Chains in Competitive AdvantageDocument2 pagesCreating Supply Chains in Competitive AdvantageMacayanan, Norlanie L.No ratings yet

- Northwestern University Laoag City Registration For Graduate School (VJSSGS) Commencement Exercise July 29, 2022Document51 pagesNorthwestern University Laoag City Registration For Graduate School (VJSSGS) Commencement Exercise July 29, 2022Macayanan, Norlanie L.No ratings yet

- CH 8 - AnswerDocument58 pagesCH 8 - Answer金沛霓No ratings yet

- Week 8 Homework - Part 2 - Financial AccountingDocument5 pagesWeek 8 Homework - Part 2 - Financial Accountinglamvolamvo0912No ratings yet

- Chapter 67 01 InvDocument45 pagesChapter 67 01 Invhaymanotandualem2015No ratings yet

- Lily Window Glass CoDocument2 pagesLily Window Glass CoSITI SARAH JAUHARINo ratings yet

- Long Test Midterm Coverage - QDocument6 pagesLong Test Midterm Coverage - QMark IlanoNo ratings yet

- Module 5 Inventory ManagementDocument20 pagesModule 5 Inventory ManagementRyan Dave MalnegroNo ratings yet

- Ch.5 Process Costing - Questions AnswersDocument7 pagesCh.5 Process Costing - Questions Answersdhfbbbbbbbbbbbbbbbbbh88% (8)

- SAP MM OverviewDocument9 pagesSAP MM OverviewRoxanaNo ratings yet

- Hangyo ProjectDocument31 pagesHangyo ProjectJessica GlennNo ratings yet

- Ibrahim Jawed WAC Scietific GlassDocument4 pagesIbrahim Jawed WAC Scietific GlassIbrahim JawedNo ratings yet

- Systematic Risk Vs Unsystematic RiskDocument4 pagesSystematic Risk Vs Unsystematic Riskgaurav112011No ratings yet

- Activity 1 - Manufacturing Accounting Cycle: Problem 1Document2 pagesActivity 1 - Manufacturing Accounting Cycle: Problem 1AJ OrtegaNo ratings yet

- Advantages of The DFF Types of Stock ValuationsDocument1 pageAdvantages of The DFF Types of Stock ValuationsvolhenryNo ratings yet

- Arbitrary Allocations-Not Significant Determinants of The CostDocument2 pagesArbitrary Allocations-Not Significant Determinants of The CostOlga SîrbuNo ratings yet

- Part 2 PRE2Document3 pagesPart 2 PRE2School FilesNo ratings yet

- Inventory Management in Supply Chain 2Document208 pagesInventory Management in Supply Chain 2cfakhryNo ratings yet

- 605 Chapter 6Document26 pages605 Chapter 6阿锭No ratings yet

- Chapter 15Document13 pagesChapter 15Brian Duela100% (1)

- 07-QTDM Chapter SevenDocument8 pages07-QTDM Chapter SevenErit AhmedNo ratings yet

- Inventory Control-MBADocument46 pagesInventory Control-MBAVenkadesh JNo ratings yet

- Index: S. NO. Topic Page NoDocument228 pagesIndex: S. NO. Topic Page NoMuskan NarulaNo ratings yet

- Tally Course BrochureDocument2 pagesTally Course BrochureRaja SenguptaNo ratings yet

- Hoba 2Document3 pagesHoba 2mariaNo ratings yet

- Formulas! 0 Current Assets Current Liabilities: Working CapitalDocument9 pagesFormulas! 0 Current Assets Current Liabilities: Working CapitalMajoy BantocNo ratings yet

- Net Requirements Planned-Order ReceiptsDocument43 pagesNet Requirements Planned-Order Receiptsajeng.saraswatiNo ratings yet

- Chap 015Document53 pagesChap 015Bagas NullNo ratings yet

- Accounting Principles: 11 Edition - US GAAPDocument73 pagesAccounting Principles: 11 Edition - US GAAPPutu Deny WijayaNo ratings yet