Professional Documents

Culture Documents

Safety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3

Safety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3

Uploaded by

davood abbasiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3

Safety Data Sheet: 1. Identification Nickel Base Alloys: See Table in Section 3

Uploaded by

davood abbasiCopyright:

Available Formats

High Performance Wire for Hardfacing, Welding and Thermal Spraying

Safety Data Sheet

------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. IDENTIFICATION

Product Name: NICKEL BASE ALLOYS: SEE TABLE in SECTION 3

Typical Use: Welding Wire, Thermal Spray Wire, Welding Electrode, Sheet

Manufacturer: Polymet Corporation

7397 Union Centre Blvd

West Chester, OH 45014

(513) 874-3586 from 8 a.m. – 5 p.m., EST

------------------------------------------------------------------------------------------------------------------------------------------------------------------

2. HAZARDS IDENTIFICATION

The ARTICLE is NOT classified as dangerous according to directive 1999/45/EC.

BYPRODUCTS generated during the thermal spray or welding process ARE considered hazardous.

WARNING DANGER

HAZARD STATEMENTS:

May cause cancer by inhalation

May cause an allergic skin reaction

PRECAUTIONARY STATEMENTS:

Obtain special instructions before use

Do not handle until all safety precautions have been read and understood

Avoid breathing dust or fume

Wear protective gloves, protective clothing, eye, and face protection

Contaminated work clothing should not be allowed out of the workplace

If exposed or concerned, get medical advice/attention

See Section 11 for more detailed information on health effects and symptoms.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

3. COMPOSITION / INFORMATION ON INGREDIENTS

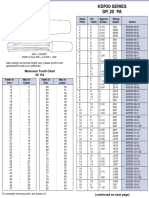

ALLOY ALTERNATE ID Co Ni Cr W Mo Ta C Fe Si Mn Al Ti Other

PMet 803 Bal <10 <40 <10 <5

PMet 806 Ni 200 Bal <1 <1 <1 <1Cu

PMet 808 R108 <10 Bal <10 10 <1 3 <1 6 <1 <2Hf, <1B, <1Zr

PMet 811 <10 Bal <15 <5 <10

PMet 818 718 1 Bal 19 3 17 <1 <1 1 5Nb

PMet 819 <1 55 20 3 Bal 1 1B, 5 Nb+Ta

PMet 820 12 Bal 19 3 3 <1 1 5Nb

PMet 821 Bal 20

PMet 822, 823 20 Bal 23 2 <1 1 <1 <1 1 2 <1Nb

PMet 831 Bal 16 7 3 3

PMet 832 1 Bal 20 <1 <1 <1 1

PMet 833 FM 62 1 Bal 16 <1 8 <1 1 2Nb

PMet 838 738 9 Bal 16 3 2 2 <1 <1 4 4 <1Nb

PMet 840 <20 Bal <25 <3 <3 <1 <1 <3 <5 <2Nb

PMet 842 12 Bal 7 5 2 6 6 3Re

PMet 844 FM 69 1 Bal 16 7 <1 1 <1 2 1Nb

PMet 845 10 Bal 20 10 1

PMet 847 10 Bal 8 10 3 <1 6 1

PMet 854 230 Bal 22 14 2 <1

PMet 860, 860B 625 1 Bal 22 9 5 1 1 4Nb, <1B

PMet 863 263 20 Bal 20 6 1 1 2

PMet 864 Bal 31 3 2.5 <1 4B

PMet 865 Waspaloy 14 Bal 20 4 2 <1 <1 <2 3

Date of Issue: 5/8/2018 Product: NICKEL ALLOYS Page 1 of 6

High Performance Wire for Hardfacing, Welding and Thermal Spraying

Safety Data Sheet

3. COMPOSITION / INFORMATION ON INGREDIENTS (continued)

ALLOY ALTERNATE ID Co Ni Cr W Mo Ta C Fe Si Mn Al Ti Other

PMet 866 Bal 20 13 6 <2 <1

PMet 867 242 <1 Bal 8 25 <1 <2 <1 <1

PMet 870 Hast W 3 Bal 5 25 <1 3 1 1

PMet 872 5 Bal 30 3 5 <1 15 <1 2 2Cu

PMet 875 Hast X 2 Bal 22 1 9 <1 19 1 1

PMet 876 <1 Bal 20 4 16 <1 <1 3 <1 <1 <1

PMet 877 Bal 2 2 30Cu

PMet 879 5 Bal 30 3 5 1 15 1 2 1Nb, 2Cu

PMet 880 10 Bal 14 4 4 <1 3 5

PMet 884 Bal 20

PMet 885 Bal 5

PMet 886 Bal 19 7

PMet 887 Bal 22 10 1Y

PMet 888 Bal 5 6

PMet 889 Bal 43 <1

PMet 895 <5 Bal <10 <5 <10 <1 <10 <3Re, <1Hf

PMet 897 Bal 10 6 5 <1 <1 6

PMet 898 Bal 15 17 4 4 3B

Component CAS No. EC No. Component CAS No. EC No.

Aluminum (Al) 7429-90-5 231-072-3 Molybdenum (Mo) 7439-98-7 231-107-2

Carbon (C) 7440-44-0 231-153-3 Nickel (Ni) 7440-02-0 231-111-4

Boron (B) 7440-42-8 231-151-2 Niobium (Nb) 7440-03-1 231-113-5

Copper (Cu) 7440-50-8 231-159-6 Silicon (Si) 7440-21-3 231-130-8

Chromium (Cr) 7440-47-3 231-157-5 Tantalum (Ta) 7440-25-7 231-135-5

Cobalt (Co) 7440-48-4 231-158-0 Titanium (Ti) 7440-32-6 231-142-3

Hafnium (Hf) 7440-58-6 231-166-4 Tungsten (W) 7440-33-7 231-143-9

Iron (Fe) 7439-89-6 231-096-4 Yttrium (Y) 7440-65-5 231-174-8

Manganese (Mn) 7439-96-5 231-105-1

------------------------------------------------------------------------------------------------------------------------------------------------------------------

4. FIRST-AID MEASURES

These measures apply primarily to the byproducts produced during thermal spray or welding.

Inhalation: Move exposed person to fresh air. Keep the person warm and at rest. If not breathing or if breathing is

irregular or if respiratory arrest occurs, provide artificial respiration or oxygen by trained personnel. It may be

dangerous to the person providing aid to give mouth-to-mouth resuscitation. Obtain medical attention if

symptoms occur. If unconscious, place in recovery position and get medical attention immediately. Maintain

an open airway. Loosen tight clothing such as a collar, tie, belt or waistband.

Ingestion: Wash out mouth with water. Remove dentures if any. Move exposed person to fresh air. Keep the person

warm and at rest. If material has been swallowed and the exposed person is conscious, give small quantities

of water to drink. Stop if the exposed person feels sick as vomiting may be dangerous. Do not induce

vomiting unless directed to do so by medical personnel. If vomiting occurs, the head should be kept low so

that vomit does not enter the lungs. Obtain medical attention if symptoms occur. Never give anything by

mouth to an unconscious person. If unconscious, place in recovery position and get medical attention

immediately. Maintain an open airway. Loosen tight clothing such as a collar, tie, belt or waistband.

Skin Contact: Flush contaminated skin with plenty of water. Remove contaminated clothing and shoes. Obtain medical

attention if symptoms occur. Wash clothing before reuse. Clean shoes thoroughly before reuse.

Eye Contact: Immediately flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower

eyelids. Check for and remove any contact lenses. Get medical attention if irritation occurs.

Protection of First Aiders: No action shall be taken involving any personal risk or without suitable training.

See Section 11 for more detailed information on health effects and symptoms.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

5. FIRE-FIGHTING MEASURES

This section applies primarily to the wire as supplied.

Extinguishing Media

Suitable: Use an extinguishing agent suitable for the surrounding fire.

Not Suitable: None known

Date of Issue: 5/8/2018 Product: NICKEL ALLOYS Page 2 of 6

High Performance Wire for Hardfacing, Welding and Thermal Spraying

Safety Data Sheet

Special Exposure Hazards: No specific hazard

Hazardous Thermal Decomposition Products: Some metallic oxides

Special Protective Equipment for Fire-Fighters: Fire-fighters should wear appropriate protective equipment and self-

contained apparatus (SCBA) with a full face-piece operated in positive pressure mode.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

6. ACCIDENTAL RELEASE MEASURES

These measures apply to the wire as supplied and the byproducts produced during the thermal spray or welding process.

Personal Precautions: Immediately contact emergency personnel. Keep unnecessary personnel away. Use

suitable protective equipment.

Environmental Precautions: Avoid dispersal of spilt material and runoff and contact with soil, waterways, drains and sewers.

Methods for Cleaning Up: Use appropriate tools to transfer the spilt solid to a convenient waste disposal container.

Recycle if possible.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

7. HANDLING AND STORAGE

This section applies primarily to the wire as supplied.

Handling: Eating, drinking and smoking should be prohibited in areas where this material is handled, stored

and processed. Workers should wash hands and face before eating, drinking and smoking.

Storage: Keep container tightly closed. Keep container in a cool, well ventilated area.

Packaging Matls Recommended: Use original container.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

8. EXPOSURE CONTROLS / PERSONAL PROTECTION

This section contains information which applies during the welding and thermal spray processes.

Components OSHA PEL (mg/m3) ACGIH TLV (mg/m3)

Al 15 total dust, 5 respirable 1

B 15 total dust, 5 respirable 10 dust

C 15 total dust, 5 respirable 10 inhalable, 3 respirable

Cr metal* 1 0.5

0.5 (as Cr III) 0.5 (as Cr III)

Cr*

0.005 (as Cr VI) 0.05 (as Cr VI)

Co 0.1 0.02

Cu 1 dust, 0.1 fume 1 dust, 0.2 fume

Hf 0.5 0.5

Fe (oxide fume) 10 5

Mn 5 0.2 (as fume)

Mo 15 Total dust 10 inhalable, 3 respirable

Ni** 1 0.1 (soluble compounds)

Nb

Si 15 total dust, 5.0 respirable –

Ta 5 –

Ti – –

W – 5

Y 1 1

Additional Information: * A portion of metallic chromium may be converted during the welding process to hexavalent

chromium. Hexavalent chromium is classified as an IARC Group 1 carcinogen. NTP classifies

hexavalent chromium as Known to be Carcinogenic.

** A portion of nickel may be converted during the thermal spray process to nickel compounds

which are classified as an IARC Group 1 Carcinogen. NTP classifies nickel compounds as Known

to be Carcinogenic.

Monitoring Procedures: If this product contains ingredients with exposure limits, personal, workplace atmosphere or

biological monitoring may be required to determine the effectiveness of ventilation or other control

measures and/or the necessity to use respiratory protective equipment. Reference should be

made to European Standard EN 689 for methods for the assessment of exposure by inhalation to

chemical agents and national guidance documents for methods for the determination of hazardous

substances.

Exposure Controls

Occupational Exposure: Use process enclosures, local exhaust ventilation or other engineering controls to keep airborne

levels below recommended exposure limits. If user operations generate dust, fumes or mist, use

ventilation to keep exposure to airborne contaminants below the exposure limit.

Respiratory Protection: Use a properly fitted, air-purifying or air-fed respirator complying with an approved standard if a risk

assessment indicates this is necessary. Respirator selection must be based on known or

anticipated exposure levels, the hazards of the product and the safe working limits of the selected

respirator.

Date of Issue: 5/8/2018 Product: NICKEL ALLOYS Page 3 of 6

High Performance Wire for Hardfacing, Welding and Thermal Spraying

Safety Data Sheet

Hand Protection: Gloves should be worn to minimize contact. During the thermal spray process, heat insulated

gloves are recommended.

Eye Protection: Safety glasses or goggles are recommended when handling this material. During the thermal

spray process, safety goggles and dark lenses must be worn.

Skin Protection: Personal protective equipment for the body should be selected based on the task being performed

and the risks involved and should be approved by a specialist before handling this product.

Hearing Protection: During the thermal spray process, the operator and other personnel close to the spray operation

must be protected from excessive noise. Use hearing protection that meets local standards.

Hygiene Measures: Wash hands, forearms and face thoroughly after handling chemical products, before eating,

smoking and using the lavatory and at the end of the working period. Appropriate techniques

should be used to remove potentially contaminated clothing. Wash contaminated clothing before

reusing. Ensure that eyewash stations and safety showers are close to the workstation location.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

9. PHYSICAL AND CHEMICAL PROPERTIES

This section applies primarily to the wire as supplied.

Appearance

Physical State: Solid (wire)

Color: Metallic grey

Odor: Odorless

Odor Threshold: Not Available

Important Health, Safety and Environmental Information

pH: Not Applicable

Boiling Point: Not Available

Melting Point: >1300°C

Flash Point: Not Available

Explosive Properties: Thermal Spray Byproducts – Fine dust clouds may form explosive mixtures in air.

Explosion Limits: Not Available

Oxidizing Properties: Not expected based on chemical composition.

Vapor Pressure: Not Applicable

Relative Density: ~8 – 9 g/cc

Solubility: Insoluble in water

Viscosity: Not Applicable

Vapor Density: Not Applicable

Evaporative Rate: Not Applicable

Other Information

Auto-Ignition Temperature: Not Available

------------------------------------------------------------------------------------------------------------------------------------------------------------------

10. STABILITY AND REACTIVITY

This section applies primarily to the wire as supplied.

Stability: The product is stable under normal storage conditions.

Conditions to Avoid: Store in a cool dry place away from incompatible materials.

Materials to Avoid: Strong acids

Hazardous Decomposition Products:

During the thermal spray or welding processes, gaseous reaction products may include carbon

monoxide and carbon dioxide. Ozone and nitrogen oxides may be formed by radiation from the arc.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

11. TOXICOLOGICAL INFORMATION

This information applies to the wire as supplied and the byproducts produced during the thermal spray process.

Potential Acute Health Effects

Inhalation: Exposure to high concentrations may result in health complaints. Irritating to respiratory system.

Exposure may result in depressed respiration, coughing, nausea and sore throat. Prolonged or

repeated exposure to large amounts may cause damage to lungs (lung edema).

Ingestion: Prolonged or repeated exposure may be irritating to mouth, throat and esophagus (sore throat,

nausea).

Skin: Exposure to high concentrations may result in health complaints. Prolonged or repeated

exposure may be irritating (redness, pain).

Eyes: Moderately irritating to eyes.

Date of Issue: 5/8/2018 Product: NICKEL ALLOYS Page 4 of 6

High Performance Wire for Hardfacing, Welding and Thermal Spraying

Safety Data Sheet

Acute Toxicity

Component Test Result Route Species

LDLo 5 mg/kg Oral Guinea Pig

Nickel

LD50 9000 mg/kg Oral Rat

LDLo 750 mg/kg Oral Rabbit

Cobalt

LD50 6171 mg/kg Oral Rat

LD50 650 mg/kg Oral Rat

Boron LD50 310 mg/kg Oral Rabbit

LD50 250 mg/kg Oral Cat

Manganese LD50 9000 mg/kg Oral Rat

Silicon LD50 3160 mg/kg Oral Rat

Potential Chronic Health Effects

Nickel Carcinogen Category 3; R40, R43

Carcinogenicity: Contains material which may cause cancer, based on animal data. Risk of cancer depends on

duration and level of exposure.

Mutagenicity: No known significant effects or critical hazards.

Reproductive Toxicity: No known significant effects or critical hazards.

Over-Exposure Signs / Symptoms

Target Organs: Contains material which causes damage to the following organs: blood, kidneys, lungs, upper

respiratory tract, skin, central nervous system (CNS), eye lens or cornea.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

12. ECOLOGICAL INFORMATION

This information applies to the wire as supplied.

Ecotoxicity Data

Component Species Period Result

Manganese Daphnia magna (EC50) 48 hours 40 mg/l

Other Adverse Effects: No known significant effects or critical hazards.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

13. DISPOSAL CONSIDERATIONS

This information applies to the wire as supplied and the byproducts produced during the thermal spray process.

Methods of Disposal: Disposal of this product, solutions and any by-products should at all times comply with the

requirements of environmental protection and waste disposal legislation and any regional

local authority requirements.

Disposal of Packaging: Contaminated packaging material should be disposed of in the same manner as the product

itself. Non-contaminated or clean packaging material should be reused for the same product,

treated as domestic waste or material for recycling.

Hazardous Waste: The classification of the product and byproducts may meet the criteria for a hazardous waste.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

14. TRANSPORT INFORMATION

This information applies to the wire as supplied.

International Transport Regulations

Regulatory UN Number Proper Class Packing Label Additional

Information Shipping Name Group Information

ADR/RID Class Not Regulated

ADNR Class Not Regulated

IMDG Class Not Regulated

IATA Class Not Regulated

------------------------------------------------------------------------------------------------------------------------------------------------------------------

15. REGULATORY INFORMATION

This information applies to the wire as supplied.

SARA Section 313 Supplier Notification:

The product covered by this MSDS may contain the following toxic chemicals subject to the reporting requirements of

Section 313 of the Emergency Planning and Community Right-To-Know act of 1986 and of 40 DFR 372: Chromium, Copper,

Manganese and Nickel. Refer to Section 3 of this MSDS for percentage of each element by weight and CAS number.

Date of Issue: 5/8/2018 Product: NICKEL ALLOYS Page 5 of 6

High Performance Wire for Hardfacing, Welding and Thermal Spraying

Safety Data Sheet

Hazard Symbol: Harmful

Risk Phrases: R40 – Limited evidence of a carcinogenic effect

R42/43: May cause sensitization by inhalation and skin contact.

R15 – Contact with water liberates extremely flammable gases

R10 – Flammable

Safety Phrases: S22 – Do not breathe dust

S24 – Avoid contact with skin

S37 – Wear suitable protective gloves

Contains: Nickel

Product Use: Classification and labeling have been performed according to EU Directives 67/548/EEC and

1999/45/EC (including amendments) and the intended use.

Industrial Applications: Used by spraying or welding.

------------------------------------------------------------------------------------------------------------------------------------------------------------------

16. OTHER INFORMATION

This information applies to the wire as supplied and the byproducts produced during the thermal spray or welding process.

Full Text of Classifications: Carc. Cat. 3 – Carcinogen Category 3

F – Highly Flammable

Xn – Harmful

Revision Date: 05/08/2018

Notice to Reader

To the best of our knowledge, the information contained herein is accurate. However, the above named supplier does not

assume liability whatsoever for the accuracy or completeness of the information contained herein.

Final determination of suitability of any material is the sole responsibility of the user. All materials may present unknown

hazards and should be used with caution. Although certain hazards are described herein, we cannot guarantee that these

are the only hazards that exist.

Date of Issue: 5/8/2018 Product: NICKEL ALLOYS Page 6 of 6

You might also like

- ChecklistDocument3 pagesChecklistReia Rueco100% (1)

- Form Darsa Desember RealDocument20 pagesForm Darsa Desember RealasepNo ratings yet

- FORM DARSA DesemberDocument20 pagesFORM DARSA DesemberasepNo ratings yet

- Material OptimDocument1 pageMaterial OptimRaDeOnXNo ratings yet

- Hardware Level 2Document20 pagesHardware Level 2Aibak IrshadNo ratings yet

- FORM DARSA JanuariDocument20 pagesFORM DARSA JanuariasepNo ratings yet

- Ssab - Q2 2021 - FDocument32 pagesSsab - Q2 2021 - FAlex NoNo ratings yet

- SFB Conveyor WraDocument1 pageSFB Conveyor WrabudiNo ratings yet

- Multi: PBF: Rek: CP: HPDocument8 pagesMulti: PBF: Rek: CP: HPSuci IndrianiNo ratings yet

- PMP Monitoring As of 19.09.2022Document98 pagesPMP Monitoring As of 19.09.2022M Dafir DhanNo ratings yet

- Man TH Et Base Pic32mxDocument29 pagesMan TH Et Base Pic32mxkongbigNo ratings yet

- Reporte PFR Multiple A 473 K.HTMDocument5 pagesReporte PFR Multiple A 473 K.HTMMaurice SeijasNo ratings yet

- Koppel Split Type Wall Mounted Inverter BrochureDocument1 pageKoppel Split Type Wall Mounted Inverter Brochure先师傅No ratings yet

- 2018 StandingsDocument1 page2018 Standingsapi-156227703No ratings yet

- 74HC4046A 74HCT4046A: 1. General DescriptionDocument50 pages74HC4046A 74HCT4046A: 1. General DescriptionMichael CastroNo ratings yet

- CAA UK December 2023 Air Transport Movements by AirportDocument2 pagesCAA UK December 2023 Air Transport Movements by AirportHarvey S.No ratings yet

- CAA UK December 2023 Air Transport Movements by TypeDocument2 pagesCAA UK December 2023 Air Transport Movements by TypeHarvey S.No ratings yet

- Kbu 35 201908Document247 pagesKbu 35 201908briceNo ratings yet

- H-BUSTER 32D06HD FonteDocument3 pagesH-BUSTER 32D06HD FonteEulerMartinsDeMelloNo ratings yet

- Contoh Soal REPORT TextDocument22 pagesContoh Soal REPORT TextAbdullah RamliNo ratings yet

- Uli 2Document89 pagesUli 2Riyandi AcewNo ratings yet

- Abb MCCB Enclosured Page 5-6Document2 pagesAbb MCCB Enclosured Page 5-6NunoNo ratings yet

- 3258 Design Revision RequestDocument7 pages3258 Design Revision RequestShafique AsifNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word Documentmohammed HumaidNo ratings yet

- Hfe Mcintosh mc225 MaintDocument5 pagesHfe Mcintosh mc225 MaintmozNo ratings yet

- Confirmed Order Q1 2023 110523 PDFDocument5 pagesConfirmed Order Q1 2023 110523 PDFSuryaNo ratings yet

- North East Audit TracerDocument3 pagesNorth East Audit TracerprinceshivamNo ratings yet

- Formula Stress Test AjaxDocument30 pagesFormula Stress Test AjaxUri UriNo ratings yet

- Upto PlinthDocument25 pagesUpto PlinthAjayvidyanand SharmaNo ratings yet

- İc KarşiliklariDocument15 pagesİc KarşiliklariZhiNga MurTadNo ratings yet

- Gearcase (Kubota - V2003TMDI - Tier II) - (Engine S - N 9FZ999 & Below) - S185Document3 pagesGearcase (Kubota - V2003TMDI - Tier II) - (Engine S - N 9FZ999 & Below) - S185David HerdezNo ratings yet

- Index: Circuit Diagram Working Principle Description Comparision With Other Application Disadvantages ReferenceDocument26 pagesIndex: Circuit Diagram Working Principle Description Comparision With Other Application Disadvantages Referenceinfinite2towersNo ratings yet

- 17 08 07Document1 page17 08 07Rajib MallickNo ratings yet

- LDA Multan Road Work (13-01-2020)Document1 pageLDA Multan Road Work (13-01-2020)Hasnain KhanNo ratings yet

- FI GalpertyDocument80 pagesFI GalpertyWahyu PamungkasNo ratings yet

- Rig: GD Chitra 09.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 09.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Scrs DatasheetDocument2 pagesScrs DatasheetenzosilviaNo ratings yet

- Rig: GD Chitra 18.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present OperationDocument7 pagesRig: GD Chitra 18.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present Operationongcchemist gd chitraNo ratings yet

- Riders PerformanceDocument2 pagesRiders PerformanceAlex ReedNo ratings yet

- Thyristor Bridge, SCR, Bridge: Disc DiodeDocument4 pagesThyristor Bridge, SCR, Bridge: Disc DiodeFran PerezNo ratings yet

- FK JK: N B Koreksi FaktorDocument9 pagesFK JK: N B Koreksi FaktorDafid SoedarsonoNo ratings yet

- Arisa Juice Recon 29 Julie 2022Document22 pagesArisa Juice Recon 29 Julie 2022Devante JustinNo ratings yet

- No Macam Material Swell Factor (In Bank Correction Factor) : 3 Tanah Liat, Basah 0,82 - 0,80Document29 pagesNo Macam Material Swell Factor (In Bank Correction Factor) : 3 Tanah Liat, Basah 0,82 - 0,80j.andry. dprNo ratings yet

- Rig: GD Chitra 06.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 06.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 16.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1063M. Present OperationDocument7 pagesRig: GD Chitra 16.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1063M. Present Operationongcchemist gd chitraNo ratings yet

- Short DPR - GD Chitra - 07.06.2022Document7 pagesShort DPR - GD Chitra - 07.06.2022ongcchemist gd chitraNo ratings yet

- Bss Fds360 Service ManualDocument8 pagesBss Fds360 Service Manualokan uysalNo ratings yet

- Tabel Material OptimDocument1 pageTabel Material OptimMagda CurcanNo ratings yet

- BROSUR PIPA & FITTING uPVC SNI 2021 - CAP - NEWDocument6 pagesBROSUR PIPA & FITTING uPVC SNI 2021 - CAP - NEWkuat jaya karyaNo ratings yet

- The Philippine Stock Exchange, Inc Daily Quotations Report February 17, 2014Document8 pagesThe Philippine Stock Exchange, Inc Daily Quotations Report February 17, 2014John Paul Samuel ChuaNo ratings yet

- Atap 2019 Kabupaten Nagekeo Edit FinalDocument9 pagesAtap 2019 Kabupaten Nagekeo Edit FinalNikolaus Kia PatiNo ratings yet

- BandidoIIuMax PDFDocument1 pageBandidoIIuMax PDFAdriano AndradeNo ratings yet

- 1st R.A DPDC NDDocument27 pages1st R.A DPDC NDAbigail SpencerNo ratings yet

- D6R JEK Parts ManualDocument4 pagesD6R JEK Parts ManualsergeyNo ratings yet

- Samsung ESQUEMA Ct3351 VDocument8 pagesSamsung ESQUEMA Ct3351 VRichard Alberto Becerra TorresNo ratings yet

- Zener BZX83CDocument2 pagesZener BZX83CPelotaDeTrapoNo ratings yet

- DP, 20 PA Shank ShaperDocument2 pagesDP, 20 PA Shank ShaperCAT MINING SHOVELNo ratings yet

- 2600 BomDocument2 pages2600 BomskyddNo ratings yet

- D6R MANUAL SmitmaDocument8 pagesD6R MANUAL SmitmaJuli AntoNo ratings yet

- Photoelastic Visualisation - Phased Array Sound FieldsDocument13 pagesPhotoelastic Visualisation - Phased Array Sound Fieldsdavood abbasiNo ratings yet

- Experimental and Numerical Analysis of A Transducer For The Generation of Guided WavesDocument9 pagesExperimental and Numerical Analysis of A Transducer For The Generation of Guided Wavesdavood abbasiNo ratings yet

- Basics On Fatigue and Fracture MechanicsDocument1 pageBasics On Fatigue and Fracture Mechanicsdavood abbasiNo ratings yet

- Multimet Alloy: Principal FeaturesDocument11 pagesMultimet Alloy: Principal Featuresdavood abbasiNo ratings yet

- Basics On Fatigue and Fracture MechanicsDocument28 pagesBasics On Fatigue and Fracture Mechanicsdavood abbasiNo ratings yet

- In 100alloyengineeringproperties 483Document19 pagesIn 100alloyengineeringproperties 483davood abbasiNo ratings yet

- WQT 316L 2 MMDocument1 pageWQT 316L 2 MMdavood abbasiNo ratings yet

- MaterialData 191425Document1 pageMaterialData 191425davood abbasiNo ratings yet

- Alloy 713C: Engineering Properties ofDocument20 pagesAlloy 713C: Engineering Properties ofdavood abbasiNo ratings yet

- بازرسی جوش لوله PDFDocument150 pagesبازرسی جوش لوله PDFdavood abbasiNo ratings yet

- GCSE English Speech DraftDocument3 pagesGCSE English Speech Draftmarckkaldas2009No ratings yet

- IV Infusion: Purpose of Starting IV'sDocument6 pagesIV Infusion: Purpose of Starting IV'sKiara Denise TamayoNo ratings yet

- Family Medicine Concept and Patient ManagementDocument36 pagesFamily Medicine Concept and Patient ManagementSapta YudhaNo ratings yet

- Isolation of Nosocomial Multi-Drug Resistant Gram-Negative Bacteria From Some Benghazi HospitalsDocument18 pagesIsolation of Nosocomial Multi-Drug Resistant Gram-Negative Bacteria From Some Benghazi HospitalsInternational Medical Publisher100% (1)

- Cases of Pneumonia Among Children Under Five Years Old in Bacolod City From 2019-2021Document35 pagesCases of Pneumonia Among Children Under Five Years Old in Bacolod City From 2019-2021ZeejayNo ratings yet

- Adobe India Benefits SummaryDocument3 pagesAdobe India Benefits SummaryShobhita SoodNo ratings yet

- (Download PDF) Emotion Focused Therapy For Complex Trauma An Integrative Approach 2Nd Edition Sandra C Paivio Online Ebook All Chapter PDFDocument42 pages(Download PDF) Emotion Focused Therapy For Complex Trauma An Integrative Approach 2Nd Edition Sandra C Paivio Online Ebook All Chapter PDFrosamond.helf109100% (12)

- 1879 Wilhelm Wundt Establishes First Formal Psychology Laboratory at The University of LeipzigDocument3 pages1879 Wilhelm Wundt Establishes First Formal Psychology Laboratory at The University of LeipzigJacqueline Acera BalingitNo ratings yet

- Harris, Nadine Burke. TED, Sept. 2014, A - LifetimeDocument15 pagesHarris, Nadine Burke. TED, Sept. 2014, A - Lifetimeapi-509240006No ratings yet

- Kuhas Syllabus 2021Document279 pagesKuhas Syllabus 2021Ansu MaliyakalNo ratings yet

- Detailed Lesson Plan Beauty CareDocument4 pagesDetailed Lesson Plan Beauty CareFrancis Joseph Del Espiritu SantoNo ratings yet

- 7 Types of DrugsDocument37 pages7 Types of DrugsThanh ThưNo ratings yet

- NCP Step 2: Nutrition DiagnosisDocument2 pagesNCP Step 2: Nutrition Diagnosisaida putriNo ratings yet

- ColonosDocument20 pagesColonosAkuMrW100% (2)

- Communicating For ImpactDocument60 pagesCommunicating For ImpactRiaz RasoolNo ratings yet

- Vacant PositionsDocument45 pagesVacant Positionsrandulf eric jalosjosNo ratings yet

- INvision Nov-2020 v2Document5 pagesINvision Nov-2020 v2Indiana Family to FamilyNo ratings yet

- Nliu Bhopal-University Reopening Guidelines-DraftDocument21 pagesNliu Bhopal-University Reopening Guidelines-DraftRashi BakshNo ratings yet

- MSDS PETROFLAG TEST KitDocument4 pagesMSDS PETROFLAG TEST Kitrogelgerardo643No ratings yet

- Scanner Trifold BrochureDocument2 pagesScanner Trifold BrochureCherry San DiegoNo ratings yet

- Effective Communications Strategies For COVID-19Document8 pagesEffective Communications Strategies For COVID-19Ana-Mihaela BalanuțaNo ratings yet

- DTP Poblacion Annex-E-2 FinalDocument7 pagesDTP Poblacion Annex-E-2 FinalMario N. MariNo ratings yet

- 2024 NM Consultative Meeting For PMNP MPMOsDocument31 pages2024 NM Consultative Meeting For PMNP MPMOssribaccayNo ratings yet

- Nursing Seminar 1 SAS Session 22Document9 pagesNursing Seminar 1 SAS Session 22ZiaNo ratings yet

- Swot Kelompok 3Document9 pagesSwot Kelompok 3ilhamcitrahamidiNo ratings yet

- Chrono PharmacologyDocument48 pagesChrono PharmacologyArun Davesar67% (3)

- Dom 13550Document12 pagesDom 13550mandaNo ratings yet

- Mapeh ReviewerDocument3 pagesMapeh ReviewerPrincess Charlea MirandaNo ratings yet

- Business Concept and Situational AnalysisDocument13 pagesBusiness Concept and Situational AnalysisfredeksdiiNo ratings yet