Professional Documents

Culture Documents

Self Evaluation by Suppliers

Self Evaluation by Suppliers

Uploaded by

ALI ASGHAROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Self Evaluation by Suppliers

Self Evaluation by Suppliers

Uploaded by

ALI ASGHARCopyright:

Available Formats

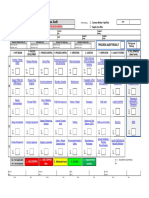

Supplier Self Evaluation for Mass Supplier Name

Supplier Top Management Approval

Production Start up Main Process

(For Example Press/Stamping or Injection Molding/Blow Molding or Casting or Machining or

Electroplating/Paint)

Prepared by Checked by Approval

Supplier Self Evaluation Summary Main Parts Supplied 1. 5.

2. 6.

3. 7.

4. 8.

[ MGR Level ] [ GM ] [ DIR / CEO ]

No Topic Detail Target (100%) Actual (%) Remark

1 Production Equipment Verification Dies / Molds condition Readiness 100%

Jigs for process condition Readiness 100%

Electroplating and Paint equipment condition Readiness 100%

Production Equipment Verification Preventive maintenance of Dies/Molds/Jigs 100% OK (As per Check Sheet)

100% 2 Machines Condition Machines for production condition Readiness 100%

Others Machine Condition

Preventive maintenance of all Machines 100% OK (As per Check Sheet)

50% 3 Measuring Equipment Verification Measuring equipment condition Readiness 100%

Inspection jigs condition Readiness 100%

Man Power Education & Training 0% Measuring Equipment Verification Inspection jigs calibration As per Calibration Check Sheet

4 Quality of Parts Parts accuracy on trials before start up As per DWG

Appearance of parts As per Q Point Check Sheet

Dimensional Inspection of Parts (3 Pc/Lot) As per Dimensinal Inspection report

4M Change Point Quality of Parts

5 Material, WIP, Finish Good Check 100% inspection of Raw Material As per Rec. Insp. Check Sheet

Material, WIP, Finish Good Check 100% Inspection of all WIP Parts

Based on Limit sample

(Rust, crack, sub part miss, any quality issue etc.)

100% inspection of Finished Parts As per Final Insp. Check Sheet

Dimensional Inspection of Parts (3 Pc/Lot) As per Dimensinal Inspection report

6 4M Change Point 4M Change Point Sheet and Procedure 100% clarified

4M Change Handling No pending item

Concern Items

7 Man Power Education & Training Man Power process training

Concern Items Countermeasure PIC Target Quality inspectors training As per Training Plan and updated skill

matrix chart

- Procedure,OPS and Check items knowledge

8 Others Trials before mass pro result

- Parameters [Based on PQCT and Parameter sheet]*

- Rejection rate [Based internal reject target]*

* To be filled by supplier based on each supplier target

Target

Actual

Contents

Production Equipment Verification 100% #DIV/0!

Machine Condition 100% #DIV/0!

Measuring Equipment Verification 100% #DIV/0!

Quality of Parts 100% #DIV/0!

Material, WIP, Finish Good Check 100% #DIV/0!

4M Change Point 100% #DIV/0!

Man Power Education & Training 100% #DIV/0!

Others 100% #DIV/0!

You might also like

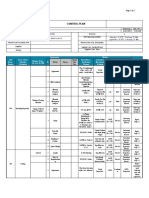

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- AIAG-VDA Pfmea FormatDocument7 pagesAIAG-VDA Pfmea FormatJohn OoNo ratings yet

- Allstate/McKinsey Bates H000001010Document495 pagesAllstate/McKinsey Bates H0000010104207west59th100% (3)

- Movie Recommendation SystemDocument41 pagesMovie Recommendation SystemSowmya Srinivasan100% (3)

- Automotive Spare Parts Study For The GCC MarketsDocument42 pagesAutomotive Spare Parts Study For The GCC MarketsAhmed Mabrouk100% (1)

- Instructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Document9 pagesInstructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Marco Antonio Jimenez CervantesNo ratings yet

- Boom Placer ChecklistDocument3 pagesBoom Placer ChecklistAlves Edattukaran100% (3)

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- Control Plan ExampleDocument1 pageControl Plan Examplelingkungan.agathaNo ratings yet

- Control Plan: Process InformationDocument20 pagesControl Plan: Process InformationGeovanni calderonNo ratings yet

- Investigation of Direct Cause: Related Depts Preparation Date: DeptDocument8 pagesInvestigation of Direct Cause: Related Depts Preparation Date: DeptBill wNo ratings yet

- Self Assessment Sheet by VendorDocument60 pagesSelf Assessment Sheet by VendorAjayNo ratings yet

- Maharashtra Polymer Products: Control PlanDocument3 pagesMaharashtra Polymer Products: Control PlanHitarth_dhamsaniaNo ratings yet

- Control Plan-General SampleDocument7 pagesControl Plan-General SampleMartin PetricNo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- Annex 2 Process Audit PDFDocument15 pagesAnnex 2 Process Audit PDFAngie GuerreroNo ratings yet

- Pro-Quality Associates Control PlanDocument1 pagePro-Quality Associates Control PlanDeepak kumarNo ratings yet

- Pro-Quality Associates Control PlanDocument1 pagePro-Quality Associates Control PlanDeepak kumarNo ratings yet

- APQP PPAP Evidence WorkbookDocument34 pagesAPQP PPAP Evidence WorkbookSead ZejnilovicNo ratings yet

- Control PlanDocument9 pagesControl Planjose antonioNo ratings yet

- Control Plan Template 2011 PDFDocument1 pageControl Plan Template 2011 PDFSenthil_KNo ratings yet

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 pagesKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganNo ratings yet

- Instructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Document13 pagesInstructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Ruanda NelNo ratings yet

- Plating Process Control Plan Template (2738)Document10 pagesPlating Process Control Plan Template (2738)George Hardy100% (1)

- CP For Assembly PartsDocument1 pageCP For Assembly Partssantosh kumarNo ratings yet

- PQ MULTI MILL LAB MODEL - SunriseDocument11 pagesPQ MULTI MILL LAB MODEL - SunriseRavii CurtisNo ratings yet

- Preventive MaintenanceDocument19 pagesPreventive Maintenancepm9286vNo ratings yet

- Suppilier Quality ManualDocument36 pagesSuppilier Quality ManualMukesh MehtaNo ratings yet

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- Etech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingDocument4 pagesEtech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingMadan PrakashNo ratings yet

- Project Tracking Template: Projects Deliverable (S) Cost / HoursDocument3 pagesProject Tracking Template: Projects Deliverable (S) Cost / HoursYvette NeethlingNo ratings yet

- Description PIC Document Procedure Test Cut Part Movement Flow ChartDocument1 pageDescription PIC Document Procedure Test Cut Part Movement Flow ChartJoeIsmailNo ratings yet

- Control Plan & FMEADocument13 pagesControl Plan & FMEAAmit LuniaNo ratings yet

- Control Plan TWIN ANCHORDocument5 pagesControl Plan TWIN ANCHORMURALIDHRANo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Page 1 of 1: Control PlanDocument1 pagePage 1 of 1: Control PlannormalNo ratings yet

- Spec MTG Detail SheetDocument1 pageSpec MTG Detail SheetSanjayNo ratings yet

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 pagesStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavNo ratings yet

- QAPDocument6 pagesQAPRahul ChandanNo ratings yet

- Ghaith PpeDocument14 pagesGhaith PpeHajri MariamNo ratings yet

- Prototype Control Plan Worksheet 1Document1 pagePrototype Control Plan Worksheet 1pankaj100% (1)

- Quality Control PlanDocument1 pageQuality Control PlanScha Affin100% (1)

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALNo ratings yet

- PFMEA New FormatDocument63 pagesPFMEA New FormatArshad AnsariNo ratings yet

- Bulk Materials Requirements ChecklistDocument1 pageBulk Materials Requirements ChecklistRene TapiaNo ratings yet

- Vda FmeaDocument30 pagesVda Fmealalit GuptaNo ratings yet

- Control PlanDocument6 pagesControl PlanEshioNo ratings yet

- Instructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Document7 pagesInstructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224IrmaMedinaNo ratings yet

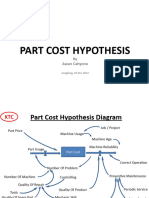

- How To Bring Down Part CostDocument6 pagesHow To Bring Down Part CostAwanNo ratings yet

- Control Plan Ingersol RandDocument2 pagesControl Plan Ingersol Randrgrao85No ratings yet

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaNo ratings yet

- ASTM 22 Instructions For Assembly Maintenance On How To Conduct Track Check Rev 02Document3 pagesASTM 22 Instructions For Assembly Maintenance On How To Conduct Track Check Rev 02lilianNo ratings yet

- Cntlplan 5Document6 pagesCntlplan 5sumeetsaini88No ratings yet

- Fmea Errata 2020Document8 pagesFmea Errata 2020r aNo ratings yet

- Inspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiaDocument6 pagesInspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiavinodNo ratings yet

- Inspection and Test Plan Quality PlanDocument6 pagesInspection and Test Plan Quality Planvinod100% (1)

- 2.quality Manual PCFF StampedDocument51 pages2.quality Manual PCFF StampedAswin ANo ratings yet

- Control Plan TRANINGDocument18 pagesControl Plan TRANINGqualityNo ratings yet

- Use This As Reference For Painting Process It May Be Similar To YoursDocument7 pagesUse This As Reference For Painting Process It May Be Similar To Yoursabdelnasser hasanNo ratings yet

- 1 - Tripod Beta Analysis, Incident Reporting & Investigation TechniquesDocument38 pages1 - Tripod Beta Analysis, Incident Reporting & Investigation TechniquesALI ASGHARNo ratings yet

- Zero Based Budget Template 05Document15 pagesZero Based Budget Template 05ALI ASGHARNo ratings yet

- Supplier Audit Check Sheet.Document1 pageSupplier Audit Check Sheet.ALI ASGHARNo ratings yet

- FF0386!01!5 Whys Slide Template 16x9 1Document6 pagesFF0386!01!5 Whys Slide Template 16x9 1ALI ASGHARNo ratings yet

- Digital Electronics MCQDocument10 pagesDigital Electronics MCQDr.D.PradeepkannanNo ratings yet

- Cut List Cheat SheetDocument1 pageCut List Cheat SheetmeredithNo ratings yet

- Portfolio AnswersDocument4 pagesPortfolio Answersa73609No ratings yet

- Shah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfDocument311 pagesShah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfTri4alNo ratings yet

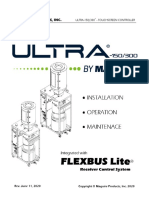

- Ultra 150 300 Ts FileDocument136 pagesUltra 150 300 Ts FileEmanuel GutierrezNo ratings yet

- Anaesthetic Considerations in Polytrauma PatientsDocument8 pagesAnaesthetic Considerations in Polytrauma PatientsMileidys LopezNo ratings yet

- Chapter 1 Computer SecurityDocument22 pagesChapter 1 Computer SecurityAjay GuptaNo ratings yet

- Indian Bank Vs Maharashtra State Cooperative Marke0827s980450COM441873Document4 pagesIndian Bank Vs Maharashtra State Cooperative Marke0827s980450COM441873Bhuvneshwari RathoreNo ratings yet

- Visual IdentityDocument38 pagesVisual IdentityyannaNo ratings yet

- Chap 6-Supply, Demand & Government PoliciesDocument30 pagesChap 6-Supply, Demand & Government PoliciesKhánh AnNo ratings yet

- Regional Trial Court: Motion To Quash Search WarrantDocument3 pagesRegional Trial Court: Motion To Quash Search WarrantPaulo VillarinNo ratings yet

- Iac Advanced Financial Accounting and ReDocument4 pagesIac Advanced Financial Accounting and ReIshi AbainzaNo ratings yet

- Basement and Retaining WallsDocument42 pagesBasement and Retaining WallsSamata Mahajan0% (1)

- 9 Polyethylene Piping SystemDocument4 pages9 Polyethylene Piping SystemPrashant PatilNo ratings yet

- AECES Night Lights Sound ReservationDocument1 pageAECES Night Lights Sound ReservationVincent Carl CatigayNo ratings yet

- Homeland Security Thesis StatementDocument8 pagesHomeland Security Thesis Statementdwtcn1jq100% (2)

- SP22 BseDocument3 pagesSP22 Bsebazm-e- wafaNo ratings yet

- Code of Practice For Power System ProtectionDocument3 pagesCode of Practice For Power System ProtectionVinit JhingronNo ratings yet

- Cable Incendio 2X18 Awg S/P: UL1424FPLRDocument1 pageCable Incendio 2X18 Awg S/P: UL1424FPLR04143510504gallucciNo ratings yet

- Steel-Concrete Composites Beams Considering Shear Slip EffectDocument23 pagesSteel-Concrete Composites Beams Considering Shear Slip EffectAnnisa Prita MelindaNo ratings yet

- State of The Art Review of CO2 Storage Site Selection and Characterisation MethodsDocument132 pagesState of The Art Review of CO2 Storage Site Selection and Characterisation MethodsApostolos ArvanitisNo ratings yet

- Q PapersDocument53 pagesQ PapersTanu RdNo ratings yet

- Final Report (NTCC) IoTDocument11 pagesFinal Report (NTCC) IoTSyed MehsherNo ratings yet

- GRAVE DISHONESTY: JurisprudenceDocument1 pageGRAVE DISHONESTY: JurisprudenceNielgem Beja0% (1)

- Licom AlphaCamDocument27 pagesLicom AlphaCamdrx11100% (1)

- Irene RAYOS-OMBAC, Complainant, Orlando A. RAYOS, RespondentDocument5 pagesIrene RAYOS-OMBAC, Complainant, Orlando A. RAYOS, RespondentGraceNo ratings yet

- D H Reid - Organic Compounds of Sulphur, Selenium, and Tellurium Vol 1-Royal Society of Chemistry (1970)Document518 pagesD H Reid - Organic Compounds of Sulphur, Selenium, and Tellurium Vol 1-Royal Society of Chemistry (1970)julianpellegrini860No ratings yet

- Exam Preparation Chartered Member Solutions 20080403Document36 pagesExam Preparation Chartered Member Solutions 20080403Jordy NgNo ratings yet