Professional Documents

Culture Documents

Basics On Fatigue and Fracture Mechanics

Basics On Fatigue and Fracture Mechanics

Uploaded by

davood abbasiCopyright:

Available Formats

You might also like

- Ams 5596K PDFDocument8 pagesAms 5596K PDFadiNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- (Tech Insp) Inspection Techniques in Reformer FurnacesDocument10 pages(Tech Insp) Inspection Techniques in Reformer FurnacesruchiniranjanNo ratings yet

- Aerospace Material SpecificationDocument5 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- SAE - AMS 4050hv004Document9 pagesSAE - AMS 4050hv004Nilesh PatilNo ratings yet

- Turbaloy 310 (SS-310) Data SheetDocument1 pageTurbaloy 310 (SS-310) Data SheetcandraNo ratings yet

- FSX 414 Weld Wire PDFDocument1 pageFSX 414 Weld Wire PDFJ. BangjakNo ratings yet

- ISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data SheetDocument1 pageISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data Sheetbunky bunkoNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- 009 Stainless PDFDocument34 pages009 Stainless PDFKamil MarszałekNo ratings yet

- Duplex-Alloy-2205-Stress ValuesDocument5 pagesDuplex-Alloy-2205-Stress ValuesShiniNo ratings yet

- Stainless Steel PlateDocument19 pagesStainless Steel PlateHarsh AdvaniNo ratings yet

- Ati 2205 PDFDocument6 pagesAti 2205 PDFGetapo RaminNo ratings yet

- Austnitic Stainless Steel 316 316LDocument2 pagesAustnitic Stainless Steel 316 316LbladdeeNo ratings yet

- Die Casting AlloysDocument6 pagesDie Casting AlloyskeeblerkhanNo ratings yet

- Technical Data Sheet: Stainless Steel: SuperausteniticDocument5 pagesTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicNo ratings yet

- Zapp Precision Wire Inc Product CatalogueDocument49 pagesZapp Precision Wire Inc Product CatalogueAyesha AleemNo ratings yet

- 10030_Type2205Document11 pages10030_Type2205LaurikNo ratings yet

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pages36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraqueNo ratings yet

- Pages de Esab Hanbook-3Document1 pagePages de Esab Hanbook-3Amin ThabetNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

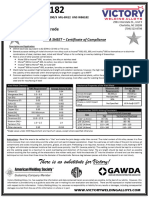

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Duplex Stainless Steel 2205 PDFDocument1 pageDuplex Stainless Steel 2205 PDFSalmanNo ratings yet

- 8-AluminiumSheet Coil PlateandTreadplateDocument9 pages8-AluminiumSheet Coil PlateandTreadplatejerimiah_manzonNo ratings yet

- GRADE 302: Element Content (%)Document3 pagesGRADE 302: Element Content (%)Shashank Saxena100% (1)

- Al Welding BrochureDocument2 pagesAl Welding BrochureRajan RajanNo ratings yet

- Avesta MA 253Document2 pagesAvesta MA 253Denar PurnamaNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- 2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesDocument2 pages2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesJairo BarragánNo ratings yet

- Special Products & InsulationsDocument1 pageSpecial Products & InsulationsAjit YadavNo ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- Specification Sheet: 2205: (UNS S32205/S31803)Document2 pagesSpecification Sheet: 2205: (UNS S32205/S31803)Haytham MohamedNo ratings yet

- Alloy309 SpecSheetDocument2 pagesAlloy309 SpecSheetBilelNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Lecture-1, Maraging SteelsDocument30 pagesLecture-1, Maraging Steelssatish chinthamNo ratings yet

- Afrox MIG/TIG 904L: Welding Consumables Stainless SteelDocument5 pagesAfrox MIG/TIG 904L: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Material Product Data Sheet Amdry 400 Braze Filler Metal: Quick FactsDocument3 pagesMaterial Product Data Sheet Amdry 400 Braze Filler Metal: Quick FactsJ. BangjakNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- Alloy 6moDocument2 pagesAlloy 6moAndre SodaNo ratings yet

- Aircraft MaterialsDocument16 pagesAircraft MaterialsManicharanNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesMatmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearhardeep SinghNo ratings yet

- Aerospace Material Specification: AMS5709 REV. HDocument6 pagesAerospace Material Specification: AMS5709 REV. Hfelipe jurema100% (1)

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- E 9018-B9 Product-SheetDocument1 pageE 9018-B9 Product-SheetjuanNo ratings yet

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKNo ratings yet

- Photoelastic Visualisation - Phased Array Sound FieldsDocument13 pagesPhotoelastic Visualisation - Phased Array Sound Fieldsdavood abbasiNo ratings yet

- Experimental and Numerical Analysis of A Transducer For The Generation of Guided WavesDocument9 pagesExperimental and Numerical Analysis of A Transducer For The Generation of Guided Wavesdavood abbasiNo ratings yet

- Multimet Alloy: Principal FeaturesDocument11 pagesMultimet Alloy: Principal Featuresdavood abbasiNo ratings yet

- Safety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3Document6 pagesSafety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3davood abbasiNo ratings yet

- Basics On Fatigue and Fracture MechanicsDocument28 pagesBasics On Fatigue and Fracture Mechanicsdavood abbasiNo ratings yet

- WQT 316L 2 MMDocument1 pageWQT 316L 2 MMdavood abbasiNo ratings yet

- In 100alloyengineeringproperties 483Document19 pagesIn 100alloyengineeringproperties 483davood abbasiNo ratings yet

- Alloy 713C: Engineering Properties ofDocument20 pagesAlloy 713C: Engineering Properties ofdavood abbasiNo ratings yet

- MaterialData 191425Document1 pageMaterialData 191425davood abbasiNo ratings yet

- بازرسی جوش لوله PDFDocument150 pagesبازرسی جوش لوله PDFdavood abbasiNo ratings yet

- Astm 2017-B564Document9 pagesAstm 2017-B564raulNo ratings yet

- Cleanlant S-Clean ENG 170113Document56 pagesCleanlant S-Clean ENG 170113DIEGONo ratings yet

- Effect of Niobium and Vanadium As An Alloying Element in Tool Steels With High Chromium ContentDocument19 pagesEffect of Niobium and Vanadium As An Alloying Element in Tool Steels With High Chromium ContentDaniel NavarroNo ratings yet

- ASTM B 333 Ni-Mo Alloy Plate Sheet & Strip - 1998Document5 pagesASTM B 333 Ni-Mo Alloy Plate Sheet & Strip - 1998ecsuperalNo ratings yet

- The ElementsDocument4 pagesThe ElementsHaider AliNo ratings yet

- CMA-106H PF-500/US-521H Tgs-2Cmh: Technical ReportDocument5 pagesCMA-106H PF-500/US-521H Tgs-2Cmh: Technical ReportAshishNo ratings yet

- Tantalum and Niobium HC StarckDocument12 pagesTantalum and Niobium HC StarckYoami PerdomoNo ratings yet

- PPTDocument20 pagesPPTronak7patel-15No ratings yet

- 15V41 PDFDocument3 pages15V41 PDFharpreet singhNo ratings yet

- LECTURE # 12, Refractory Metals and AlloysDocument16 pagesLECTURE # 12, Refractory Metals and AlloysMalik Nazim ChannarNo ratings yet

- WRL Corporate Presentation WebsiteDocument108 pagesWRL Corporate Presentation WebsiteGirish PillayNo ratings yet

- JIS G 0321: Product Analysis and Its Tolerance For Wrought SteelDocument13 pagesJIS G 0321: Product Analysis and Its Tolerance For Wrought SteelAnonymous SLI4aGNo ratings yet

- Astm b637-98Document6 pagesAstm b637-98Jesus VelizNo ratings yet

- Transition Metal Oxides - Crystal Chemistry, Phase Transition and Related AspectsDocument144 pagesTransition Metal Oxides - Crystal Chemistry, Phase Transition and Related AspectsHeiddy Paola Quiroz G.100% (1)

- Astm E3047-16Document15 pagesAstm E3047-16Ismail Tp100% (1)

- Joining Depleted Uranium To High-Strength Aluminum Using An Explosively Clad Niobium InterlayerDocument7 pagesJoining Depleted Uranium To High-Strength Aluminum Using An Explosively Clad Niobium InterlayertayefehNo ratings yet

- Ann Knox - Austrian CookingDocument8 pagesAnn Knox - Austrian CookingVladNo ratings yet

- Duplex Stainless SteelsDocument19 pagesDuplex Stainless SteelsdinaksNo ratings yet

- Hydrogen in Magnesium New Perspectives Toward Functional StoresDocument19 pagesHydrogen in Magnesium New Perspectives Toward Functional StoresSaumya SinhaNo ratings yet

- Elemantal AnalysisDocument24 pagesElemantal AnalysisAsad Bin Ala QatariNo ratings yet

- ASTM A992/A572 Grade 50 Steel Beam and ChannelDocument7 pagesASTM A992/A572 Grade 50 Steel Beam and ChannelAlbert SebanNo ratings yet

- Coremax H43Document1 pageCoremax H43LIM hoon boonNo ratings yet

- PD Cen TR 10261-2018 PDFDocument38 pagesPD Cen TR 10261-2018 PDFMaiDuyNo ratings yet

- Ch-27.12 Common Applications of Various MaterialsDocument44 pagesCh-27.12 Common Applications of Various MaterialsSmruti Ranjan PattanayakNo ratings yet

- Hot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. TsunetomiDocument12 pagesHot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. Tsunetomipradip meneNo ratings yet

- NB - Pbe-Mt Fhi - UPFDocument65 pagesNB - Pbe-Mt Fhi - UPFarnoldNo ratings yet

- Heat TreatmentDocument33 pagesHeat TreatmentPinto CarlosNo ratings yet

- The Illustrated Encyclopedia of The Elements Periodic TableDocument1 pageThe Illustrated Encyclopedia of The Elements Periodic TableChronicleBooksNo ratings yet

- Astm A709 A709m 2009 PDFDocument7 pagesAstm A709 A709m 2009 PDFenjiniringNo ratings yet

Basics On Fatigue and Fracture Mechanics

Basics On Fatigue and Fracture Mechanics

Uploaded by

davood abbasiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basics On Fatigue and Fracture Mechanics

Basics On Fatigue and Fracture Mechanics

Uploaded by

davood abbasiCopyright:

Available Formats

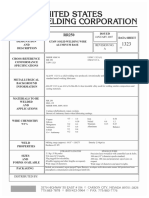

ISO 9001

USW ALLOY TURBALOY® 155 AS 9100 DATA SHEET

DESIGNATION HQ-GRADE

AND GTAW SOLID BARE WELDING WIRE Revision A

5794

DESCRIPTION IRON BASE

AMS 5794 31Fe 21Cr 20Ni 20Co 3.0Mo 2.5W 1.0Cb 0.15N

N155 MSRR 9500/214

CROSS-REFERENCE UNS R 30155 OMAT 3/166A

CONFORMANCE MIL-R-5031 (Comp 9) Multimet Alloy. 20-20-20

USWC 5794 (A) AISI 661

SPECIFICATIONS

TURBALOY® 155 undergoes a series of proprietary abrading and cleaning processes to remove

all surface contaminants. These manufacturing processes ensure a consistent ultra-clean

weld wire surface.

METALLURGICAL

BACKGROUND TURBALOY® 155 is a high temperature, high strength, oxide resisting alloy widely used

INFORMATION in the hot section of gas turbine engines. It is used to weld materials of similar composition.

MATERIALS TO BE

AMS 5768, 5769, GE B50 A484.

WELDED

AND AMS 5531, 5532, 5585, 5376.

APPLICATIONS

ASTM 639

Carbon - 0.10 Tantalum - 0.05

WIRE CHEMISTRY Manganese 1.00 2.00 Cobalt 18.50 21.00

WT% Silicon - 1.00 Molybdenum 2.5 3.5

Sulfur - 0.03 Tungsten 2.0 3.0

Phosphorus - 0.04 Columbium 0.75 1.25

Chromium 20.00 22.50 Nitrogen 0.10 0.20

Nickel 19.00 21.00 Iron Balance

WELD Melting Point: 2470°F Density: 8.20gm/cc

Hardness of sheet material:

PROPERTIES Soft condition: 92 HRB, Aged : 94 HRB

STRAIGHT LENGTHS SPOOLED WIRE

5 lb. (2.2kg) packs Precision layer wound, with controlled cast and helix

SIZES 36” (914mm) lengths 12” (300mm) diameter spools standard

AND Flag tagged for traceability. 8” (200mm), 4” (100mm) and proprietary spool sizes

(Double tagging and other lengths on request) on request.

FORMS AVAILABLE Wide range of diameters. Wide range of diameters and spool weights.

Sealed polyethylene envelopes. (Desiccants optional)

PACKAGING

DFARS Compliant www.usweldingcorp.com

You might also like

- Ams 5596K PDFDocument8 pagesAms 5596K PDFadiNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- (Tech Insp) Inspection Techniques in Reformer FurnacesDocument10 pages(Tech Insp) Inspection Techniques in Reformer FurnacesruchiniranjanNo ratings yet

- Aerospace Material SpecificationDocument5 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- SAE - AMS 4050hv004Document9 pagesSAE - AMS 4050hv004Nilesh PatilNo ratings yet

- Turbaloy 310 (SS-310) Data SheetDocument1 pageTurbaloy 310 (SS-310) Data SheetcandraNo ratings yet

- FSX 414 Weld Wire PDFDocument1 pageFSX 414 Weld Wire PDFJ. BangjakNo ratings yet

- ISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data SheetDocument1 pageISO 9001 AS 9100 Revision A: Usw Alloy Designation AND Description Data Sheetbunky bunkoNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- 009 Stainless PDFDocument34 pages009 Stainless PDFKamil MarszałekNo ratings yet

- Duplex-Alloy-2205-Stress ValuesDocument5 pagesDuplex-Alloy-2205-Stress ValuesShiniNo ratings yet

- Stainless Steel PlateDocument19 pagesStainless Steel PlateHarsh AdvaniNo ratings yet

- Ati 2205 PDFDocument6 pagesAti 2205 PDFGetapo RaminNo ratings yet

- Austnitic Stainless Steel 316 316LDocument2 pagesAustnitic Stainless Steel 316 316LbladdeeNo ratings yet

- Die Casting AlloysDocument6 pagesDie Casting AlloyskeeblerkhanNo ratings yet

- Technical Data Sheet: Stainless Steel: SuperausteniticDocument5 pagesTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicNo ratings yet

- Zapp Precision Wire Inc Product CatalogueDocument49 pagesZapp Precision Wire Inc Product CatalogueAyesha AleemNo ratings yet

- 10030_Type2205Document11 pages10030_Type2205LaurikNo ratings yet

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pages36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraqueNo ratings yet

- Pages de Esab Hanbook-3Document1 pagePages de Esab Hanbook-3Amin ThabetNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Duplex Stainless Steel 2205 PDFDocument1 pageDuplex Stainless Steel 2205 PDFSalmanNo ratings yet

- 8-AluminiumSheet Coil PlateandTreadplateDocument9 pages8-AluminiumSheet Coil PlateandTreadplatejerimiah_manzonNo ratings yet

- GRADE 302: Element Content (%)Document3 pagesGRADE 302: Element Content (%)Shashank Saxena100% (1)

- Al Welding BrochureDocument2 pagesAl Welding BrochureRajan RajanNo ratings yet

- Avesta MA 253Document2 pagesAvesta MA 253Denar PurnamaNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- 2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesDocument2 pages2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesJairo BarragánNo ratings yet

- Special Products & InsulationsDocument1 pageSpecial Products & InsulationsAjit YadavNo ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- Specification Sheet: 2205: (UNS S32205/S31803)Document2 pagesSpecification Sheet: 2205: (UNS S32205/S31803)Haytham MohamedNo ratings yet

- Alloy309 SpecSheetDocument2 pagesAlloy309 SpecSheetBilelNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Lecture-1, Maraging SteelsDocument30 pagesLecture-1, Maraging Steelssatish chinthamNo ratings yet

- Afrox MIG/TIG 904L: Welding Consumables Stainless SteelDocument5 pagesAfrox MIG/TIG 904L: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Material Product Data Sheet Amdry 400 Braze Filler Metal: Quick FactsDocument3 pagesMaterial Product Data Sheet Amdry 400 Braze Filler Metal: Quick FactsJ. BangjakNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- Alloy 6moDocument2 pagesAlloy 6moAndre SodaNo ratings yet

- Aircraft MaterialsDocument16 pagesAircraft MaterialsManicharanNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesMatmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearhardeep SinghNo ratings yet

- Aerospace Material Specification: AMS5709 REV. HDocument6 pagesAerospace Material Specification: AMS5709 REV. Hfelipe jurema100% (1)

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- E 9018-B9 Product-SheetDocument1 pageE 9018-B9 Product-SheetjuanNo ratings yet

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKNo ratings yet

- Photoelastic Visualisation - Phased Array Sound FieldsDocument13 pagesPhotoelastic Visualisation - Phased Array Sound Fieldsdavood abbasiNo ratings yet

- Experimental and Numerical Analysis of A Transducer For The Generation of Guided WavesDocument9 pagesExperimental and Numerical Analysis of A Transducer For The Generation of Guided Wavesdavood abbasiNo ratings yet

- Multimet Alloy: Principal FeaturesDocument11 pagesMultimet Alloy: Principal Featuresdavood abbasiNo ratings yet

- Safety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3Document6 pagesSafety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3davood abbasiNo ratings yet

- Basics On Fatigue and Fracture MechanicsDocument28 pagesBasics On Fatigue and Fracture Mechanicsdavood abbasiNo ratings yet

- WQT 316L 2 MMDocument1 pageWQT 316L 2 MMdavood abbasiNo ratings yet

- In 100alloyengineeringproperties 483Document19 pagesIn 100alloyengineeringproperties 483davood abbasiNo ratings yet

- Alloy 713C: Engineering Properties ofDocument20 pagesAlloy 713C: Engineering Properties ofdavood abbasiNo ratings yet

- MaterialData 191425Document1 pageMaterialData 191425davood abbasiNo ratings yet

- بازرسی جوش لوله PDFDocument150 pagesبازرسی جوش لوله PDFdavood abbasiNo ratings yet

- Astm 2017-B564Document9 pagesAstm 2017-B564raulNo ratings yet

- Cleanlant S-Clean ENG 170113Document56 pagesCleanlant S-Clean ENG 170113DIEGONo ratings yet

- Effect of Niobium and Vanadium As An Alloying Element in Tool Steels With High Chromium ContentDocument19 pagesEffect of Niobium and Vanadium As An Alloying Element in Tool Steels With High Chromium ContentDaniel NavarroNo ratings yet

- ASTM B 333 Ni-Mo Alloy Plate Sheet & Strip - 1998Document5 pagesASTM B 333 Ni-Mo Alloy Plate Sheet & Strip - 1998ecsuperalNo ratings yet

- The ElementsDocument4 pagesThe ElementsHaider AliNo ratings yet

- CMA-106H PF-500/US-521H Tgs-2Cmh: Technical ReportDocument5 pagesCMA-106H PF-500/US-521H Tgs-2Cmh: Technical ReportAshishNo ratings yet

- Tantalum and Niobium HC StarckDocument12 pagesTantalum and Niobium HC StarckYoami PerdomoNo ratings yet

- PPTDocument20 pagesPPTronak7patel-15No ratings yet

- 15V41 PDFDocument3 pages15V41 PDFharpreet singhNo ratings yet

- LECTURE # 12, Refractory Metals and AlloysDocument16 pagesLECTURE # 12, Refractory Metals and AlloysMalik Nazim ChannarNo ratings yet

- WRL Corporate Presentation WebsiteDocument108 pagesWRL Corporate Presentation WebsiteGirish PillayNo ratings yet

- JIS G 0321: Product Analysis and Its Tolerance For Wrought SteelDocument13 pagesJIS G 0321: Product Analysis and Its Tolerance For Wrought SteelAnonymous SLI4aGNo ratings yet

- Astm b637-98Document6 pagesAstm b637-98Jesus VelizNo ratings yet

- Transition Metal Oxides - Crystal Chemistry, Phase Transition and Related AspectsDocument144 pagesTransition Metal Oxides - Crystal Chemistry, Phase Transition and Related AspectsHeiddy Paola Quiroz G.100% (1)

- Astm E3047-16Document15 pagesAstm E3047-16Ismail Tp100% (1)

- Joining Depleted Uranium To High-Strength Aluminum Using An Explosively Clad Niobium InterlayerDocument7 pagesJoining Depleted Uranium To High-Strength Aluminum Using An Explosively Clad Niobium InterlayertayefehNo ratings yet

- Ann Knox - Austrian CookingDocument8 pagesAnn Knox - Austrian CookingVladNo ratings yet

- Duplex Stainless SteelsDocument19 pagesDuplex Stainless SteelsdinaksNo ratings yet

- Hydrogen in Magnesium New Perspectives Toward Functional StoresDocument19 pagesHydrogen in Magnesium New Perspectives Toward Functional StoresSaumya SinhaNo ratings yet

- Elemantal AnalysisDocument24 pagesElemantal AnalysisAsad Bin Ala QatariNo ratings yet

- ASTM A992/A572 Grade 50 Steel Beam and ChannelDocument7 pagesASTM A992/A572 Grade 50 Steel Beam and ChannelAlbert SebanNo ratings yet

- Coremax H43Document1 pageCoremax H43LIM hoon boonNo ratings yet

- PD Cen TR 10261-2018 PDFDocument38 pagesPD Cen TR 10261-2018 PDFMaiDuyNo ratings yet

- Ch-27.12 Common Applications of Various MaterialsDocument44 pagesCh-27.12 Common Applications of Various MaterialsSmruti Ranjan PattanayakNo ratings yet

- Hot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. TsunetomiDocument12 pagesHot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. Tsunetomipradip meneNo ratings yet

- NB - Pbe-Mt Fhi - UPFDocument65 pagesNB - Pbe-Mt Fhi - UPFarnoldNo ratings yet

- Heat TreatmentDocument33 pagesHeat TreatmentPinto CarlosNo ratings yet

- The Illustrated Encyclopedia of The Elements Periodic TableDocument1 pageThe Illustrated Encyclopedia of The Elements Periodic TableChronicleBooksNo ratings yet

- Astm A709 A709m 2009 PDFDocument7 pagesAstm A709 A709m 2009 PDFenjiniringNo ratings yet