Professional Documents

Culture Documents

Sika Monotop R: High Performance Polymer Modified Repair Mortar

Sika Monotop R: High Performance Polymer Modified Repair Mortar

Uploaded by

Viet LeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sika Monotop R: High Performance Polymer Modified Repair Mortar

Sika Monotop R: High Performance Polymer Modified Repair Mortar

Uploaded by

Viet LeCopyright:

Available Formats

Product Data Sheet

Edition 04,2009.

Identification no. 3.2. 004

Version No. 07

Sika MonoTop® R

® ®

Sika MonoTop R

High Performance Polymer

Modified Repair mortar

Description Sika Monotop R is a one component, thixotropic, polymer modified, fibre

reinforced, cementitious mortar containing silica fume.

Uses Q Fast repairs to horizontal and vertical concrete or mortar surfaces

above and below ground level.

Construction

Q Filling/ repair mortar for voids, honeycombed areas, etc.

Q Repair of spalled concrete caused by reinforcement corrosion.

Q Repairs with improved resistance to oils, sewage, chemicals, etc.

Advantages Q Fast and easy to apply

Q Requires only the addition of clean water

Q Adjustable consistency

Q Compatible with thermal expansion properties of concrete

Q Chloride-free, non-corrosive

Q Non-toxic

Q Fibre incorporated to prevent micro crack

Q Minimized shrinkage tendency

Q High bond strength

Q Greatly reduced water and carbon dioxide permeability

Q Good sulfate resistance

Q Improved resistance to oils and chemicals

Product Data

Form/Colour Powder / Grey

Packaging 25 kg bag

Storage Dry, cool, shaded place

Shelf life Min. 6 months if stored properly in unopened, original packaging

Sika Limited (Vietnam)

Head Office:

Nhon Trach 1 Industrial Zone,

Nhon Trach Dist., Dong Nai Province

Tel: (84-61) 3560 700

Fax: (84-61) 3560 699

® ®

4 Sika MonoTop R 4/4 1 Sika MonoTop R 1/3

Technical Data Mixing Sika Monotop R should be mechanically mixed in a clean container using

a low-speed electric mixer (max. 500 rpm). Place quantity of water re-

Density ~ 1.45 kg/ltr (bulk density of powder) quired (3.4 – 3.5 ltr for 25-kg of Sika Monotop R) into a clean container and

then add Sika Monotop R slowly while mixing. A minimum mixing time of

~ 2.15 kg/ltr (density of fresh mortar)

3 minutes is recommended to thoroughly blends the components.

Mixing ratio Water : Sika Monotop R powder = 1 : 7.15 – 7.40 (parts by weight)

Application Brush apply a bonding coat onto the saturated surface dry substrate.

Water : Sika Monotop R powder = 1 : 4.95 – 5.10 (parts by volume) Then, working wet-on-wet, work the mixed mortar well into the substrate

using a rendering rather than a placing technique to fill all pores and

3.40 - 3.50 litres of clean water per 25 kg bag voids. Compact well. Force material against the edge of the repair, work-

Consumption 1 bag yields approx. 13.3 litres of mortar ing towards the centre. For repairs in excess of 20 mm deep, apply in

3

Approx. 75 bags required for 1 (one) m of mortar layers ensuring previous layers are well keyed and hardened. Finish

lower layers with a heavy brush stipple to form a key for subsequent

o

Pot life ~ 30 minutes (at 27 C / 65 % r.H) layers. If previous layers are over 48 hours old, needle gun the surface

2 and dampen. Steel trowel the final coat if required.

Compressive strength ∼ 15 N/mm (1 day), ASTM C-349

2

∼ 45 N/mm (28 days) Curing To achieve the full potential of any cement based material, curing is es-

2 sential. In warm or windy weather, the use of standard curing methods

Flexural strength ∼ 8 N/mm (28 days), ASTM C-348

are necessary (use of polythene sheets or damp hessian) to prevent

2

Bond strength ∼ 1.5 N/mm (on concrete surface with bonding bridge) premature drying out of mortar.

Construction

Layer thickness per Minimum 5 mm Cleaning Remove non-hardened Sika Monotop products from tools and equip-

ment with water. Hardened material can only be removed mechanically.

application Maximum 30 mm

o Notes on application /Limits Q Mix to a uniform consistency (no lumps). A small reduction in the

Application temperature Minimum 6 C water gives a stiffer mix.

o

Maximum 40 C

Q Repairs with Sika Monotop system cannot bridge live cracks or mov-

ing joints, etc.

Application Q Repairs in excess of 20 mm deep must be layered as indicated

Surface preparation All concrete and mortar substrate must be sound, clean and free from oil, above.

grease and surface contaminants. All loose materials and surface laitance Q Sika Monotop mortars that are wetted during the initial cure period

must be removed. For large areas, grit or grit-water blasting or scabbling may produce a white “bloom” on the surface which does not affect the

is recommended. For small areas and for “spot” repairs, needle gunning long term properties of the mortar.

or jack-hammering is effective. The concrete or mortar substrate must

have a minimum compressive strength of 20 MPa.

Health and Safety information

The prepared substrate should be thoroughly soaked with clean water

until uniformly saturated but with no surface water. This condition is re- Ecology Water poluting

ferred to as saturated surface dry and care should be taken to remove any

cement slurry or dust produced during surface preparation. Steel Transportation class Non hazardous

reinforcements should have all traces of rust removed and be primed Waste disposal According to local law

with two coats of Sika Monotop 610.

Important notes Sika Monotop R is cement based and is therefore alkaline. Suitable

Priming Concrete precautions should be taken to minimize direct contact with the skin. If

Prior to the application of Sika Monotop R, Sika Monotop 610 should be the material gets into the eyes, rinse immediately with clean water and

applied as bonding bridge. Always work “wet on wet” on priming coats seek medical attention.

(refer to Sika Monotop 610 Data Sheet)

Disclaimer The information, and, in particular, the recommendations relating to the application and end-use

Reinforcement of Sika products, are given in good faith based on Sika’s current knowledge and experience of

the products when properly stored, handled and applied under normal conditions in accordance

Two coats of Sika Monotop 610 should be brush applied to the prepared with Sika’s recommendations. In practice, the differences in materials, substrates and actual site

steel (refer to Sika Monotop 610 Data Sheet). conditions are such that no warranty in respect of merchantability or of fitness for a particular

purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either

from this information, or from any written recommendations, or from any other advice offered. The

user of the product must test the product’s suitability for the intended application and purpose.

Sika reserves the right to change the properties of its products. The proprietary rights of third

parties must be observed. All orders are accepted subject to our current terms of sale and

delivery. Users must always refer to the most recent issue of the local Product Data Sheet for the

product concerned, copies of which will be supplied on request.

Sika Limited (Vietnam)

Head Office:

Nhon Trach 1 Industrial Zone,

Nhon Trach Dist., Dong Nai Province

Tel: (84-61) 3560 700

Fax: (84-61) 3560 699

® ®

2 Sika MonoTop R 2/3 3 Sika MonoTop R 3/4

Technical Data Mixing Sika Monotop R should be mechanically mixed in a clean container using

a low-speed electric mixer (max. 500 rpm). Place quantity of water re-

Density ~ 1.45 kg/ltr (bulk density of powder) quired (3.4 – 3.5 ltr for 25-kg of Sika Monotop R) into a clean container and

then add Sika Monotop R slowly while mixing. A minimum mixing time of

~ 2.15 kg/ltr (density of fresh mortar)

3 minutes is recommended to thoroughly blends the components.

Mixing ratio Water : Sika Monotop R powder = 1 : 7.15 – 7.40 (parts by weight)

Application Brush apply a bonding coat onto the saturated surface dry substrate.

Water : Sika Monotop R powder = 1 : 4.95 – 5.10 (parts by volume) Then, working wet-on-wet, work the mixed mortar well into the substrate

using a rendering rather than a placing technique to fill all pores and

3.40 - 3.50 litres of clean water per 25 kg bag voids. Compact well. Force material against the edge of the repair, work-

Consumption 1 bag yields approx. 13.3 litres of mortar ing towards the centre. For repairs in excess of 20 mm deep, apply in

3

Approx. 75 bags required for 1 (one) m of mortar layers ensuring previous layers are well keyed and hardened. Finish

lower layers with a heavy brush stipple to form a key for subsequent

o

Pot life ~ 30 minutes (at 27 C / 65 % r.H) layers. If previous layers are over 48 hours old, needle gun the surface

2 and dampen. Steel trowel the final coat if required.

Compressive strength ∼ 15 N/mm (1 day), ASTM C-349

2

∼ 45 N/mm (28 days) Curing To achieve the full potential of any cement based material, curing is es-

2 sential. In warm or windy weather, the use of standard curing methods

Flexural strength ∼ 8 N/mm (28 days), ASTM C-348

are necessary (use of polythene sheets or damp hessian) to prevent

2

Bond strength ∼ 1.5 N/mm (on concrete surface with bonding bridge) premature drying out of mortar.

Layer thickness per Minimum 5 mm Cleaning Remove non-hardened Sika Monotop products from tools and equip-

Construction

ment with water. Hardened material can only be removed mechanically.

application Maximum 30 mm

o Notes on application /Limits Q Mix to a uniform consistency (no lumps). A small reduction in the

Application temperature Minimum 6 C water gives a stiffer mix.

o

Maximum 40 C

Q Repairs with Sika Monotop system cannot bridge live cracks or mov-

ing joints, etc.

Application Q Repairs in excess of 20 mm deep must be layered as indicated

Surface preparation All concrete and mortar substrate must be sound, clean and free from oil, above.

grease and surface contaminants. All loose materials and surface laitance Q Sika Monotop mortars that are wetted during the initial cure period

must be removed. For large areas, grit or grit-water blasting or scabbling may produce a white “bloom” on the surface which does not affect the

is recommended. For small areas and for “spot” repairs, needle gunning long term properties of the mortar.

or jack-hammering is effective. The concrete or mortar substrate must

have a minimum compressive strength of 20 MPa.

Health and Safety information

The prepared substrate should be thoroughly soaked with clean water

until uniformly saturated but with no surface water. This condition is re- Ecology Water poluting

ferred to as saturated surface dry and care should be taken to remove any

cement slurry or dust produced during surface preparation. Steel Transportation class Non hazardous

reinforcements should have all traces of rust removed and be primed Waste disposal According to local law

with two coats of Sika Monotop 610.

Important notes Sika Monotop R is cement based and is therefore alkaline. Suitable

Priming Concrete precautions should be taken to minimize direct contact with the skin. If

Prior to the application of Sika Monotop R, Sika Monotop 610 should be the material gets into the eyes, rinse immediately with clean water and

applied as bonding bridge. Always work “wet on wet” on priming coats seek medical attention.

(refer to Sika Monotop 610 Data Sheet)

Disclaimer The information, and, in particular, the recommendations relating to the application and end-use

Reinforcement of Sika products, are given in good faith based on Sika’s current knowledge and experience of

the products when properly stored, handled and applied under normal conditions in accordance

Two coats of Sika Monotop 610 should be brush applied to the prepared with Sika’s recommendations. In practice, the differences in materials, substrates and actual site

steel (refer to Sika Monotop 610 Data Sheet). conditions are such that no warranty in respect of merchantability or of fitness for a particular

purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either

from this information, or from any written recommendations, or from any other advice offered. The

user of the product must test the product’s suitability for the intended application and purpose.

Sika reserves the right to change the properties of its products. The proprietary rights of third

parties must be observed. All orders are accepted subject to our current terms of sale and

delivery. Users must always refer to the most recent issue of the local Product Data Sheet for the

product concerned, copies of which will be supplied on request.

Sika Limited (Vietnam)

Nhon Trach 1 Industrial Zone,

Nhon Trach Dist., Dong Nai Province

Tel: (84-61) 3560 700 Fax: (84-61) 3560 699

www.sika.com.vn, sikavietnam@vn.sika.com

® ®

2 Sika MonoTop R 2/4 3 Sika MonoTop R 3/3

You might also like

- IHA AssessmentDocument4 pagesIHA Assessmentbmanojkumar16No ratings yet

- SikaTop Seal-107 2011-10 - 1Document4 pagesSikaTop Seal-107 2011-10 - 1hanifNo ratings yet

- Dispersion ModelDocument16 pagesDispersion ModelpijanNo ratings yet

- Sikafloor 2530W NewDocument3 pagesSikafloor 2530W NewNguyen Anh TuanNo ratings yet

- NG NP Sikatop Seal 107Document3 pagesNG NP Sikatop Seal 107NourhoudaNo ratings yet

- (Sika) Sika LatexDocument4 pages(Sika) Sika Latex_at_to_No ratings yet

- Sikafloor 2420Document3 pagesSikafloor 2420Nguyen Anh TuanNo ratings yet

- Standard Product Proposal For High Rise Building 07-07-2017Document18 pagesStandard Product Proposal For High Rise Building 07-07-2017eufrosina hernandezNo ratings yet

- Polybit Ma Polybond SBR Tds LeedDocument2 pagesPolybit Ma Polybond SBR Tds LeedMuhammad hussainNo ratings yet

- PDS SikaTop 107SealPlusIN en in 08 2022-2-1Document4 pagesPDS SikaTop 107SealPlusIN en in 08 2022-2-1Hiren ShahNo ratings yet

- Sika Poxitar MyDocument3 pagesSika Poxitar Myhijur ChenNo ratings yet

- (Sika) Sika Monotop 612Document5 pages(Sika) Sika Monotop 612_at_to_No ratings yet

- SikaTop Seal 200Document5 pagesSikaTop Seal 200Levi Leonardo Abayon JuniorNo ratings yet

- TDS VETOBOND pb434Document4 pagesTDS VETOBOND pb434PeshteenNo ratings yet

- 6.6 Bondit SBRDocument4 pages6.6 Bondit SBRCristal Haze VictoriaNo ratings yet

- Industrial Shutdowns: Product Portfolio For Time Critical Industrial ApplicationsDocument4 pagesIndustrial Shutdowns: Product Portfolio For Time Critical Industrial ApplicationsMuzamil ArshadNo ratings yet

- Sika MonoTop-610 MY 2011-10 - 1Document4 pagesSika MonoTop-610 MY 2011-10 - 1siranepNo ratings yet

- Sika MonoTop 615 PDS (CE)Document6 pagesSika MonoTop 615 PDS (CE)Mihai CîrsteaNo ratings yet

- Sika Rapid Repair Mortar PDS - CE - PDFDocument6 pagesSika Rapid Repair Mortar PDS - CE - PDFLouis BirNo ratings yet

- Sika MonoTop 620 PDS (CE)Document4 pagesSika MonoTop 620 PDS (CE)smproposalNo ratings yet

- Sika Rep: Multi-Purpose Patching and Repair MortarDocument2 pagesSika Rep: Multi-Purpose Patching and Repair MortarMohamed AzabNo ratings yet

- Adva SBR TDSDocument2 pagesAdva SBR TDSMohammed AbugharbiehNo ratings yet

- Advabond SBR TDSDocument2 pagesAdvabond SBR TDSMohammed AbugharbiehNo ratings yet

- Sikatop 109 SealingDocument4 pagesSikatop 109 SealingRajdeep ShitNo ratings yet

- Fosroc Nukote BGIIDocument4 pagesFosroc Nukote BGIIm.elsanee.cubicNo ratings yet

- Conbextra BB80: Constructive SolutionsDocument3 pagesConbextra BB80: Constructive SolutionsWahlee SatuNo ratings yet

- Sika Monotop RDocument3 pagesSika Monotop Rtengok69No ratings yet

- Sika Poxitar FDocument3 pagesSika Poxitar FBudhi KurniawanNo ratings yet

- Bonding AgentDocument7 pagesBonding Agentmohamed ragabNo ratings yet

- Sika TopSeal-107 - 231111 - 161028Document3 pagesSika TopSeal-107 - 231111 - 161028Evello MercanoNo ratings yet

- Nitobond SBR Latex: Constructive SolutionsDocument3 pagesNitobond SBR Latex: Constructive SolutionsKamal RaoNo ratings yet

- PACTOBond SBR-DatasheetDocument2 pagesPACTOBond SBR-DatasheethidiNo ratings yet

- DCP - Product SummeryDocument36 pagesDCP - Product SummeryMina RemonNo ratings yet

- Nitobond SBR TDSDocument3 pagesNitobond SBR TDSHariom GuptaNo ratings yet

- SikaTop Seal 107 Fact SheetDocument2 pagesSikaTop Seal 107 Fact SheetVicktorNo ratings yet

- MAPEI Solutions For Concrete - 2022-02-16Document24 pagesMAPEI Solutions For Concrete - 2022-02-16Carlos CabanasNo ratings yet

- Sikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface SealingDocument5 pagesSikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface SealingHaradhon DattaNo ratings yet

- TDS - Nitomortar SDocument4 pagesTDS - Nitomortar SDipNo ratings yet

- Sikagrout® - 200 PDFDocument2 pagesSikagrout® - 200 PDFMohamed SalahNo ratings yet

- SanGrip T Rib PE Concrete LinerDocument8 pagesSanGrip T Rib PE Concrete LineranandNo ratings yet

- Construction Chemicals: Total Solution ofDocument4 pagesConstruction Chemicals: Total Solution ofdwijNo ratings yet

- Pactocure RBDocument2 pagesPactocure RBNNo ratings yet

- G 90 Coumarone Indene ResinDocument2 pagesG 90 Coumarone Indene ResinGorkem TanrıverogluNo ratings yet

- Naphthaplast G 808Document2 pagesNaphthaplast G 808imran jamalNo ratings yet

- Sika PDS - E - Sika MonoTop - 610Document3 pagesSika PDS - E - Sika MonoTop - 610lwin_oo2435No ratings yet

- Nitobond SBR TDS PDFDocument3 pagesNitobond SBR TDS PDFravi0% (1)

- Sikagrout 214-11HSDocument3 pagesSikagrout 214-11HSvu hungNo ratings yet

- Sikagrout®-214: Product Data SheetDocument4 pagesSikagrout®-214: Product Data Sheetvirat_daveNo ratings yet

- MasterEase 3604 v1Document2 pagesMasterEase 3604 v1dachepalli963No ratings yet

- BPCL - 221019 PDFDocument55 pagesBPCL - 221019 PDFMaymole Boben100% (1)

- Advabond SBR Plus TDSDocument2 pagesAdvabond SBR Plus TDSMohammed AbugharbiehNo ratings yet

- (Sika) Sikatop 122hbDocument5 pages(Sika) Sikatop 122hb_at_to_No ratings yet

- Cem CreteDocument3 pagesCem CreteMadhukar SMNo ratings yet

- DR Fixit Coal Tar EpoxyDocument3 pagesDR Fixit Coal Tar EpoxyPritha DasNo ratings yet

- Fosroc Renderoc HB: Technical Data SheetDocument4 pagesFosroc Renderoc HB: Technical Data SheetRJNo ratings yet

- MRS MicroprojectDocument9 pagesMRS MicroprojectOm DeshmukhNo ratings yet

- AdmixturesDocument12 pagesAdmixturesdeepakNo ratings yet

- Concrete RepairsDocument12 pagesConcrete RepairsdeepakNo ratings yet

- Renderoc HB40 TDSDocument4 pagesRenderoc HB40 TDSLucasNo ratings yet

- CON ABR DryMortarApplications ENDocument12 pagesCON ABR DryMortarApplications ENPradchaya ThepvorrachaiNo ratings yet

- Running Collection MUDE Online Shop 2Document1 pageRunning Collection MUDE Online Shop 2Viet LeNo ratings yet

- Thong Bao Tang Gia 2022Document1 pageThong Bao Tang Gia 2022Viet LeNo ratings yet

- Permeability Testing of Radiation Shielding Concrete Manufactured at Industrial ScaleDocument15 pagesPermeability Testing of Radiation Shielding Concrete Manufactured at Industrial ScaleViet LeNo ratings yet

- De000wch8881 Ja 2011 Na e 00Document274 pagesDe000wch8881 Ja 2011 Na e 00Viet LeNo ratings yet

- Letter of Warning For Basement Waterproofing With Sikaproof A+12Document2 pagesLetter of Warning For Basement Waterproofing With Sikaproof A+12Viet LeNo ratings yet

- THINK8 Pitch DeskDocument21 pagesTHINK8 Pitch DeskViet LeNo ratings yet

- ScientificIsrael PaperDocument19 pagesScientificIsrael PaperViet LeNo ratings yet

- Presentation - Precast in Low-Rise BuildingDocument15 pagesPresentation - Precast in Low-Rise BuildingViet LeNo ratings yet

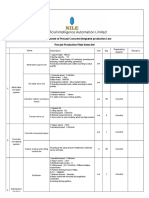

- NILE AIA - Company Items List Prices 2022.8Document4 pagesNILE AIA - Company Items List Prices 2022.8Viet LeNo ratings yet

- Migrating Vs Admixed Corrosion Inhibitors For SteeDocument14 pagesMigrating Vs Admixed Corrosion Inhibitors For SteeViet LeNo ratings yet

- Sika Monotop®-610: Product Data SheetDocument3 pagesSika Monotop®-610: Product Data SheetViet LeNo ratings yet

- Asseisementofbroadbandattenuaton GoueygouPiwakowskiDocument7 pagesAsseisementofbroadbandattenuaton GoueygouPiwakowskiViet LeNo ratings yet

- Masonry Support, Windposts & Lintels: For The Construction IndustryDocument36 pagesMasonry Support, Windposts & Lintels: For The Construction IndustryViet LeNo ratings yet

- L1. Coal Formation and RanksDocument3 pagesL1. Coal Formation and RanksNoor jameel IsehaqiNo ratings yet

- 1 PPT FM Introduction & Fluid PropertiesDocument104 pages1 PPT FM Introduction & Fluid PropertiesArjun NairNo ratings yet

- SSPC Paint ComDocument10 pagesSSPC Paint ComanoopkumarNo ratings yet

- Micoco c40 Technical Data SheetDocument2 pagesMicoco c40 Technical Data SheetNilesh GuptaNo ratings yet

- Biomaterial AssignmentDocument4 pagesBiomaterial AssignmentAhmad DboukNo ratings yet

- 101 Special Bearing CompoundDocument7 pages101 Special Bearing CompoundSlobodan PetrovicNo ratings yet

- Manual Booster OB-30Document41 pagesManual Booster OB-30Ivo SilvaNo ratings yet

- NCERT Solutions For Class 6 Science Chapter 4 Sorting Materials Into GroupsDocument8 pagesNCERT Solutions For Class 6 Science Chapter 4 Sorting Materials Into GroupsavinashNo ratings yet

- Dispersion of LightDocument2 pagesDispersion of LightEmman Revilla100% (1)

- Presentation of Joule Thomson EffectDocument16 pagesPresentation of Joule Thomson EffectAli Raza100% (6)

- 2015 Transdermal Patches A Review On Novel Approach For Drug Delivery PDFDocument18 pages2015 Transdermal Patches A Review On Novel Approach For Drug Delivery PDFDolih Gozali100% (1)

- Liqui-Cel Technical Brief Ammonia in Flue Gas Condensate For Biomass Power Stations LC-1004 CelumDocument2 pagesLiqui-Cel Technical Brief Ammonia in Flue Gas Condensate For Biomass Power Stations LC-1004 CelumOkko NNo ratings yet

- 2.2 Air Release and Cavitation: Saturation Pressure Induces Aeration. This Is The Process Where TheDocument2 pages2.2 Air Release and Cavitation: Saturation Pressure Induces Aeration. This Is The Process Where TheRichard De Medeiros CastroNo ratings yet

- BCH 312 Carbohydrate Metabolsim (DR OSSAI)Document8 pagesBCH 312 Carbohydrate Metabolsim (DR OSSAI)maryjanenzubechukwu901No ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- Fire Prevention & Control: Fire & Safety Dept-MRDocument65 pagesFire Prevention & Control: Fire & Safety Dept-MRnvaradharajan1971No ratings yet

- Chemistry PDFDocument79 pagesChemistry PDFVictor CantuárioNo ratings yet

- 01 Samss 041 PDFDocument14 pages01 Samss 041 PDFFAPM1285No ratings yet

- Physics Formula BookletDocument8 pagesPhysics Formula BookletramexistsNo ratings yet

- A Review On The Medicinal Importance of Pyridine DerivativesDocument12 pagesA Review On The Medicinal Importance of Pyridine DerivativesMuhammad ZahidNo ratings yet

- Flawed Specimen Kit - API-K1, UT-1Qualification Kit (FlawTech) - Welding Store - Weldperfect, Weld Inspection, Weld ToolsDocument2 pagesFlawed Specimen Kit - API-K1, UT-1Qualification Kit (FlawTech) - Welding Store - Weldperfect, Weld Inspection, Weld ToolsAnonymous DXCsjJNo ratings yet

- Gas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task AnalysisDocument6 pagesGas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task Analysisgowtham_venkat_4No ratings yet

- Production TechnologyDocument101 pagesProduction TechnologyHegdeVenugopalNo ratings yet

- Hydrotest Water Quality: NIOEC-SP-80-06Document7 pagesHydrotest Water Quality: NIOEC-SP-80-06Mohammad AminiNo ratings yet

- EU Stage V Emissions - Product Information GuideDocument16 pagesEU Stage V Emissions - Product Information GuideRichárd StefanicsNo ratings yet

- Heat Exchangers in NPP - SPDocument5 pagesHeat Exchangers in NPP - SPPreeti SheteNo ratings yet

- NOVAX Hair Care - PresentationDocument14 pagesNOVAX Hair Care - PresentationJudy LavyNo ratings yet

- Nitrox Stik Instruction ManualDocument15 pagesNitrox Stik Instruction ManualRicardo BanderasNo ratings yet