Professional Documents

Culture Documents

Selecting Spreader Beam Check Beam For ES/EEC 1 Compression Stress

Selecting Spreader Beam Check Beam For ES/EEC 1 Compression Stress

Uploaded by

Sudar MyshaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selecting Spreader Beam Check Beam For ES/EEC 1 Compression Stress

Selecting Spreader Beam Check Beam For ES/EEC 1 Compression Stress

Uploaded by

Sudar MyshaCopyright:

Available Formats

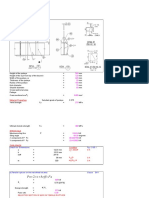

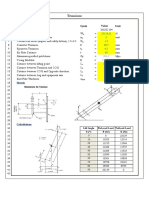

Selecting Spreader Beam

Check beam for ES/EEC

1 COMPRESSION STRESS

Wgt tot = 11023 lbs 5000 kg

safety factor = 1.5 times

Wgt tot = 16535 lbs

Y c.g = 48.82 in

Ytot = 98 in 2480 mm

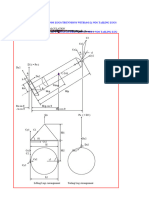

b1 = 60.0 o

b2 = 60.0 o

b1 b2

h = 10.20 in

Fc1 Fc2

h

W1 W2

L =Ytot

Beam selected : Seamless Pipe 6" SCH XXS YC.G

Properties :

r xx = 0.339 in

r yy = 0.221 in

C.G

A = 9.85 in^2

Sx = 28.792 in^3

Material : A106 Gr.B Sy = 36000 psi

W1 = ((Ytot-Yc.g)/ Ytot)*Wgt tot = 8267.3348 lbs

W2 = (Yc.g/ Ytot)*Wgt tot = 8267.3348 lbs

Fc1 = W1/ tan (b1) = 4773 lbs = Fc2

Fc = Fc1 = Fc2 4773 lbs

Compression Stress : fa = Fc/A = 484.72 psi

kL/r= 353.025 , Allowable stress From AISC table 3-31 :

Fa = 1157 psi , hence fa < Fa , ( OK)

5.2 BENDING STRESS

M1 = Fc1*h = 48686 lb.in = M2

M = M1 48686 lb.in

Stress due to moment fb = M/Sx = 1691 psi

Bending stress allowable : Fb = 0.66*Sy = 23760 psi, hence fb < Fb ( O K )

Cm = 1

F'ex = 1196.2 psi

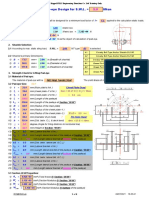

Unity Check :

Checking against AISC (equation H1-1)

fa/Fa + Cmx*fbx/((1-fa/F'ex)*Fbx) + Cmy*fby/((1-fa/F'ey)*Fby) = 0.538632 < 1 ( O K )

Checking against AISC (equation H1-2)

fa/0.6Sy + fbx/Fbx + fby/Fby = 0.09360925 < 1 ( O K )

0.155

You might also like

- Spreader BeamDocument2 pagesSpreader Beamwisnu_bayusakti80% (5)

- Toaz - Info Lifting Beam Design PRDocument4 pagesToaz - Info Lifting Beam Design PRHari Kiran100% (1)

- Standard Hooks Card-ASTMDocument2 pagesStandard Hooks Card-ASTMAnonymous ANo ratings yet

- Lug 31-50 Ton DesignDocument6 pagesLug 31-50 Ton DesignkalpanaadhiNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- Bridge Inspection Manual For Streel Truss Bridge Complete (Special Bridge)Document232 pagesBridge Inspection Manual For Streel Truss Bridge Complete (Special Bridge)Maan Valencia - RevillaNo ratings yet

- Report SPeaDer BarDocument24 pagesReport SPeaDer BarMochammad Shokeh100% (2)

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- Round Bar Suppot Plate Design CalculationDocument3 pagesRound Bar Suppot Plate Design CalculationinnovativekarthiNo ratings yet

- Spreader Beam DesignDocument3 pagesSpreader Beam DesignCHENo ratings yet

- LiftingLug TrunnionDocument22 pagesLiftingLug Trunnionrichardchiam100% (2)

- Lifting Lug CalculationDocument8 pagesLifting Lug CalculationLathesh JanarthananNo ratings yet

- Collapse AnalysisDocument27 pagesCollapse AnalysisLaxmi StrulNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionNicoleta cristianNo ratings yet

- Rigging DesignDocument8 pagesRigging DesignDurgesh HingnekarNo ratings yet

- Multi Lift Point CalcsDocument3 pagesMulti Lift Point CalcsLuis LuperdiNo ratings yet

- LiftingDocument13 pagesLiftingrichardchiamNo ratings yet

- Lifting Analysis Report - Mahadi KurniawanDocument31 pagesLifting Analysis Report - Mahadi KurniawanDian Sas100% (1)

- Calculation Sheet: Tubular Brace ParametersDocument52 pagesCalculation Sheet: Tubular Brace ParametersRamesh SelvarajNo ratings yet

- Specialist Services: Force Resolution CalculationDocument5 pagesSpecialist Services: Force Resolution CalculationNaresh KumarNo ratings yet

- RD339 (1MB File) Spreader BeamsDocument20 pagesRD339 (1MB File) Spreader Beamsnamasral100% (1)

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Spreader BarDocument2 pagesSpreader BarAmi PutraNo ratings yet

- Weight&Lifting - To CheckDocument54 pagesWeight&Lifting - To Checknamasral0% (1)

- Padeye Check SttandardDocument36 pagesPadeye Check SttandardRiandi HartartoNo ratings yet

- Spreader Beam Calculation ReportDocument15 pagesSpreader Beam Calculation ReportGurhan Atalay100% (1)

- Lifting Analysis TK. Flolift 200 PDFDocument35 pagesLifting Analysis TK. Flolift 200 PDFAhmed HossamNo ratings yet

- Structure Calculation of Loading DockDocument19 pagesStructure Calculation of Loading Dockmhajaraswadi2023No ratings yet

- Calculation of Trunnions Rev3Document3 pagesCalculation of Trunnions Rev3Bilel MahjoubNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document6 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Enrique BarajasNo ratings yet

- Spreader Bar3 - L.9 M-CertificationDocument10 pagesSpreader Bar3 - L.9 M-CertificationsiagiandobahNo ratings yet

- Hand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF FreeDocument24 pagesHand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF Freeel000011No ratings yet

- GratingDocument8 pagesGratingGhanshyam PandeyNo ratings yet

- Padeye PATIDocument43 pagesPadeye PATIbayu_23RNo ratings yet

- A. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDocument6 pagesA. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingShabirNo ratings yet

- Padeye DesignDocument32 pagesPadeye DesignMuhammad Iqbal100% (1)

- Moses Mooring Analysis - Introduction - 230903 - 101634Document42 pagesMoses Mooring Analysis - Introduction - 230903 - 101634Hermawan Saini100% (1)

- Padeye Shackle Sling Calculation r2Document7 pagesPadeye Shackle Sling Calculation r2Peja JusohNo ratings yet

- 17 TonsDocument8 pages17 TonsFernando Humberto100% (1)

- PPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaDocument80 pagesPPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaThanh Anh MaiNo ratings yet

- Lifting Lug Calc-Single CPI - RFDocument7 pagesLifting Lug Calc-Single CPI - RFRustam RiyadiNo ratings yet

- Lifting Lug Design-MrDocument5 pagesLifting Lug Design-MrMiguelRagasNo ratings yet

- Chapter J Design of ConnectionsDocument16 pagesChapter J Design of Connectionsghosh73No ratings yet

- Main Crane CC 2800-1 Main Crane 80t C-054-14 Tailing Crane SL6000 Tailing Crane 43.2t C-054-14Document2 pagesMain Crane CC 2800-1 Main Crane 80t C-054-14 Tailing Crane SL6000 Tailing Crane 43.2t C-054-14Bangun DjiwandonoNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument15 pagesCalculation Sheet: Padeye Calculations Loadsshani5573No ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Multi Lift Point CalcsDocument3 pagesMulti Lift Point CalcsLarry DeemNo ratings yet

- JETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyDocument2 pagesJETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyAnonymous nXGOGxyeNo ratings yet

- Ground Bearing Capacity Calculation and Jetty Bearing Capacity Calculation Load Out Topside SvneDocument6 pagesGround Bearing Capacity Calculation and Jetty Bearing Capacity Calculation Load Out Topside SvneTran Van DaiNo ratings yet

- SC-292 - Lift Point DesignDocument39 pagesSC-292 - Lift Point DesignSantanu100% (2)

- 1a. Lifting Data Sheet (Cage 24m)Document4 pages1a. Lifting Data Sheet (Cage 24m)Mohd FadliNo ratings yet

- SWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Document2 pagesSWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Paulo MoreiraNo ratings yet

- Seafastening For Pelikan - 12mm Thickness PlateDocument12 pagesSeafastening For Pelikan - 12mm Thickness PlateHafidNo ratings yet

- Clean - Copy - LiftingLugStress - 4 - Points - Rev - 1 - 5Document11 pagesClean - Copy - LiftingLugStress - 4 - Points - Rev - 1 - 5Hansen A JamesNo ratings yet

- Calculation and Analysis of Sea-Fastening Support and Welding Strength of Topside ModuleDocument8 pagesCalculation and Analysis of Sea-Fastening Support and Welding Strength of Topside Modulepartha.fernandoNo ratings yet

- Lifting Plan Loading and Unloading of Structural MaterialDocument10 pagesLifting Plan Loading and Unloading of Structural MaterialMUHMMED HETHAMNo ratings yet

- Spreader Bar SpreadsheetDocument1 pageSpreader Bar SpreadsheetIlham KelanaNo ratings yet

- Spreader BarDocument5 pagesSpreader Barmramico100% (1)

- Spreader BarDocument5 pagesSpreader BarSteve MoonNo ratings yet

- Design of Intermediate Beam: S E: 200000 MPO B T F D: 554.50 MM T H: D 2t H 0.502 M R W M CB PLL: 4800 Pa H IDocument3 pagesDesign of Intermediate Beam: S E: 200000 MPO B T F D: 554.50 MM T H: D 2t H 0.502 M R W M CB PLL: 4800 Pa H IMike GocotanoNo ratings yet

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- Twintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Document4 pagesTwintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Sudar MyshaNo ratings yet

- Attach 3Document1 pageAttach 3Sudar MyshaNo ratings yet

- Pola Air - Air Dryer BrochureDocument2 pagesPola Air - Air Dryer BrochureSudar MyshaNo ratings yet

- Piston CompressorsDocument6 pagesPiston CompressorsSudar MyshaNo ratings yet

- Air and Gas DryerDocument5 pagesAir and Gas DryerSudar MyshaNo ratings yet

- SMN-V-KMI-M-MA-00-001 - Rev A - Project Execution PlanDocument11 pagesSMN-V-KMI-M-MA-00-001 - Rev A - Project Execution PlanSudar MyshaNo ratings yet

- Qcy 892165Document5 pagesQcy 892165Sudar MyshaNo ratings yet

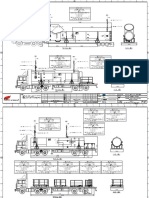

- AP-16 Drawing (PDF, 76kb)Document1 pageAP-16 Drawing (PDF, 76kb)Sudar MyshaNo ratings yet

- Bma 901679Document6 pagesBma 901679Sudar MyshaNo ratings yet

- Instruction Operation and Maintenance - Vent Tip and Co2 Snuffing PackageDocument32 pagesInstruction Operation and Maintenance - Vent Tip and Co2 Snuffing PackageSudar MyshaNo ratings yet

- Inspection & Insatallation Flare Ignition EPC South Sembakung Development ServiceDocument1 pageInspection & Insatallation Flare Ignition EPC South Sembakung Development ServiceSudar MyshaNo ratings yet

- 73-Water Motor Alarm-FinalDocument2 pages73-Water Motor Alarm-FinalSudar MyshaNo ratings yet

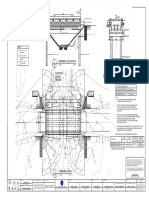

- Pid FP 400e 7dm PW - Amd74 (Optional)Document1 pagePid FP 400e 7dm PW - Amd74 (Optional)Sudar MyshaNo ratings yet

- Data Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PWDocument1 pageData Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PWSudar MyshaNo ratings yet

- PORVDocument1 pagePORVSudar MyshaNo ratings yet

- 4834-STC-0001 R1Document3 pages4834-STC-0001 R1Sudar MyshaNo ratings yet

- Data Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PW - AMD74 - OptionalDocument2 pagesData Sheet - FP 400E-7DM-G-C-A5-ER-4DC-NN-PW - AMD74 - OptionalSudar MyshaNo ratings yet

- UPD-KM-W6-VL-CL-2002 - Lifting Lug Calculation For WHP D Vent Tip Rev.0Document9 pagesUPD-KM-W6-VL-CL-2002 - Lifting Lug Calculation For WHP D Vent Tip Rev.0Sudar MyshaNo ratings yet

- Cert. Turntable Bearing Tts 2 134 217 15Document3 pagesCert. Turntable Bearing Tts 2 134 217 15Sudar MyshaNo ratings yet

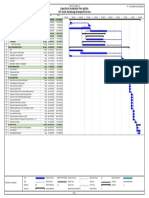

- UPD-KM-G8-VL-SC-2001 - Project Schedule Rev.0Document4 pagesUPD-KM-G8-VL-SC-2001 - Project Schedule Rev.0Sudar MyshaNo ratings yet

- UPD-KM-G8-VL-MN-2002 - Installation, Operation and Maintenance Manual Rev.0Document8 pagesUPD-KM-G8-VL-MN-2002 - Installation, Operation and Maintenance Manual Rev.0Sudar MyshaNo ratings yet

- UPD-KM-G8-VL-LT-2002 - Spare Part List For Commissioningstart Up Rev.0Document4 pagesUPD-KM-G8-VL-LT-2002 - Spare Part List For Commissioningstart Up Rev.0Sudar MyshaNo ratings yet

- A2frc MetricDocument1 pageA2frc MetricSudar MyshaNo ratings yet

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- HIgh Energy Igniter Tips Specialty Line PDFDocument1 pageHIgh Energy Igniter Tips Specialty Line PDFSudar MyshaNo ratings yet

- Master of Lifting CalculationDocument7 pagesMaster of Lifting CalculationSudar MyshaNo ratings yet

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Master Bolt CalculationDocument2 pagesMaster Bolt CalculationSudar MyshaNo ratings yet

- Membrane Generator PDFDocument2 pagesMembrane Generator PDFSudar MyshaNo ratings yet

- JHOELLA Construction Estimate 1,2,3Document13 pagesJHOELLA Construction Estimate 1,2,3jhoella Marie PapasinNo ratings yet

- Conjugate Beam MethodDocument3 pagesConjugate Beam MethodBlessy Marie SottoNo ratings yet

- EC3 Part 4-2 PDFDocument3 pagesEC3 Part 4-2 PDFveraNo ratings yet

- Effect of Pylon Shape On Analysis of Cable Stayed BridgeDocument7 pagesEffect of Pylon Shape On Analysis of Cable Stayed BridgeTanjil MominNo ratings yet

- 6 PDFDocument1 page6 PDFLady Mae BrigoliNo ratings yet

- At Support: Typical Truss DetailDocument1 pageAt Support: Typical Truss DetailRA CruzNo ratings yet

- 1993 AndradeDocument12 pages1993 AndradeDaniel JamesNo ratings yet

- How To Make Stone Masonry Buildings Earthquake ResistantDocument20 pagesHow To Make Stone Masonry Buildings Earthquake Resistantkishan0% (1)

- TCE Consulting Engineers Limited: Design of Structural Steel Elements AS PER IS: 800-2007Document1 pageTCE Consulting Engineers Limited: Design of Structural Steel Elements AS PER IS: 800-2007Neeraj DubeyNo ratings yet

- RVR-Building Tech. 3 - Steel Construction - Ppt. PresentationDocument47 pagesRVR-Building Tech. 3 - Steel Construction - Ppt. Presentationtoyi kamiNo ratings yet

- Design Example 9: Cantilevered Monotube Support For A Dynamic Message SignDocument39 pagesDesign Example 9: Cantilevered Monotube Support For A Dynamic Message SignMohamed Zakaria ZaidiNo ratings yet

- One Way Slab Design: Ref: Nilson-13Th Edition-418 Page ExampleDocument4 pagesOne Way Slab Design: Ref: Nilson-13Th Edition-418 Page Examplerasedul islamNo ratings yet

- Objective of Concrete Mix DesignDocument10 pagesObjective of Concrete Mix Designutachi93No ratings yet

- RFI Check List CivilDocument54 pagesRFI Check List CivilRazi KhanNo ratings yet

- Course OutlineDocument1 pageCourse OutlineTyn MaturanNo ratings yet

- Design of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsDocument71 pagesDesign of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsLavender HoneyNo ratings yet

- Br2 GEN. PLAN & ELEV. & GIRDER DETAILDocument2 pagesBr2 GEN. PLAN & ELEV. & GIRDER DETAILjharealoNo ratings yet

- Design of Masonry Structures EC6Document136 pagesDesign of Masonry Structures EC6roscii100% (4)

- 1 Mat Foundation ReportDocument6 pages1 Mat Foundation Reportmbarqawi13100% (1)

- Foundation Loads 18Th NBML: Span 1 Span 2 Span 3 DLDocument1 pageFoundation Loads 18Th NBML: Span 1 Span 2 Span 3 DLShaileshRastogiNo ratings yet

- Cement Details PDFDocument292 pagesCement Details PDFcristyjayNo ratings yet

- Mathcad - Anchor Bolt - Concrete Related FailureDocument29 pagesMathcad - Anchor Bolt - Concrete Related FailureValentinNo ratings yet

- Wind Loading in Steel Joist Design PDFDocument95 pagesWind Loading in Steel Joist Design PDFnitroxx7No ratings yet

- 53-62 CHECK LIST FormateDocument13 pages53-62 CHECK LIST FormatejitendraNo ratings yet

- Column Capacity With Site Imperfection Splice WeldDocument8 pagesColumn Capacity With Site Imperfection Splice WeldRaja GopalNo ratings yet

- Akta A1407 Fourth Schedule CIDB Standards For Certification of Construction MaterialDocument8 pagesAkta A1407 Fourth Schedule CIDB Standards For Certification of Construction Materialsunghilee70No ratings yet

- ITP-FW For Civil & Building WorksDocument17 pagesITP-FW For Civil & Building WorksRizki KresnaNo ratings yet

- 2933 Tencent Seafront Tower Practice On Binding BuildingsDocument8 pages2933 Tencent Seafront Tower Practice On Binding BuildingskhatribharatNo ratings yet