Professional Documents

Culture Documents

HH701 User Manual

HH701 User Manual

Uploaded by

Andres LaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HH701 User Manual

HH701 User Manual

Uploaded by

Andres LaiCopyright:

Available Formats

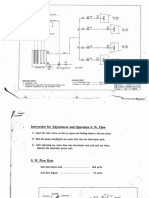

TESTMASTER 3 HARTRIDGE

Section 1

Introduction

1.1 General

This manual provides1he inform叩"'neo蕊S可for 1he lnslallallon, Pressure re忒泗s andbackleaktimes are displayed油沮ronicall y:

叩ra11on 叩d mam1enance ol lhe H訊ndge Tesl函固3 區tplans can be pr叩rammed and stored, and區I results printed

The Testmaster 3 ls a的eumalically叩e<aledI區I unil for p成,se The no221e fuel spray ,s capCured in an nluminated spray cham區

analysis of in1ec1or noz血pertonmance before a叩函er recondilto面` wh1Ch IS ev記oa1ed by a11.

1he operator ,s able 10 accurately measure 叨d set fuel pressu1e m

`如lo四rt01m1,訕11onal ,njeclo, 1es1S (0-700區r) In add油加, 1he

pneumal心1ny dn,en叩叩al心s a conltnuous fuel pressure lo be

maon1a囧!d enabling eas,er 1es11Jlg a,,d di句函is of more c叩!piex

mi氏IOIS

Section 2

Installation

Nole: Oonot 「的10ve1he plugfr磾 the fuel outtet (7) uni�the fuel 2.4 Air Supp ly

lank has been OIied, 認 desc,,bed in seciJOO 2 5

Un也ew lhe l汛w,cato, bowl Fill the bowl lo the maximum傭le汨呻a

2.1 General Specification/Requirements 函eral pu中se讜rflneoll(e g .• S<lkoleoe S.lkairVG22. OIS1而lar)and

面I lhe bowlDo nol OV画n

We,ghl-Nelt 22kg

E1ectnc,1y Supply 100-240Va.c. 47-63Hz Connect a compr蕊認d airSt」叩ly 3 to 6 bar IO the connccto, (17)al the

rear Secure with a hose dip Ensure Ihat awaler trap is filled 10 the

All Supply 3-6七r

supply

Exuooion Rate 0.057 -0.142 m1/str

「estOII 1S04113 (SAE J9670) 2.5 Fuel System

Osl Ca四City 3ht res 2.5.1 Approved Test Oil

2.2 Mounting Cahbrall()n lluid to 1$04 t13 s俘ciflcallon 叩Sl be used (SAE

吲uivalenl J9670) The llu,d vi 埡s,ty ,s to be betw蜘 245迢2.75

Tt,e汛此SU油ace should be strong and rigid 的 ough 10 support lhe

cenbSl吡esa140"C

面ghl nod operallon ol the Testmaster 3 and have sutfio的t area to

`如easy叩函lion and mainienance e.g Shell-Serre'Non面lluld'

Shell 4379

Mounttng Mies are pcov,函and lhe machine shoold be secured

加ooqb the呤 us,ng su,tallle scs邸邙,olts (1ele< to丙1) Castro!Di缸el Catlbrallon 01141 IJ

Dalton Silk豳e 2323

2.3 Electrical Installation ShcU 1996

The 洄k aieawinng muS1 com的wilh lhe current f記囧y, IEE or local

CAUTtON·Do nol u蕊 �el fuel (gazole) or used區illuid

哂ulat,oos Tho Testmaster ,s su叩led Wl1h a 12Vd c 1ranslorme,

wh,ch ,s1n區回to the ma,ns plug and requ 呤s a single pl,ase四,ns 2.5.2 Filling the Reservoir

supply ol 100 240Va.c. 47 -63 liz Ensure thal the dra,n pl四(4) IS 蕊畑ely filled Remove lhe lid (19)

Foll the re紉r,011 up 10 the level bar (21) and呣above ot. The ca四city

2.3.1 Spray Chamber Lamp

is a叨oximalely 3 hires

The bu1b for lhe spr.,y cham坪tamp (8) Is not filled lo the main uni!

when supplied To ht the bulb, remove lhe r畸r panel from 1he CAUTION: 函e mustoetaken whenfilhng1nereservoir. Clear all

machine and insen the加lb firmly into the holder Refit the rear co汨 sp,llages lh010呣hly Do not overfiR

CAUTION: Before renK>ving the rea, panel, ensure lhal the eleclncal 氐place lhe lid (19) ood remove the plug ficm lhe區I OU睏(7)

and lhe air su叩ly ace ,solaled

2.5.3 Spray Chamber Extraction

2.3.2 Connechon Connecl lhe spray chambet ouilel ( 13) via ducbng10 a su,1able

Se底I !he app(OJ)(函e plug 忒叩tor for the focal sockel confi!JUratoon cxlcmal e,I 成t,on sysletn

and as認mble the ma,n plug (simple push fil) Coo鴴CIIOI區m師5 Refet 10 lhe l-fealil1 Warnings al 1he froni of this manual

咄汜11,:al sod<el ai1d plug 1he jack plug 1n10 1he socke頃the rear of Ille

machine

4 (@) HL010

You might also like

- BMW Case Study SolutionDocument10 pagesBMW Case Study SolutionsarasNo ratings yet

- 1970-72 CHEVELLE: W/O Factory AirDocument25 pages1970-72 CHEVELLE: W/O Factory AirKiki SlaytanaNo ratings yet

- IOSK 72,5 .550 KV: Instructions For Assembling and Maintenance of Current Transformer TypeDocument17 pagesIOSK 72,5 .550 KV: Instructions For Assembling and Maintenance of Current Transformer TypeRonald MoreiraNo ratings yet

- Philips FR-930 Service ManualDocument52 pagesPhilips FR-930 Service ManualManuel Gomez MerquezNo ratings yet

- Oil and Water Retort, 50mL ModelsDocument14 pagesOil and Water Retort, 50mL ModelsFirdaus SyafruddinNo ratings yet

- Ultra Stick LW RCM-1307 ArticleDocument11 pagesUltra Stick LW RCM-1307 Articleluis pulidoNo ratings yet

- Recommended Installation of A Bop Control SystemDocument8 pagesRecommended Installation of A Bop Control SystemHamid Reza BabaeiNo ratings yet

- Testingscr FsDocument6 pagesTestingscr Fslucas ronaldo coronel mendozaNo ratings yet

- MGPSDocument9 pagesMGPSMikhail BagliukNo ratings yet

- 2C Diesel Generator Set Engine Unit PDFDocument337 pages2C Diesel Generator Set Engine Unit PDFTaufik Perdana100% (1)

- Canon A1 SPT Guide PDFDocument10 pagesCanon A1 SPT Guide PDFWeijia MaNo ratings yet

- 1973 1990.johnson - Evinrude.2 40HP - Outboards.repair - ManualDocument356 pages1973 1990.johnson - Evinrude.2 40HP - Outboards.repair - ManualSimon King100% (1)

- PS-203 Rev B LO Range ManualDocument16 pagesPS-203 Rev B LO Range ManualRussbelth OrtegaNo ratings yet

- Instruction Manual FOR Brushless A.C. Generaior Tilodel TWYDocument17 pagesInstruction Manual FOR Brushless A.C. Generaior Tilodel TWYTahan Lodewyk Butar ButarNo ratings yet

- Master Solenoid Kit: MS KM-175 93Document1 pageMaster Solenoid Kit: MS KM-175 93Guilherme ZoboliNo ratings yet

- CYLINDER 200barDocument1 pageCYLINDER 200barrusli bahtiarNo ratings yet

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarNo ratings yet

- NAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFDocument113 pagesNAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFBlaze123xNo ratings yet

- Manual de Válvula de Prevención de SobrellenadoDocument14 pagesManual de Válvula de Prevención de SobrellenadoEmiliano CamarenaNo ratings yet

- RTAC Customer PackageDocument15 pagesRTAC Customer PackageAldo MartinezNo ratings yet

- Electrical Submersible Pump HandbookDocument67 pagesElectrical Submersible Pump HandbookAnonymous Xy309m9Sm9No ratings yet

- Volvo 240 Electrical System Instruments Excl ScematicsDocument66 pagesVolvo 240 Electrical System Instruments Excl Scematicsmichaelovitch100% (1)

- Service Manual A10 & A12 EEDocument32 pagesService Manual A10 & A12 EErabitosanNo ratings yet

- 2049 - 075600 (1) - 718-753Document36 pages2049 - 075600 (1) - 718-753Sandro Lopez SolanoNo ratings yet

- SH 8Document28 pagesSH 8ابو حميد ابو حميدNo ratings yet

- Disamatic GatingDocument7 pagesDisamatic Gatingtanto_deep_15No ratings yet

- Power Transformer Protection: ObjectivesDocument13 pagesPower Transformer Protection: ObjectivesAnonymous dqbb02DUhNo ratings yet

- PI - Fault Diagnosis CardsDocument11 pagesPI - Fault Diagnosis Cardsaakk75No ratings yet

- Westfalia Separator AGDocument192 pagesWestfalia Separator AGstepewolf100% (4)

- Amot 8071A Thermocontroller PDFDocument14 pagesAmot 8071A Thermocontroller PDFИван ПарлапановNo ratings yet

- European Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Document4 pagesEuropean Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Sergio RodriguezNo ratings yet

- SC502Document21 pagesSC502Ferhat BozdumanNo ratings yet

- D1 Brosur - SA 300VFDocument1 pageD1 Brosur - SA 300VFmasif katenaNo ratings yet

- Air Pilot Operated Series N/SA: Matics, IncDocument25 pagesAir Pilot Operated Series N/SA: Matics, IncvishadkapadiaNo ratings yet

- Sy - 2Document1 pageSy - 2cherif yahyaouiNo ratings yet

- Advance PP3 Twin DC SupplyDocument13 pagesAdvance PP3 Twin DC SupplyJohn DosherNo ratings yet

- Alternatives of Buchholz Relay and MoreDocument6 pagesAlternatives of Buchholz Relay and MoreTwinsNo ratings yet

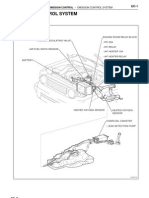

- 10 - Engine Control SystemDocument13 pages10 - Engine Control SystemZee ShanNo ratings yet

- Bulletin: ErviceDocument27 pagesBulletin: Ervicethilo eckardtNo ratings yet

- 1967-68 Mustang Without Factory AirDocument23 pages1967-68 Mustang Without Factory AirnilusomegaNo ratings yet

- Injection Pump Specification: .Lff.R.Document2 pagesInjection Pump Specification: .Lff.R.Miguel RojasNo ratings yet

- PMO801N0615398Document2 pagesPMO801N0615398Jose ExtremeraNo ratings yet

- Emission ControlDocument26 pagesEmission ControllogammicNo ratings yet

- Imjectlqn PU: 1545 K.P.M. / r-1 4. Keducr SPC - Ed Co I R T C"1 8Document2 pagesImjectlqn PU: 1545 K.P.M. / r-1 4. Keducr SPC - Ed Co I R T C"1 8dieselmotorsbogotasasNo ratings yet

- Lorin RamjetDocument81 pagesLorin RamjetAlexandre Pereira100% (1)

- Wired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder ShortsDocument4 pagesWired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder Shortslucas praisNo ratings yet

- Electronic Fishing Lure (P) : FtnfillectiffimmlhleilcrDocument4 pagesElectronic Fishing Lure (P) : FtnfillectiffimmlhleilcrtihomihoNo ratings yet

- PumptestDocument4 pagesPumptestshwetsovitNo ratings yet

- Deinking Cell 25-50Document24 pagesDeinking Cell 25-50onlywork35No ratings yet

- Calibracion StanadineDocument3 pagesCalibracion StanadineAndres ContrerasNo ratings yet

- 9 Antifouling SystemDocument24 pages9 Antifouling SystemYuri DuriNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Center Point LawsuitDocument52 pagesCenter Point LawsuitLarryDCurtisNo ratings yet

- 1.1.2the Direct Method GoodDocument6 pages1.1.2the Direct Method GoodKevin RodriguezNo ratings yet

- 7 PDFDocument6 pages7 PDFjoseNo ratings yet

- Critical ValuesDocument45 pagesCritical Valuesshaun tanNo ratings yet

- Stress Due To Surface LoadDocument7 pagesStress Due To Surface LoadDesalegn TamirNo ratings yet

- PICA Hose Problem - Sept-Nov 2012Document20 pagesPICA Hose Problem - Sept-Nov 2012Edwin FitrianNo ratings yet

- Splintered Truths Splintered Promises Duet Book One M George All ChapterDocument49 pagesSplintered Truths Splintered Promises Duet Book One M George All Chaptermarcus.culnane57883% (6)

- Middleware SystemsDocument5 pagesMiddleware Systemsdameantd0310No ratings yet

- Service Manual: 23" / 26" / 27" / 30" / 32" / 37" / 42" TFT-LCD Tv/MonitorDocument68 pagesService Manual: 23" / 26" / 27" / 30" / 32" / 37" / 42" TFT-LCD Tv/MonitorpasantitoNo ratings yet

- Advanced Flight ManeuversDocument12 pagesAdvanced Flight ManeuversNath AnielNo ratings yet

- Top 20 Questions of Profit Loss For Du Jat Ipm 025d90a264b90Document4 pagesTop 20 Questions of Profit Loss For Du Jat Ipm 025d90a264b90Chawhan RaghuNo ratings yet

- TAX 2: Digest - Winebrenner & Iñigo Insurance Brokers, Inc. v. CIRDocument2 pagesTAX 2: Digest - Winebrenner & Iñigo Insurance Brokers, Inc. v. CIRFaith Marie Borden100% (2)

- Transaxle Part No'sDocument9 pagesTransaxle Part No'sRon BonnevilleNo ratings yet

- KL 002.10 Eng Student Guide sp2 v1.0.1 PDFDocument414 pagesKL 002.10 Eng Student Guide sp2 v1.0.1 PDFalexusmatrixNo ratings yet

- (Dry Type Transformer)Document23 pages(Dry Type Transformer)togirishsharmaNo ratings yet

- English One EditDocument120 pagesEnglish One Edit20036 -Bagas Andrian PermanaNo ratings yet

- Discharge Summary: General FormatDocument6 pagesDischarge Summary: General Formatf archiveNo ratings yet

- Service Manual: Heat Pump ModelDocument45 pagesService Manual: Heat Pump ModelRicardo PereiraNo ratings yet

- Install LogDocument36 pagesInstall Logfrans parulianNo ratings yet

- IKCS12F60BBDocument1 pageIKCS12F60BBAbdeljalil ElhimaniNo ratings yet

- Unit 3 Prepare and Interpret Technical DrawingDocument20 pagesUnit 3 Prepare and Interpret Technical Drawingtracert_atanNo ratings yet

- Group 3Document11 pagesGroup 3Sharp MIER TVNo ratings yet

- Fault Detection in Solar Power Plants Using Predictiveanalytic TechniquesDocument7 pagesFault Detection in Solar Power Plants Using Predictiveanalytic TechniquesRodrigoNo ratings yet

- Buisness Plan OutlineDocument10 pagesBuisness Plan OutlinevangheliexNo ratings yet

- Authors BookDocument189 pagesAuthors Bookمحمد رضا رضوانیNo ratings yet

- APICS BSCM Chapter 1 NotesDocument11 pagesAPICS BSCM Chapter 1 NotesvayugaramNo ratings yet

- Envi ScienceDocument13 pagesEnvi ScienceNestor Navarro Jr.No ratings yet

- The Computer Contradictionary - Stan Kelly-BootieDocument249 pagesThe Computer Contradictionary - Stan Kelly-BootiedanielghroNo ratings yet

- Major Ammonia Leak From HP Ammonia Feed Pump2Document3 pagesMajor Ammonia Leak From HP Ammonia Feed Pump2Rana ImtiazNo ratings yet