Professional Documents

Culture Documents

Polane T, Polyurethane Enamel A

Polane T, Polyurethane Enamel A

Uploaded by

김도균Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polane T, Polyurethane Enamel A

Polane T, Polyurethane Enamel A

Uploaded by

김도균Copyright:

Available Formats

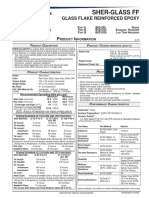

Chemical Coatings

CC-D5

POLANE® T

Polyurethane Enamel

Profile Gray .......................... F63A33 Nitro Blue ............................. F63L17 Organic Yellow Light ............ F63YY10

Carbide Black ....................... F63B12 P. C. Blue ............................ F63LY5 Yellow Oxide ........................ F63YY4

Green ................................... F63GY7 Red Oxide ........................... F63RY3 Organic Yellow Medium ........ F63YY7

Precision Tan ....................... F63H12 Magenta .............................. F63RY6 Catalyst (interior) ................. V66V27

Instrument Tan ..................... F63H13 Linear White ........................ F63W12 Catalyst (exterior) ................ V66V29

Blending Clear ...................... F63F10 Blending White ..................... F63W9

DESCRIPTION CHARACTERISTICS SPECIFICATIONS

POLANE® T Polyurethane Enamel is a Gloss: Low (20-25 units at 60 General: Substrate should be free of

two component, low gloss coating pro- degrees) as a smooth grease, oil, dirt, fingerprints, drawing com-

viding superior appearance and durabil- coat pounds, any contamination, and surface

ity. Polane T can be used as a smooth or Volume Solids: 30-36% passivation treatments to ensure optimum

textured finish. Its textured appearance catalyzed and reduced, varies by color adhesion and coating performance proper-

Viscosity: ties. Consult Metal Preparation Brochure

camouflages imperfections left by pro-

CC-T1 for additional details.

duction operations such as grinding 30-35 seconds #4 Zahn Cup

Aluminum: Prime with Industrial Wash

marks, welding seams, and molding. Recommended film thickness: Primer, P60G2.

Mils Wet 4.5 Galvanized Steel: Prime with Industrial

Advantages: Mils Dry 1.0-1.25 Wash Primer, P60G2.

• Excellent appearance over many Spreading Rate (no application loss) Steel or Iron: Remove rust, mill scale, and

types of substrates—metal, plastics, @ 1.0-1.25 mil dft: 384-576 sq ft/gal oxidation products. For best results, treat

and wood Drying (1.0 mils dft, 77°F, 50% RH): the surface with a proprietary surface chemi-

• Air dry or force dry catalyzed with V66V27 cal treatment of zinc or iron phosphate to

To Touch: 20 minutes improve corrosion protection.

• Excellent chemical and water For untreated steel, prime with Industrial

To Handle: 60 minutes

resistance Wash Primer, P60G2, for a smoother fin-

To Pack Overnight

• Excellent adhesion, mar, and ish, follow with Polane Primer/Sealer,

To Recoat: no critical recoat time

abrasion resistance E65A4. For the best corrosion protection,

Force Dry: 30 minutes at

• Excellent hardness and impact 140-180°F prime with Catalyzed Epoxy Primer,

resistance E61RC22.

Do not exceed the heat distortion tempera-

• Widely used for coating business For treated steel, to improve performance,

ture of the substrate. prime with Polane Primer/Sealer, E65A4.

machines and computers because of Spatter or texture coat can be applied im- Plastic: Due to the diverse nature of plas-

resistance to stains, chemicals and mediately after flash off of smooth coat. Af- tic substrates, a coating or coating system

abrasion and for long-term durability ter 7 days, scuff sand to ensure adhesion. must be tested for acceptable adhesion to

• Texturing minimizes surface irregu- Mixing Ratio: the substrate prior to use in production. Re-

larities and provides a 3 dimensional 6 parts Polane T ground and recycled plastics along with vari-

appearance 1 part Catalyst V66V27 or ous fire retardants, flowing agents, mold

• Full color range available through V66V29 release agents, and foaming/blowing agents

intermixing Reduce 33% for smooth coat. Reduce as will affect coating adhesion. A filler or primer/

• Lower glosses are available by using needed for texture coat with Polane Reducer barrier coat may be required. Please con-

Polane Flattening Paste, F63T1 R7K69 or R7K84 . sult your Sherwin-Williams Chemical Coat-

Pot Life: 6-8 hours ings Sales Representative for system rec-

• Compatible with VIC™ Process for

ommendations.

accelerated dry times Flash Point: 37-65°F Pensky-

Wood (interior only): Must be clean, dry,

• Can be used on structural plastics Martens Closed Cup

and finish sanded. Seal with a full coat of

that cannot tolerate high baking Package Life: 3 years, unopened Polane SprayFil.

temperatures

• Free of lead and chromate hazards Air Quality Data: Testing: Due to the wide variety of sub-

Non-photochemically reactive strates, surface preparation methods, ap-

Volatile Organic Compounds (VOC) plication methods, and environments, the

as packaged, maximum customer should test the complete system

5.5 lb/gal, 660 g/L for adhesion and compatibility prior to full

catalyzed and reduced as above, maximum scale application.

5.7 lb/gal, 684 g/L

An Environmental Data Sheet is available

from your local Sherwin-Williams facility.

CC-D5 2000052 9/01 continued on back

APPLICATION SPECIFICATIONS CAUTIONS

Typical Setups

Product Limitations: Thoroughly review product label for

Reduction: Reduce 33% for smooth • Polane Catalyst, V66V27, interior, or safety and cautions prior to using this

coat or as need for texture coat with V66V29, exterior, must be used to product.

Polane Reducer R7K69 or R7K84 . achieve proper performance. Do not A Material Safety Data Sheet is available

Polane Reducer R7K69 is photochemi- vary catalyst ratio which has been es- from your local Sherwin-Williams facility.

cally reactive, R7K84 is non-photochemi- tablished to provide optimum hardness, Please direct any questions or comments

cally reactive. flexibility, gloss, and chemical resistance. to your local Sherwin-Williams facility.

Retarder, R7K216, may be used for bet- • Use catalyst V66V27 for interior use.

ter flow. V66V27 will lead to early chalking and LABEL CAUTIONS

gloss loss on exterior exposures. Use Contents are FLAMMABLE. Vapors may cause flash

V66V29 for exterior use. Polane T cata- fires. Keep away from heat, sparks, and open flame.

Texture: During use and until all vapors are gone: Keep area

Allow 5-10 minutes flash off of the lyzed with V66V29 is not intended for ventilated - Do not smoke - Extinguish all flames, pi-

smooth coat before applying the texture long term exterior exposures, extended lot lights, and heaters - Turn off stoves, electric tools

coat. The texture may be varied by ad- exposure to strong sun will lead to chalk- and appliances, and any other sources of ignition.

ing, gloss loss, and color fading. SEE CONTENTS STATEMENT ON LABEL.

justing the atomizing and fluid pressures VAPOR HARMFUL. Use only with adequate ventila-

until the desired texture size is obtained. • For applications involving V66V29 cata- tion. This product must be used with an appropiate

Lower atomizing pressures give a larger lyst, V66VB11 accelerator may be used catalyst. Follow the respirator requirement and in-

to speed up the dry time. Up to 2 ounces structions on the catalyst.

texture pattern. Higher atomizing pres- Avoid contact with eyes and skin. Wash hands after

sure reduces the texture size. of V66VB11 per gallon of the paint com-

using. Keep container closed when not in use. Do

ponent side is recommended. not transfer contents to other containers for storage.

Conventional Spray pressure feed, • Heat shortens pot life. Do not spray hot. FIRST AID: If INHALED: If affected, remove from

Do not pump catalyzed material into cir- exposure. Restore breathing, Keep warm and quiet.

smooth or textured coat: If on SKIN: Wash affected area thoroughly with soap

Gun .............................. DeVilbiss MBC culating systems. Friction heat devel- and water. Remove contaminated clothing. Launder

Air Pressure, smooth ............ 40-50 psi oped by pumps and circulation will before re-use. If in EYES: Flush eyes with large

Air pressure, texture ............. 25-30 psi shorten pot life. amounts of water for 15 minutes. Get medical atten-

• Protect from moisture, water affects pot tion. If SWALLOWED: Get medical attention imme-

Fluid Pressure ......................... 8-10 psi diately.

Cap/Tip ....................................... 765/E life and product properties. Store in- SPILL AND WASTE: Remove all sources of ignition.

doors. Ventilate and remove with inert absorbent. Inciner-

• Do not package Polane coated products ate in approved facility. Do not incinerate closed con-

Conventional Spray suction feed, tainer. Dispose of in accordance with Federal, State,

in air tight plastic bags unless completely

smooth coat only: and Local regulation regarding pollution.

cured. Polane continues to cure for sev- DELAYED EFFECTS FROM LONG TERM OVEREX-

Gun .............................. DeVilbiss MBC

eral weeks, the buildup of organic sol- POSURE.

Air Pressure .......................... 40-50 psi

vents and reaction by-products could Contains solvents which can cause permanent brain

Cap/Tip ......................................... 30/E and nervous system damage. Intentional misuse by

cause improper cure and adhesion fail-

deliberately concentrating and inhaling the contents

ure in use. can be harmful or fatal.

Cleanup:

• Do not apply to wood for exterior use. This product must be mixed with other components

Clean tools/equipment immediately af- before use. Before opening the packages, READ AND

• Do not blend with any polyurethane

ter use with Polane Reducer. quality except Polane B or T. No other FOLLOW WARNING LABELS ON ALL COMPO-

Follow manufacturer's safety recommen- NENTS.

catalyst, colorants, or reducers are rec- WARNING: This product contains chemicals known

dations when using any solvent. ommended because foreign materials, to the State of California to cause cancer and birth

such as alcohols and glycols, destroy defects or other reproductive harm.

DO NOT TAKE INTERNALLY. KEEP OUT OF THE

performance properties. Do not use lac- REACH OF CHILDREN.

quer thinners or alcohol-containing sol- FOR INDUSTRIAL USE ONLY.

vents. SEE MATERIAL SAFETY DATA SHEET. 19444-

051701.

Catalyst CONTAINS ISOCYANATES. People who

Performance Tests

have chronic (long-term) lung or breathing problems

Bonderite 1000 steel panels, 1.0 mils dry, 30 days or have had a reaction to isocyanates, must not be in

air cure, using V66V27 the area where this product is being applied. Where

Salt Spray Test .............................. 200 hours overspray is present, a positive pressure air-supplied

1/8" rust creep on scribe respirator should be worn. If unavailable, a properly

Humidity, 100% RH, 100°F ............ 200 hours fitted organic vapor/particulate respirator may be ef-

Conical Mandrel ............. passes 1/8" mandrel fective. Consult catalyst MSDS and product label for

complete handling instructions.

Impact Resistance, Direct ................ 100 in lb

Impact Resistance, Reverse .............. 80 in lb Note: Product Data Sheets are periodically updated

Pencil Hardness ................................ H to 2H to reflect new information relating to the product.

Crosshatch Adhesion ............................... psi It is important that the customer obtain the most

Taber Abrasion recent Product Data Sheet for the product being

CS 17 wheel, 1000 g, 1000 cycles ..... 100 mg used. The information, rating, and opinions stated

Water Immersion ........................... 100 hours here pertain to the material currently offered and

Lacquer thinner, acetone, MEK, gasoline, represent the results of tests believed to be reli-

xylene .................................... 20 double rubs able. However, due to variations in customer han-

dling and methods of application which are not

Chemical Resistance known or under our control, The Sherwin-Williams

Lubricating & Cutting Oils ................ Excellent Company cannot make any warranties as to the

Hydraulic Fluids ............................... Excellent end result.

CC-D5 POLANE® T Polyurethane Enamel

You might also like

- Procedure For Inspection of Piston & Liners - ManDocument74 pagesProcedure For Inspection of Piston & Liners - ManMarcelo RA100% (7)

- Permeability ReportDocument21 pagesPermeability ReportMaclean Jacob Eneotu100% (3)

- Isolation & Control Butterfly ValvesDocument62 pagesIsolation & Control Butterfly Valvesmanmohansingh1999No ratings yet

- CBDD Standard Paint Spec (With SW Data)Document5 pagesCBDD Standard Paint Spec (With SW Data)lightsonsNo ratings yet

- PolaneSolarReflective 1Document2 pagesPolaneSolarReflective 1cenoscottpatrickNo ratings yet

- Polane HS Plus Polyurethane Enamel: Chemical CoatingsDocument2 pagesPolane HS Plus Polyurethane Enamel: Chemical CoatingsRafael ArandaNo ratings yet

- Polane 700T, Water Reducible EnamelDocument2 pagesPolane 700T, Water Reducible Enamel김도균No ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Carboguard 504 PDSDocument4 pagesCarboguard 504 PDSNicholas ColesNo ratings yet

- Carbozinc Data SheetDocument2 pagesCarbozinc Data SheetIra Purnama SariNo ratings yet

- Carboguard 193: Selection & Specification DataDocument4 pagesCarboguard 193: Selection & Specification DataGraciele SantosNo ratings yet

- 670.bull.2022 (22.0)Document3 pages670.bull.2022 (22.0)Francisco RodríguezNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification DataDuongthithuydungNo ratings yet

- COLD GALVANISING Spray - GBDocument2 pagesCOLD GALVANISING Spray - GBANIL PLAMOOTTILNo ratings yet

- Carboguard 60: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard 60: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- Carboguard 893 SG PDFDocument2 pagesCarboguard 893 SG PDFQA QCNo ratings yet

- C PLATE TdsDocument1 pageC PLATE TdsEdwin TacoNo ratings yet

- New 1550HTDocument2 pagesNew 1550HTSantiago MonteroNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Thermaline Heat Shield PDSDocument2 pagesThermaline Heat Shield PDSKhemaraj Path100% (1)

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- SHER-WOOD® CAB-Acrylic Lacquer: Product FinishesDocument2 pagesSHER-WOOD® CAB-Acrylic Lacquer: Product Finishesdavid hallNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- High Temperature CoatingsDocument12 pagesHigh Temperature CoatingsWagiyanto MulyaNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Carboguard 893 SG PDSDocument2 pagesCarboguard 893 SG PDSAhmed ElbahrawyNo ratings yet

- Maskote Zinc Stop OffDocument1 pageMaskote Zinc Stop OffshenoibrijithmaxNo ratings yet

- PPA 571 EsDocument4 pagesPPA 571 EsRohit Sangwan0% (1)

- DEC Riston EM213 DataSheetDocument7 pagesDEC Riston EM213 DataSheetks_spyroNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSKhemaraj Path100% (1)

- PR 1776 BDocument4 pagesPR 1776 BAznil aznilNo ratings yet

- Carboguard 893 SG: Selection & Specification DataDocument5 pagesCarboguard 893 SG: Selection & Specification DataPraveen Sreekumaran NairNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification Databalangce1No ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Carboguard 193 PrimerDocument2 pagesCarboguard 193 Primerdibujante3No ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSfazeel mohammedNo ratings yet

- Carboguard 893 SG PDSDocument5 pagesCarboguard 893 SG PDSshameelNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Jotacoat UniversalDocument5 pagesJotacoat UniversalpcNo ratings yet

- Caulk-PSC TDDocument4 pagesCaulk-PSC TDjuanNo ratings yet

- Carboguard 60 LH PDSDocument4 pagesCarboguard 60 LH PDSRicardo SantosNo ratings yet

- Rust O Cap PDFDocument1 pageRust O Cap PDFTitus PraveenNo ratings yet

- ENVIROCRON Powder Coat PCTA89105 RAL 9010 Pure White UD PolyesterDocument1 pageENVIROCRON Powder Coat PCTA89105 RAL 9010 Pure White UD Polyesterlong chanNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- Phenoline 187 Primer PDSDocument5 pagesPhenoline 187 Primer PDSQuy RomNo ratings yet

- Zinc Dust Primer P296 V1.4Document3 pagesZinc Dust Primer P296 V1.4Yango JukopilaNo ratings yet

- TDS - Masterseal SP 120 PFDocument3 pagesTDS - Masterseal SP 120 PFAlexi ALfred H. TagoNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- Bipigard ST Cte Black PDFDocument2 pagesBipigard ST Cte Black PDFKhirod KroutNo ratings yet

- Maskote WB Zinc Stop Off Zyp02Document1 pageMaskote WB Zinc Stop Off Zyp02bondsivamaniNo ratings yet

- X Roc EpoxyBondDocument2 pagesX Roc EpoxyBondLakmal JayashanthaNo ratings yet

- Product Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichDocument2 pagesProduct Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichJORGE HOLGUINNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSAnhera enterpriseNo ratings yet

- Polane 700T, Water Reducible EnamelDocument2 pagesPolane 700T, Water Reducible Enamel김도균No ratings yet

- #4019 MIL-PRF-22750G SpectrumDocument2 pages#4019 MIL-PRF-22750G Spectrum김도균No ratings yet

- Topcoat F69: Coatings For Aircraft Structure ProtectionDocument4 pagesTopcoat F69: Coatings For Aircraft Structure Protection김도균No ratings yet

- 02Y040B, MIL-PRF-23377, Ty I-II, Cla C2, Fast Dry Epoxy Primer, DeFTDocument1 page02Y040B, MIL-PRF-23377, Ty I-II, Cla C2, Fast Dry Epoxy Primer, DeFT김도균No ratings yet

- 03 Series, MIL-PRF-85285, Ty I, CL H, Polyurethane Topcoat, DEFT, 10-29CDocument1 page03 Series, MIL-PRF-85285, Ty I, CL H, Polyurethane Topcoat, DEFT, 10-29C김도균No ratings yet

- Bms 10-11Y Type Ii Class B Grade D Epoxy Topcoat 02W037: Product Information Data SheetDocument1 pageBms 10-11Y Type Ii Class B Grade D Epoxy Topcoat 02W037: Product Information Data Sheet김도균No ratings yet

- Control of Cracking in Concrete - State of The ArtDocument56 pagesControl of Cracking in Concrete - State of The ArtRances CastilloNo ratings yet

- Salami Catalog Group3 Zupcaste PumpeDocument32 pagesSalami Catalog Group3 Zupcaste Pumpeado_22No ratings yet

- Onsrud Catalog - Milling and Drilling ToolsDocument40 pagesOnsrud Catalog - Milling and Drilling ToolsDaniel AustinNo ratings yet

- Attachment: " How To Make Smart Walking Stick For Blind Person"Document8 pagesAttachment: " How To Make Smart Walking Stick For Blind Person"Hima-to PpnsNo ratings yet

- Marine Corrosion ProtectionDocument13 pagesMarine Corrosion ProtectionHitesh VishnuNo ratings yet

- TS 112 Process and Instrument DiagramsDocument27 pagesTS 112 Process and Instrument DiagramsGeetha_jagadish30100% (1)

- 8a-Advanced Waste Water TreatmentDocument43 pages8a-Advanced Waste Water TreatmentSathish GlNo ratings yet

- Technical Data Sheet - Freshgard 700 (Imazalıl)Document1 pageTechnical Data Sheet - Freshgard 700 (Imazalıl)Serhan AyranNo ratings yet

- Imperial TubingtoolsntDocument32 pagesImperial TubingtoolsntvovobossNo ratings yet

- Report For RCC Practical FinalDocument23 pagesReport For RCC Practical FinalBollywood RetroNo ratings yet

- Technology: Answers Drawing BDocument5 pagesTechnology: Answers Drawing BWellington S. França100% (1)

- Merino Industries Limited: Head Office: Village Achheja, Delhi Road, Hapur - 245 101Document2 pagesMerino Industries Limited: Head Office: Village Achheja, Delhi Road, Hapur - 245 101United Construction Est. TechnicalNo ratings yet

- DVC 99wierDocument2 pagesDVC 99wierMohamed ElmakkyNo ratings yet

- Asc FPC Ds pd1000 50f PDFDocument2 pagesAsc FPC Ds pd1000 50f PDFandres fernandoNo ratings yet

- Elcb, RCCB, ElboDocument5 pagesElcb, RCCB, ElboNisitha Tharushan DarmarathnaNo ratings yet

- Erv Eu Im Db68-05252a-03 en 180221 2Document44 pagesErv Eu Im Db68-05252a-03 en 180221 2Tsamis IoannisNo ratings yet

- Designing With Composite DeckDocument17 pagesDesigning With Composite Deckhuynhvanchau0% (1)

- 1 K-Tron K2MLS100, Loss-In-Weight Feeder - Food Processing Machines and Equipment - Second Hand Machinery - WotolDocument5 pages1 K-Tron K2MLS100, Loss-In-Weight Feeder - Food Processing Machines and Equipment - Second Hand Machinery - WotolrajabalaNo ratings yet

- Kty 10Document11 pagesKty 10Adriana VasovićNo ratings yet

- Smart MaterialsDocument1 pageSmart MaterialsAntSWNo ratings yet

- Abrasion Resistance of Polypropylene (Tech Note A4.03)Document3 pagesAbrasion Resistance of Polypropylene (Tech Note A4.03)fazlulfaisalNo ratings yet

- Testing For Autogenous and Semi-Autogenous GrindingDocument17 pagesTesting For Autogenous and Semi-Autogenous GrindingricardoarmijoNo ratings yet

- Matter in Nature: Unit Test ADocument4 pagesMatter in Nature: Unit Test Aloprofesor01No ratings yet

- MDS Foam AFFDocument2 pagesMDS Foam AFFIqra AngelsNo ratings yet

- UC AFSAM Technical Proposal For Johor PortDocument28 pagesUC AFSAM Technical Proposal For Johor Portmuhamadrafie1975No ratings yet

- 31 ARC enDocument6 pages31 ARC enlggomezupbNo ratings yet

- Metodologia de La Investigacion Cientifica Carrasco Diaz PDFDocument3 pagesMetodologia de La Investigacion Cientifica Carrasco Diaz PDFArmando Chiclla SalazarNo ratings yet