Professional Documents

Culture Documents

Master Bolt Calculation

Master Bolt Calculation

Uploaded by

Sudar Mysha0 ratings0% found this document useful (0 votes)

39 views2 pagesThe document calculates bolt sizes for securing a skid based on expected wind, blast, and transportation loads. It determines:

1) The maximum horizontal wind force of 6090.54 N and maximum blast load of 17280 N based on the skid dimensions and load pressures.

2) Horizontal and vertical transportation forces of 21631.05 N and 9613.80 N respectively based on acceleration loads and the package weight.

3) The required number (8) and diameter (14 mm) of anchor bolts to withstand the maximum combined force of 37335.39 N, with a safety factor of less than 1.

4) The weld size (6 mm) and number (

Original Description:

Original Title

MASTER BOLT CALCULATION

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document calculates bolt sizes for securing a skid based on expected wind, blast, and transportation loads. It determines:

1) The maximum horizontal wind force of 6090.54 N and maximum blast load of 17280 N based on the skid dimensions and load pressures.

2) Horizontal and vertical transportation forces of 21631.05 N and 9613.80 N respectively based on acceleration loads and the package weight.

3) The required number (8) and diameter (14 mm) of anchor bolts to withstand the maximum combined force of 37335.39 N, with a safety factor of less than 1.

4) The weld size (6 mm) and number (

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

39 views2 pagesMaster Bolt Calculation

Master Bolt Calculation

Uploaded by

Sudar MyshaThe document calculates bolt sizes for securing a skid based on expected wind, blast, and transportation loads. It determines:

1) The maximum horizontal wind force of 6090.54 N and maximum blast load of 17280 N based on the skid dimensions and load pressures.

2) Horizontal and vertical transportation forces of 21631.05 N and 9613.80 N respectively based on acceleration loads and the package weight.

3) The required number (8) and diameter (14 mm) of anchor bolts to withstand the maximum combined force of 37335.39 N, with a safety factor of less than 1.

4) The weld size (6 mm) and number (

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 2

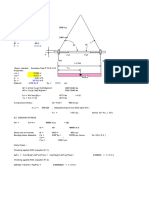

BOLT CALCULATION FOR SKID

1.0 DESIGN CONDITION

1.1 Horizontal Wind Force, Uo

Maximum wind load, = 15 m/s

Design Wind Speed, Vw = 34.3 m/s

76.727 mph

Shape Coefficient, Cs = 1.5

Design Wind Pressure, Pwh =0.0025 x Vw2 x Cs

= 22.08 psf

= 0.00106 N/mm2

Dimensions of Skid

Length, l = 2400 mm

Height, h = 2400 mm

Width, w = 1100 mm

Maximum wind load, Mwl = Pwh x l x h

= 6090.54 N

Blast Load Pressure, Pbh = 0.003 N/mm2

Maximum blast load, Mbl = Pbh x l x h

= 17280 N

1.2 Horizontal Transportation Force,

Horizontal Transportation Acceleration Aht = 0.9 g

Weight of Package Wt = 2450 kg 223,694 N

Aht x Wt x g = 21631.05 N

1.3 Vertical Transportation Force,

Vertical Transportation Acceleration Aht = 0.4 g

Weight of Package Wt = 2450 kg 223,694 N

Aht x Wt x g = 9613.80 N

1.4 Anchor Bolts

Number of Anchor bolts, N = 8

Nominal diameter of bolt d = 14.00 mm

Area of each bolt, A = 153.86 mm2

Allowable shear stress of anchor bolts (A 193 B7) Ss = 120000 psi

Ss = 82.77 N/mm2

Max. Combinned Force Fms = 37335.39 N

Shear Stress on each bolt, ss = Fms/N.A

= 30.33 N/mm2

UC Ratio : 0.37 < 1 OK

1.5 Shear check on sole plate to deck weldment

Considering the weld material as the weak element rather than the plate material

Min yield strenght of E 7018 material fw = 137.93 N/mm2

Allowable stress fs = 41.38 N/mm2

Maximum combined force Fh = (Pwh x l x h, Pbh x l x h, Avt Wt g)

= 54615.39 N

Assumed fillet weld size Fw = 6.00 mm

Pad plate perimeter Pl = 2*(l+w) = 96.00 mm

Number of sole plate Np = 6.00 EA

Shear stress on the weldment fh= Fh/(Pi*Np)Fw = 15.80 N/mm2

You might also like

- The Black BookDocument126 pagesThe Black BookAy Nine Dişi Bilgeliği100% (21)

- Lifting Lug Excel SheetDocument8 pagesLifting Lug Excel Sheetshazan67% (3)

- GR 9 Eng BaselineDocument12 pagesGR 9 Eng BaselineMalie SibisiNo ratings yet

- PH Lab ReportDocument8 pagesPH Lab ReportHaider Ali ShahidNo ratings yet

- Pad Type NozzleDocument2 pagesPad Type NozzleSajal Kulshrestha0% (1)

- Lab Experiment UV SpectrosDocument4 pagesLab Experiment UV SpectrosFazsroul100% (4)

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh Patel100% (1)

- Ellipsoidal Flange To Circular ConverterDocument3 pagesEllipsoidal Flange To Circular Converternaveenkumar_madasett100% (1)

- Platform Attachement Parameter Calculation For LP Compressor Inlet Ko DrumDocument1 pagePlatform Attachement Parameter Calculation For LP Compressor Inlet Ko DrumKpNo ratings yet

- Lug On SkidDocument8 pagesLug On Skidmiteshpatel191No ratings yet

- Final Weld Strength CalnsDocument5 pagesFinal Weld Strength CalnsamachmouchiNo ratings yet

- Foundation Load Table.Document1 pageFoundation Load Table.Lcm TnlNo ratings yet

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542No ratings yet

- Pipe Davit & Guide & Support Calculation 1/3) : (For Pressure Vessel Design Manual Procedure 6-1 (Type-B) )Document4 pagesPipe Davit & Guide & Support Calculation 1/3) : (For Pressure Vessel Design Manual Procedure 6-1 (Type-B) )vamsi100% (1)

- Design of Horizontal Flat Headed PressurDocument60 pagesDesign of Horizontal Flat Headed PressurKumarNo ratings yet

- Skirt Design - For Small VesselsDocument7 pagesSkirt Design - For Small VesselsSakthi VelNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDocument1 pageExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinNo ratings yet

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Sendai: Eversendai Consulting Engineers (P) LTDDocument6 pagesSendai: Eversendai Consulting Engineers (P) LTDfsijestNo ratings yet

- LiftingLugStress Rev 1.5Document17 pagesLiftingLugStress Rev 1.5mohdshakir bahariNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Lifting Lug Stress - 4 - PointsDocument2 pagesLifting Lug Stress - 4 - PointsDipak ZopeNo ratings yet

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Air SeparatorsDocument2 pagesAir SeparatorsНемања КараклајићNo ratings yet

- Large Horizontal Vessel Supported by Two Saddles Stress AnalysisDocument7 pagesLarge Horizontal Vessel Supported by Two Saddles Stress AnalysisSiva baalan100% (1)

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- 7-12-0009 Rev 6Document2 pages7-12-0009 Rev 6cynideNo ratings yet

- Wind / Seismic Design For Horizontal Vessels: Longitudinal ForcesDocument2 pagesWind / Seismic Design For Horizontal Vessels: Longitudinal ForcesMasoodMiyanNo ratings yet

- Saddle Support CalculationDocument7 pagesSaddle Support CalculationrichardchiamNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Spreaer Beam&Lifting Line Beam p3Document2 pagesSpreaer Beam&Lifting Line Beam p3Sabrang LorNo ratings yet

- R D H W FW: Design of Tailing LugDocument2 pagesR D H W FW: Design of Tailing LugvpjagannaathNo ratings yet

- Dennis R Moss 4th EditionDocument5 pagesDennis R Moss 4th Editionsenthil kumarNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- WRC-107 Lifting Trunnions - Horz. LiftDocument5 pagesWRC-107 Lifting Trunnions - Horz. LiftManoj MulikNo ratings yet

- UES - Weld Bending Stress CalculationDocument3 pagesUES - Weld Bending Stress CalculationsridharNo ratings yet

- Rectangular Flange DesignDocument6 pagesRectangular Flange DesignTAHIR MAHMOODNo ratings yet

- Curriculum VitaeDocument3 pagesCurriculum VitaeAbdallah El Amine SoufiNo ratings yet

- Xcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseDocument2 pagesXcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseayushNo ratings yet

- Stack Gas Specification: Project Name Client Location GeneralDocument6 pagesStack Gas Specification: Project Name Client Location Generalbudi utomo0% (1)

- HeatExchanger DrawingDocument7 pagesHeatExchanger DrawingSivateja Nallamothu100% (1)

- Beam Simply SupportedDocument16 pagesBeam Simply SupportedVengatesh HariNo ratings yet

- Engineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsDocument1 pageEngineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsAnonymous EarAM2100% (1)

- Calculation Cpi Tank: I. Design Parameters I.1 Design DataDocument5 pagesCalculation Cpi Tank: I. Design Parameters I.1 Design DataikramNo ratings yet

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDocument3 pages8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Weld Neck Flange DesignDocument2 pagesWeld Neck Flange DesignKashif KaziNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- Lifting Lug AnalysisDocument8 pagesLifting Lug AnalysisTrishul Nath PallayNo ratings yet

- Vessel THKDocument8 pagesVessel THKdigm25No ratings yet

- V-340 OutDocument14 pagesV-340 OutSachin5586No ratings yet

- FEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01Document52 pagesFEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01jahiranazri100% (1)

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Torispherical Cone With KnuckleDocument2 pagesTorispherical Cone With KnuckleSajal KulshresthaNo ratings yet

- Anchor BTD DefgDocument5 pagesAnchor BTD DefgAKSHAY BHATKARNo ratings yet

- Design Sheet: WELDING CHECK (Nozzle To Repad)Document5 pagesDesign Sheet: WELDING CHECK (Nozzle To Repad)Muhamad Amar Hakimmie SuhaimiNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationrustamriyadi100% (2)

- Lifting Padeye DesignDocument7 pagesLifting Padeye DesignShridhar AmatiNo ratings yet

- LOUVERDocument24 pagesLOUVERزين ال عابدينNo ratings yet

- Master of Lifting CalculationDocument7 pagesMaster of Lifting CalculationSudar MyshaNo ratings yet

- Twintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Document4 pagesTwintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Sudar MyshaNo ratings yet

- Attach 3Document1 pageAttach 3Sudar MyshaNo ratings yet

- Pola Air - Air Dryer BrochureDocument2 pagesPola Air - Air Dryer BrochureSudar MyshaNo ratings yet

- Piston CompressorsDocument6 pagesPiston CompressorsSudar MyshaNo ratings yet

- Air and Gas DryerDocument5 pagesAir and Gas DryerSudar MyshaNo ratings yet

- SMN-V-KMI-M-MA-00-001 - Rev A - Project Execution PlanDocument11 pagesSMN-V-KMI-M-MA-00-001 - Rev A - Project Execution PlanSudar MyshaNo ratings yet

- Qcy 892165Document5 pagesQcy 892165Sudar MyshaNo ratings yet

- AP-16 Drawing (PDF, 76kb)Document1 pageAP-16 Drawing (PDF, 76kb)Sudar MyshaNo ratings yet

- Bma 901679Document6 pagesBma 901679Sudar MyshaNo ratings yet

- Instruction Operation and Maintenance - Vent Tip and Co2 Snuffing PackageDocument32 pagesInstruction Operation and Maintenance - Vent Tip and Co2 Snuffing PackageSudar MyshaNo ratings yet

- Inspection & Insatallation Flare Ignition EPC South Sembakung Development ServiceDocument1 pageInspection & Insatallation Flare Ignition EPC South Sembakung Development ServiceSudar MyshaNo ratings yet

- 73-Water Motor Alarm-FinalDocument2 pages73-Water Motor Alarm-FinalSudar MyshaNo ratings yet

- Pid FP 400e 7dm PW - Amd74 (Optional)Document1 pagePid FP 400e 7dm PW - Amd74 (Optional)Sudar MyshaNo ratings yet

- Data Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PWDocument1 pageData Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PWSudar MyshaNo ratings yet

- PORVDocument1 pagePORVSudar MyshaNo ratings yet

- 4834-STC-0001 R1Document3 pages4834-STC-0001 R1Sudar MyshaNo ratings yet

- Data Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PW - AMD74 - OptionalDocument2 pagesData Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PW - AMD74 - OptionalSudar MyshaNo ratings yet

- UPD-KM-W6-VL-CL-2002 - Lifting Lug Calculation For WHP D Vent Tip Rev.0Document9 pagesUPD-KM-W6-VL-CL-2002 - Lifting Lug Calculation For WHP D Vent Tip Rev.0Sudar MyshaNo ratings yet

- Cert. Turntable Bearing Tts 2 134 217 15Document3 pagesCert. Turntable Bearing Tts 2 134 217 15Sudar MyshaNo ratings yet

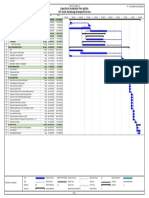

- UPD-KM-G8-VL-SC-2001 - Project Schedule Rev.0Document4 pagesUPD-KM-G8-VL-SC-2001 - Project Schedule Rev.0Sudar MyshaNo ratings yet

- UPD-KM-G8-VL-MN-2002 - Installation, Operation and Maintenance Manual Rev.0Document8 pagesUPD-KM-G8-VL-MN-2002 - Installation, Operation and Maintenance Manual Rev.0Sudar MyshaNo ratings yet

- UPD-KM-G8-VL-LT-2002 - Spare Part List For Commissioningstart Up Rev.0Document4 pagesUPD-KM-G8-VL-LT-2002 - Spare Part List For Commissioningstart Up Rev.0Sudar MyshaNo ratings yet

- A2frc MetricDocument1 pageA2frc MetricSudar MyshaNo ratings yet

- Master of Lifting CalculationDocument7 pagesMaster of Lifting CalculationSudar MyshaNo ratings yet

- HIgh Energy Igniter Tips Specialty Line PDFDocument1 pageHIgh Energy Igniter Tips Specialty Line PDFSudar MyshaNo ratings yet

- Selecting Spreader Beam Check Beam For ES/EEC 1 Compression StressDocument2 pagesSelecting Spreader Beam Check Beam For ES/EEC 1 Compression StressSudar MyshaNo ratings yet

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- Membrane Generator PDFDocument2 pagesMembrane Generator PDFSudar MyshaNo ratings yet

- J S University Diploma 5th Elect Assignment 1Document8 pagesJ S University Diploma 5th Elect Assignment 1Microsoft RewardNo ratings yet

- Yusuf Auwal ProjectDocument37 pagesYusuf Auwal ProjectYahya MusaNo ratings yet

- Heidenhain Touch ProbeDocument72 pagesHeidenhain Touch ProbeHoho Hahov100% (1)

- SLICE 141 Offical Manual S 716133Document50 pagesSLICE 141 Offical Manual S 716133joseguadalupe19canoNo ratings yet

- Absolute Value Equations ConceptDocument8 pagesAbsolute Value Equations Conceptapi-127466285No ratings yet

- Rish Split Current TransformerDocument6 pagesRish Split Current TransformerluisNo ratings yet

- E70 PDFDocument900 pagesE70 PDFАлексей100% (1)

- T1 Relaxation: Exchange Between Parallel and Anti-Parallel SpinsDocument25 pagesT1 Relaxation: Exchange Between Parallel and Anti-Parallel Spinskajal rajNo ratings yet

- TVS Diode - ApplicationDocument6 pagesTVS Diode - ApplicationntchtdNo ratings yet

- Estimation of Back Emf For PMSM at Low Speed RangeDocument6 pagesEstimation of Back Emf For PMSM at Low Speed Rangeyasserali.1041992No ratings yet

- MATHS FormulasDocument73 pagesMATHS FormulasAarun ArasanNo ratings yet

- Rofin FL Series Rofin Sealed-Off LasersDocument2 pagesRofin FL Series Rofin Sealed-Off LasersAhmet KayurNo ratings yet

- MEF268 Contents SYLLABUSDocument2 pagesMEF268 Contents SYLLABUSchicknaliaNo ratings yet

- Aluminium Conductor Sag Tension CalculatorDocument10 pagesAluminium Conductor Sag Tension Calculator1382aceNo ratings yet

- GC1 Q1 Week-3a-1Document10 pagesGC1 Q1 Week-3a-1Michelle AmznNo ratings yet

- The Formation of Heavier Elements During Star Formation and EvolutionDocument8 pagesThe Formation of Heavier Elements During Star Formation and EvolutionJohn Nerlo DequiñaNo ratings yet

- BIN WISE STOCK For U TypeDocument9 pagesBIN WISE STOCK For U TypenadeemNo ratings yet

- 100 Kva Isb CPG Parts CatlugeDocument62 pages100 Kva Isb CPG Parts CatlugeNikkikumar MaisuriyaNo ratings yet

- 5.materials of Pharmaceutical Plant ConstructionDocument36 pages5.materials of Pharmaceutical Plant ConstructionJaneNo ratings yet

- Formula Who - F100 20CCDocument2 pagesFormula Who - F100 20CCARDINo ratings yet

- High Precision Spectroradiometer Integrating Sphere System 9000bDocument12 pagesHigh Precision Spectroradiometer Integrating Sphere System 9000blisun008No ratings yet

- TGD Part EDocument88 pagesTGD Part EOlivia SaferNo ratings yet

- Method Statement For Testing & Commissioning of Smoke Extract FansDocument2 pagesMethod Statement For Testing & Commissioning of Smoke Extract FanslipsonNo ratings yet

- Electrostatics DPP - 230503 - 234530Document6 pagesElectrostatics DPP - 230503 - 234530duttsharmashiv0001No ratings yet

- CHAPTER 1. Soil Formation.: A. Geotechnical Engineering C. Soil and Its ConstituentsDocument5 pagesCHAPTER 1. Soil Formation.: A. Geotechnical Engineering C. Soil and Its ConstituentsAngel RondillaNo ratings yet

- Chemistry Form 6 Organic Chemistry Chapter 8: AmineDocument52 pagesChemistry Form 6 Organic Chemistry Chapter 8: AmineChin Bao ErNo ratings yet